When it comes to the stability and maneuverability of any vehicle, understanding the essential elements responsible for its smooth operation is crucial. These components work in unison to ensure safe and efficient movement, particularly in situations that demand precise handling and control. By diving into the details of these integral mechanisms, we can better appreciate their role in the overall performance of a vehicle.

In this section, we will take a closer look at how each individual element plays a part in maintaining balance and direction. From supporting the vehicle’s weight to managing intricate movements during turns, these parts collectively ensure a seamless driving experience. Understanding the layout and function of these mechanisms is essential for anyone seeking to improve or maintain their vehicle’s functionality.

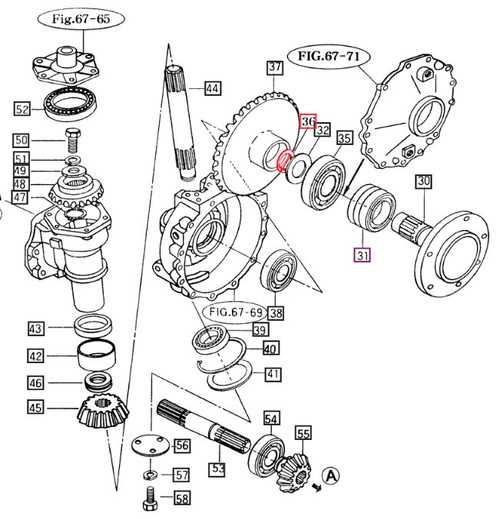

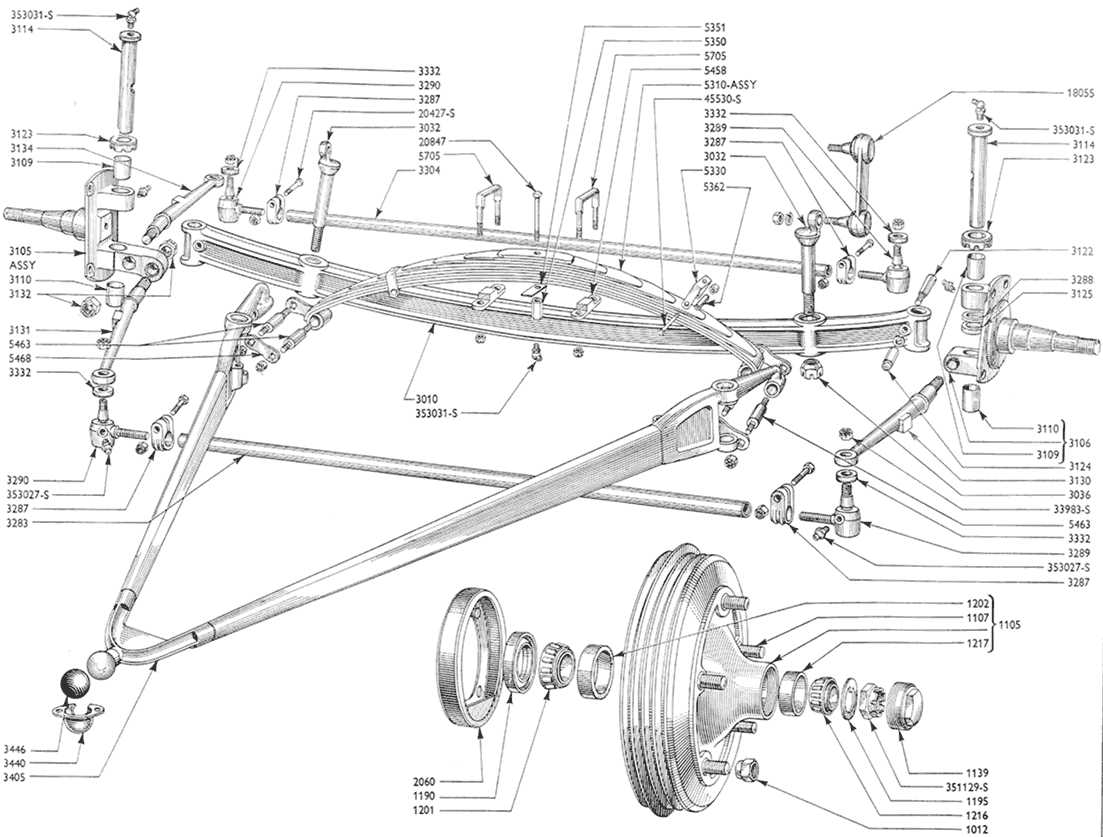

Understanding the Functionality of a Front Axle

The key component under consideration plays a vital role in supporting the overall structure of the vehicle while enabling smooth and controlled movement. Its primary function revolves around connecting critical elements, allowing the wheels to turn effortlessly and maintain stability during motion. Without this crucial element, the system’s balance and performance would be significantly compromised.

Operational efficiency is ensured through the effective transfer of rotational force from the engine to the wheels, which is essential for maintaining traction and directional control. The mechanism also plays a role in absorbing shock from uneven surfaces, enhancing overall ride comfort. Additionally, various intricate components work in harmony to facilitate steering precision, ensuring the driver maintains control in various driving conditions.

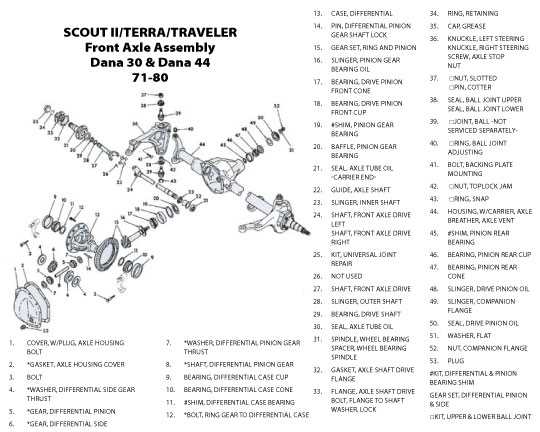

Key Components of a Wheel Hub Assembly

The intricate system responsible for ensuring smooth rotation and support of the wheel is composed of several essential elements. These elements work in unison to provide stability and control during vehicle operation. Understanding the core components within this mechanism is vital for maintaining overall performance and safety.

Bearing

Bearings are at the heart of the assembly, enabling frictionless movement and ensuring the wheel can spin freely. They are designed to handle the forces exerted during rotation, reducing wear and tear.

Mounting Elements

Critical to the connection of the entire unit, mounting elements include bolts and fasteners that secure the assembly in place. These components guarantee a reliable attachment to the vehicle, ensuring that all parts remain aligned and stable.

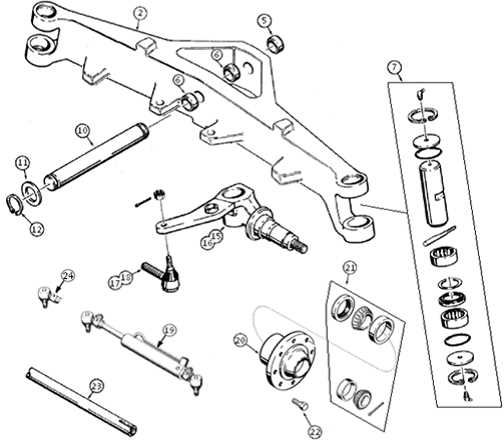

The Role of CV Joints in Steering

The smooth operation of a vehicle’s movement relies on various interconnected elements working together to ensure consistent power delivery and maneuverability. One of the key components in this process is responsible for allowing flexibility and motion transfer between different systems, even when sharp turns or uneven roads are encountered.

These specialized connectors are vital for maintaining control and stability. They adjust to changes in direction while ensuring the energy from the engine reaches the wheels without interruption. This ability to flex while maintaining power transfer is essential for safe and efficient handling.

| Component | Function | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Outer Connector | Facilitates motion at the wheel end during turns | ||||||||

| Inner Connector | Maintains energy flow from the drivetrain to the moving sections | ||||||||

| Component | Function |

|---|---|

| Steering Knuckle | Links suspension and steering, allowing for wheel rotation. |

| Control Arm | Connects the knuckle to the vehicle frame, absorbing shocks. |

| Ball Joint | Facilitates movement between the knuckle and control arm. |

| Spindle | Holds the wheel hub and provides a pivot point for steering. |

Understanding the dynamics of this connection is vital for maintenance and repairs, as any failure in this assembly can lead to severe handling issues. Regular inspections can ensure the integrity of the steering knuckle and its associated components, promoting safety and enhancing the vehicle’s performance on the road.

Ball Joints and Their Impact on Handling

Ball joints play a crucial role in the performance and stability of a vehicle, serving as pivotal connections between various components. Their proper functioning is essential for maintaining the desired handling characteristics, ensuring that the vehicle responds predictably to steering inputs. The condition of these joints can significantly influence overall driving dynamics and safety.

Functionality and Wear

As flexible connectors, these elements allow for a range of motion while supporting the weight of the vehicle. Over time, exposure to various stresses and environmental factors can lead to wear and tear, causing a decline in performance. When these connectors deteriorate, drivers may notice symptoms such as uneven tire wear, reduced responsiveness, and an overall decrease in ride quality.

Enhancing Driving Experience

Maintaining optimal condition of these connections is vital for ensuring a smooth and controlled driving experience. Regular inspections and timely replacements can help preserve vehicle handling, allowing for precise maneuvering and increased safety on the road. By prioritizing the health of these joints, drivers can enhance both comfort and control during their journeys.

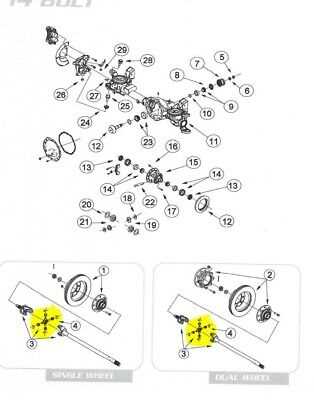

Understanding the Function of Axle Seals

Seals play a critical role in ensuring the longevity and efficiency of vehicle components. These essential elements act as barriers to prevent the escape of lubricants while simultaneously keeping contaminants at bay. By maintaining a proper seal, the overall functionality of the surrounding mechanisms is enhanced, leading to improved performance and reduced wear.

The primary function of these seals is to retain essential fluids, such as oil, within the system. This retention is vital for lubricating moving components, minimizing friction, and preventing premature failure. Additionally, seals help protect sensitive areas from dirt, moisture, and debris, which can significantly affect operational efficiency and longevity.

Furthermore, the integrity of these seals directly influences the overall performance of the vehicle. When seals become worn or damaged, leaks can occur, leading to insufficient lubrication and increased wear on mechanical components. Regular inspection and maintenance of these elements are crucial for ensuring optimal performance and preventing costly repairs.

Maintenance Tips for Front Axle Components

Regular upkeep of critical vehicle elements ensures optimal performance and longevity. By adhering to specific maintenance practices, you can enhance the reliability of your automobile and prevent costly repairs down the line. This section outlines essential tips to help you maintain these vital components effectively.

Routine Inspections

Conducting frequent examinations is essential for identifying wear and tear. Look for any signs of damage, such as cracks or unusual wear patterns. Ensure all connections are secure and free from corrosion, which can significantly impact functionality. Timely detection of issues can save you from more extensive repairs in the future.

Lubrication and Cleaning

Keeping components well-lubricated is crucial for minimizing friction and wear. Use high-quality lubricants recommended by manufacturers to ensure optimal performance. Additionally, regularly clean all surfaces to remove dirt and debris, which can contribute to premature wear. Proper lubrication and cleanliness play a significant role in the overall efficiency of your vehicle’s system.