In agricultural and landscaping tasks, certain equipment proves indispensable for maintaining efficiency and ensuring effective performance. The structure and arrangement of key elements can greatly influence the tool’s durability and functionality. Knowing how each piece fits and works together is crucial for proper maintenance and smooth operation.

This overview explores the intricate layout and assembly of various elements, offering insights into how they interconnect. By familiarizing oneself with the arrangement and the function of each component, users can enhance the longevity and reliability of the equipment, ensuring it runs smoothly even under demanding conditions.

The following sections aim to provide a detailed look into each segment, helping users navigate the setup with ease. Whether it’s for routine upkeep or more involved repairs, understanding the connections and their placement can significantly streamline the process, saving both time and effort.

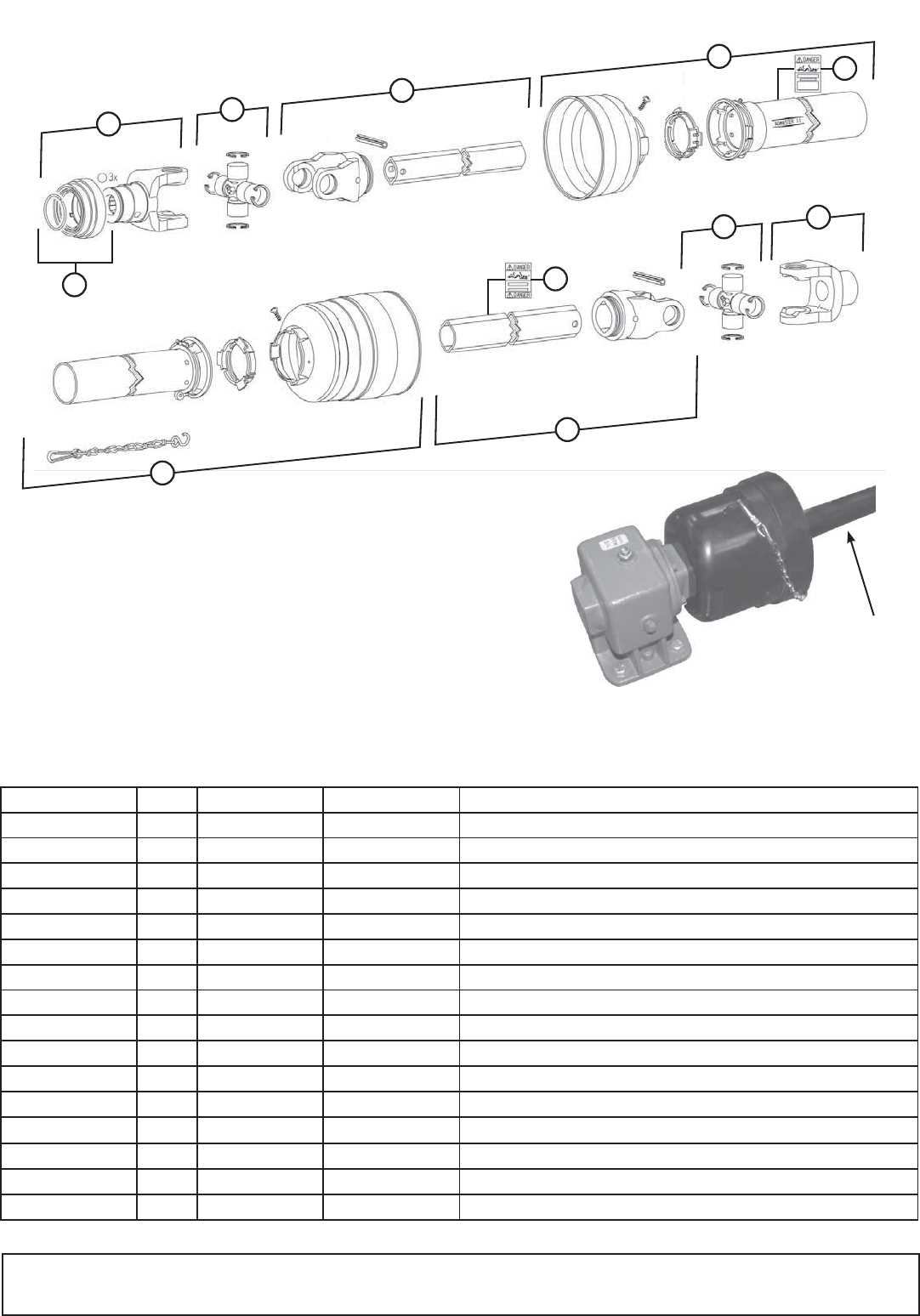

Overview of Frontier RC2060 Components

The system’s structure integrates various elements that work together to ensure smooth operation and durability. Each element plays a crucial role, from the frame that provides stability to the mechanisms that handle cutting and adjustments. Understanding the arrangement and functionality of these elements helps users maintain and optimize the unit’s performance.

At the core is the robust frame, providing a solid foundation that supports all other elements. This frame is designed to endure challenging conditions, ensuring that the entire setup remains stable during use. Coupled with the frame are adjustable arms, allowing precise control over the equipment’s angle and position for varied terrains.

The rotational mechanism is another key aspect, responsible for efficient power transfer. It connects to the primary cutting apparatus, ensuring that the blades receive adequate force for consistent operation. The cutting mechanism itself is built to handle tough vegetation, with sharpened edges that maintain their efficiency over time.

To ensure the equipment remains secure during use, safety features are integrated throughout. These include protective covers over sensitive areas and reinforced fasteners, which prevent any unwanted movement or damage during operation. Such features not only prolong the equipment’s lifespan but also enhance user safety.

Additionally, the drive system connects seamlessly with the power source, translating energy into movement. This arrangement ensures that the operation remains smooth, even under significant workloads. Regular checks and adjustments of these elements are essential for maintaining peak efficiency and preventing wear.

Main Blade Assembly Breakdown

The central mechanism focuses on the arrangement and structure of the rotating components. Understanding each element’s role is crucial for efficient operation and maintenance, ensuring smooth performance and reducing wear over time.

Key Components Overview

The primary section consists of various interconnected elements, including the rotating shaft, cutting edges, and support fixtures. Each part contributes to the overall balance, allowing the system to function without unnecessary vibrations. Proper alignment is essential to maintain optimal functioning.

Detailed Component Functions

The rotating shaft serves as the core axis, providing stability and driving the motion of the sharpened edges. These edges, designed for precision, are engineered to cut through materials effectively. Supporting brackets and fasteners hold the entire structure together, ensuring safety and durability during use. Regular inspection of these elements can extend the lifespan and efficiency of the mechanism.

Gearbox Structure and Functionality

The mechanical assembly discussed here plays a critical role in transforming power and adjusting speed. It efficiently channels force through a series of internal components, ensuring smooth transitions and proper energy management during operation. Understanding the arrangement and role of each element is key to maintaining peak performance and longevity.

Key Components and Their Roles

Within this assembly, gears interlock precisely to modify the rotational force, distributing it evenly across various parts. Shafts support the gears, guiding movement and transferring torque effectively. Bearings minimize friction between moving sections, reducing wear and ensuring a consistent motion flow. Together, these elements enable a robust power transfer system.

Adjustment and Maintenance Considerations

Regular adjustments ensure the assembly operates at optimal levels. Proper alignment of internal parts helps maintain balance, preventing unnecessary strain. Lubrication of moving elements is crucial to avoid overheating and extend the lifespan of the entire mechanism. Awareness of wear patterns can help detect issues early, allowing for timely intervention.

Identifying Key Deck Parts

Understanding the essential components of the cutting platform is crucial for effective maintenance and repair. By knowing each element’s function and location, one can ensure smooth operation and prolong the lifespan of the equipment. This section provides a detailed overview of the various sections that make up the platform, highlighting their roles and significance.

Cutting Blades and Assembly

The core of the cutting system includes the rotary blades, which handle the primary cutting tasks. Mounted securely beneath the platform, these blades rotate at high speeds, driven by the central spindle. Regular inspection of the blades ensures sharpness and efficient trimming, while checking the assembly around them helps prevent any mechanical issues.

Drive Mechanism and Gearbox

The drive setup is responsible for transferring power from the engine to the cutting system. This includes the gearbox, which regulates speed and torque, allowing for controlled movement of the blades. Keeping the drive system well-lubricated and free of debris ensures that the overall platform functions without interruptions, especially under demanding conditions.

Hitch Connection Elements Analysis

The components involved in the attachment process are crucial for ensuring a secure and effective linkage between the implement and the towing vehicle. Understanding these elements aids in optimizing stability and safety during operation.

Attachment Points: The primary interface includes multiple reinforced areas designed to connect with the tow bar. These areas must be robust to endure the mechanical stresses encountered during movement.

Locking Mechanism: This element ensures the linkage remains stable under dynamic conditions. It typically involves levers or pins that secure the equipment, preventing accidental detachment.

Support Structures: These include reinforced frames and brackets that distribute weight evenly. They are designed to minimize stress on specific points, enhancing the durability of the entire connection system.

Adjustable Linkage: Adjustability allows for a tailored fit to various towing systems. It includes adaptable arms or connectors that accommodate different height or angle requirements, providing versatility for diverse applications.

Proper maintenance of these elements can significantly extend the lifespan of the attachment system and ensure reliable performance during operation.

Blade Carrier Design Features

The design of a blade carrier plays a crucial role in the overall functionality and performance of agricultural equipment. Its construction directly impacts the efficiency of operations, ensuring that tasks such as mowing, tilling, and cutting are executed effectively. By understanding the key features that define a blade carrier, users can better appreciate its significance in enhancing productivity in various farming applications.

Material and Durability

The choice of materials in a blade carrier is vital for its longevity and reliability. High-strength alloys or composites are often utilized to withstand the rigors of heavy use, reducing the risk of wear and tear. This ensures that the carrier maintains its structural integrity over time, leading to fewer replacements and maintenance efforts.

Attachment Mechanism

An efficient attachment mechanism is another essential feature of a blade carrier. It allows for easy installation and removal of blades, facilitating quick adjustments and replacements as needed. This user-friendly aspect enhances operational efficiency, enabling farmers to adapt swiftly to varying conditions or requirements without significant downtime.

Detailing the Driveline Mechanism

The driveline system plays a crucial role in ensuring efficient power transmission within machinery. This intricate assembly is designed to facilitate the transfer of energy from the engine to the wheels, thereby enabling movement and enhancing overall performance. Understanding its components and functionality is essential for maintaining optimal operation and addressing any potential issues that may arise during usage.

Key Components

At the heart of the driveline are several integral elements, including the transmission, drive shaft, and differential. Each component has a specific function that contributes to the seamless transfer of torque. The transmission regulates the engine’s power output and adjusts the gear ratio to meet varying demands. Meanwhile, the drive shaft connects the transmission to the differential, which further distributes power to the wheels. This harmonious interplay among parts is essential for achieving desired performance.

Importance of Maintenance

Regular upkeep of the driveline mechanism is vital to prevent wear and tear that could lead to mechanical failures. Routine inspections should include checking fluid levels, ensuring proper alignment, and identifying any signs of damage or corrosion. By proactively addressing these concerns, users can prolong the lifespan of the system and maintain reliable functionality.

Rear Wheel and Support Assembly

The rear wheel and support structure play a crucial role in the overall functionality and stability of the equipment. This assembly not only provides mobility but also ensures a secure foundation during operation. Understanding its components is essential for maintenance and troubleshooting.

Key Components

- Wheel Hub

- Tire

- Axle

- Support Bracket

- Mounting Hardware

Assembly Instructions

- Begin by securing the wheel hub to the axle.

- Attach the tire to the wheel hub, ensuring proper alignment.

- Position the support bracket and fasten it with the appropriate hardware.

- Check the entire assembly for stability and make necessary adjustments.

Regular inspection of this assembly is recommended to ensure safe and efficient operation. Proper care will extend the lifespan of the components and enhance performance.

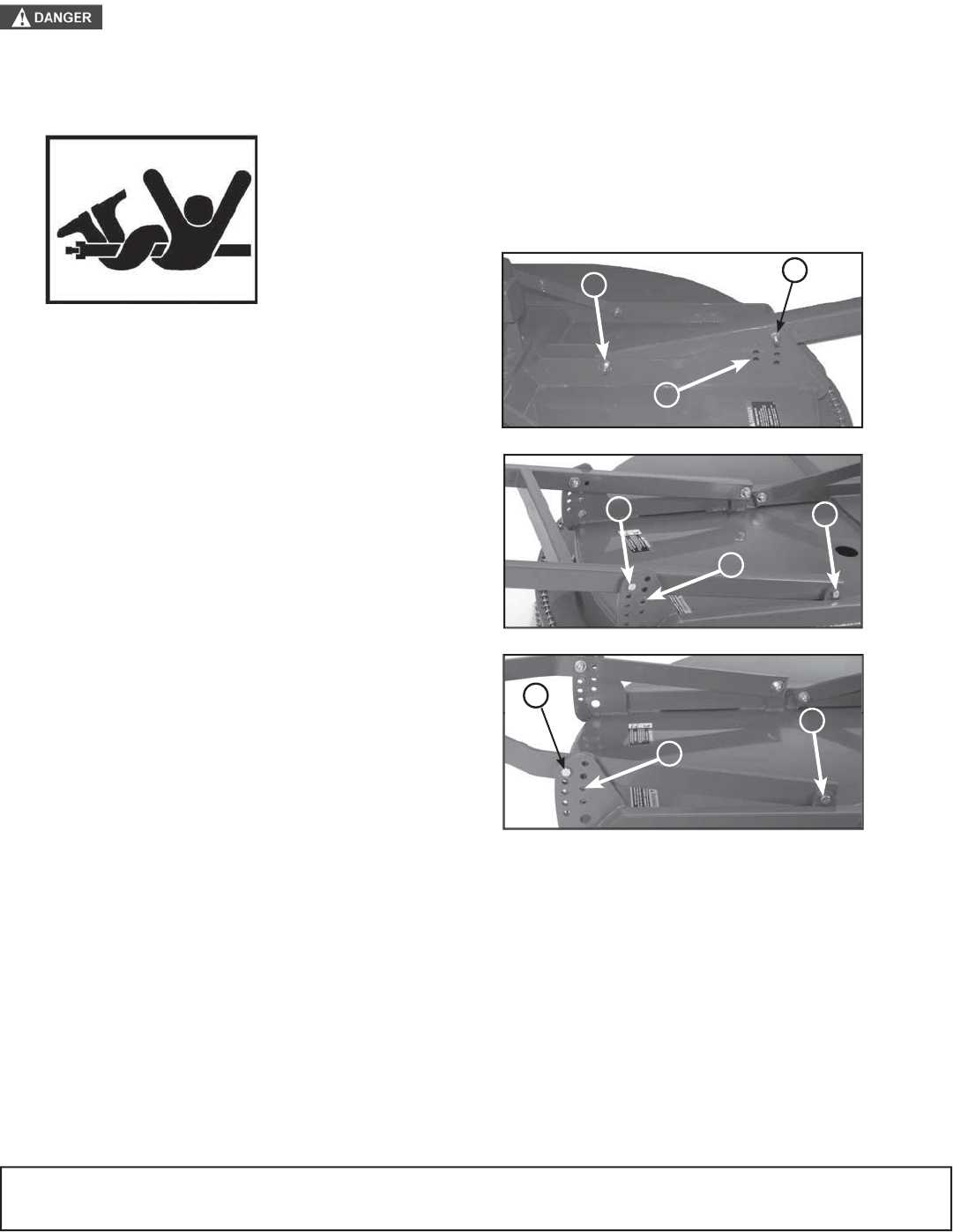

Protective Guards and Shields

In the realm of machinery, the implementation of protective barriers and coverings is essential for ensuring safe operation and prolonging the lifespan of components. These features serve to shield critical parts from external elements, minimize wear and tear, and provide safety for the user. Understanding the various types of protective mechanisms can enhance both performance and reliability.

- Functionality: These safeguards prevent debris and contaminants from entering sensitive areas, thus maintaining operational integrity.

- Material Choices: Typically made from durable plastics or metals, the selection of materials impacts the effectiveness and longevity of the guards.

- Design Variations: Shields come in various shapes and sizes, tailored to specific components and operational environments.

Proper installation and maintenance of these protective features are crucial for optimal performance. Regular inspections can help identify any damage or wear, ensuring that the safeguards remain effective.

- Inspect for signs of damage regularly.

- Clean guards to prevent accumulation of dirt and debris.

- Replace any worn or damaged components promptly to maintain safety standards.

Attachment Points and Mounting Options

Understanding the various connection sites and installation methods is crucial for ensuring proper assembly and functionality. Each segment of the machinery requires specific locations for secure fastening, which helps maintain stability during operation. Selecting the appropriate mounting techniques is essential for optimizing performance and ensuring safety during use.

Key Connection Sites

The primary connection sites are strategically positioned to facilitate efficient assembly. These points are designed to accommodate various components, allowing for seamless integration. Proper alignment at these locations is vital to ensure that the structure remains robust and can withstand operational stresses.

Installation Methods

Several installation methods can be employed, depending on the specific requirements of the machinery. Options may include bolting, welding, or using brackets, each offering different advantages. Selecting the right method is essential to achieving a secure fit while also allowing for potential adjustments or replacements in the future.

Understanding the Cutting Height Adjuster

The cutting height adjuster is a crucial component in optimizing the performance of mowing equipment. It enables users to modify the height at which grass or other vegetation is cut, ensuring a clean and even finish. This feature is essential for achieving desired aesthetics and promoting healthy growth.

Key aspects of the cutting height adjuster include:

- Precision Control: The adjuster allows for precise height modifications, accommodating different grass types and conditions.

- User-Friendly Mechanism: Most models are designed for easy adjustment, often featuring intuitive levers or knobs.

- Durability: Constructed from robust materials, these components are built to withstand wear and tear over time.

When operating mowing equipment, consider the following tips for effective use of the cutting height adjuster:

- Assess the current grass height before making adjustments to avoid cutting too low.

- Make incremental changes to the height settings to achieve the desired result.

- Regularly check the adjuster for any signs of wear or damage to ensure optimal performance.

Understanding and utilizing the cutting height adjuster effectively can significantly enhance the mowing experience, providing a clean and professional appearance to any lawn or landscape.

Common Wear and Replacement Items

Regular maintenance is essential to ensure the longevity and efficiency of machinery. Over time, certain components are prone to wear due to continuous use. Identifying these elements and replacing them promptly can prevent more significant issues and costly repairs. Understanding which items typically require attention can help maintain optimal performance.

| Component | Signs of Wear | Recommended Replacement Frequency |

|---|---|---|

| Belt | Cracks, fraying, or stretching | Every 500 hours of operation |

| Blades | Dull edges, chipping, or bending | As needed, typically every season |

| Filters | Discoloration or clogging | Every 100 hours of use |

| Spark Plug | Corrosion or wear | Every 200 hours or annually |

| Wheels/Tires | Uneven wear or cracks | Inspect regularly; replace as needed |

Monitoring these items will help ensure that the equipment operates smoothly and efficiently. Adopting a proactive approach to maintenance can lead to extended service life and enhanced reliability.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment requires regular upkeep and attention. By following a few essential maintenance practices, you can significantly extend the lifespan of your device and enhance its efficiency. These guidelines are designed to help you maintain your machinery in peak condition.

Start by routinely cleaning the exterior and interior components to prevent dust and debris accumulation. Pay close attention to moving parts and ensure they are lubricated appropriately. Additionally, regularly inspect all connections and wiring for any signs of wear or damage.

Following a structured maintenance schedule will help you identify potential issues early. Keep track of any repairs or replacements made to the system, as this can assist in maintaining a comprehensive history of the equipment’s condition.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Clean surfaces | Monthly | Use a soft cloth and appropriate cleaner. |

| Lubricate moving parts | Quarterly | Ensure to use the correct lubricant type. |

| Inspect connections | Biannually | Look for frayed wires and loose connections. |

| Check for software updates | Annually | Ensure the latest firmware is installed for optimal performance. |

Implementing these practices will not only enhance functionality but also promote a safer working environment. Regular maintenance is an investment that pays off through improved performance and fewer unexpected repairs.