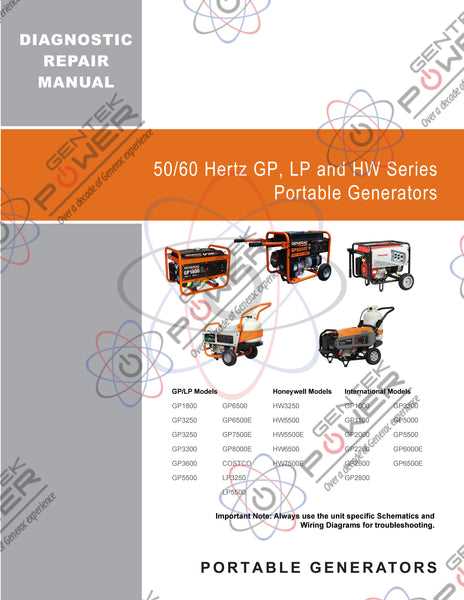

In the realm of portable power solutions, grasping the intricate layout of essential elements can significantly enhance both performance and maintenance. This section delves into the various components that comprise these reliable machines, illuminating their functionalities and interactions. By familiarizing oneself with the internal structure, users can optimize their experience and ensure longevity in operation.

The efficient functioning of any portable power device relies heavily on its individual parts, each playing a vital role in delivering reliable energy. From the engine to the electrical output systems, understanding how these elements work together can aid in troubleshooting and performance enhancement. Whether for recreational use or emergency backup, recognizing the importance of each component is crucial for maximizing utility.

Moreover, comprehending the configuration of these systems allows for informed decisions regarding repairs and upgrades. With a solid grasp of the machinery, users can navigate the complexities of maintenance with confidence. This knowledge ultimately empowers users to not only utilize their devices effectively but also prolong their lifespan through proper care.

Understanding Generac GP5000 Components

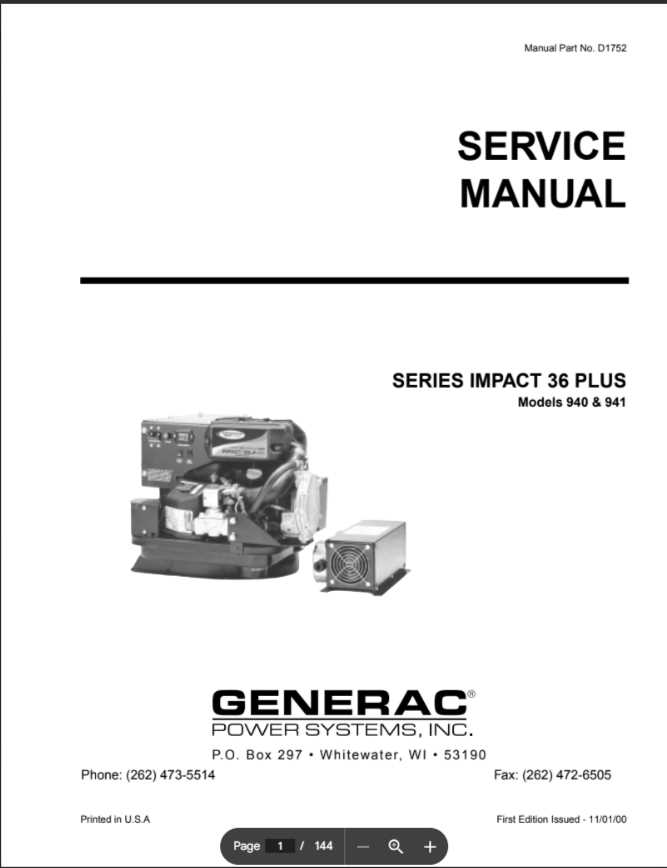

This section aims to provide a comprehensive overview of the various elements that comprise a specific power generation unit. By exploring the key components, readers can gain insight into how each part contributes to the overall functionality and efficiency of the system. Recognizing the roles of these individual elements enhances the understanding of maintenance and troubleshooting practices, ultimately leading to better performance and reliability.

Core Elements of the System

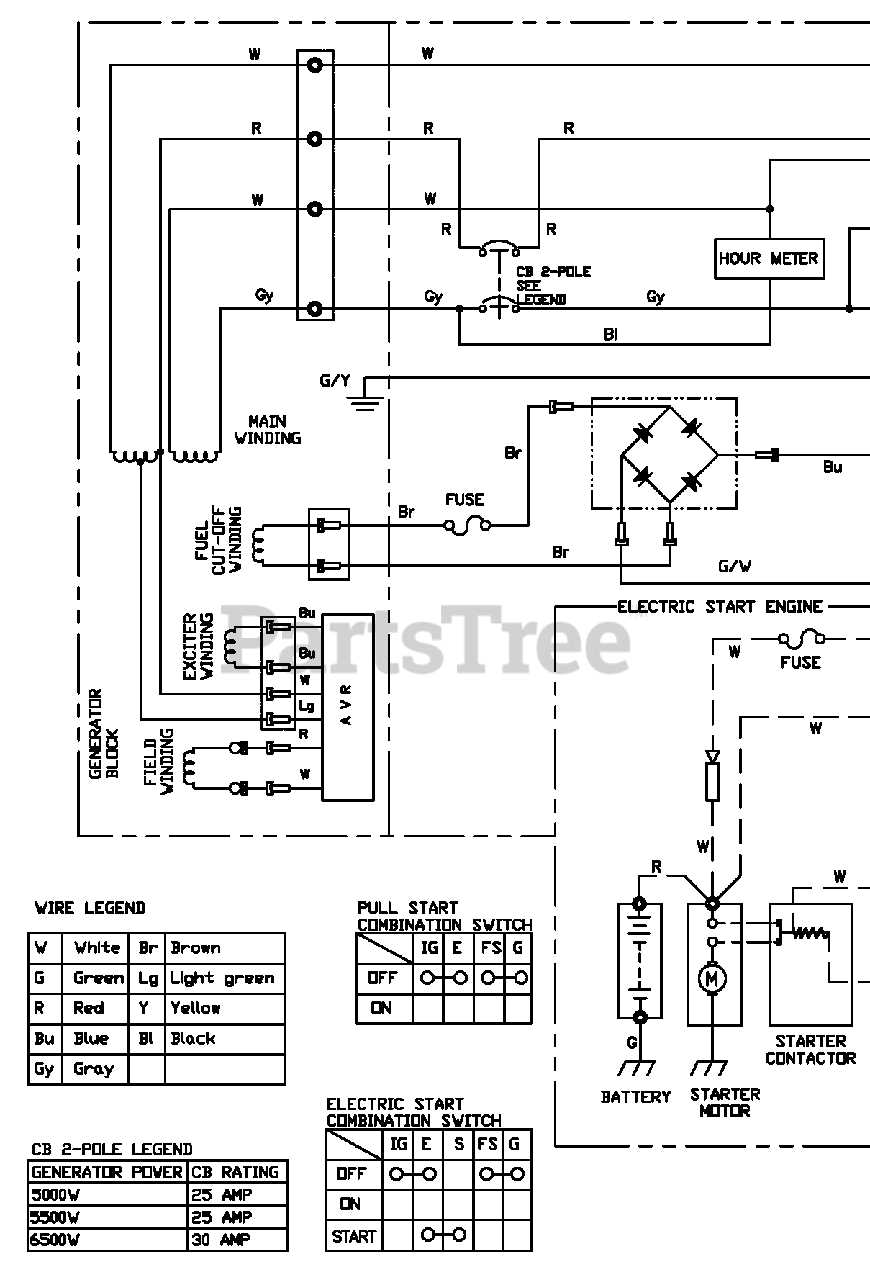

The foundation of the unit includes essential components such as the engine, alternator, and control panel. Each part plays a crucial role in the operation of the generator, with the engine providing the necessary power, the alternator converting mechanical energy into electrical energy, and the control panel managing and monitoring the system’s performance. Familiarity with these core elements allows for informed decision-making when it comes to repairs and upgrades.

Supporting Components

In addition to the main parts, various supporting elements are vital for optimal operation. Fuel tanks, exhaust systems, and cooling mechanisms ensure the generator runs efficiently and safely. Understanding the function of these auxiliary components can assist users in maintaining the unit and preventing potential issues. Proper attention to each part promotes longevity and reliability, making it essential for users to engage with their equipment thoroughly.

Key Features of the GP5000 Model

The model in question stands out in its category, offering a blend of performance, reliability, and convenience for users. This unit is designed to meet a variety of power needs, making it a suitable choice for both home and outdoor applications.

- Power Output: Delivers ample wattage to support multiple devices simultaneously.

- Engine Type: Features a robust engine that ensures efficient fuel consumption and optimal performance.

- Portability: Equipped with wheels and a lightweight frame, making it easy to transport wherever needed.

- Durable Construction: Built with high-quality materials to withstand harsh conditions and provide long-lasting use.

- Safety Features: Includes essential safety mechanisms to protect both the unit and connected devices.

These characteristics contribute to its popularity among users looking for a reliable source of power. With its versatile applications and strong performance, this model meets the demands of various power requirements effectively.

Identifying Essential Parts for Repair

When it comes to restoring functionality to your equipment, understanding the crucial components is vital. Familiarizing yourself with the main elements involved can simplify the repair process and ensure you have everything needed for a successful fix. Below are key aspects to consider when assessing what needs attention.

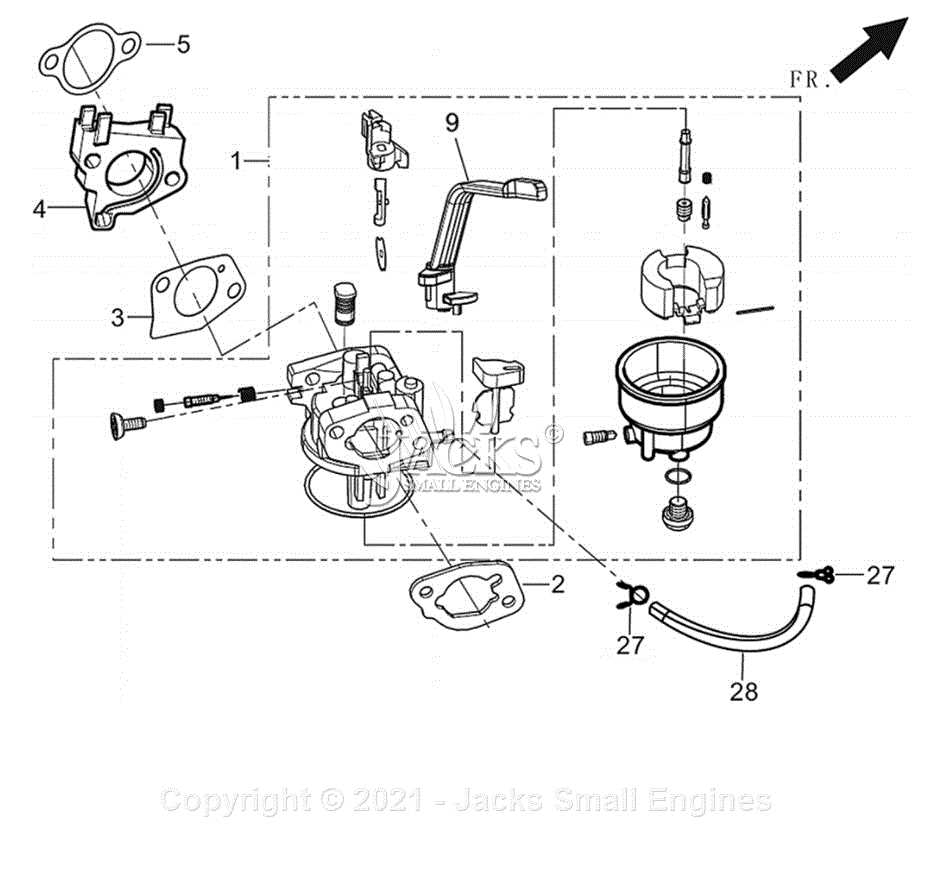

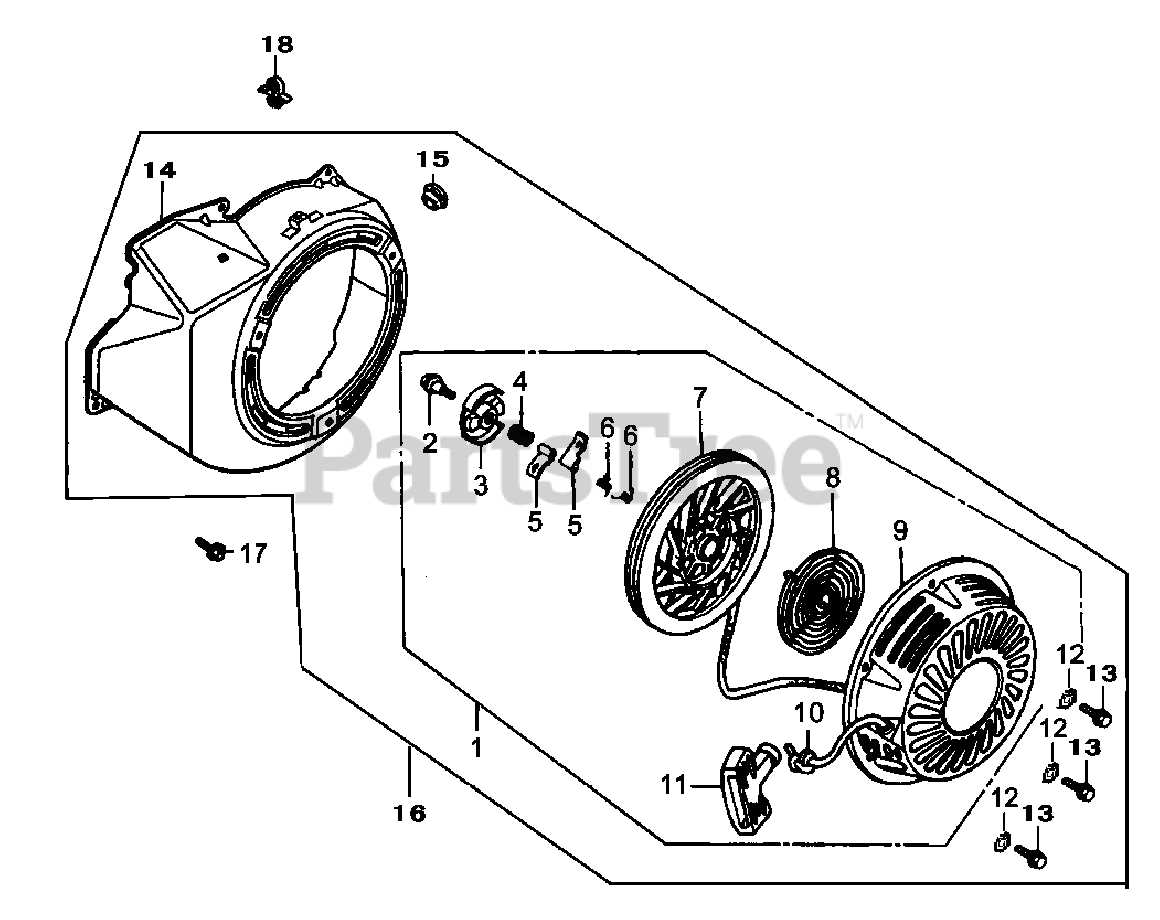

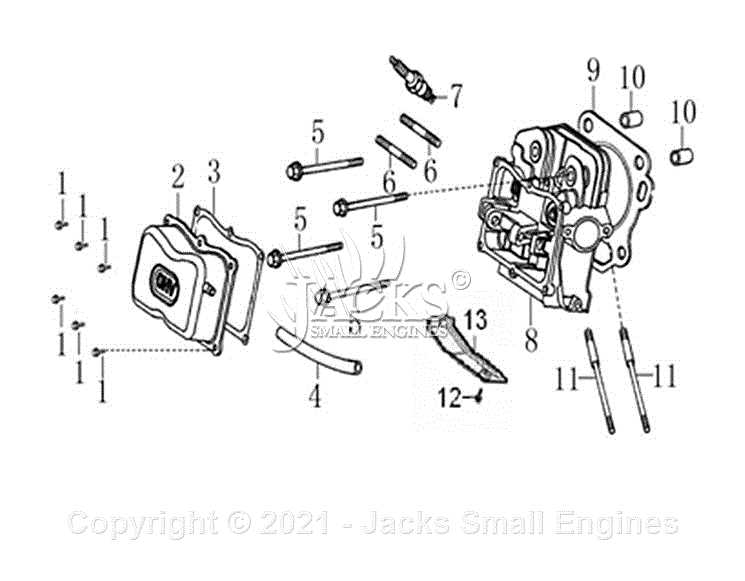

- Engine Components: Examine the vital parts responsible for power generation. Look for issues with the spark plug, fuel system, and air filter.

- Electrical Elements: Inspect the wiring and connectors. Issues with the battery or ignition system can hinder performance.

- Frame and Chassis: Check for any physical damage or wear. Ensuring structural integrity is important for overall safety and operation.

- Cooling System: Evaluate the cooling components to prevent overheating. This includes the fan, radiator, and any associated hoses.

By pinpointing these essential components, you can effectively address any malfunctions and keep your machine running smoothly. A systematic approach to identifying and evaluating each part will enhance your repair efforts.

Common Issues and Solutions

When dealing with power generators, users may encounter a variety of challenges that can hinder performance. Understanding these common problems and their respective solutions is essential for maintaining efficient operation and ensuring longevity.

Frequent Problems

- Starting difficulties: Generators may struggle to start due to various factors, including fuel issues or electrical faults.

- Overheating: This can occur when the unit is overworked or not adequately ventilated.

- Noisy operation: Excessive noise can be a sign of mechanical wear or improper installation.

- Inconsistent power output: Fluctuations in voltage can lead to equipment damage and operational inefficiencies.

Solutions to Common Issues

- Starting difficulties: Check fuel levels, replace old fuel, and inspect the battery and ignition components for proper function.

- Overheating: Ensure the generator is in a well-ventilated area, clean air filters, and avoid overloading the unit.

- Noisy operation: Tighten loose components, lubricate moving parts, and ensure the generator is placed on a stable surface.

- Inconsistent power output: Inspect electrical connections for corrosion or damage and consider using a voltage regulator to stabilize output.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment requires regular upkeep and attention. By adopting a proactive approach to maintenance, you can prevent potential issues and extend the life of your device. Below are essential practices that will contribute to its longevity.

Regular Inspection: Frequently check for any signs of wear or damage. Look for loose connections, frayed wires, and any unusual sounds during operation. Early detection of problems can save time and resources in the long run.

Cleanliness: Keep the machine free from dust and debris. Accumulation of dirt can obstruct airflow and cause overheating. Periodically wipe down surfaces and ensure that air vents are clear for efficient operation.

Fluid Levels: Regularly monitor oil and fuel levels. Maintaining the correct levels ensures smooth operation and reduces the risk of engine damage. Always use recommended fluids to avoid compatibility issues.

Storage Practices: When not in use, store the equipment in a dry, sheltered area. Protect it from harsh weather conditions that could lead to corrosion or other forms of damage. Using a cover can provide additional protection.

Scheduled Servicing: Adhere to a routine maintenance schedule as outlined in the user manual. This includes changing filters, checking spark plugs, and servicing other critical components. Professional servicing can identify potential problems before they escalate.

By following these simple yet effective maintenance strategies, you can ensure that your equipment remains in top condition, ready to meet your needs whenever required.

How to Order Replacement Parts

Ensuring your equipment operates smoothly often requires obtaining new components. Understanding the process of acquiring these items can simplify repairs and maintenance. Here’s a comprehensive guide to help you navigate this essential task.

Steps to Follow

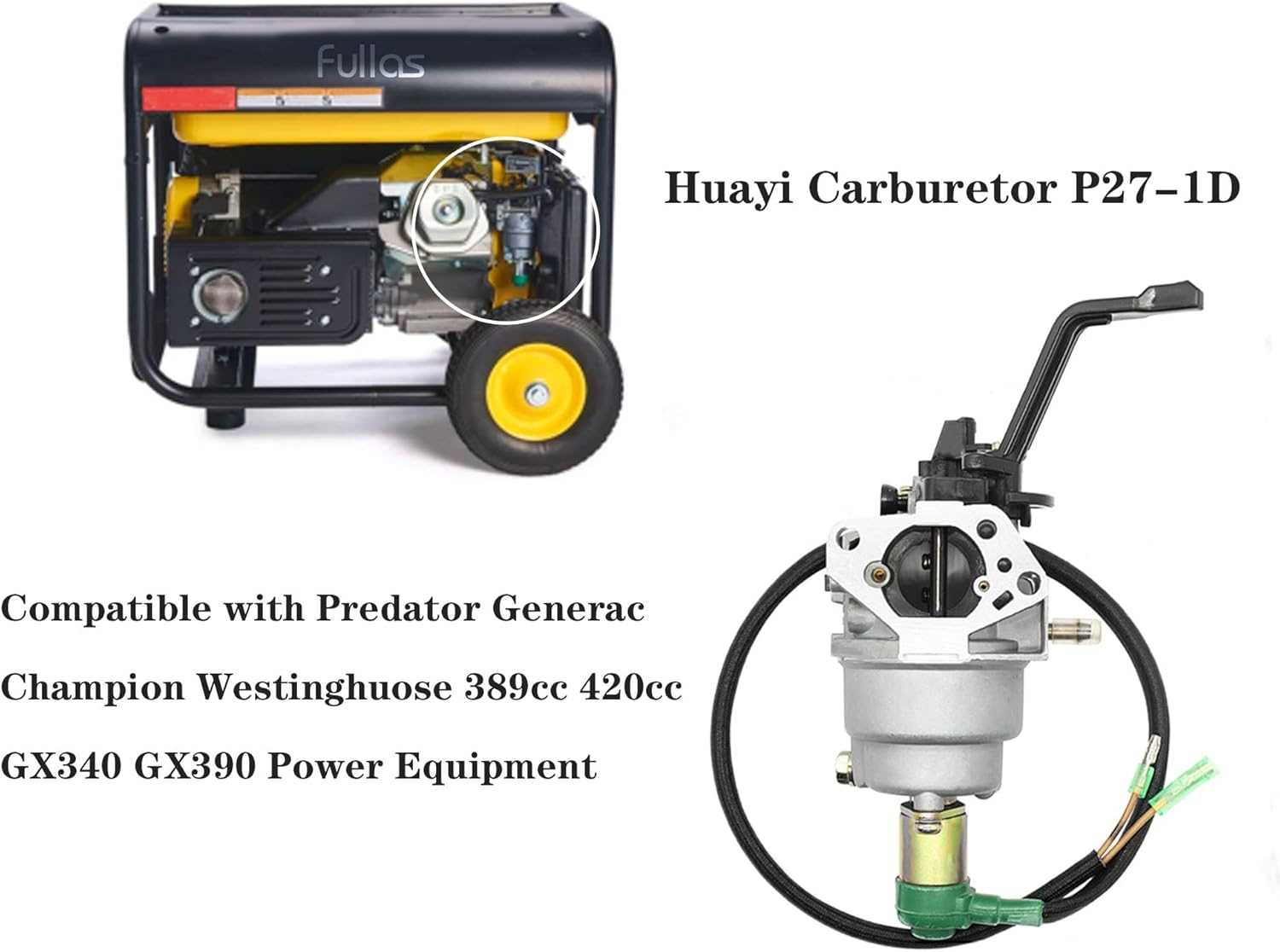

- Identify the Component: Start by determining the specific element that needs replacement. Refer to your user manual or consult an online resource to ensure accurate identification.

- Check Compatibility: Verify that the replacement component is compatible with your equipment model. Look for specifications or part numbers to match the required item.

- Choose a Supplier: Select a reliable retailer or authorized dealer. Options include online marketplaces, local hardware stores, or specialized suppliers. Make sure to check their reputation for quality and service.

- Gather Necessary Information: Before placing an order, have all relevant details on hand, including the model number, serial number, and any part numbers associated with the item.

- Place the Order: Use the supplier’s website or contact them directly to complete your purchase. Ensure you provide accurate information to avoid any discrepancies.

Additional Tips

- Consider Bulk Purchasing: If you anticipate needing multiple components, inquire about bulk purchasing options for potential savings.

- Review Return Policies: Before finalizing your order, familiarize yourself with the return and exchange policies in case the component does not meet your needs.

- Keep Records: Maintain a file of your orders and receipts for future reference. This will be useful for warranty claims or potential issues with compatibility.

Assembly Instructions for the Generator

This section provides a comprehensive guide for assembling your power-producing unit. Following these steps will ensure that all components are correctly fitted, promoting optimal performance and longevity. It is essential to handle each part with care and to refer to this guide throughout the process.

| Step | Description |

|---|---|

| 1 | Begin by laying out all components on a flat surface to ensure everything is accessible and organized. |

| 2 | Carefully attach the frame pieces together, ensuring that all bolts and fasteners are secure. |

| 3 | Install the power source into the frame, ensuring it fits snugly and is oriented correctly. |

| 4 | Connect the wiring harness to the designated ports, making sure all connections are firm and correctly aligned. |

| 5 | Attach the protective cover, ensuring all clips and fasteners are in place to safeguard internal components. |

| 6 | Conduct a thorough inspection to verify that all parts are assembled correctly and securely. |

By following these assembly instructions diligently, you will ensure the proper setup of your power-generating unit. Always consult the manufacturer’s guidelines for any additional recommendations or safety precautions.

Safety Precautions During Usage

Ensuring safety during operation is essential for preventing accidents and maintaining the longevity of the equipment. By following specific guidelines and employing caution, users can create a secure environment while utilizing their generator.

First and foremost, always read the user manual thoroughly before beginning any tasks. Familiarizing oneself with the device’s features and limitations is crucial for effective and safe operation. Additionally, keep the work area clean and well-organized to avoid potential hazards.

It is also important to wear appropriate personal protective equipment (PPE), such as gloves and safety goggles. This gear can protect against injuries from moving parts or accidental splashes of fuel. Furthermore, ensure that the generator is placed on a stable, dry surface away from flammable materials.

Regular maintenance is another vital aspect of safety. Inspect the generator before use, checking for any leaks, loose wires, or worn components. Addressing these issues promptly can prevent malfunctions and enhance operational reliability.

Finally, never operate the generator in enclosed spaces. Carbon monoxide buildup can pose a significant threat to health. Always ensure proper ventilation when using the equipment, and monitor it closely for any signs of malfunction.

Comparing GP5000 with Other Generators

When evaluating different power sources, it is essential to understand how various models stack up against one another. Each generator offers unique features, performance metrics, and reliability, which can significantly influence a user’s decision. This section aims to highlight the strengths and weaknesses of a specific model in relation to its competitors, providing a clearer picture for potential buyers.

Performance and Power Output: One of the most critical factors in selecting a generator is its ability to deliver adequate power. Many options on the market boast similar wattage capabilities, yet differences in engine design and efficiency can lead to variations in fuel consumption and overall performance. Comparing these aspects can help identify the most efficient choice for individual needs.

Portability and Design: The physical characteristics of generators play a significant role in their usability. Some models are designed for ease of transport, featuring lightweight materials and compact structures, while others may prioritize durability and sturdiness. Evaluating the design can provide insight into how well a generator will perform in different environments and applications.

Noise Levels: Noise production is another important consideration. Many users prefer quieter machines, especially for residential use or during outdoor activities. Comparing sound output levels can help consumers find a generator that meets their noise tolerance while still delivering the necessary power.

Maintenance and Longevity: Finally, the long-term reliability of a generator is crucial. Some units require more frequent maintenance than others, which can affect ownership costs and convenience. Assessing the maintenance needs and expected lifespan can guide buyers in selecting a generator that aligns with their expectations for performance and upkeep.

Expert Recommendations for Upgrades

When considering enhancements for your generator, a thoughtful approach can significantly boost performance and longevity. Upgrading specific components not only enhances efficiency but also improves the overall user experience. Below are some recommendations from seasoned professionals that can help you achieve optimal results.

1. Enhanced Fuel System: Upgrading to a more efficient fuel delivery system can improve engine performance and reduce consumption. Consider high-flow fuel filters and improved fuel injectors to ensure optimal operation.

2. Battery Upgrades: Investing in a high-quality battery can enhance starting reliability, especially in colder climates. Look for batteries designed for deep cycling to withstand the demands of extended use.

3. Advanced Control Panels: Modern control panels with digital displays offer better monitoring and diagnostics. These systems can provide real-time data, allowing for proactive maintenance and quicker troubleshooting.

4. Exhaust System Improvements: Upgrading the exhaust system can lead to better airflow and reduced noise levels. Consider options such as high-performance mufflers or larger diameter pipes to enhance exhaust flow.

5. Regular Maintenance Kits: Utilizing quality maintenance kits can ensure that essential parts are replaced regularly. This practice not only prevents unexpected breakdowns but also extends the life of the unit.

By implementing these upgrades, you can ensure your generator remains a reliable and efficient power source for years to come.

FAQs About Generac GP5000

This section addresses common inquiries related to a specific portable power generator model, providing valuable insights for users seeking to enhance their understanding and troubleshoot effectively. Below are frequently asked questions that cover essential information about features, maintenance, and operational tips.

| Question | Answer |

|---|---|

| What are the key features of this generator? | This unit is designed with reliability in mind, offering a powerful engine, user-friendly controls, and multiple outlets for various applications. |

| How often should I perform maintenance? | Regular maintenance is recommended every 50 hours of operation, which includes checking the oil level, air filter, and spark plug condition. |

| Can it be used during emergencies? | Yes, this generator is suitable for backup power during outages, ensuring essential appliances remain operational. |

| What type of fuel does it require? | The unit operates on unleaded gasoline, ensuring convenient refueling options. |

| Are there any safety precautions to consider? | Always operate in a well-ventilated area, avoid overloading circuits, and follow all manufacturer’s safety guidelines for safe usage. |