When maintaining or repairing your vehicle, understanding the structure and connections of various systems is crucial. This knowledge helps in diagnosing issues and ensuring proper care during replacements or upgrades. Recognizing how different elements interact under the hood is essential for a well-functioning vehicle.

In this section, we will explore the intricate setup of vital systems, paying close attention to their configuration. Properly grasping this information will help with identifying wear and tear, and guide you through selecting suitable replacements. Understanding the mechanical layout ensures both safety and efficiency on the road.

By focusing on the various assemblies and their relationships, we aim to simplify complex topics. You’ll gain insights into how components are linked, making it easier to handle future maintenance. These details are fundamental for anyone looking to enhance their vehicle’s performance or ensure its long-term reliability.

2013 F250 Front End Parts Overview

Understanding the essential components located at the forefront of the vehicle is key to ensuring its performance and durability. These elements play a significant role in both handling and safety, offering drivers a stable and controlled experience on the road. Regular maintenance and awareness of how these systems work together can prevent potential issues and prolong the vehicle’s life.

Key Components of the Vehicle’s Fore Structure

The system involves several interconnected parts that contribute to steering and stability. Among the most important are suspension components, which help absorb shocks and vibrations, ensuring a smoother ride. Additionally, the steering mechanisms allow for precise control, providing both comfort and safety in various driving conditions.

Importance of Regular Inspections

Frequent check-ups of the front mechanisms are crucial for maintaining optimal performance. Identifying wear and tear early can help prevent larger, more costly repairs down the road. Keep an eye on any signs of alignment issues or unusual noises, as these can indicate underlying problems with the core elements of the vehicle.

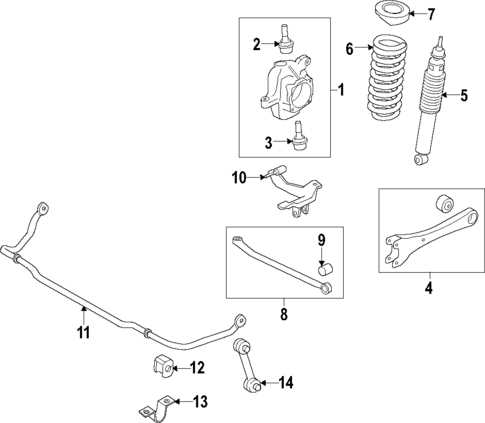

Key Components of the F-Series Suspension

The suspension system plays a crucial role in ensuring the vehicle’s stability, handling, and overall ride comfort. Its main function is to absorb the impact from uneven roads while maintaining the vehicle’s alignment and tire contact with the ground. Below, we will explore the essential elements that make up this system, which are designed to work in unison for optimal performance.

Suspension Springs

These are responsible for supporting the weight and absorbing shock from the road. They allow vertical movement while maintaining balance, helping the vehicle handle bumps and dips smoothly.

- Coil Springs: Typically found in the front section, they compress and expand to cushion the ride.

- Leaf Springs: Commonly used in the rear, offering durability and strength, especially when carrying heavy loads.

Shock Absorbers and Struts

These components reduce the bounce and movement of the springs, ensuring a smoother ride and better control. They help stabilize the vehicle during turns and on rough terrain.

- Shock Absorbers: Designed to dampen the energy from the springs, preventing excessive movement and improving comfort.

- Struts: A structural component t

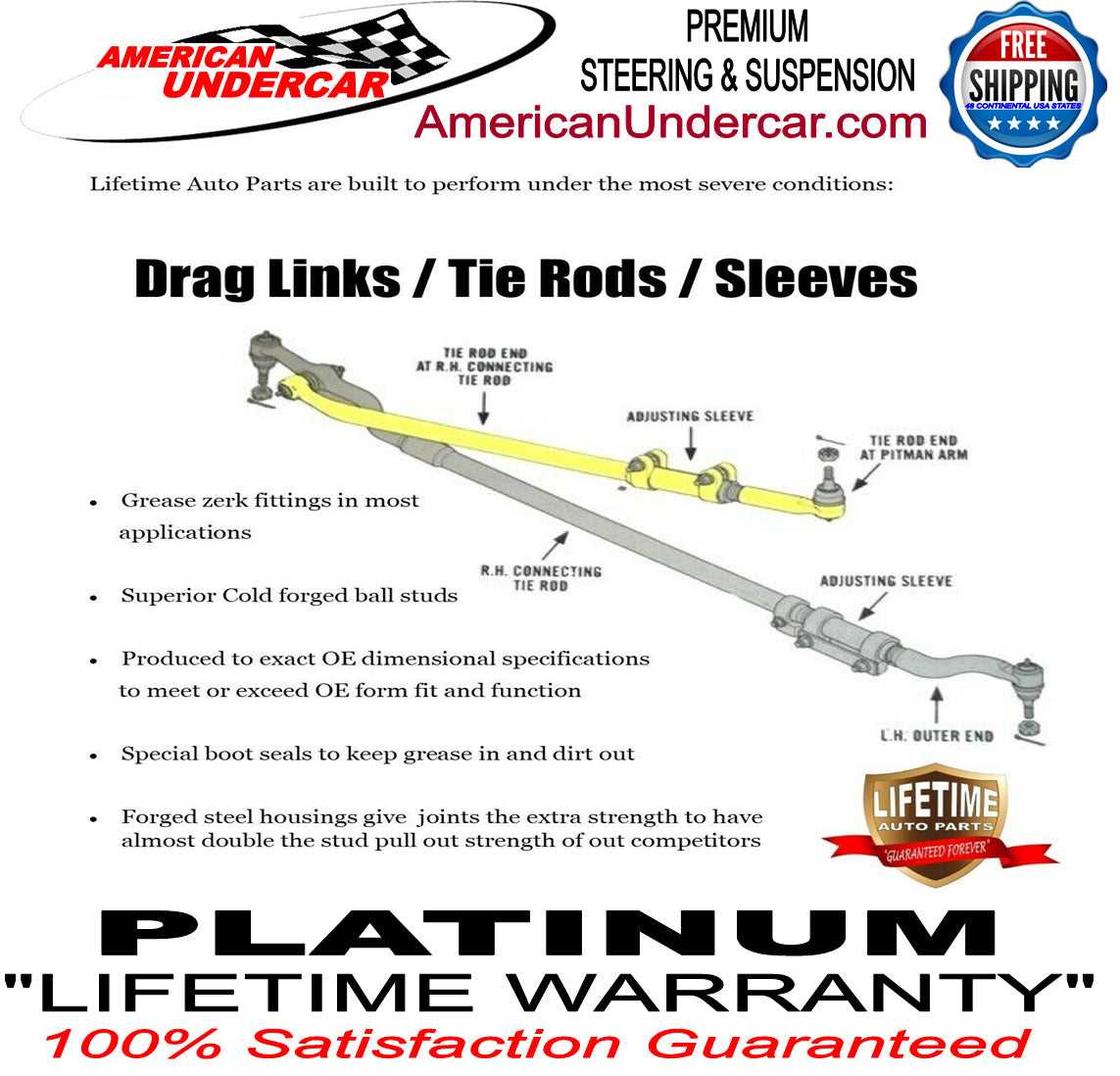

Steering Mechanism and Its Role

The steering system is crucial in maintaining control and direction of a vehicle. It serves as the link between the driver and the wheels, enabling smooth and precise maneuverability. Through a combination of components, it allows the vehicle to respond accurately to the driver’s input, ensuring safety and stability on the road.

Core Functions: The steering system is responsible for converting the driver’s rotational movement of the steering wheel into a corresponding motion of the tires. This process involves several mechanisms that work in unison to ensure the vehicle follows the intended path.

Importance of Maintenance: Regular maintenance of the steering mechanism is vital to ensure proper functioning. Any malfunctions in this system can lead to poor handling, reduced control, and increased wear on other components. Ensuring optimal performance of the steering system significantly contributes to overall driving safety and comfort.

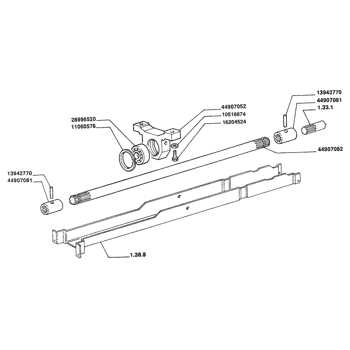

Understanding the F-Series Axle Assembly

The axle system in this heavy-duty truck plays a critical role in ensuring stability, power transfer, and overall handling. It is designed to bear significant weight and maintain vehicle alignment during various driving conditions. The assembly connects the wheels, allowing for the proper distribution of torque and supporting the overall suspension system.

Main Components of the Axle Structure

The axle assembly includes several key elements that work together to provide durability and strength. These components include the axle shaft, differential, and housing. The axle shaft is responsible for transferring rotational power to the wheels, while the differential adjusts power between them, ensuring smooth turns. The housing protects these vital parts from external damage and wear.

Importance of Regular Maintenance

Proper upkeep of the axle assembly is essential for the longevity and performance of the vehicle. Regular inspection for wear and tear, along with timely lubrication, helps prevent issues like excessive friction or component failure. Maintaining these elements ensures optimal performance and enhances the vehicle’s capability to handle various terrains.

Braking System Components in the Front End

The braking system plays a crucial role in vehicle safety, ensuring that the driver can effectively reduce speed or come to a complete stop. Various elements within this system work in unison to provide optimal performance. Understanding how each component functions helps in diagnosing issues and maintaining the overall reliability of the vehicle’s operation.

Brake Calipers are essential for controlling the pressure applied to the brake pads. They house the pistons and force the brake pads against the rotor when the driver applies pressure to the brake pedal. This action creates the necessary friction to slow down the rotation of the wheels.

Brake Pads are wear-and-tear components that come into direct contact with the rotor. Their function is to generate friction, which allows the vehicle to decelerate smoothly. Over time, these pads require replacement to ensure the system maintains its efficiency.

Brake Rotors are metal discs connected to the wheels. As the brake pads clamp down on the rotor, friction is produced, which slows down the rotation of the wheels. These rotors must remain in good condition to ensure proper braking and should be inspected regularly for wear.

Hydraulic Lines are responsible for transmitting the hydraulic pressure from the brake pedal to the brake calipers. These lines are critical for ensuring a smooth and responsive braking experience. Regular checks for leaks or damage are essential to maintain optimal performance.

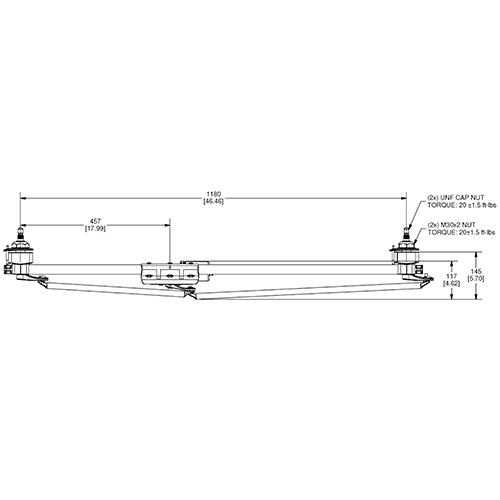

Importance of the Stabilizer Bar

The stabilizer bar plays a crucial role in enhancing vehicle stability and overall performance. By reducing body roll during cornering, this component significantly improves handling and driver confidence. A well-functioning stabilizer bar is essential for maintaining proper alignment and ensuring a smooth ride.

Key Benefits

- Improved Handling: This element helps distribute weight evenly across the axle, resulting in better traction and control.

- Enhanced Comfort: By minimizing the effects of road imperfections, it contributes to a smoother driving experience.

- Increased Safety: A stable vehicle is less prone to tipping over, especially during sudden maneuvers.

Maintenance Tips

- Regularly inspect for wear and tear to prevent potential failures.

- Check mounting brackets and bushings for signs of damage.

- Ensure proper torque specifications are followed during installation.

Wheel and Tire Compatibility for the Front

Choosing the right wheel and tire combination is crucial for optimal performance and safety. The compatibility of these components affects handling, stability, and overall driving experience. Understanding the specifications and recommendations will help ensure a suitable fit for your vehicle.

Key Factors to Consider

- Diameter: Ensure the size aligns with the manufacturer’s guidelines for the vehicle.

- Width: The width of the tire should match the wheel size for proper fitment.

- Offset: This measurement influences the wheel’s position relative to the suspension components.

- Load Rating: Tires must support the weight requirements of the vehicle for safe operation.

Recommended Tire Types

- All-Season Tires: Suitable for varied weather conditions, providing balanced performance.

- Off-Road Tires: Designed for rugged terrain, enhancing traction in challenging environments.

- Performance Tires: Focused on handling and responsiveness for spirited driving.

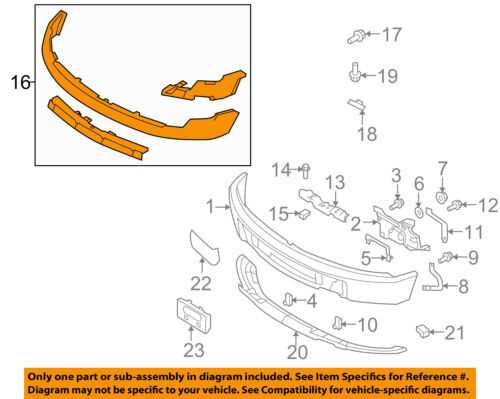

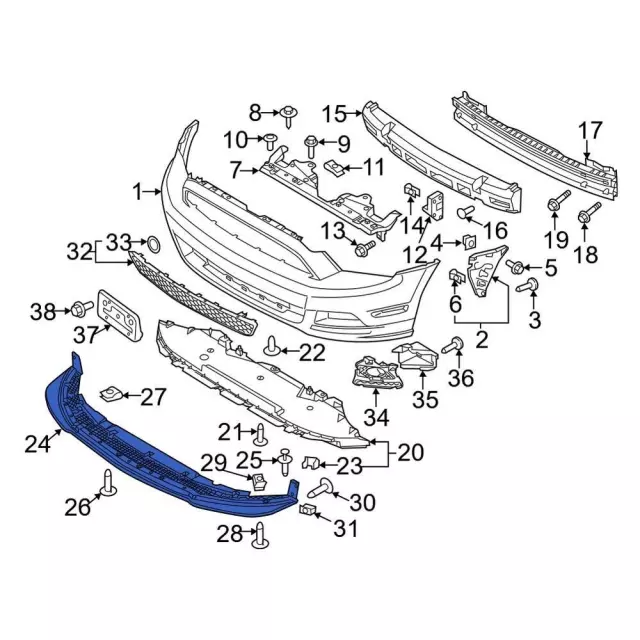

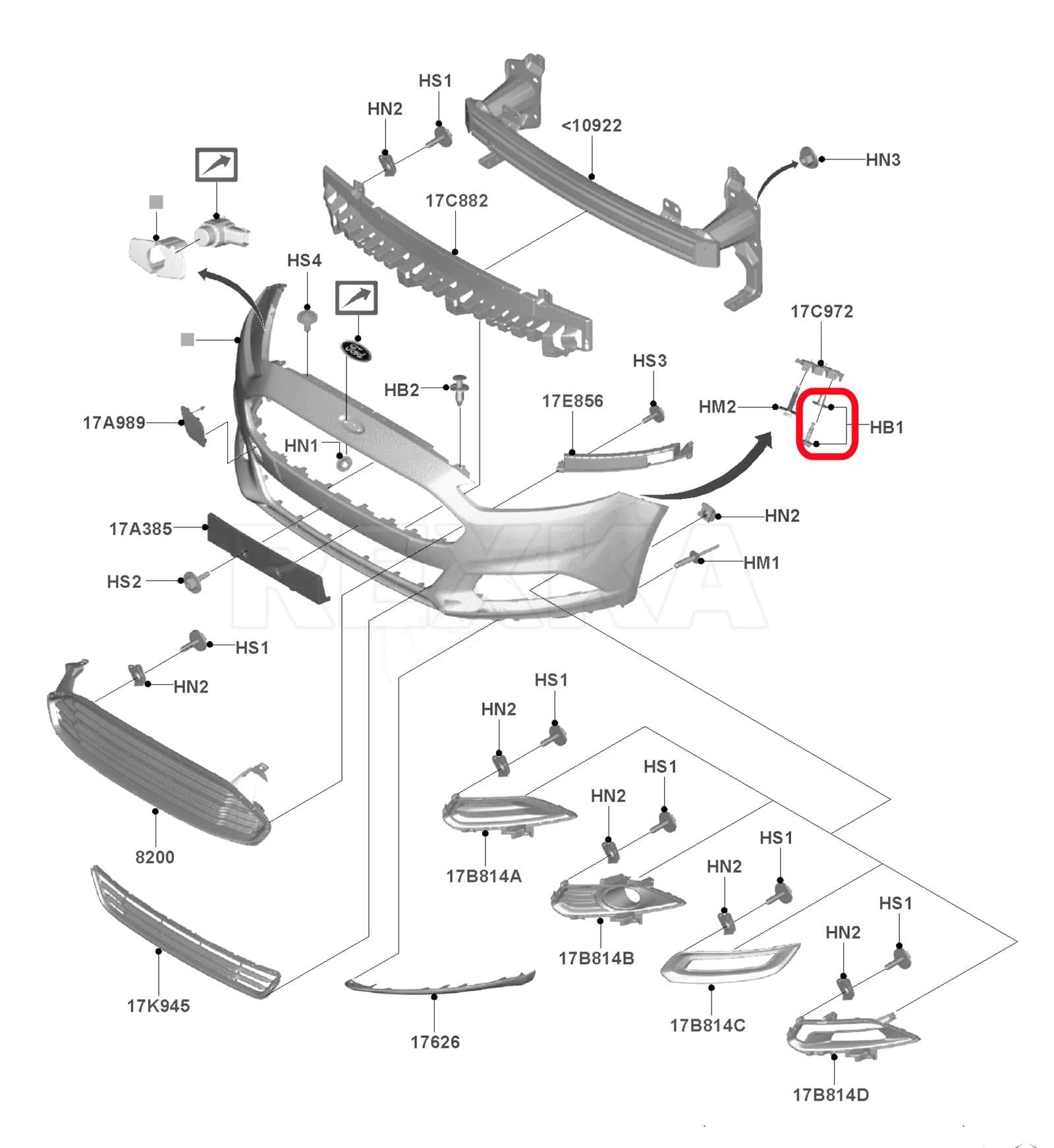

Front Bumper Structure and Materials

The construction of the frontal protective component of a vehicle plays a crucial role in both safety and aesthetics. It is designed to absorb impacts, shield vital systems, and enhance the overall appearance of the automobile. Understanding the materials and design elements that comprise this structure can provide insights into its performance and durability.

Material Composition

The materials used in the manufacturing of this protective element are selected based on their strength, weight, and resistance to environmental factors. Commonly utilized substances include:

Material Properties Steel High strength, excellent durability, corrosion resistance Aluminum Lightweight, good resistance to rust, decent strength Plastic Lightweight, cost-effective, impact-absorbing Structural Design

The design of the bumper is not only about aesthetics but also functionality. The geometry often includes reinforcement zones to better distribute force during collisions, reducing the risk of damage to the vehicle’s frame and components. Various designs may incorporate aerodynamic features to enhance vehicle performance and fuel efficiency.

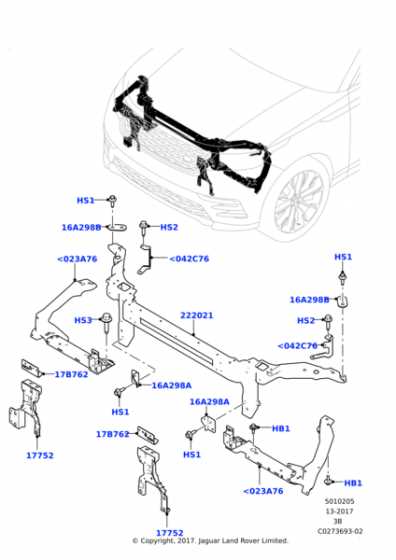

Headlight and Electrical Wiring Diagram

This section provides a comprehensive overview of the lighting system and its associated electrical connections. Understanding the layout and functionality of the components is essential for effective maintenance and troubleshooting.

The headlight assembly includes various elements such as bulbs, sockets, and connectors that work together to provide illumination. Each component plays a crucial role in ensuring optimal performance and safety during nighttime driving or adverse weather conditions.

Additionally, the electrical wiring plays a vital part in powering the headlights. A clear representation of the wiring routes and connections helps in identifying potential issues, such as short circuits or damaged wires, facilitating efficient repairs.

By familiarizing yourself with this layout, you can ensure your vehicle’s lighting system remains in top condition, enhancing visibility and safety on the road.

F250 Grille Design and Airflow

The grille is a crucial component of a vehicle’s front fascia, serving both aesthetic and functional purposes. Its design not only enhances the overall appearance but also plays a significant role in managing airflow to the engine and cooling systems. Understanding the intricacies of this component is essential for optimizing vehicle performance and ensuring efficient operation.

Design Features

- Streamlined shape for improved aerodynamics.

- Strategic placement of vents to facilitate airflow.

- Material selection that balances durability and weight.

- Customization options for personal expression and style.

Impact on Airflow

Effective airflow management is vital for engine cooling and overall vehicle efficiency. The grille’s design significantly influences how air enters and circulates through the engine compartment. Key aspects include:

- Enhanced cooling capabilities due to increased airflow.

- Reduction of drag, contributing to better fuel efficiency.

- Prevention of overheating by directing air to critical components.

By understanding the role of grille design in airflow dynamics, owners can appreciate the engineering that goes into optimizing vehicle performance.

Shock Absorbers and Their Functionality

Shock absorbers play a crucial role in enhancing vehicle performance and safety by maintaining stability and control. These components are designed to dampen the oscillations created by the suspension system, ensuring a smooth and comfortable ride.

The primary function of these devices is to manage the impact and rebound of the vehicle’s springs. By controlling the movement of the suspension, shock absorbers minimize the transfer of road irregularities to the vehicle’s body, reducing discomfort for passengers and improving traction on various surfaces.

Additionally, they contribute to better handling by maintaining consistent tire contact with the road. This is vital for effective steering and braking, especially in challenging driving conditions. Overall, well-functioning shock absorbers are essential for a safe and enjoyable driving experience.

Front End Alignment Tips for 2013 F250

Ensuring optimal wheel positioning is essential for enhancing vehicle performance and longevity. Proper adjustments can lead to improved handling, tire wear, and overall driving experience. This section provides practical advice on achieving accurate adjustments for your vehicle.

1. Regular Inspections: Schedule routine assessments to check for misalignment signs. Uneven tire wear or steering wheel off-center can indicate a need for adjustments.

2. Professional Assistance: Consider enlisting a qualified technician with experience in alignment procedures. Their expertise can help diagnose issues and perform precise calibrations.

3. Utilize Quality Equipment: Invest in reliable alignment tools or visit a service center that employs advanced technology. Accurate equipment ensures correct angles for optimal vehicle performance.

4. Follow Manufacturer Guidelines: Adhere to the recommended specifications outlined in the vehicle manual. This information is vital for setting the proper angles during adjustments.

5. Test Drive: After completing the adjustments, take the vehicle for a test drive. Pay attention to how it handles, and make any necessary tweaks to ensure a smooth ride.