Understanding the structure and components of a vehicle’s rear-end system is essential for ensuring its optimal performance. This section provides a detailed breakdown of the various mechanical elements that contribute to the efficient functioning of the system. By exploring the key elements, you will gain insights into how these elements work together to maintain stability and power distribution.

Each section of the system is interconnected, playing a crucial role in handling torque and delivering power to the wheels. From the housing structure to the gear mechanisms, every part is designed to withstand high pressure and maintain longevity under various driving conditions.

In the following sections, we will delve deeper into the intricate components that make up this system. You’ll learn how each part interacts, how they contribute to the overall performance, and what to look for when maintaining or upgrading these essential elements.

Overview of the Rear-End Axle Assembly

The rear-end axle is known for its robust and versatile design, making it a popular choice in performance and off-road applications. This type of axle offers exceptional durability and reliability under high-stress conditions, which has contributed to its widespread use in various automotive modifications and custom builds.

One of the key features of this axle assembly is its modularity, allowing for easy customization and repair. Its simple yet effective design includes a strong housing that protects internal components, ensuring longevity even in demanding environments. The axle is also known for its compatibility with numerous gearing options, providing flexibility for various driving needs, from street performance to heavy-duty use.

Main Components of the Ford 9 Inch

One of the most reliable and widely recognized rear axle assemblies, this unit is celebrated for its durability and adaptability. Understanding its core elements is key to appreciating how it contributes to overall vehicle performance and handling.

Key Elements of the Structure

- Center Housing: The robust center housing serves as the backbone of the entire assembly, providing support for internal gears and other critical components.

- Axle Shafts: These shafts transfer power from the differential to the wheels, ensuring smooth rotation and driving force.

- Pinion Gear: The pinion gear engages with the ring gear to drive the assembly, allowing power to be distributed evenly.

Additional Components

- Ring Gear

Common Upgrades for 9-Inch Rear Assemblies

Enhancing the durability and performance of rear-end assemblies is a common goal for vehicle enthusiasts looking to improve drivetrains. There are several widely used modifications that can increase both the strength and efficiency of these components, making them ideal for high-performance applications or heavy-duty use.

Upgrade Benefit Heavy-Duty Axles Increases load capacity and prevents axle twisting under extreme stress. Limited-Slip Differentials Improves traction by ensuring power is distributed to both wheels, reducing slippage. Aftermarket Gears Allows customization of gear ratios to suit specific driving conditions, enhancing acceleration or top speed. Rein How to Identify Key Components of the 9-Inch Assembly

Recognizing the crucial elements of a well-known rear axle assembly can be challenging without proper knowledge. This section will provide guidance on distinguishing the primary components, helping enthusiasts and mechanics understand the differences and specific characteristics of this classic setup.

First, locate the differential housing. It’s the largest section and serves as the anchor point for other parts. Pay attention to its unique shape and the bolts holding it in place. The cover, often rounded or slightly angled, may differ from other assemblies in its distinctive design.

Next, inspect the axles, which extend from either side of the housing. These elements are typically robust and thick, designed to handle higher torque. Their length and spline count can vary, so measuring these details can assist in proper identification.

Another important element is the pinion gear. This component can be identified by its location near the front of the housing, often connected to the driveshaft. Its size and teeth configuration are key indicators of its type, affecting the overall performance of the assembly.

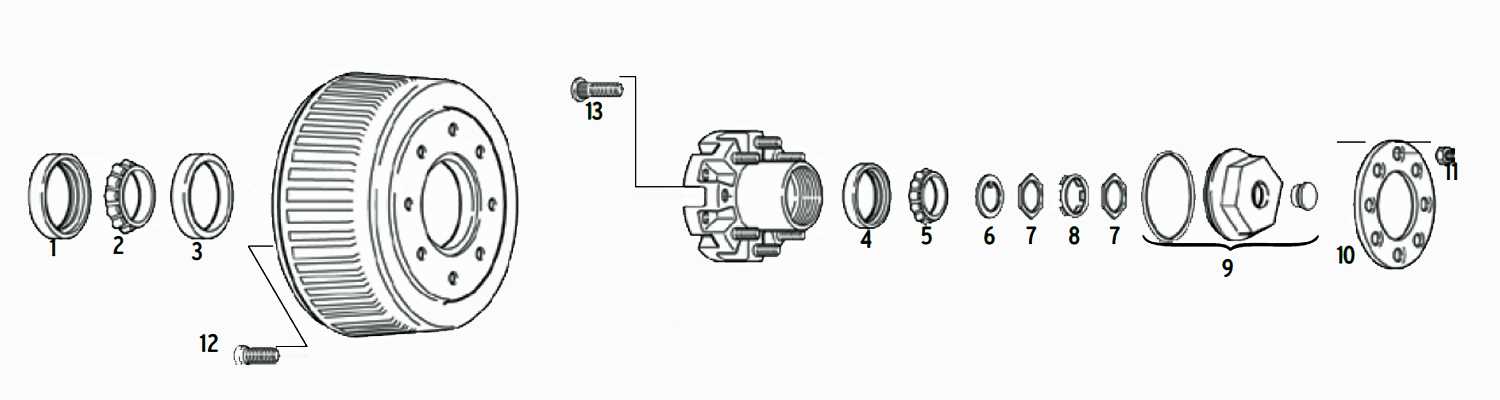

Exploded View of the Ford 9 Inch

An exploded view offers a clear visual breakdown of various components and how they connect in a mechanical system. This type of illustration is especially helpful for understanding the internal layout and assembly process, allowing users to easily identify individual elements and their placement within the structure. By examining such a layout, one can gain a comprehensive understanding of how each piece contributes to the overall functionality, ensuring better maintenance and repair practices.

Component Breakdown

The exploded view typically showcases every essential element, from the core mechanism to the smaller fasteners, all depicted in relation to one another. This layered representation highlights the sequence of assembly, helping users follow a logical progression when dis

Ford 9 Inch Rear End Setup Tips

Setting up the rear differential assembly is crucial for optimizing vehicle performance. This process involves careful consideration of various components to ensure the best handling, traction, and overall driving experience. Here are some essential tips to keep in mind when configuring your rear end.

- Choose the Right Gear Ratio: Selecting the appropriate gear ratio is vital for balancing acceleration and top speed. Consider your vehicle’s purpose, whether it’s for racing or daily driving, to find the best match.

- Check Pinion Angle: Maintaining the correct pinion angle is essential for reducing vibrations and improving traction. A common angle is between 2-3 degrees downward towards the transmission.

- Use Quality Bearings: Investing in high-quality bearings will ensure longevity and reliability. Ensure they are correctly installed to prevent premature wear and failure.

- Proper Fluid Level: Always check the lubricant level in the differential housing. Keeping it at the correct level helps maintain optimal performance and reduces friction.

- Inspect Seal Integrity: Ensure that the seals are in good condition to prevent fluid leaks. Replacing worn or damaged seals can save you from costly repairs later.

- Utilize a Torque Wrench: When tightening bolts, use a torque wrench to adhere to the manufacturer’s specifications. This prevents over-tightening, which can lead to component failure.

- Test Drive: After installation, take your vehicle for a test drive to listen for any unusual noises and to feel for any performance issues. Address any concerns immediately.

By following these guidelines, you can enhance the performance and reliability of your rear differential assembly, ensuring a smoother and more efficient ride.

Maintenance and Care for the Ford 9 Inch

Proper upkeep and attention are essential for ensuring optimal performance and longevity of your vehicle’s rear differential system. Regular maintenance not only enhances efficiency but also minimizes the risk of unexpected failures during operation.

Routine Inspections: Conduct frequent checks to identify any signs of wear or damage. Look for fluid leaks, unusual noises, or any irregularities in performance. Early detection of issues can prevent more significant problems down the line.

Fluid Changes: It is crucial to replace the lubricant at recommended intervals to maintain smooth operation. Use high-quality gear oil that meets or exceeds the manufacturer’s specifications. This practice helps reduce friction and prolongs the life of the internal components.

Component Care: Ensure all components, such as bearings and seals, are in good condition. Any signs of deterioration should be addressed immediately to avoid further complications. Regular cleaning and greasing of moving parts can enhance performance and reduce wear.

Professional Servicing: Consider seeking professional assistance for thorough inspections and servicing. Experts can provide valuable insights and perform necessary repairs or adjustments that may not be easily identifiable to the untrained eye.

By following these maintenance practices, you can ensure that your differential operates efficiently, providing reliable performance for many miles ahead.

Ford 9 Inch vs Other Axles

This section explores the comparisons between a well-known rear assembly and alternative configurations available in the automotive market. By evaluating various characteristics such as strength, versatility, and performance, enthusiasts can better understand their options for enhancing their vehicles.

Strength and Durability

When considering different axle systems, strength and durability are paramount. A robust assembly typically provides better support for high-performance applications. Key aspects include:

- Material quality: High-grade steel components contribute to longevity.

- Design: An optimized structure can withstand greater stress and torque.

- Maintenance: Some assemblies require less frequent service, enhancing reliability.

Versatility and Customization

Another crucial factor is the versatility offered by different axle configurations. Customization options can greatly affect performance and handling. Points to consider include:

- Gear ratios: The ability to change ratios allows for tuning the assembly to specific driving styles.

- Compatibility: Certain setups may fit a wider range of vehicle models, making upgrades easier.

- Aftermarket support: A strong community and available parts can enhance the modification process.

Pinion and Ring Gear Replacement Guide

Replacing the pinion and ring gear is a crucial maintenance task that ensures optimal performance of your vehicle’s drivetrain. This process involves several steps, including disassembly, inspection, and reassembly, to guarantee that the components function correctly and efficiently. Proper attention to detail during this procedure can enhance the longevity of the gear system and improve overall driving experience.

Tools and Materials Needed

Before beginning the replacement, gather the necessary tools and materials. You will need a torque wrench, a suitable socket set, a gear puller, and new seals and gaskets. It’s also advisable to have gear oil on hand for lubrication after installation. Ensure that all tools are in good condition to facilitate a smooth workflow.

Step-by-Step Replacement Process

Start by safely lifting the vehicle and securing it on jack stands. Remove the differential cover to access the internal components. Carefully detach the old pinion and ring gear by following the manufacturer’s specifications for disassembly. Inspect the housing for any signs of wear or damage. Once the old gear set is removed, install the new components, ensuring they are properly aligned and secured. Finally, refill the differential with fresh gear oil and reattach the cover, making sure all bolts are tightened to the specified torque.

Performance Benefits of Ford 9 Inch Axles

The engineering behind certain rear-end assemblies significantly enhances vehicle dynamics and overall performance. These components are designed to withstand high power outputs, improve traction, and ensure durability, making them a favored choice among automotive enthusiasts and professionals alike.

Strength and Durability

One of the primary advantages of these assemblies is their robust construction. They feature a high-strength design that can handle increased torque and weight, providing reliability during intense driving conditions. This strength translates into longevity, reducing the frequency of repairs and replacements, which can be both time-consuming and costly.

Enhanced Traction and Handling

Another notable benefit is the improved grip offered by these assemblies. With the ability to accommodate wider tires and better gear ratios, they enhance a vehicle’s traction, especially in high-performance scenarios. This leads to superior handling characteristics, allowing for greater cornering capabilities and responsiveness on various terrains.

Overall, the incorporation of these rear-end assemblies can significantly elevate a vehicle’s performance metrics, making them a wise investment for those looking to maximize their automotive experience.