Understanding the structure of various mechanical systems is essential for efficient maintenance and troubleshooting. Each machine comprises multiple elements that work together to achieve optimal performance, and knowing their arrangement can greatly assist in both repairs and upgrades. By familiarizing oneself with these layouts, one can ensure smooth operation and quickly identify any issues.

The following guide explores the organization of key components within a typical power system. This breakdown helps in visualizing the connections and interactions between various mechanical elements. Such knowledge is invaluable for ensuring long-term reliability and performance in demanding environments.

In this guide, we aim to highlight the critical mechanical sections and how they integrate with each other. Whether for routine inspections or significant repairs, understanding the configuration of these parts will streamline the process and ensure that your equipment functions effectively.

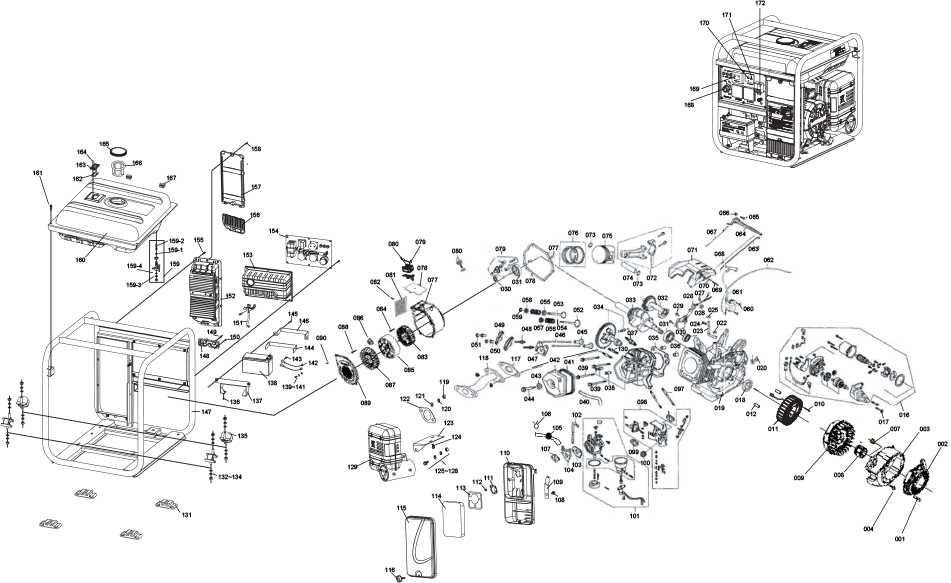

Overview of the System Components

The system is composed of several essential elements, each contributing to its overall performance and reliability. These components are carefully designed to work together, ensuring seamless operation in various conditions. Understanding how these parts interact is crucial for proper maintenance and troubleshooting.

Engine: The central unit powering the device, responsible for generating the required mechanical energy. It plays a vital role in ensuring consistent performance over extended periods of use.

Fuel Tank: This part holds the necessary fuel to run the engine. The tank is designed to optimize fuel consumption, ensuring efficient energy use while providing sufficient capacity for long operation times.

Control Panel: The interface through which users can monitor and control the system. It

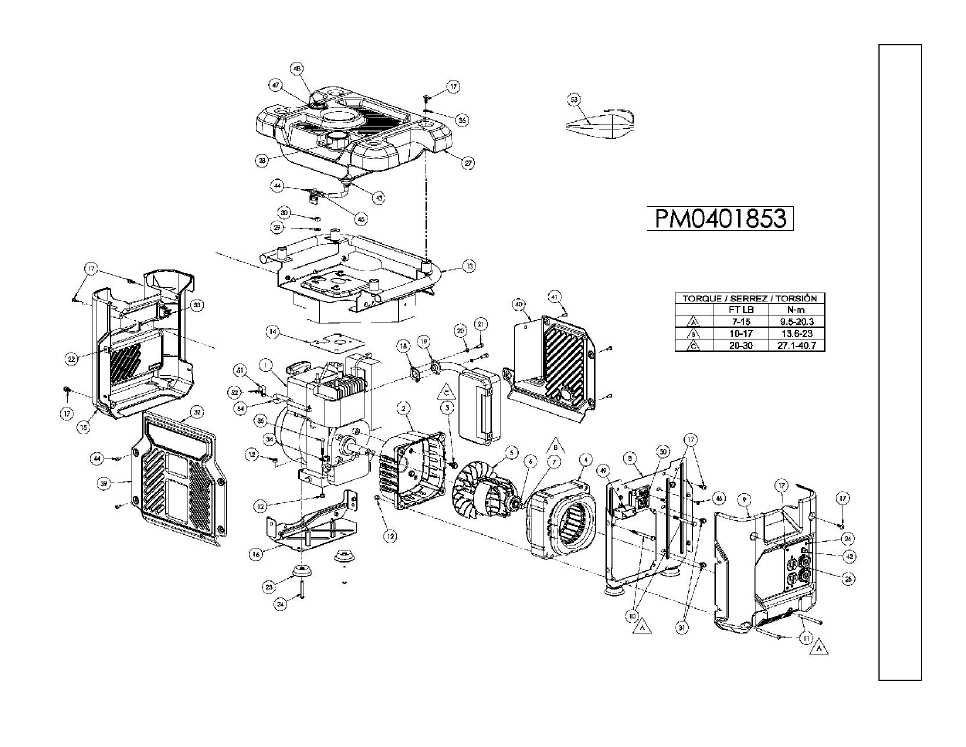

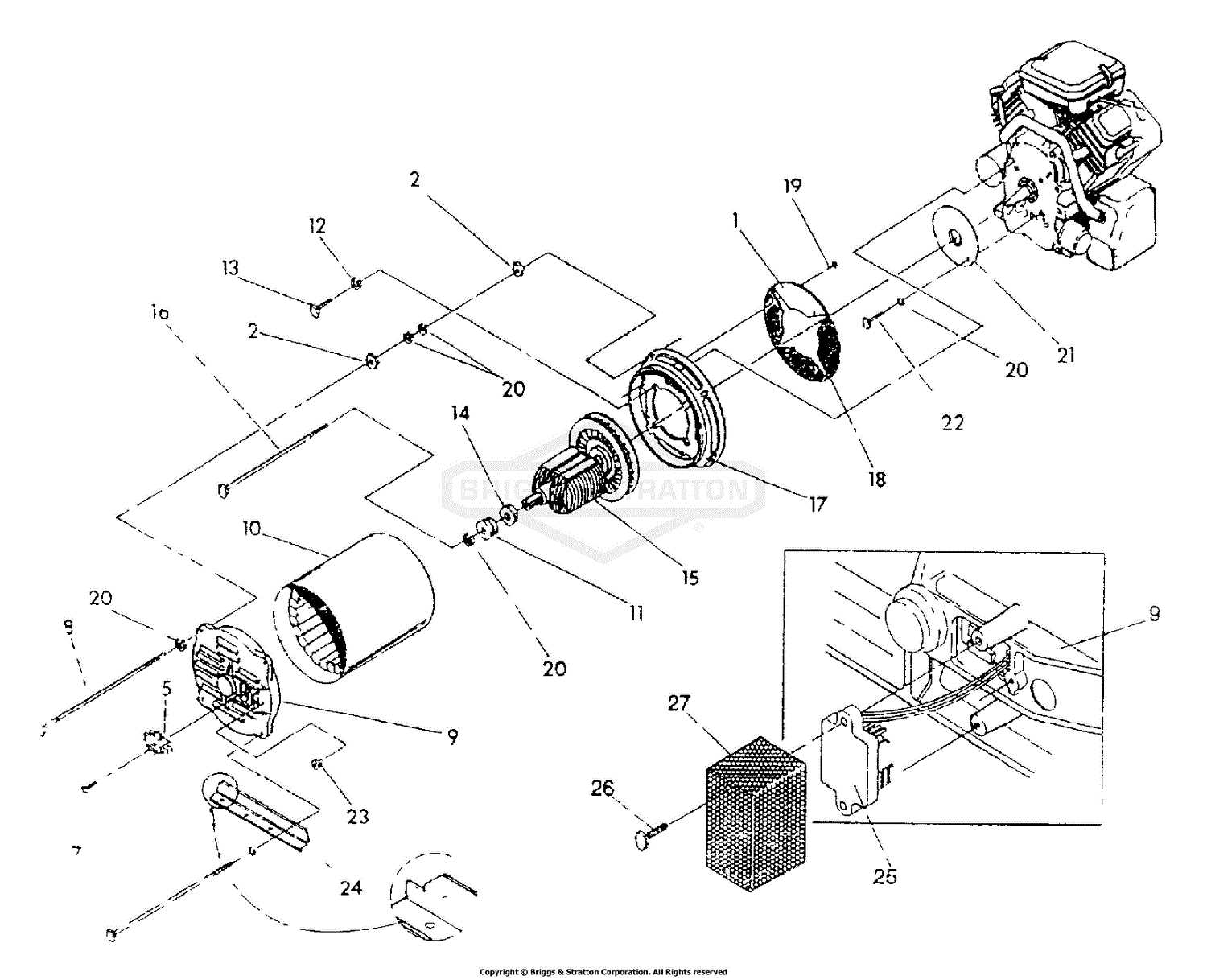

Main Engine Parts Breakdown

The primary components of the engine can be identified and categorized for a better understanding of its structure and function. This section provides a clear overview of the various elements that contribute to the engine’s performance, including mechanical and electrical units.

Mechanical Components

The mechanical elements include critical sections such as the crankshaft, pistons, and valves. These elements work in harmony to convert fuel into motion, ensuring the engine operates efficiently. Each part plays a distinct role in the energy transfer process, affecting both power output and overall performance.

Electrical and Control Elements

Another vital aspect of the engine is the electrical system, which includes wiring, sensors, and ignition modules. These parts ensure that the engine starts smoothly and maintains stable operation. The control systems also help regulate various functions, such as temperature and fuel delivery, contributing to the engine’s efficiency.

Electrical System and Wiring Layout

The electrical system of any generator or power unit plays a crucial role in its overall functionality. Understanding how the wiring is structured helps in maintaining efficiency and ensuring proper operation. This section provides a clear overview of the key components and the logical arrangement of the wiring network that ensures stable power output and safety.

- Power Distribution: The system is designed to evenly distribute power across various circuits, ensuring no overload occurs during operation.

- Control Wiring: This layout manages the connection between the control panel and different internal components, allowing for smooth communication and command execution.

- Grounding System: Proper grounding is essential to protect the unit from electrical surges and to ensure user safety during operation.

- Circuit Breakers: Integrated within the wiring structure, these safety devices prevent electrical faults and overloads from causing damage to the system.

- Fuel Tank: Stores the fuel before it is delivered to the engine.

- Fuel Pump: Responsible for transporting fuel from the tank to the engine.

- Fuel Filter: Cleans the fuel before it enters the engine, preventing contaminants from causing damage.

- Fuel Lines: Transport fuel between the tank, pump, filter, and engine.

- Injector: Atomizes the fuel, ensuring it mixes properly with air for combustion.

Fuel System Assembly Details

The fuel system is a crucial component of any engine, ensuring the proper delivery of fuel for optimal performance. Understanding its assembly is essential for maintenance and troubleshooting. This section outlines the various elements involved in the fuel delivery mechanism and highlights their significance in the overall functionality of the engine.

Key Components

Assembly Considerations

- Ensure all connections are secure to prevent leaks.

- Regularly inspect and replace the fuel filter to maintain fuel quality.

- Check for any signs of wear or damage in fuel lines and connectors.

- Follow manufacturer guidelines for installation and maintenance to ensure efficiency.

By understanding the components and assembly of the fuel delivery system, users can effectively maintain their engines and address any potential issues that may arise.

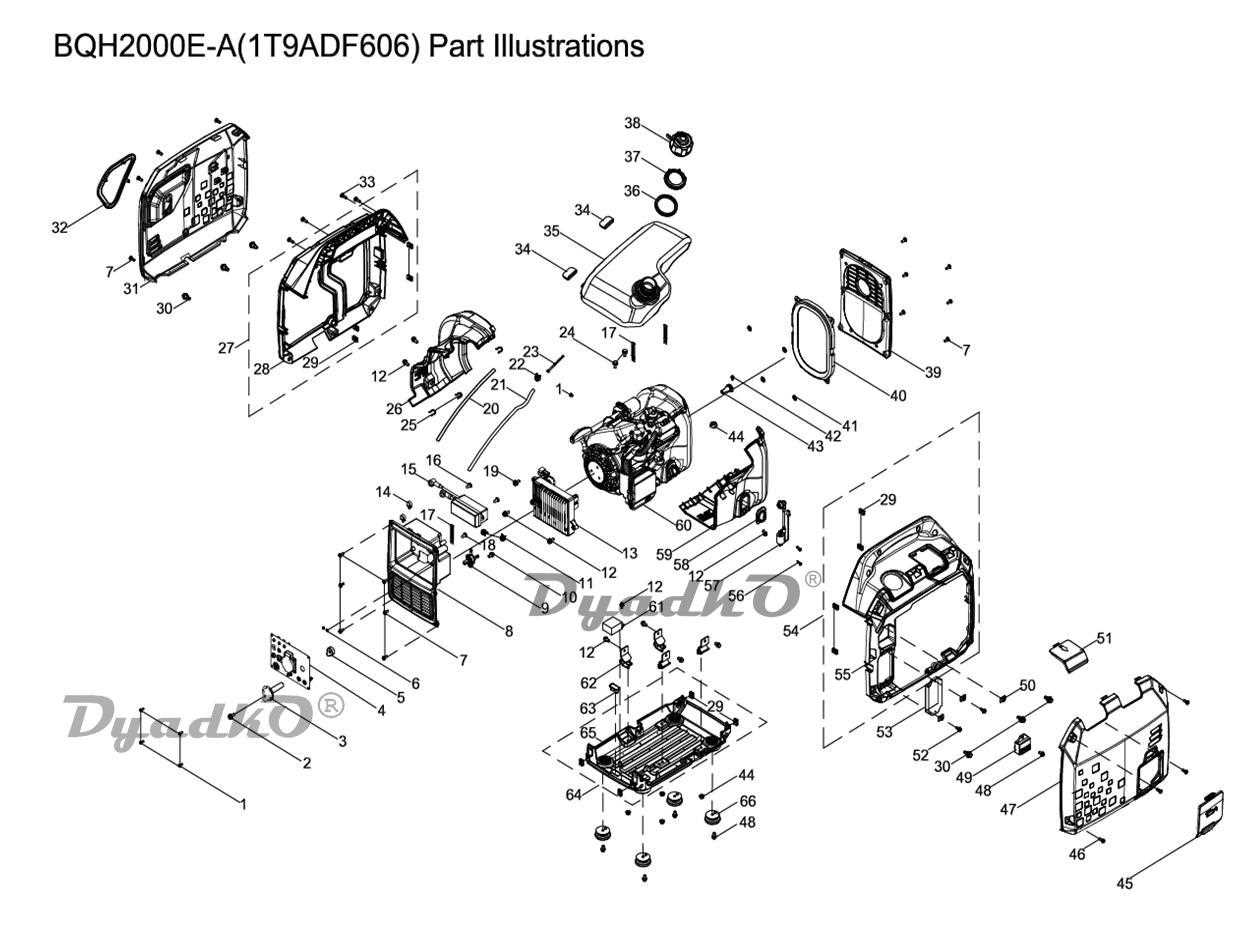

Control Panel and Interface Components

The control panel serves as the central hub for managing the operation of a generator. It houses various interface elements that enable users to monitor and regulate the generator’s functions efficiently. Understanding these components is essential for effective operation and maintenance.

Key Features of the Control Interface

The control interface typically includes indicators, buttons, and displays that provide real-time information about the generator’s status. Users can observe metrics such as output voltage, frequency, and operational hours, ensuring optimal performance. Additionally, control buttons allow for easy adjustments and activation of essential functions, enhancing usability.

Safety and Monitoring Elements

Safety indicators and alarms are crucial components of the control panel. They alert users to any irregularities or potential issues, enabling timely interventions. Monitoring features, such as automatic shut-off mechanisms, protect the equipment from damage, ensuring longevity and reliability. Familiarity with these safety components contributes to a more secure operating environment.

Cooling System Diagram and Parts

The efficiency of an engine’s thermal management system is crucial for optimal performance and longevity. This section explores the various components involved in regulating temperature, ensuring that the machinery operates within safe limits.

Key Components of the Thermal Management System

At the heart of the cooling mechanism is the radiator, which dissipates heat generated during operation. The water pump circulates coolant through the engine, facilitating heat exchange. Additionally, thermostats play a vital role by controlling the flow of coolant based on temperature, thus maintaining an optimal thermal state.

Understanding the Cooling Circuit

The cooling circuit comprises interconnected elements that work in unison. Hoses transport the coolant to and from the engine and radiator, while the fan assists in airflow, enhancing heat dissipation. A properly functioning cooling circuit is essential for preventing overheating and ensuring efficient engine operation.

Exhaust System Components and Layout

The exhaust system plays a crucial role in the efficient operation of any engine, guiding the byproducts of combustion safely away from the engine. Understanding its components and layout is essential for optimal performance and maintenance.

- Exhaust Manifold: This part collects exhaust gases from the engine’s cylinders and directs them into the exhaust system.

- Exhaust Pipes: These pipes transport the gases away from the engine, allowing for proper flow and minimizing back pressure.

- Silencer (Muffler): Designed to reduce noise, the silencer minimizes the sound produced by the exhaust gases exiting the system.

- Exhaust Tip: The final section of the exhaust system, the tip directs exhaust gases out of the vehicle, often designed for aesthetic appeal.

Proper alignment and connection of these components are vital for maintaining engine efficiency and performance. Regular inspections and maintenance can help identify wear or damage, ensuring the system operates smoothly.

In summary, understanding the layout and components of the exhaust system is important for ensuring reliable performance and longevity. Each part contributes to the overall function, making routine checks essential for any engine’s upkeep.

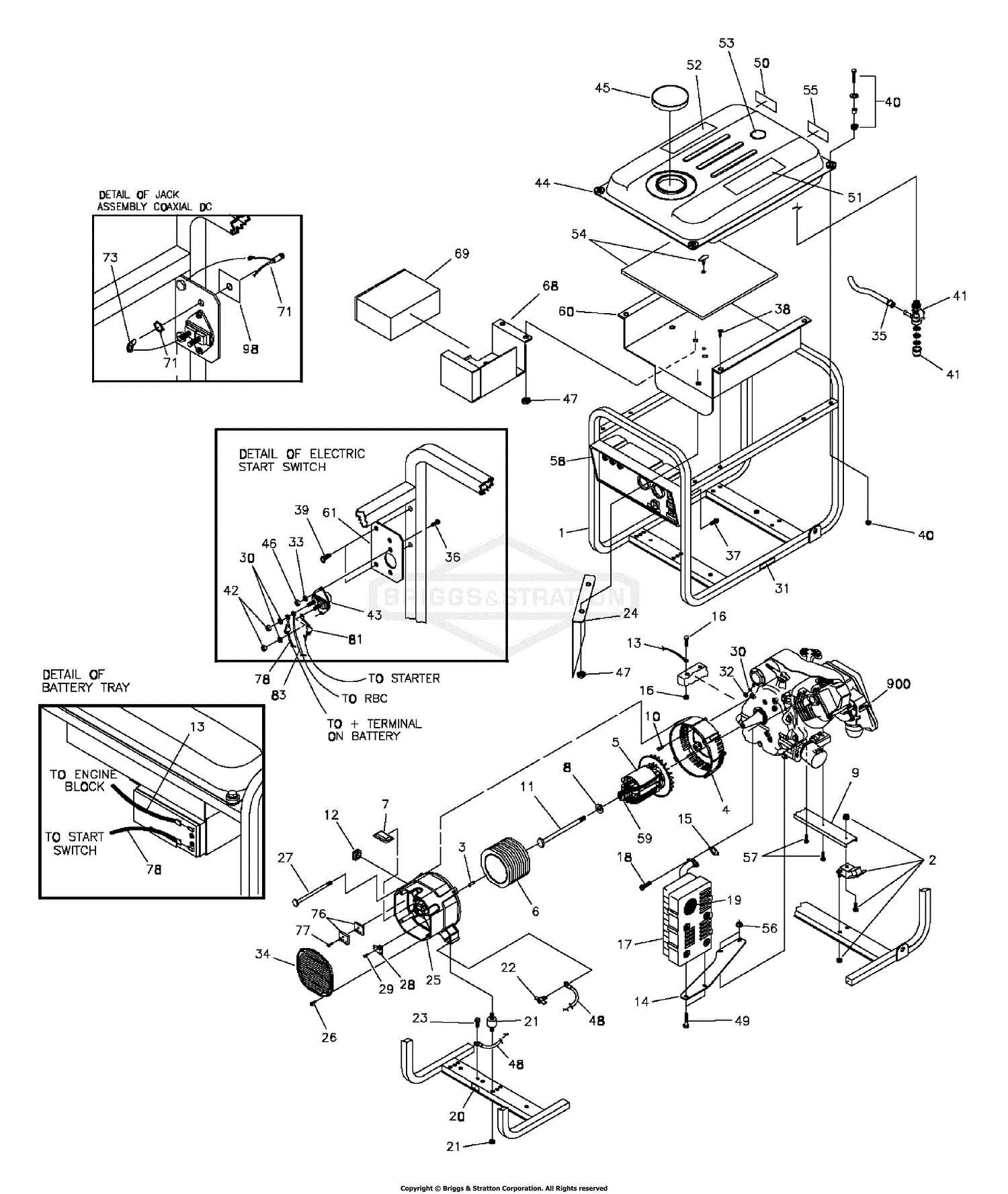

Chassis and Frame Structural Parts

The integrity of any machinery is heavily reliant on its underlying structure, which includes the framework and chassis components. These elements provide essential support, ensuring stability and durability during operation. A well-designed framework not only enhances performance but also contributes to the overall safety and functionality of the equipment.

Framework Components play a crucial role in maintaining the overall strength of the equipment. These parts are typically crafted from robust materials to withstand the rigors of use. The choice of materials is essential, as it impacts both weight and resilience. Structural integrity is paramount, as it prevents deformation and potential failure under stress.

In addition to the framework, the chassis serves as the foundation that supports other critical components. It must be engineered to absorb vibrations and shocks while providing a stable base for operational mechanisms. Proper alignment and assembly of these structural elements are vital for optimal performance.

Furthermore, the connections between various parts are designed to facilitate easy maintenance and replacement. Understanding the layout of these structural elements can significantly aid in troubleshooting and repair processes, ensuring prolonged usability of the equipment.

Maintenance Kit and Accessory Parts

Regular upkeep of equipment is essential for ensuring optimal performance and longevity. A well-organized maintenance kit includes various components that facilitate routine care, helping to prevent potential issues before they arise. Accessory elements play a vital role in enhancing functionality and adapting the machinery for specific tasks, ensuring versatility in usage.

Essential Components for Upkeep

A comprehensive maintenance kit typically contains filters, lubricants, and cleaning supplies designed to keep the machinery operating smoothly. Regular replacement of these elements not only maintains efficiency but also reduces wear and tear on critical parts. Utilizing high-quality supplies ensures that each maintenance session yields the best results.

Accessories for Enhanced Functionality

In addition to maintenance supplies, various accessories are available to optimize performance and tailor the equipment for specific applications. Items such as extension cords, protective covers, and specialized attachments allow users to customize their setup. Investing in these accessories can significantly enhance the overall experience and productivity of the machinery.

Replacement Parts for the Generator

Maintaining a reliable power source requires attention to various components that may need substitution over time. Understanding the key elements that contribute to optimal functionality can help ensure the generator operates efficiently. This section will outline essential components typically considered for replacement, along with their roles in the overall system.

Common Components for Substitution

- Fuel System Elements: These components, including filters and pumps, are crucial for maintaining proper fuel delivery.

- Electrical Parts: Items such as ignition systems and voltage regulators are vital for effective energy conversion.

- Cooling System Components: Radiators and fans help prevent overheating, ensuring the generator runs smoothly.

- Lubrication Elements: Oil filters and pumps play a key role in maintaining engine health.

Considerations for Replacement

- Evaluate the condition of each component regularly to identify signs of wear or damage.

- Choose high-quality substitutes that meet or exceed the original specifications for durability and performance.

- Consult with a professional if unsure about compatibility or installation procedures.

Common Wear Items and Upgrades

In the realm of portable power equipment, certain components are prone to wear and tear due to regular usage. Recognizing these elements and considering potential enhancements can significantly improve the efficiency and longevity of the unit. Upgrading these items not only ensures optimal performance but also provides peace of mind during operation.

One of the most frequently replaced components includes the oil filter, which plays a crucial role in maintaining engine health. Additionally, air filters should be routinely checked and swapped out to prevent dirt and debris from compromising engine performance. Fuel systems also require attention; using high-quality fuel and regularly inspecting the fuel filter can enhance overall functionality.

Moreover, replacing worn-out spark plugs is vital for maintaining ignition efficiency. Upgrading to higher-grade spark plugs can yield better fuel efficiency and smoother operation. Lastly, considering alternative battery options may offer extended power duration and reliability. By focusing on these common wear items and potential upgrades, users can ensure their equipment remains in peak condition.