When working with compact machinery, having a clear grasp of its internal structure is crucial for maintenance and troubleshooting. This guide delves into the intricate layout of a popular small motor, providing an insightful overview of its various elements. By comprehending the configuration and function of each component, users can ensure optimal performance and longevity of their equipment.

Many enthusiasts and professionals alike benefit from visual references that break down complex systems into manageable parts. A well-organized representation of the various sections of a small motor aids in identifying specific areas that may require attention. Whether you’re an experienced mechanic or a novice, having access to such resources simplifies the repair process and enhances overall understanding.

In this exploration, we will highlight key features and functions within the motor’s framework. From the ignition to the fuel system, recognizing how these components interact is vital for effective operation. Armed with this knowledge, you will be better prepared to tackle any challenges that may arise during usage or servicing.

Tecumseh 10 HP Engine Overview

This section provides a comprehensive look at a robust power unit known for its reliability and efficiency. Designed for various applications, this engine type has earned a reputation for delivering consistent performance in challenging environments. Understanding its structure and functionality can enhance maintenance and troubleshooting efforts.

Key Features

This unit boasts a compact design, making it suitable for a range of machines. With a powerful output, it effectively handles demanding tasks, ensuring optimal productivity. Additionally, its user-friendly controls and maintenance accessibility contribute to its popularity among users.

Applications

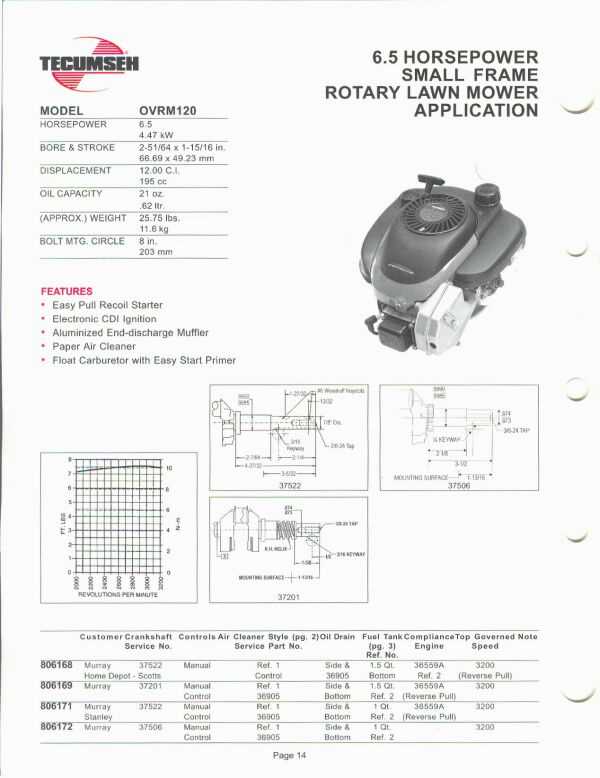

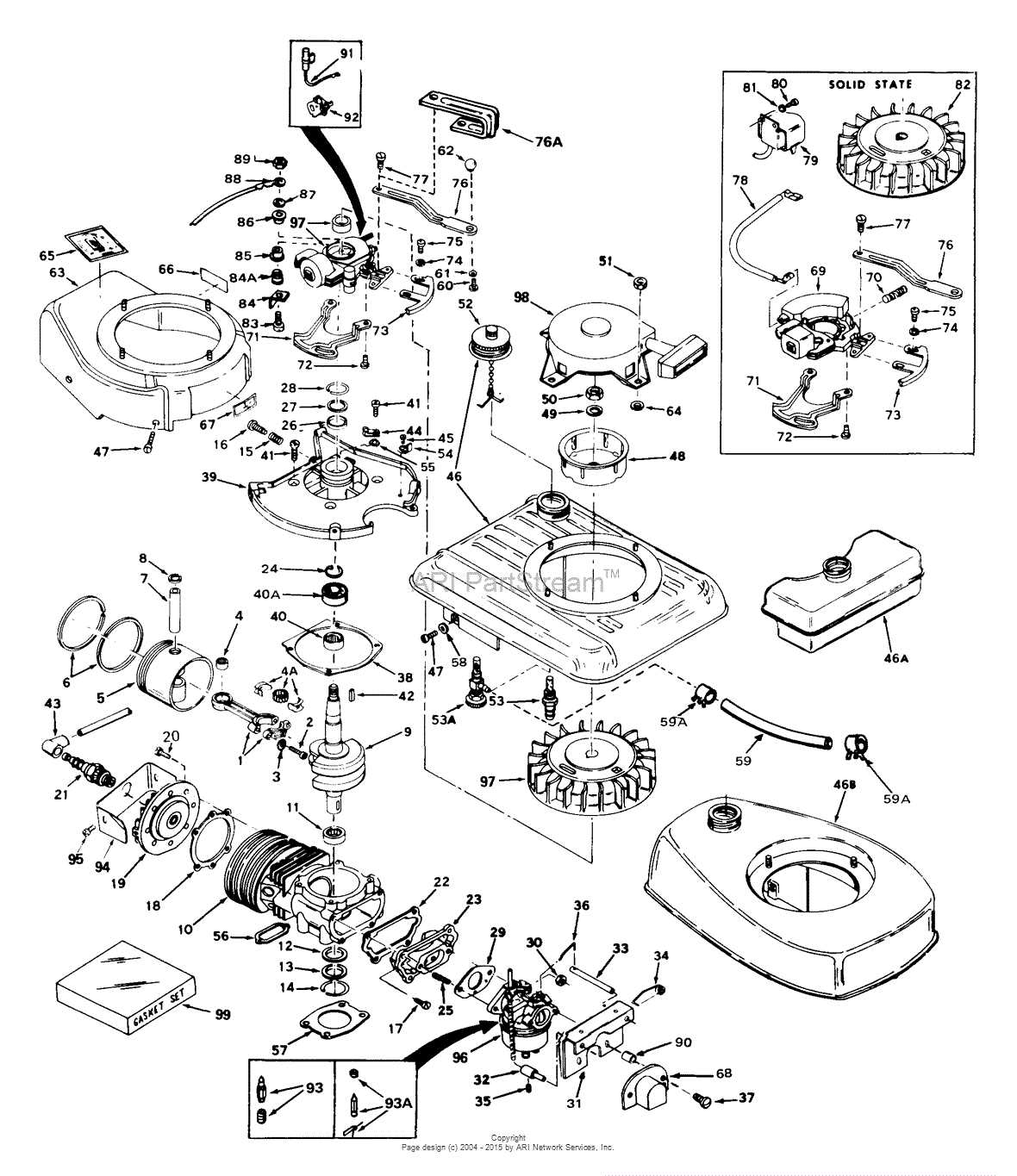

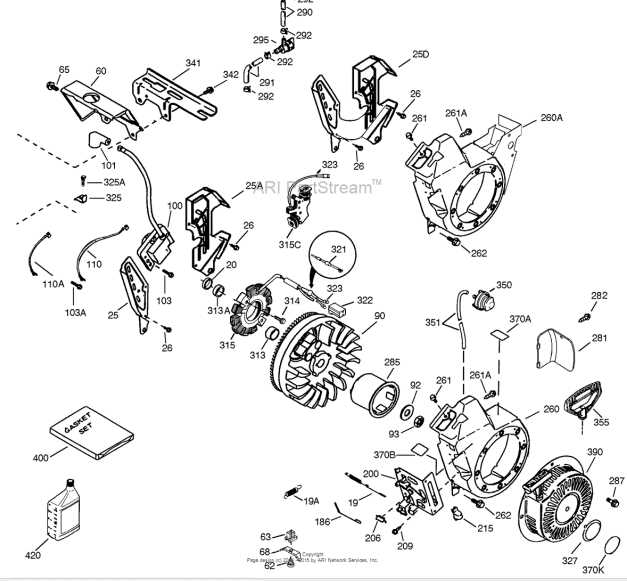

Essential Components of the Engine

Understanding the vital elements that contribute to the operation of a power unit is crucial for anyone looking to maintain or repair their machinery. Each component plays a specific role, ensuring efficiency and performance while working together seamlessly.

| Component | Description |

|---|---|

| Cylinder | The space where combustion occurs, generating power. |

| Piston | A moving element that transfers energy from combustion to mechanical motion. |

| Crankshaft | A rotating shaft that converts linear motion into rotational force. |

| Fuel System | Delivers fuel to the combustion area for optimal performance. |

| Ignition System | Responsible for igniting the fuel-air mixture to initiate combustion. |

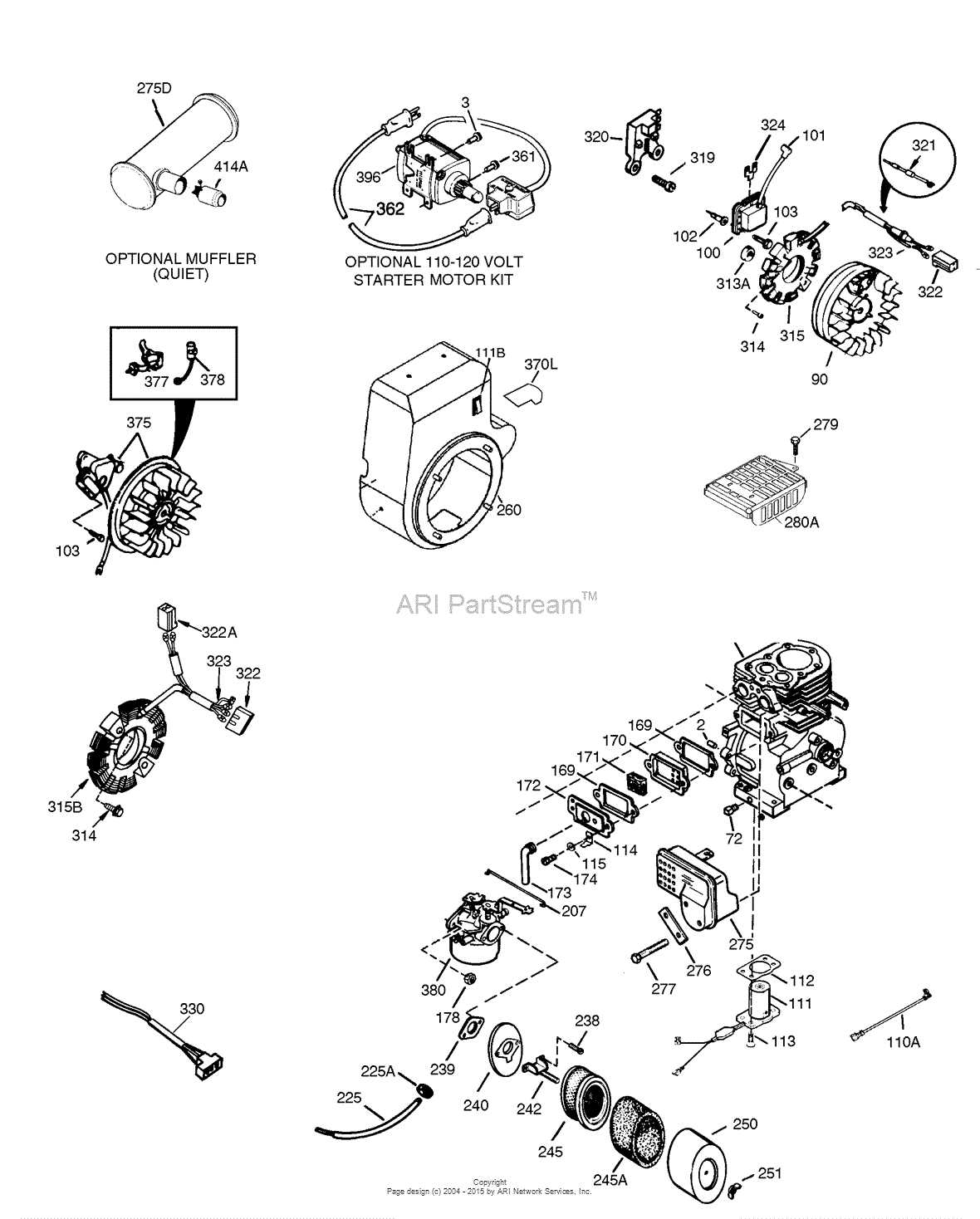

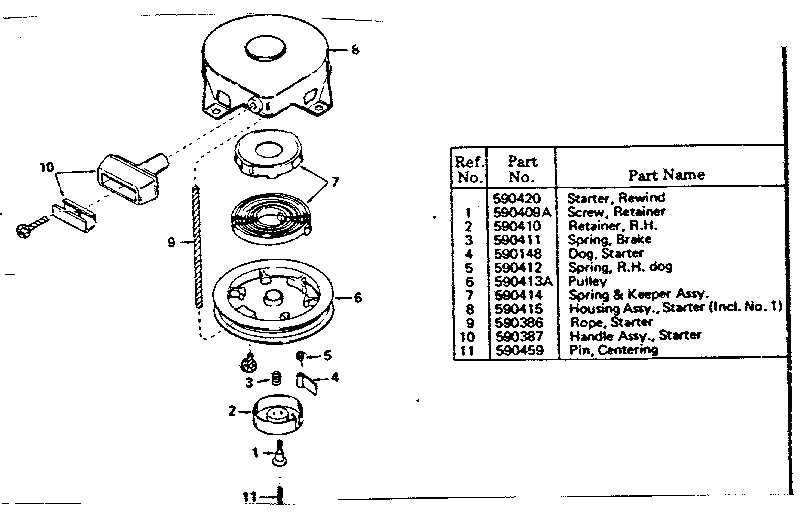

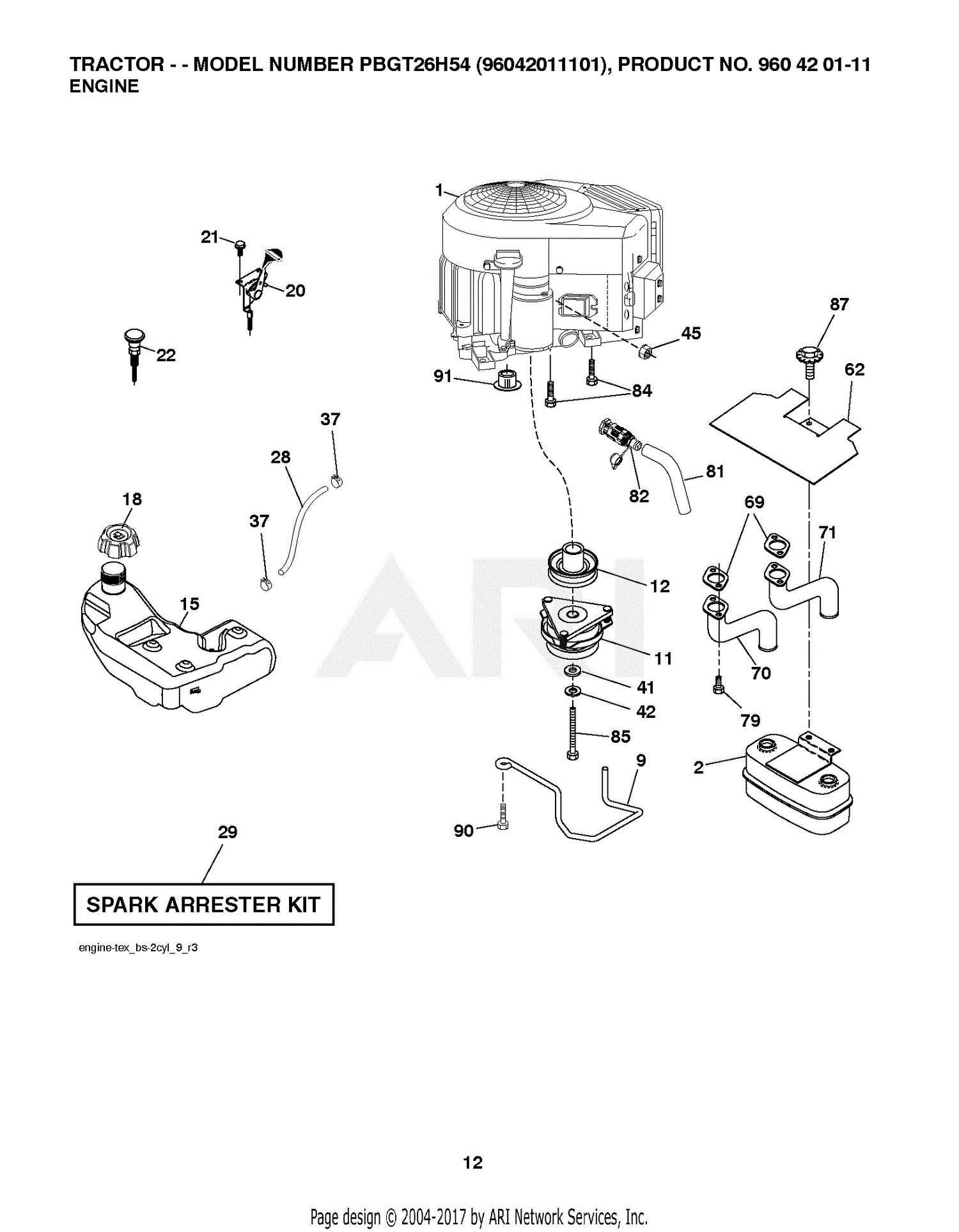

Importance of a Parts Diagram

Understanding the layout and components of machinery is crucial for effective maintenance and repair. A visual representation offers clarity, making it easier to identify individual elements and their functions.

- Enhances comprehension of assembly and disassembly processes.

- Facilitates accurate troubleshooting by pinpointing specific components.

- Streamlines ordering and replacing elements, reducing downtime.

- Assists in visualizing modifications or upgrades for improved performance.

In summary, a well-structured illustration serves as an ultimate tool for both novices and experts, ensuring efficient operation and longevity of equipment.

Common Issues with Tecumseh Engines

Understanding the frequent challenges that can arise with these small power units is essential for effective maintenance. Users often encounter specific malfunctions that can hinder performance and reliability, requiring attention and solutions to ensure smooth operation.

Fuel System Problems

One of the most prevalent issues involves the fuel delivery mechanism. Clogs in the lines or filters can restrict flow, leading to poor performance. Additionally, stale fuel can cause starting difficulties and erratic operation, making it vital to regularly check and refresh fuel supplies.

Electrical Failures

Electrical components are also prone to faults, affecting overall functionality. Issues with the ignition system, such as faulty spark plugs or wiring, can result in failure to start or inconsistent power output. Regular inspections can help identify these electrical anomalies before they become major headaches.

How to Read the Diagram

Understanding visual representations of mechanical assemblies is essential for effective maintenance and repairs. These illustrations provide a comprehensive view of the various components and their relationships, making it easier to identify parts and their functions.

Key Elements to Identify

When examining the visual representation, pay attention to the following aspects:

| Element | Description |

|---|---|

| Labels | Each section typically includes clear annotations that indicate the name and function of each component. |

| Lines and Arrows | Connecting lines and directional arrows show how components interact and their placement relative to each other. |

| Color Coding | Different colors may be used to categorize parts by function, making it easier to distinguish between them. |

Steps for Effective Interpretation

To effectively interpret the illustration, follow these steps:

- Begin by familiarizing yourself with the overall layout and the main components highlighted in the visual.

- Next, consult the accompanying key or legend to understand the symbols and color codes used.

- Identify and trace connections between components to grasp their interactions and dependencies.

Key Replacement Parts Available

This section outlines essential components for ensuring optimal functionality and longevity of your machinery. Having the right replacements can significantly enhance performance and reduce downtime.

- Fuel System Components

- Ignition Parts

- Cooling Mechanisms

- Air Filters

- Oil Seals

Each of these elements plays a critical role in maintaining efficiency and reliability. It is advisable to select high-quality replacements to achieve the best results.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended life of your machinery. By following a consistent maintenance routine, you can enhance performance and prevent potential issues that may arise over time.

Regular Inspections

Conduct routine checks to identify any signs of wear or damage. Look for leaks, unusual noises, or changes in performance, which can indicate underlying problems that need addressing promptly.

Fluid Changes and Cleanliness

Regularly replace lubricants and coolants to maintain optimal function. Additionally, keep the unit clean from debris and dirt, as this can significantly impact efficiency and longevity.

Finding Quality Replacement Parts

When it comes to maintaining your machinery, sourcing high-quality components is crucial for optimal performance and longevity. With numerous options available, it’s essential to ensure that the substitutes you choose meet rigorous standards to avoid future complications.

Research is key. Begin by exploring reputable suppliers that specialize in reliable components. Look for reviews and testimonials to gauge customer satisfaction and product reliability.

Consider compatibility with your specific model, as well as the manufacturer’s specifications. Opting for trusted brands often leads to enhanced durability and performance.

Additionally, warranty information can provide peace of mind. Components backed by a solid guarantee signal a commitment to quality, ensuring you’re making a wise investment.

In conclusion, taking the time to delve into your options will lead to the ultimate satisfaction in your repair or upgrade process, allowing your equipment to function seamlessly for years to come.

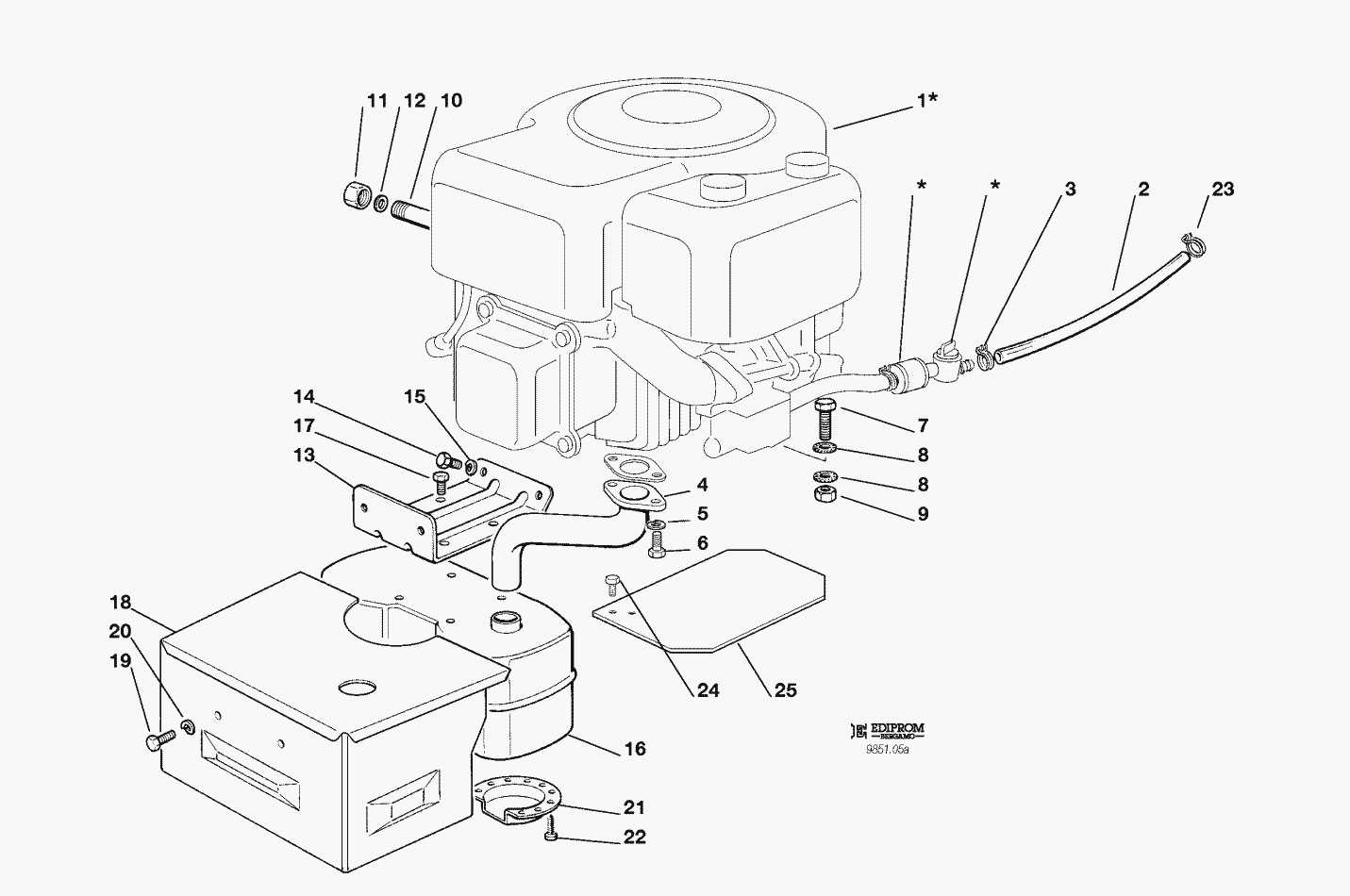

Assembly Instructions for Beginners

Constructing a mechanical unit can seem daunting, but with clear guidance and a systematic approach, even novices can successfully complete the task. This section provides straightforward steps to help you navigate through the assembly process, ensuring a smooth and enjoyable experience.

Essential Tools and Materials

Before you begin, gather the necessary tools and components. Having everything at hand will streamline your workflow.

- Wrenches

- Screwdrivers

- Pliers

- Lubricant

- Safety goggles

Step-by-Step Assembly Guide

- Start by reviewing the instruction manual. Familiarize yourself with the various components.

- Lay out all parts in an organized manner to avoid confusion.

- Begin with the base assembly. Secure all necessary brackets and supports first.

- Attach the main component to the base. Ensure all fasteners are tight but not over-tightened.

- Continue adding auxiliary components, following the order specified in the manual.

- Once everything is in place, double-check all connections for stability.

- Finally, apply lubricant to moving parts as recommended, and conduct a test to ensure functionality.

By following these steps, beginners can build their mechanical unit with confidence and ease. Happy assembling!

Tools Needed for Repairs

When undertaking maintenance tasks, having the right equipment is essential for ensuring a smooth and efficient process. Proper tools not only enhance the quality of the work but also minimize the risk of damage to components. A well-equipped workspace can make all the difference in completing repairs successfully.

Wrenches are crucial for loosening and tightening various fasteners. A set of both metric and imperial sizes will allow for flexibility in dealing with different specifications.

Screwdrivers are indispensable for working with screws of various types. It’s advisable to have a selection of flathead and Phillips options to tackle a variety of assemblies.

Pliers, including needle-nose and slip-joint varieties, are useful for gripping, twisting, and cutting wires or small components. These tools provide the necessary leverage and precision for intricate tasks.

Torque wrench is vital for applying the correct amount of force to bolts and screws, ensuring they are secured without being over-tightened, which can lead to damage.

Safety gear should not be overlooked. Protective eyewear and gloves can prevent injuries while working, making it essential to prioritize safety during any repair job.

By gathering these essential tools, anyone can enhance their ability to perform repairs efficiently and effectively, ensuring long-lasting functionality of the equipment.

Upgrading Your Tecumseh Engine

Enhancing the performance of your small power unit can lead to significant improvements in efficiency and reliability. By focusing on key components and making thoughtful modifications, you can maximize output and extend the lifespan of your machinery. This process often involves replacing outdated elements and optimizing existing systems.

Key Components to Consider

Start by evaluating the fuel system. Upgrading to a higher-quality carburetor can enhance air-fuel mixture precision, leading to better combustion. Additionally, examining the ignition system for potential upgrades can result in improved starting and smoother operation.

Maintenance Tips for Longevity

Regular maintenance is crucial for any overhaul. Ensure that you change the oil frequently and inspect all moving parts for wear. Keeping the cooling system clean can also prevent overheating, which is essential for long-term performance.

Resources for Further Learning

For those eager to expand their knowledge in mechanical components and maintenance, numerous resources are available that cater to various learning styles. Engaging with these materials can significantly enhance your understanding and proficiency.

Books: Consider exploring technical manuals and guides that provide in-depth explanations and illustrations. These texts often break down complex concepts into manageable sections, making it easier to grasp essential principles.

Online Tutorials: Websites and platforms like YouTube offer visual demonstrations that can help clarify assembly and maintenance techniques. Watching experts in action can be incredibly beneficial for visual learners.

Forums and Communities: Participating in online forums allows for the exchange of ideas and solutions. Engaging with fellow enthusiasts can provide valuable insights and troubleshooting tips.

Workshops: Look for local workshops or classes focused on mechanical skills. Hands-on experience with guidance from professionals can solidify your understanding and give you practical skills.

Utilizing a variety of these resources can lead to a comprehensive understanding and ultimate proficiency in the subject matter.