The efficient operation of a reliable power source is crucial for various tasks, whether at home or on the job site. A thorough grasp of its structure and internal elements can significantly enhance functionality and troubleshooting capabilities. This section will explore the essential components that contribute to optimal performance.

Identifying these elements will empower users to maintain and repair their equipment effectively. By delving into the intricate details of each part, individuals can ensure longevity and reliability in their power tools. Understanding how these components work together can lead to better decision-making regarding maintenance and upgrades.

Equipped with this knowledge, users can approach issues with confidence, knowing they possess the insight needed to tackle challenges. Whether replacing a malfunctioning piece or performing routine upkeep, familiarity with the inner workings is the ultimate asset for any operator.

Champion 3500 Watt Generator Overview

This section provides a comprehensive overview of a reliable power source designed for various applications. Its efficient performance and user-friendly features make it an essential tool for both professional and recreational use. Understanding its components and functionality can enhance the overall experience for users.

Key Features

This device offers several notable characteristics that contribute to its effectiveness. It is designed for portability, allowing easy transportation. Additionally, its fuel efficiency ensures prolonged usage, making it suitable for extended activities.

Applications

Versatile in nature, this equipment is utilized in numerous scenarios, including outdoor events, construction sites, and emergency situations. Its adaptability ensures that users can rely on it for their diverse power needs.

Key Components of the Generator

This section explores the essential elements that contribute to the functionality of a portable power source. Understanding these components is crucial for effective maintenance and operation, ensuring optimal performance and longevity.

Main Parts Overview

- Engine: The driving force that converts fuel into mechanical energy.

- Alternator: Responsible for transforming mechanical energy into electrical energy.

- Fuel System: Supplies the necessary fuel to the engine for operation.

- Cooling System: Maintains the appropriate operating temperature by dissipating heat.

- Exhaust System: Directs and manages the gases produced during operation.

Supporting Components

- Frame: Provides structural support and stability.

- Control Panel: Interfaces for monitoring and managing operation settings.

- Wheels: Facilitate mobility for easy transport.

- Battery: Supplies power for starting the engine and supporting electrical functions.

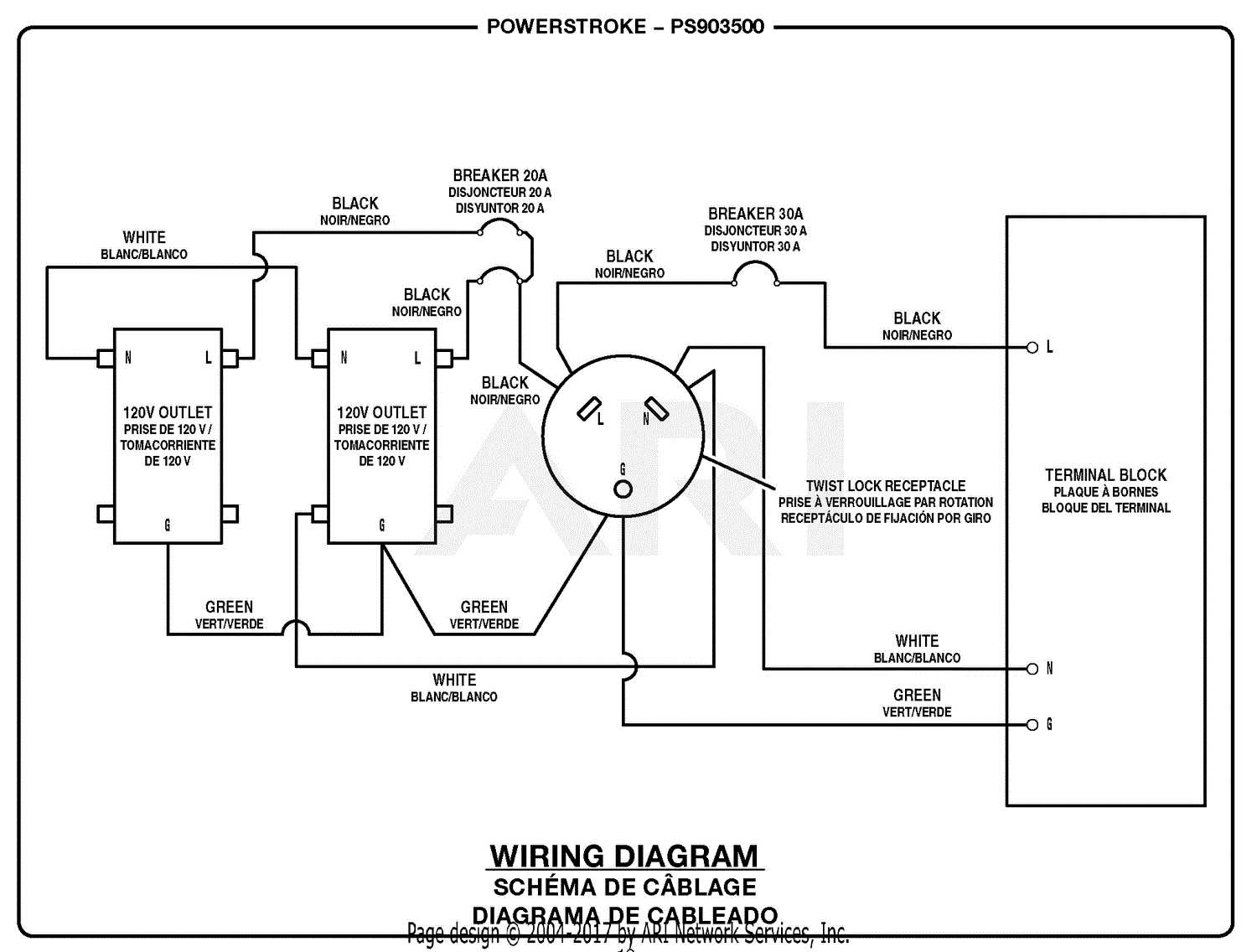

Understanding the Parts Diagram

Grasping the layout of essential components is crucial for effective maintenance and troubleshooting. This visual representation serves as a guide to identify and understand the various elements involved in the equipment’s operation.

Key Elements to Recognize

- Components: Each item plays a specific role in the overall functionality.

- Connections: Understanding how parts interlink can aid in efficient repairs.

- Labels: Clearly marked sections help in locating parts quickly.

Benefits of Familiarity

- Enhances repair skills and confidence.

- Reduces downtime through swift identification of issues.

- Increases overall knowledge of the equipment’s workings.

Identifying Common Spare Parts

Understanding the essential components of a power-producing device is crucial for effective maintenance and repairs. Recognizing these elements can significantly enhance the longevity and efficiency of the machine.

Fuel Tank: This is a critical element that stores the necessary liquid for operation. Ensuring its cleanliness and proper sealing is vital for performance.

Air Filter: This component plays a significant role in maintaining optimal airflow, thereby affecting the overall functionality. Regular inspection and replacement can prevent unnecessary damage.

Oil Filter: Essential for keeping the internal lubrication system clean, this part aids in extending the lifespan of the engine. It should be changed periodically to maintain efficiency.

Spark Plug: A crucial element in igniting the fuel mixture, this piece requires routine checks and replacements to ensure smooth starting and operation.

Battery: Providing the necessary electrical power, this component needs regular maintenance to ensure reliability during usage.

Maintenance Tips for Longevity

Regular upkeep is essential for maximizing the lifespan of any machinery. By following a few key practices, users can ensure their equipment operates efficiently for years to come.

- Cleanliness: Keep the exterior and interior free from dirt and debris.

- Fluid Checks: Regularly inspect and replenish oils and other necessary fluids.

- Filter Maintenance: Clean or replace filters as recommended to promote airflow and performance.

- Inspect Connections: Regularly check electrical connections for signs of wear or corrosion.

- Run Periodically: Operate the machine occasionally to keep components lubricated and functional.

- Store Properly: When not in use, store the unit in a dry, protected location to prevent damage.

Implementing these strategies will greatly enhance reliability and efficiency, leading to a longer operational life.

How to Replace Worn Components

Maintaining your equipment is essential for optimal performance. Over time, certain elements may become worn and require replacement to ensure efficiency and reliability. This section will guide you through the process of identifying and substituting these components effectively.

Step 1: Identify Worn Parts

Begin by inspecting the machinery for signs of wear, such as cracks, discoloration, or excessive wear on moving parts. Regular checks can prevent major issues later.

Step 2: Gather Necessary Tools

Collect the tools required for the task. Common items include wrenches, screwdrivers, and replacement components that match the specifications of your device.

Step 3: Remove the Old Components

Carefully detach the worn parts, ensuring you follow any specific instructions relevant to your model. Take note of the arrangement for reassembly.

Step 4: Install New Parts

Position the new components accurately, securing them firmly. Ensure everything is aligned properly to avoid complications during operation.

Step 5: Test the Equipment

After installation, conduct a test run to verify that everything functions correctly. Monitor for unusual noises or issues, as these may indicate improper installation.

Importance of Quality Replacement Parts

Utilizing high-quality components for machinery maintenance is essential for optimal performance and longevity. Reliable replacements ensure that equipment operates smoothly, minimizing the risk of breakdowns and enhancing efficiency. When choosing new elements, it is crucial to prioritize durability and compatibility to support overall functionality.

Enhancing Performance and Reliability

Quality replacements play a significant role in maintaining the efficiency of devices. They help to prevent potential malfunctions that can arise from inferior substitutes, which may lead to costly repairs or downtime. By investing in superior materials, users can ensure their machines function at peak levels.

Long-Term Cost Savings

Choosing premium components can lead to substantial long-term savings. Although the initial investment may be higher, the increased durability and performance reduce the frequency of replacements and repairs. This proactive approach ultimately results in lower overall maintenance costs and extended equipment lifespan.

Safety Features in the Generator

Ensuring safety during operation is paramount when dealing with power-producing machines. These devices are equipped with various protective mechanisms designed to minimize risks and enhance user security.

| Safety Feature | Description |

|---|---|

| Overload Protection | This feature prevents the unit from operating beyond its capacity, reducing the risk of damage and potential hazards. |

| Low Oil Shutdown | The machine automatically shuts off when oil levels are too low, preventing engine damage and ensuring longevity. |

| Ground Fault Circuit Interrupter (GFCI) | This mechanism helps protect against electrical shocks by shutting off power in case of a ground fault. |

| Automatic Voltage Regulation | This feature maintains a steady output voltage, safeguarding connected devices from voltage spikes. |

Troubleshooting Common Issues

When operating portable power sources, users may encounter various challenges that can hinder performance. Understanding common problems and their potential solutions can enhance efficiency and reliability. This section aims to provide insights into frequent issues and how to address them effectively.

One prevalent issue is difficulty starting the unit. This may result from insufficient fuel, a drained battery, or faulty spark plugs. Ensuring proper fuel levels and maintaining battery health can mitigate such problems.

Another common concern is irregular output. This can stem from improper load management or issues within the internal circuitry. Users should verify that the load is within acceptable limits and inspect connections for any signs of wear or damage.

Finally, excessive noise can be a nuisance. This may indicate loose components or the need for maintenance. Regular inspections and tightening of loose parts can help minimize unwanted sound levels.

Operating the Generator Efficiently

To maximize performance and longevity, it is essential to follow best practices when utilizing a portable energy source. Understanding how to manage fuel, maintenance, and load can significantly enhance efficiency and reliability.

Fuel Management

Proper fuel management is crucial for optimal functioning. Consider the following tips:

- Use high-quality fuel to ensure smooth operation.

- Regularly check for fuel leaks to prevent waste.

- Store fuel in a cool, dry place to maintain its integrity.

Regular Maintenance

Routine maintenance helps avoid unexpected breakdowns. Here are some key tasks:

- Change the oil at recommended intervals.

- Clean or replace air filters to improve airflow.

- Inspect spark plugs regularly for wear and tear.

By adhering to these guidelines, users can ensure their device operates effectively and remains in good condition over time.

Storing the Generator Properly

Ensuring the longevity and optimal performance of your power source requires careful storage. Proper techniques can prevent damage and maintain functionality for future use.

Here are essential tips for effective storage:

- Clean Thoroughly: Remove any dirt or debris before storing.

- Drain Fuel: Empty the tank to avoid fuel degradation and potential engine issues.

- Use a Dry Environment: Store in a dry location to prevent rust and corrosion.

- Check the Battery: If applicable, disconnect and store the battery in a cool, dry place.

- Cover Properly: Use a breathable cover to protect against dust while allowing moisture to escape.

By following these steps, you can ensure that your equipment remains in excellent condition and is ready for use when needed.

Resources for Further Assistance

For those seeking additional support and information regarding their equipment, various avenues are available. Engaging with the right resources can significantly enhance your understanding and help address any issues that may arise.

| Resource Type | Description | Link |

|---|---|---|

| Online Manuals | Access user guides and technical documents for detailed instructions. | Visit here |

| Community Forums | Join discussions with fellow users to share experiences and solutions. | Join now |

| Customer Support | Contact experts for personalized assistance and troubleshooting help. | Get support |