The complexity of modern vehicles requires a thorough understanding of their various components and how they interact. In this section, we will explore the intricate layout of essential elements that contribute to the efficient functioning of a specific model. By delving into the arrangement of parts, one can gain insights into the overall performance and maintenance requirements of the vehicle.

For those looking to enhance their knowledge or conduct repairs, having a visual representation of the assemblies can be invaluable. This guide aims to provide a detailed overview of the arrangement and relationships among different components, facilitating a deeper comprehension of the vehicle’s construction.

Whether you are an experienced mechanic or a novice enthusiast, familiarizing yourself with the setup of crucial elements can significantly improve your repair skills and maintenance strategies. Understanding the functionality of these components ensures that every aspect of the vehicle operates smoothly, leading to a safer and more reliable driving experience.

Understanding the Components of 2009 F150

Every vehicle comprises a variety of elements that work in unison to ensure optimal functionality and performance. Recognizing these individual components enhances one’s appreciation for engineering and design. Each section contributes significantly to the overall driving experience, from the powertrain to the suspension system.

Key Elements of the Vehicle

The core systems include the engine, transmission, and braking mechanisms. The engine serves as the powerhouse, converting fuel into motion. The transmission facilitates gear changes, ensuring smooth acceleration. Meanwhile, the braking system guarantees safety by providing reliable stopping power.

Supporting Structures

In addition to the primary systems, various supporting structures like the chassis and suspension contribute to the vehicle’s stability and comfort. The chassis provides the framework, while the suspension system absorbs shocks from the road, enhancing ride quality. Understanding these components is crucial for maintaining and troubleshooting any vehicle.

Overview of Major Parts

This section provides an insight into the essential components of a popular vehicle model, focusing on the crucial elements that contribute to its overall functionality and performance. Understanding these key parts can greatly aid in maintenance and repairs, ensuring that the vehicle operates efficiently.

| Component | Description |

|---|---|

| Engine | The powerhouse of the vehicle, responsible for converting fuel into mechanical energy. |

| Transmission | Facilitates the transfer of power from the engine to the wheels, enabling the vehicle to move. |

| Suspension | Ensures a smooth ride by absorbing shocks and maintaining tire contact with the road. |

| Braking System | Essential for safety, it slows down or stops the vehicle when necessary. |

| Electrical System | Powers various components, including lights, infotainment, and engine management systems. |

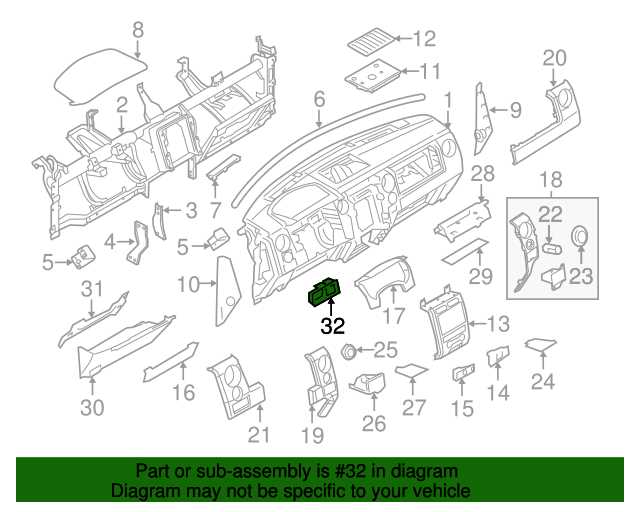

Identifying Key Electrical Systems

Understanding the primary electrical components of a vehicle is crucial for effective maintenance and repair. These systems are responsible for various functionalities, from starting the engine to powering essential accessories. Recognizing these elements can greatly aid in troubleshooting issues and ensuring optimal performance.

Central Power Distribution

The central power distribution unit plays a pivotal role in managing electrical energy throughout the vehicle. This component is responsible for routing power to various subsystems, ensuring that each part receives the necessary voltage. Identifying the location and functionality of this unit can streamline the diagnostic process and help in resolving electrical malfunctions.

Lighting and Signal Systems

Lighting and signaling systems are vital for safe operation, providing visibility and communication with other road users. These components include headlights, taillights, and turn signals. Understanding how these systems are interconnected and their respective wiring can facilitate effective repairs and upgrades.

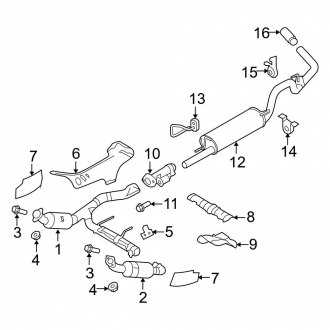

Engine Assembly Breakdown

This section provides an overview of the various components involved in the construction of an internal combustion engine. Understanding these elements is crucial for anyone engaged in automotive repair or enhancement. Each part plays a significant role in the overall functionality and performance of the engine.

The engine assembly typically consists of several key components, each contributing to the operation of the engine as a whole. Below are the primary sections of the assembly:

- Engine Block: The main structure housing various components, including cylinders and oil passages.

- Cylinder Head: Seals the top of the cylinders and contains intake and exhaust valves.

- Pistons: Move within the cylinders, converting fuel energy into mechanical energy.

- Crankshaft: Converts the linear motion of the pistons into rotational motion.

- Timing Belt/Chain: Synchronizes the rotation of the crankshaft and camshaft.

In addition to these core components, several ancillary parts ensure optimal engine performance:

- Oil Pump: Circulates oil throughout the engine for lubrication.

- Water Pump: Maintains engine temperature by circulating coolant.

- Fuel Injector: Delivers precise amounts of fuel to the combustion chamber.

- Ignition System: Initiates the combustion process for engine operation.

A thorough understanding of these elements is essential for effective troubleshooting, maintenance, and upgrades to enhance vehicle performance.

Transmission and Drivetrain Insights

The efficiency of a vehicle’s performance significantly relies on its transmission and drivetrain systems. Understanding these components is essential for maintaining optimal functionality and ensuring a smooth driving experience. The interplay between the transmission and drivetrain is crucial for power delivery, enhancing both acceleration and overall handling.

Key Components

- Transmission: This system is responsible for shifting gears, allowing the engine to operate efficiently at various speeds.

- Driveshaft: A critical component that transmits power from the transmission to the wheels, facilitating movement.

- Differential: This mechanism enables the wheels to rotate at different speeds, especially important during turns, providing better traction.

- Axles: These components connect the wheels to the vehicle’s structure, playing a vital role in supporting weight and facilitating movement.

Maintenance Considerations

- Regularly check fluid levels to ensure optimal lubrication and prevent overheating.

- Inspect components for wear and tear, particularly in high-stress areas such as the driveshaft and differential.

- Monitor for unusual noises, as these can indicate potential issues within the drivetrain system.

- Schedule routine maintenance to address any concerns before they escalate, preserving the integrity of the entire system.

Suspension System Overview

The suspension system plays a crucial role in providing a comfortable and stable ride by absorbing shocks from uneven surfaces. This essential assembly enhances vehicle handling and stability, allowing for improved control while driving. Understanding its components and functionality is vital for maintaining optimal performance and safety.

Key Components

The main elements of the suspension assembly include springs, shock absorbers, control arms, and stabilizer bars. Springs support the vehicle’s weight and allow for vertical movement, while shock absorbers dampen the oscillations created by the springs, ensuring a smoother ride. Control arms connect the wheels to the frame, facilitating movement during turns, and stabilizer bars help minimize body roll during cornering.

Benefits of a Well-Maintained System

Regular maintenance of the suspension system leads to improved handling, enhanced tire life, and increased comfort for passengers. A well-functioning assembly minimizes wear on other components and contributes to overall vehicle stability, especially during adverse driving conditions.

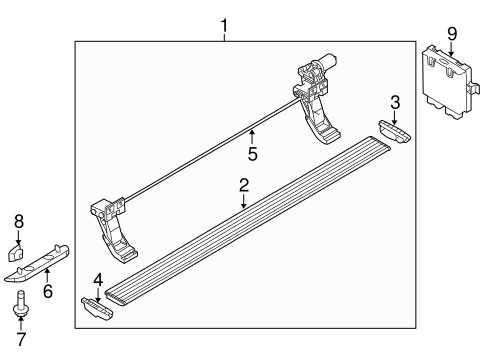

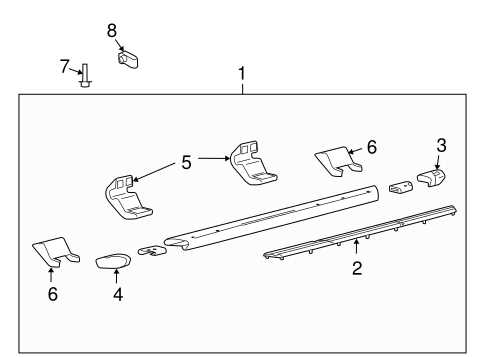

Body and Exterior Parts Guide

This section provides an overview of the essential components that make up the structure and exterior of a vehicle. Understanding these elements is crucial for maintenance, repairs, and modifications. Each part contributes to the overall functionality, aesthetics, and safety of the automobile.

Key Components of the Vehicle Structure

The framework of a vehicle includes various crucial components, such as the chassis, panels, and bumpers. The chassis serves as the foundation, providing support and stability. Body panels, including the doors, fenders, and hood, not only enhance the visual appeal but also protect internal mechanisms from external elements. Additionally, bumpers are designed to absorb impacts, safeguarding both the vehicle and its occupants.

Exterior Features and Accessories

Exterior accessories play a significant role in the functionality and style of an automobile. Features like headlights, taillights, and mirrors are essential for visibility and safety. Furthermore, additional elements such as roof racks and side steps can enhance utility and convenience. Selecting the right accessories can improve both performance and aesthetics, allowing for personalization of the vehicle.

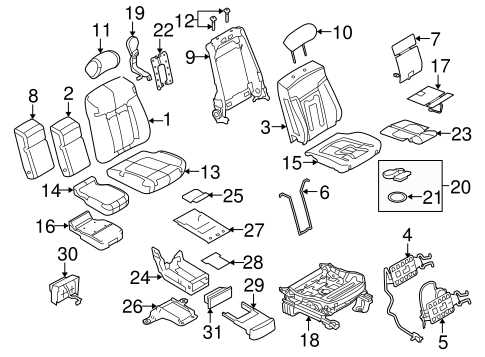

Interior Features and Components

The interior of a modern pickup is designed to provide both comfort and functionality for drivers and passengers alike. It combines various elements that enhance the driving experience, from user-friendly controls to convenient storage solutions. Each component plays a vital role in ensuring that the cabin is not only aesthetically pleasing but also practical for everyday use.

Key Elements of the Cabin

Various components contribute to the overall functionality of the interior space. These features include seating arrangements, instrument panels, and infotainment systems, all engineered to create an inviting atmosphere while ensuring accessibility to essential functions. Below is a summary of some critical interior components:

| Component | Description |

|---|---|

| Dashboard | Central area housing gauges, controls, and infotainment system for easy access. |

| Seating | Comfortable, adjustable seats designed to accommodate both driver and passengers. |

| Storage Compartments | Various storage options including glove compartments and console trays for convenience. |

| Climate Control | Systems for heating, ventilation, and air conditioning to maintain comfort levels. |

Technology Integration

In addition to traditional components, technology plays a crucial role in enhancing user experience. Features such as Bluetooth connectivity, touch-screen displays, and advanced audio systems offer a seamless interface for entertainment and communication. These advancements make modern vehicles more connected and convenient for users, highlighting the importance of integrating technology within the cabin design.

Wiring and Connector Locations

This section focuses on the various electrical connections and their placements within the vehicle, which are crucial for ensuring proper functionality and connectivity among components. Understanding these locations can assist in troubleshooting and maintenance tasks.

Knowing where to find wiring harnesses and connectors simplifies the process of diagnosing issues and performing repairs. Below is a table highlighting the key locations of these electrical connections.

| Component | Location |

|---|---|

| Engine Control Unit (ECU) | Under the dashboard, near the steering column |

| Headlight Connector | Behind the headlight assembly |

| Battery Connector | Near the engine bay, on the driver’s side |

| Fuel Pump Connector | Above the fuel tank, accessible through the access panel |

| ABS Module Connector | Near the brake master cylinder |

Maintenance Parts for Longevity

Ensuring the durability and optimal performance of your vehicle requires attention to various essential components. Regularly replacing and servicing these elements can significantly extend the life of your automobile, enhancing reliability and safety on the road.

Key Components to Consider

Identifying critical elements that contribute to the overall functionality is essential for effective upkeep. Focus on aspects that require routine maintenance, such as filtration systems, lubricants, and structural supports. The following table summarizes these vital components and their maintenance frequency.

| Component | Maintenance Frequency |

|---|---|

| Air Filter | Every 15,000 miles |

| Oil Filter | Every 5,000 miles |

| Brake Pads | Every 30,000 miles |

| Battery | Every 3-5 years |

Importance of Regular Inspection

Conducting periodic checks on these components helps identify potential issues before they escalate. A proactive approach ensures that each part functions efficiently, promoting a seamless driving experience and reducing the likelihood of unexpected breakdowns.

Common Replacement Parts Explained

Understanding the various components of a vehicle is essential for maintaining its performance and reliability. Over time, certain elements may wear out or become damaged, necessitating replacement to ensure optimal functionality. This section outlines frequently needed components and their roles in vehicle maintenance.

- Battery: A crucial element that provides the electrical energy required for starting the engine and powering accessories.

- Brake Pads: Essential for vehicle safety, these components create friction against the brake rotors to slow down or stop the vehicle.

- Oil Filter: This component removes contaminants from engine oil, helping to prolong engine life and efficiency.

- Air Filter: Responsible for ensuring that clean air reaches the engine, enhancing performance and fuel efficiency.

- Starter Motor: A device that initiates engine operation, crucial for starting the vehicle.

Regular inspection and timely replacement of these components can prevent more significant issues and extend the lifespan of the vehicle. Familiarity with these essential parts allows for better maintenance practices and informed decisions regarding repairs.

Understanding OEM vs. Aftermarket Parts

When it comes to vehicle maintenance and repairs, the choice between original equipment manufacturer components and third-party alternatives can significantly impact performance, reliability, and cost. Each type offers unique advantages and disadvantages that may suit different needs and preferences.

Original components are produced by the vehicle manufacturer and are designed specifically for each model. In contrast, third-party alternatives are manufactured by independent companies, often providing a range of options that may vary in quality and price.

- Quality and Reliability: OEM components typically meet strict quality standards, ensuring compatibility and durability. Aftermarket options can vary widely, with some high-quality products available alongside lower-grade alternatives.

- Cost: Original components often come at a premium price due to their brand association and warranty guarantees. Aftermarket alternatives can be more budget-friendly, making them attractive for cost-conscious consumers.

- Availability: OEM items may not always be readily available, particularly for older models. Aftermarket solutions often provide a wider selection and faster access, especially for common repair needs.

Ultimately, the decision between original and third-party components depends on individual preferences, budget considerations, and specific vehicle requirements. Assessing these factors carefully can help ensure optimal performance and satisfaction.