In the realm of maritime technology, the intricacies of energy production units play a vital role in ensuring seamless operation on the water. A thorough comprehension of these essential mechanisms not only enhances performance but also aids in efficient maintenance. By dissecting the structure of these systems, users can gain valuable insights into their functionality and longevity.

The assembly of energy units comprises various elements, each serving a specific purpose. Familiarizing oneself with these components and their interrelationships is crucial for anyone involved in marine operations. This knowledge empowers users to troubleshoot effectively and optimize the performance of their systems.

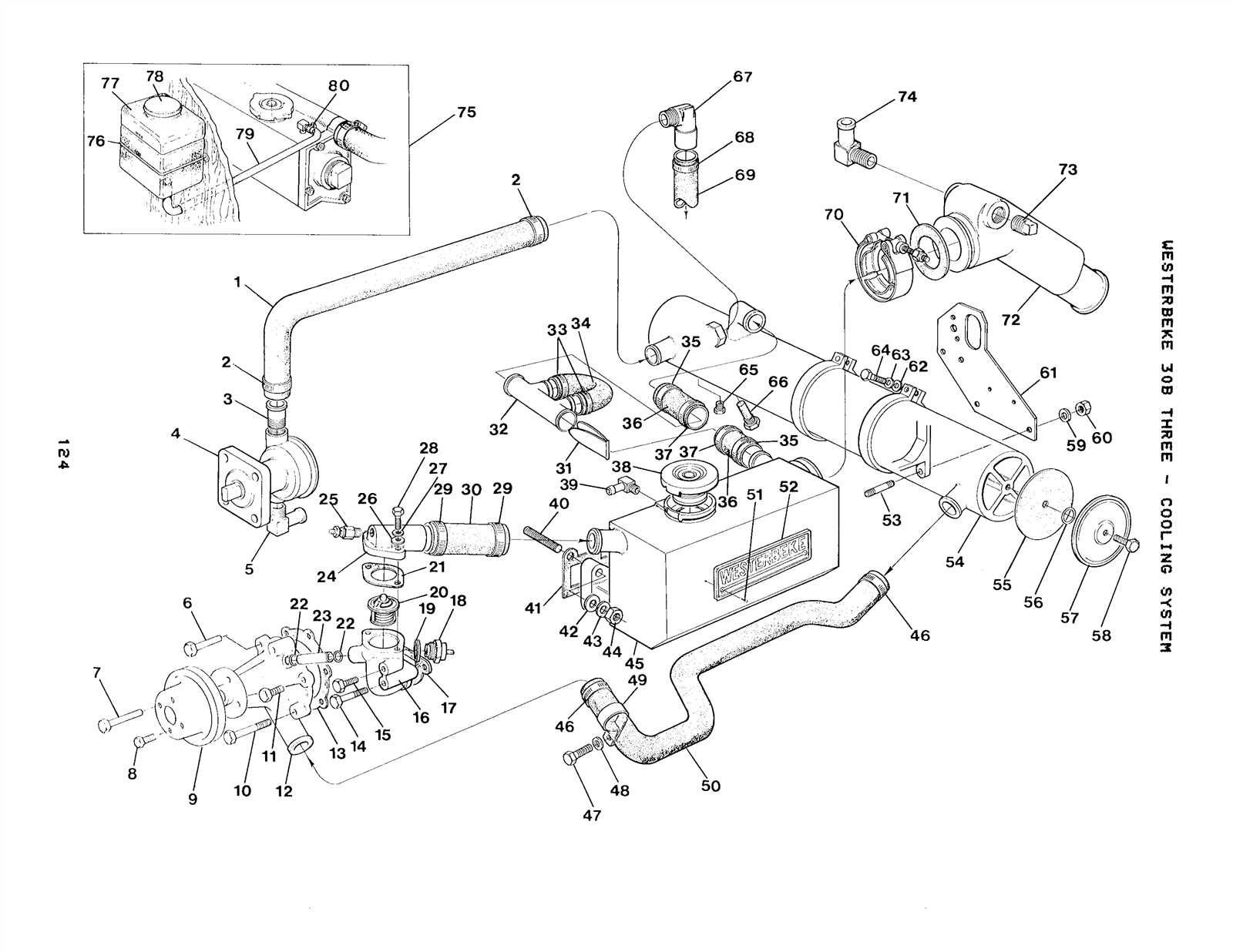

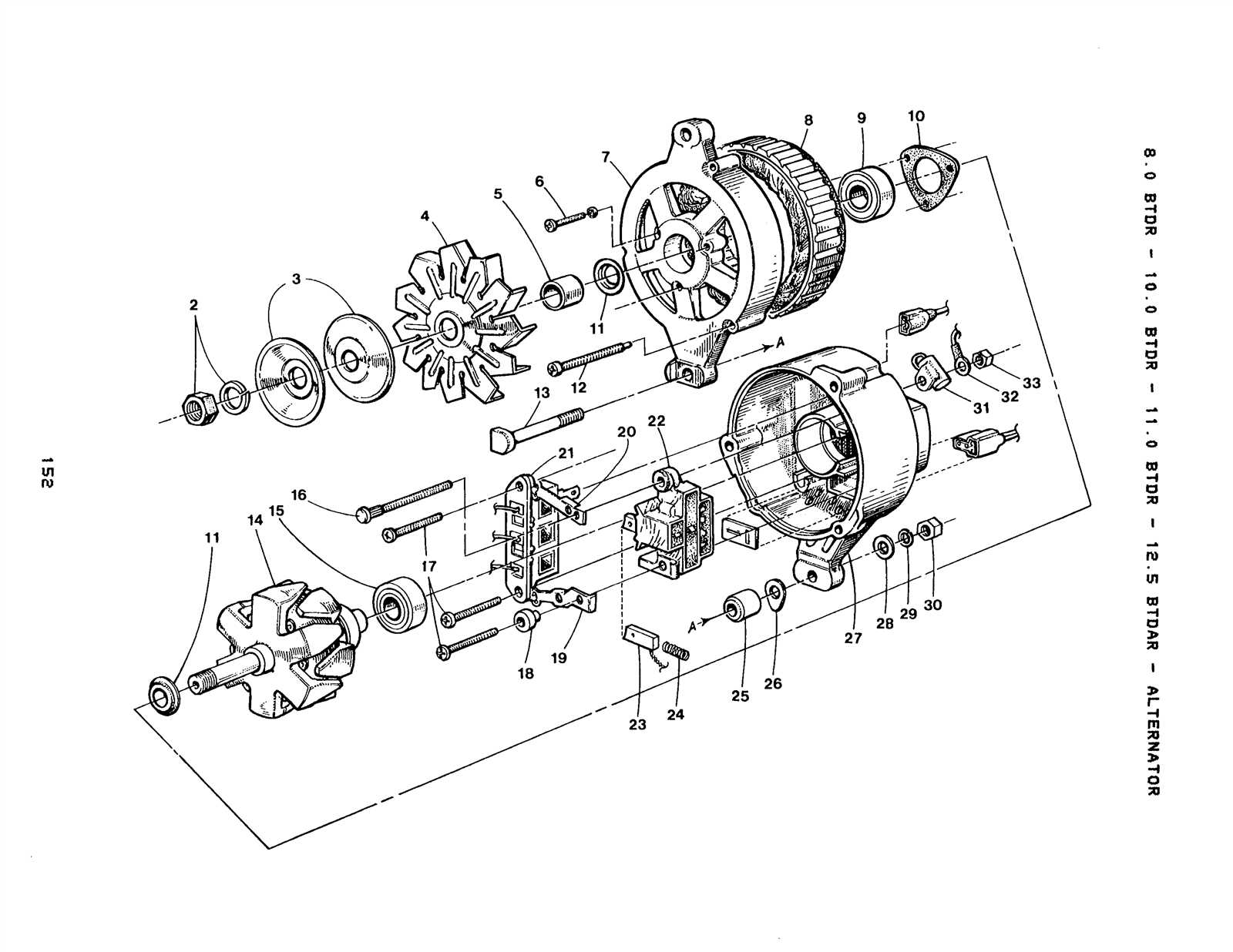

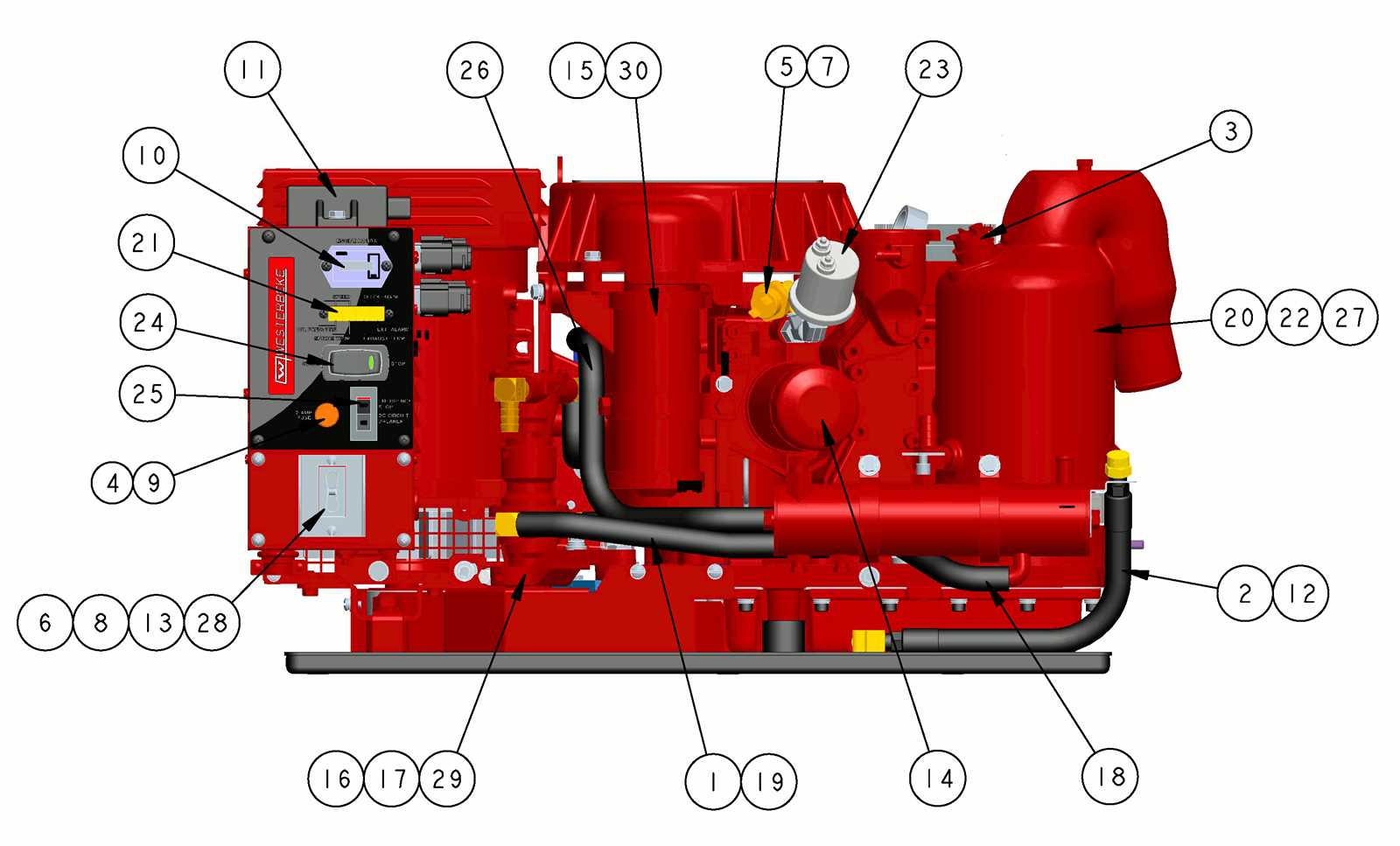

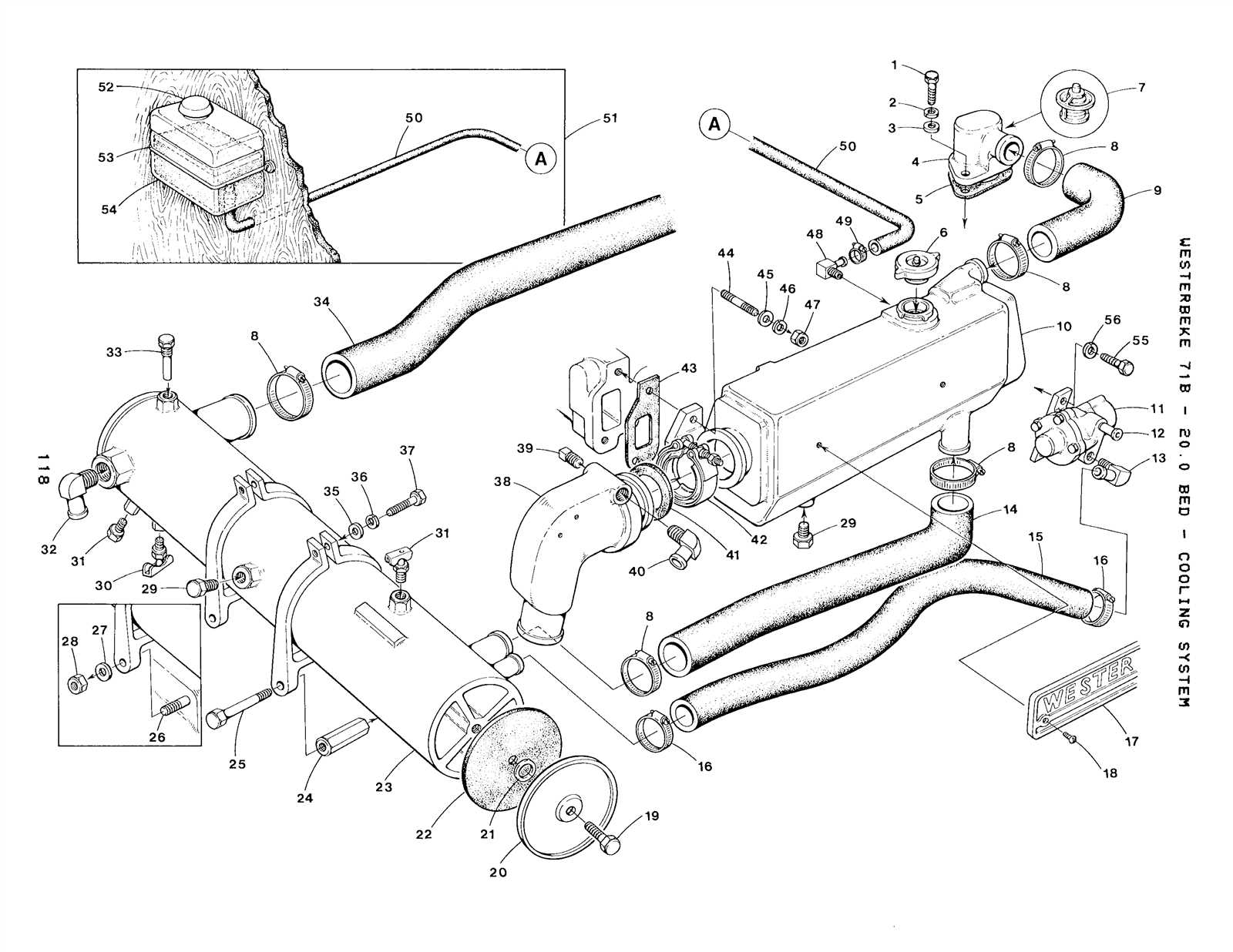

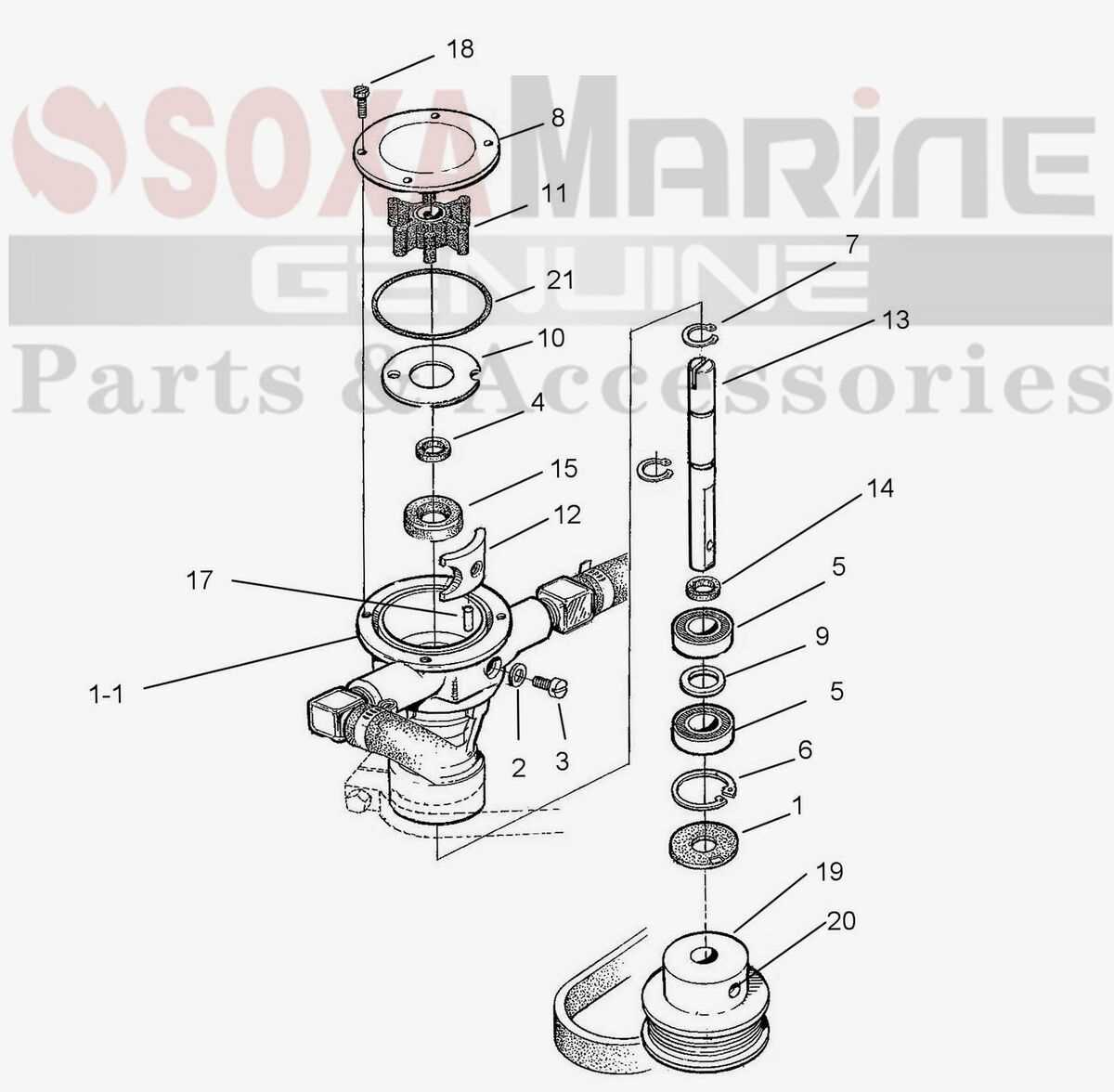

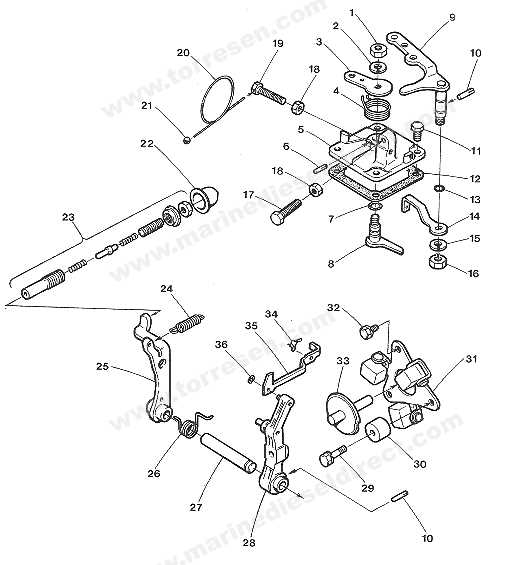

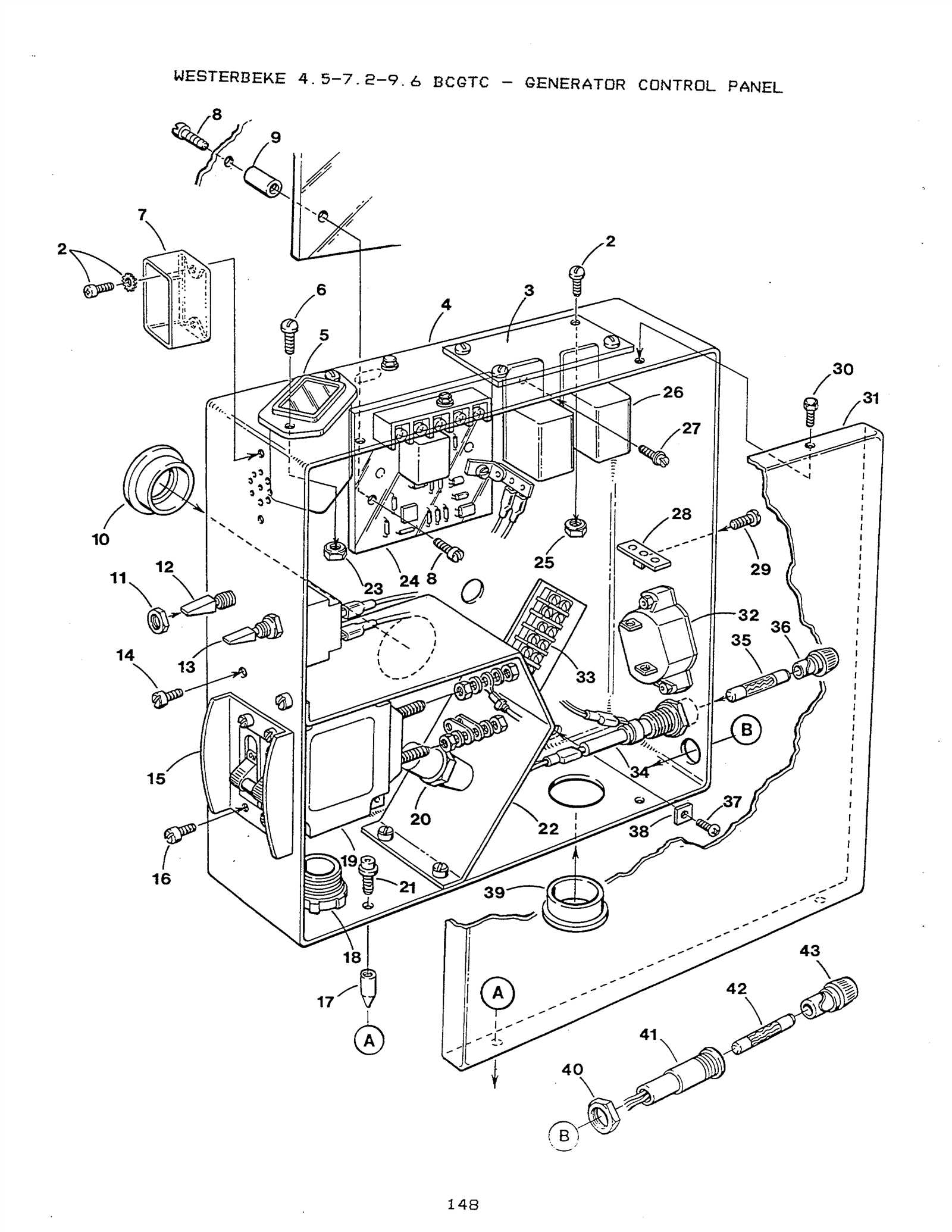

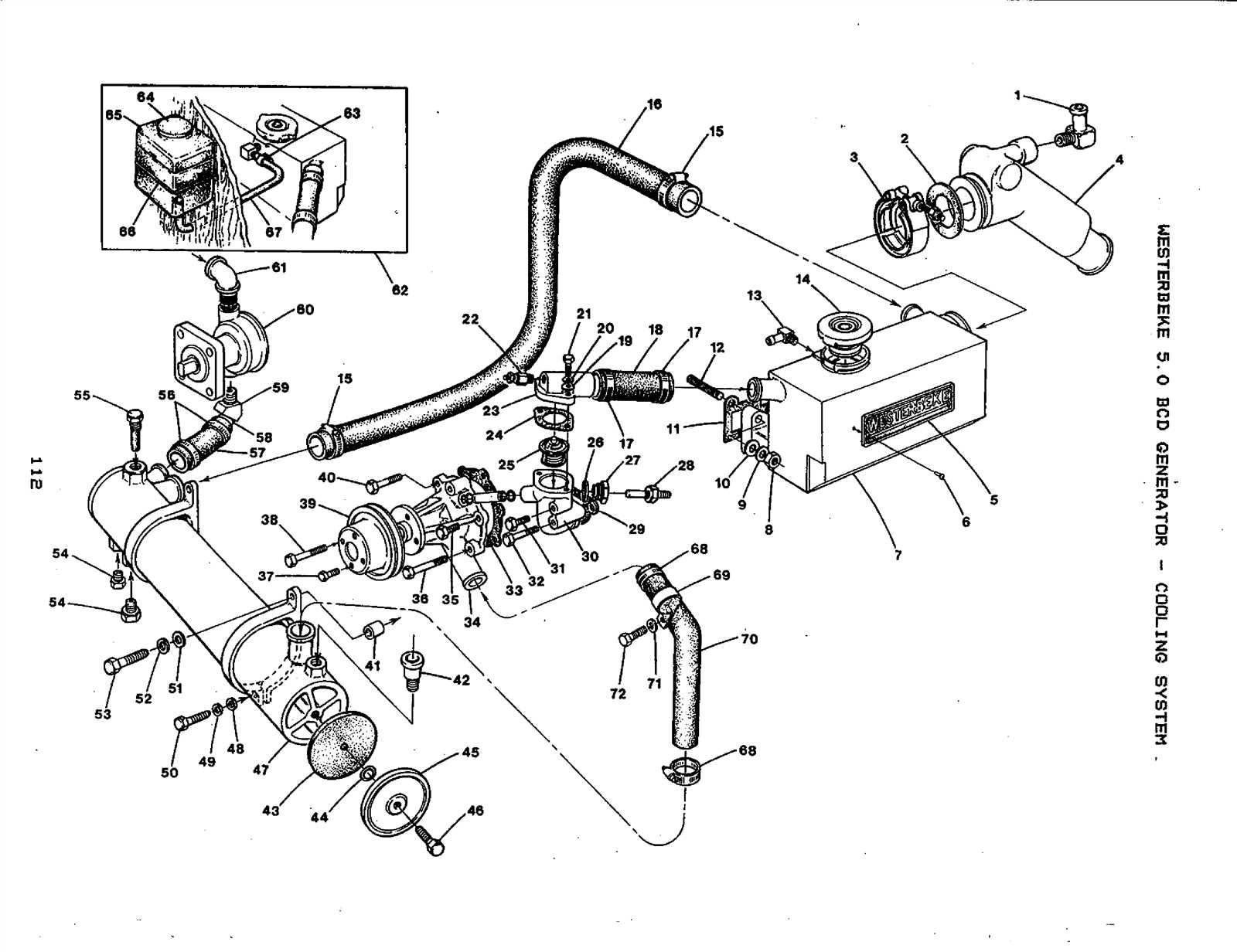

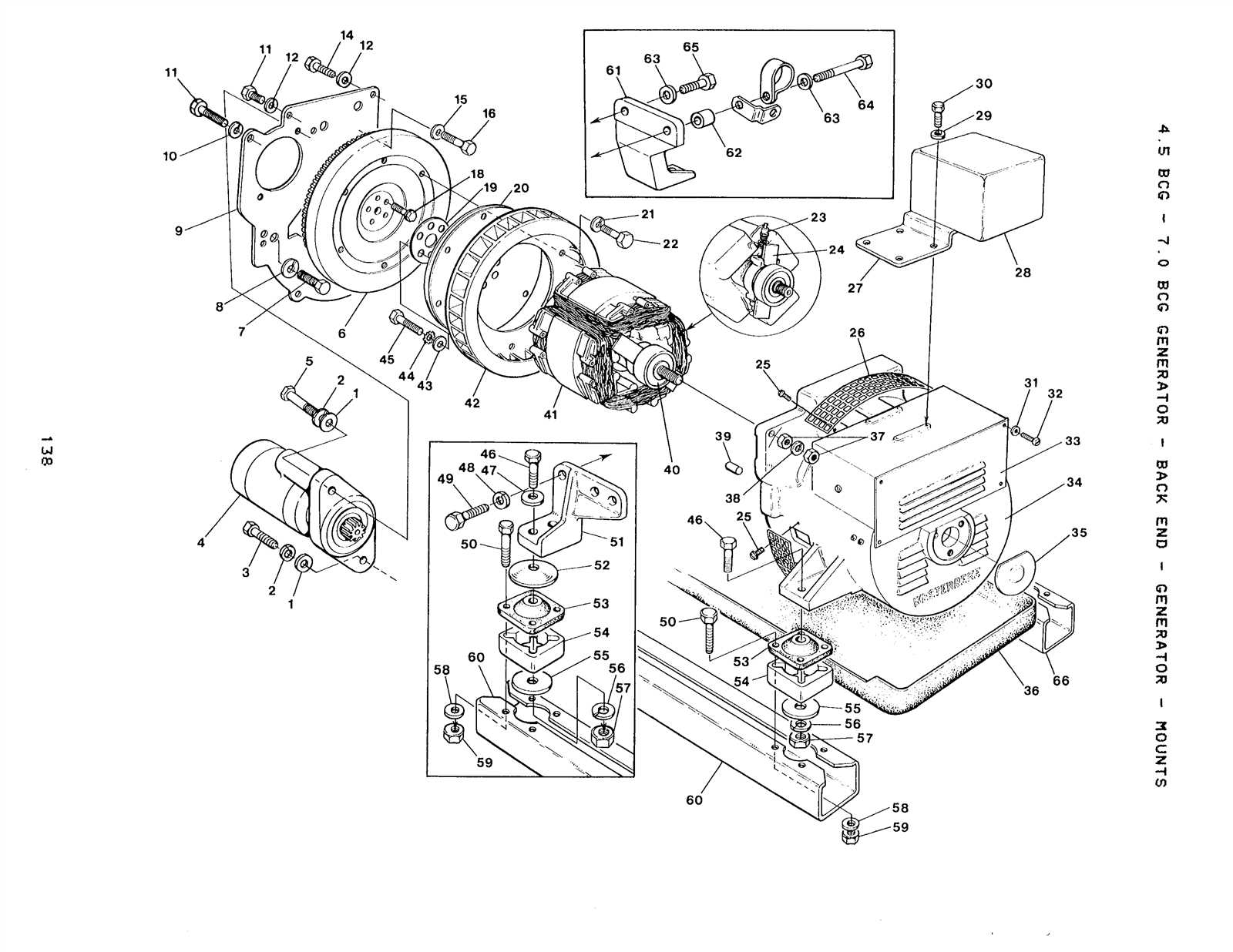

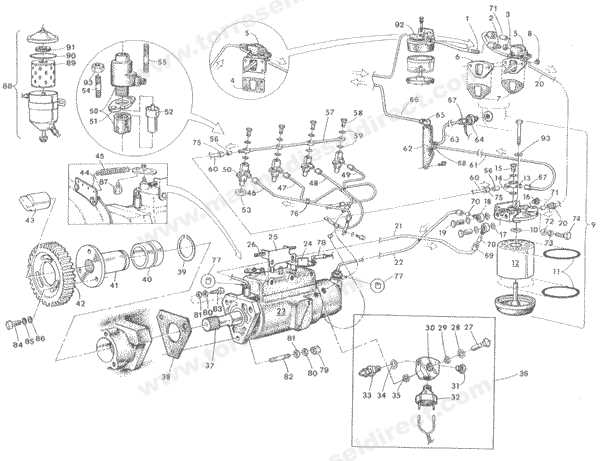

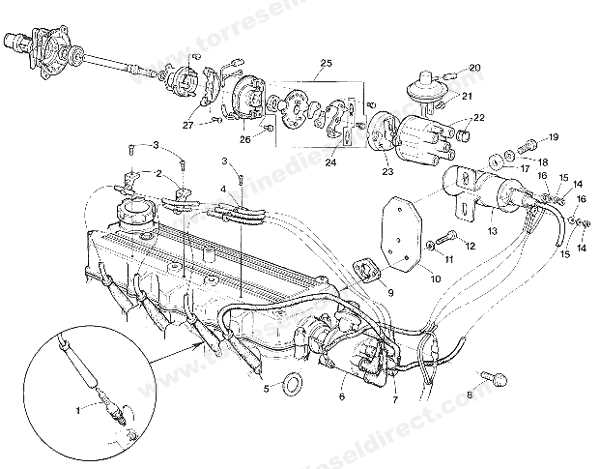

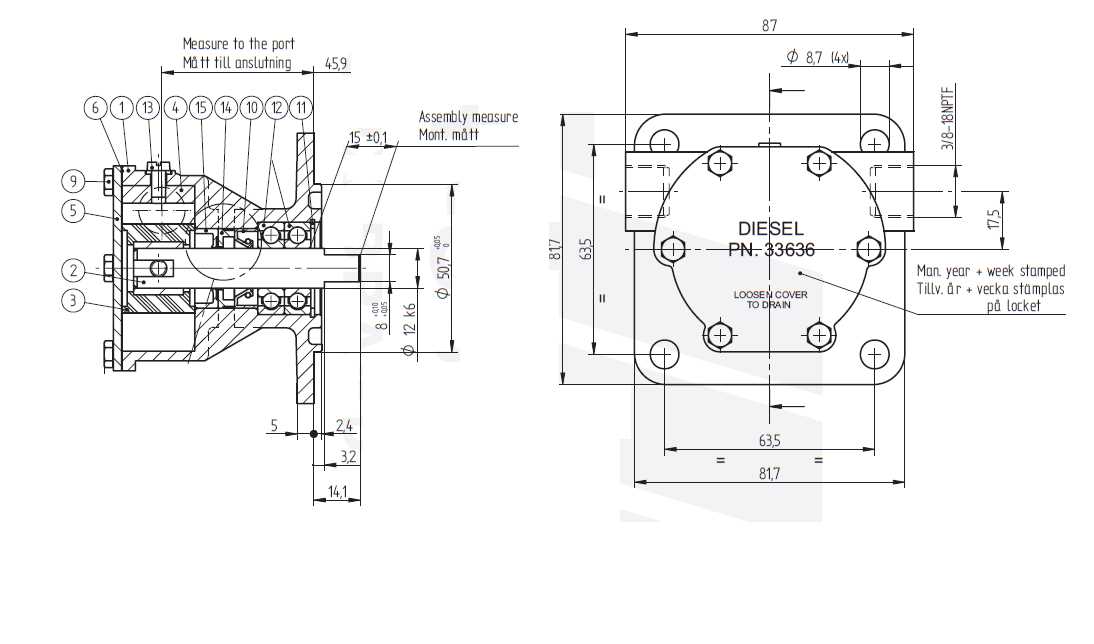

To facilitate this understanding, visual representations can be incredibly beneficial. Detailed illustrations of the inner workings of these energy solutions allow for a clearer perspective on how each part interacts within the larger framework. By analyzing these schematics, operators can enhance their skills and ensure the reliability of their maritime power sources.

Understanding Westerbeke Generators

Exploring the intricacies of portable energy systems reveals the importance of their components and how they function together to provide reliable power. Knowledge of these elements enhances the ability to maintain and troubleshoot, ensuring optimal performance in various applications.

Key Components and Their Functions

Each system consists of several critical elements, each contributing to the overall efficiency and effectiveness of the unit. Familiarity with these components allows users to identify issues and understand the operational dynamics.

| Component | Function |

|---|---|

| Engine | Converts fuel into mechanical energy to drive the system. |

| Alternator | Transforms mechanical energy into electrical energy. |

| Control Panel | Facilitates user interaction and monitoring of operational status. |

| Cooling System | Maintains optimal operating temperature by dissipating heat. |

| Fuel System | Stores and supplies fuel to the engine for combustion. |

Importance of Regular Maintenance

Routine inspection and upkeep of these essential elements significantly extend the lifespan and reliability of the device. Understanding how each part works and its role in the larger system enables users to perform effective maintenance and promptly address any emerging issues.

Key Components of Westerbeke Generators

The efficient operation of portable power systems relies on several crucial elements that work in harmony to ensure reliability and performance. Understanding these components is essential for maintenance and troubleshooting, allowing users to maximize functionality and longevity.

Power Unit: This is the core element responsible for converting fuel into mechanical energy. It typically features a combustion chamber and associated systems to optimize fuel efficiency and minimize emissions.

Cooling System: Essential for maintaining optimal operating temperatures, this assembly includes radiators and fans that help dissipate heat generated during operation. Proper cooling prevents overheating and enhances performance stability.

Control Panel: This interface allows users to monitor and manage the operation of the unit. It displays critical information such as voltage output, current load, and operational status, facilitating real-time adjustments and diagnostics.

Fuel Delivery Mechanism: This system ensures that fuel reaches the engine effectively. It comprises pumps, filters, and lines designed to maintain a steady flow, preventing interruptions in power supply.

Starting System: An integral part that enables the initial ignition of the power unit, this may include electric starters or manual pull cords, depending on the design. A reliable starting mechanism is vital for quick deployment and use.

Each of these elements plays a significant role in the overall functionality of the system, and understanding their interconnections can greatly enhance user experience and operational efficiency.

Importance of Parts Diagrams

Understanding the components and their relationships within a mechanical system is crucial for efficient maintenance and repair. Visual representations play a vital role in simplifying complex assemblies, making it easier for technicians to identify and locate each element. This clarity enhances troubleshooting processes and reduces the time needed for repairs, ultimately leading to increased operational reliability.

Utilizing these visual aids can significantly improve communication among team members and ensure everyone is on the same page. Additionally, they serve as invaluable resources for training new personnel, allowing them to quickly grasp the configuration and functionality of each section.

| Benefit | Description |

|---|---|

| Efficiency | Streamlines the identification and replacement of components. |

| Clarity | Offers a clear view of the assembly, reducing confusion. |

| Training | Facilitates the onboarding of new technicians with visual learning. |

| Communication | Enhances team collaboration through standardized references. |

In summary, effective visual representations of components are essential for the seamless operation and maintenance of any mechanical system, driving both efficiency and clarity in processes.

Common Issues with Generator Parts

Understanding the frequent challenges faced by machinery components is essential for effective maintenance and optimal performance. Various elements can encounter wear and tear, leading to diminished efficiency and potential breakdowns.

Electrical Failures

Malfunctions in the electrical system often stem from loose connections or damaged wiring. These issues can result in erratic operation, making it crucial to regularly inspect and secure all electrical connections.

Fuel System Problems

Obstructions in the fuel delivery system can cause operational inconsistencies. Blocked filters or damaged lines may prevent adequate fuel flow, so routine checks and replacements are recommended to ensure smooth functioning.

How to Read Parts Diagrams

Understanding visual schematics is essential for effective maintenance and repair. These illustrations serve as valuable guides, enabling users to identify components, their functions, and interconnections. Grasping how to interpret these visuals can significantly enhance troubleshooting and assembly processes.

First, familiarize yourself with the key symbols used in the illustration. Each shape or line typically represents a specific element or connection type. Pay attention to legends or keys provided, as they clarify what each symbol signifies. This foundational knowledge allows for quicker comprehension of the overall layout.

Next, observe the arrangement of elements. Components are often grouped according to their function or location within the system. Recognizing patterns in organization can aid in understanding how different parts interact with one another, leading to more efficient diagnostics.

Furthermore, take note of any accompanying annotations. These notations often include part numbers, specifications, or notes on maintenance procedures. Being attentive to these details can save time during repairs, as they provide crucial insights that are not immediately obvious from the visual alone.

Finally, practice makes perfect. Regularly consulting these visuals will enhance your ability to interpret them quickly and accurately. As you gain experience, your confidence in navigating these technical illustrations will grow, making maintenance tasks simpler and more efficient.

Maintenance Tips for Westerbeke Generators

Regular upkeep is essential for ensuring the longevity and efficiency of your energy system. Proper care not only enhances performance but also minimizes the risk of unexpected failures. Following a routine maintenance schedule can help you identify potential issues early and keep your equipment running smoothly.

Routine Checks

Performing consistent inspections is crucial. Check oil levels, coolant, and fuel regularly to ensure they are within recommended limits. Clean air filters and replace them as needed to maintain optimal airflow. Regularly examine electrical connections for signs of wear or corrosion.

Seasonal Maintenance

At the start of each season, conduct a more thorough examination. Replace any worn belts or hoses, and check battery health. Ensure all safety features are functioning correctly. Consider consulting the user manual for specific seasonal guidelines to enhance the reliability of your system.

Where to Find Replacement Parts

Locating components for your equipment can often seem daunting, but several resources can simplify the process. Understanding where to look and what options are available can save you time and ensure you obtain quality replacements. From authorized dealers to online marketplaces, there are various avenues to explore.

Authorized Dealers

One of the most reliable sources for acquiring quality components is through authorized dealers. These suppliers typically offer genuine products and often provide expert advice on installation and maintenance. To find a local dealer, consult the manufacturer’s website or contact their customer service for recommendations.

Online Marketplaces

The internet has revolutionized the way we shop for equipment supplies. Numerous online platforms specialize in selling both new and refurbished items. Websites like eBay and Amazon often feature a wide array of components, and customer reviews can guide your purchasing decisions. Additionally, specialized online retailers might carry hard-to-find items, providing a broader selection.

Always ensure that the seller has a good reputation and check for return policies to avoid potential issues.

Identifying Part Numbers Easily

Locating specific component identifiers can streamline maintenance and repair tasks. Understanding how to efficiently find these numbers enhances the overall experience and reduces downtime.

- Utilize manufacturer manuals for accurate references.

- Employ online databases that catalog various identifiers.

- Consider cross-referencing with similar models for additional clarity.

By following these strategies, users can navigate the identification process with confidence and precision.

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components offers numerous advantages that can enhance the overall performance and longevity of machinery. These high-quality items are specifically designed to fit and function seamlessly within their intended systems, ensuring optimal efficiency and reliability.

Quality Assurance

One of the primary benefits of OEM components is the assurance of quality. These products undergo rigorous testing and adhere to strict manufacturing standards, which helps maintain the integrity of the equipment.

Perfect Fit and Compatibility

Another significant advantage is the perfect fit and compatibility that OEM components provide. This ensures that installations and replacements are straightforward, minimizing the risk of malfunctions that can arise from using generic alternatives.

| Advantage | Description |

|---|---|

| Quality Assurance | Manufactured to stringent standards, ensuring reliability and durability. |

| Compatibility | Designed specifically for certain systems, promoting seamless integration. |

| Long-Term Savings | Investing in quality components reduces the frequency of repairs and replacements. |

| Warranty Protection | Many OEM products come with warranties that safeguard your investment. |

Aftermarket Options: Pros and Cons

When considering alternative solutions for machinery components, it’s essential to evaluate the benefits and drawbacks of these secondary market offerings. While they can provide cost savings and increased availability, there are factors that may affect their reliability and performance.

Advantages

Cost-Effectiveness: One of the primary benefits is the potential for significant savings. Many aftermarket solutions are priced lower than original equipment, making them accessible for budget-conscious consumers.

Disadvantages

Quality Concerns: The trade-off for lower prices can be subpar quality. Some aftermarket items may not meet the same stringent standards as their original counterparts, leading to performance issues or increased wear over time.

Westerbeke Generator Repair Techniques

Effective maintenance and repair strategies are essential for ensuring the longevity and efficiency of energy-producing machines. Understanding common issues and employing the right techniques can help minimize downtime and extend the operational lifespan of your equipment. This section explores practical methods for troubleshooting and fixing various components, making the repair process more straightforward and effective.

Common Issues and Troubleshooting

Identifying frequent problems is the first step in effective repairs. Some typical challenges include electrical malfunctions, fuel system leaks, and mechanical wear. Conducting a thorough inspection can reveal underlying issues. Start by checking connections and wiring for corrosion or damage. Next, examine the fuel system for leaks or blockages, and inspect moving parts for signs of wear. Keeping detailed records of any anomalies can assist in future troubleshooting efforts.

Repair Techniques and Best Practices

Once issues are identified, employing appropriate repair techniques is crucial. For electrical issues, ensure all connections are secure and clean any corrosion. If dealing with fuel leaks, replace damaged hoses and seals promptly. Regularly lubricating moving parts can prevent wear and tear. Following manufacturer guidelines for maintenance and repairs is essential to ensure compliance and optimal performance. Utilizing quality replacement components can significantly enhance reliability and efficiency.

Resources for Further Research

This section offers valuable references for those seeking in-depth knowledge about equipment components and maintenance. By exploring various sources, readers can enhance their understanding and find practical solutions for their needs.

| Resource Type | Description | Link |

|---|---|---|

| Manufacturer Manuals | Official documentation detailing specifications and maintenance procedures. | View Manuals |

| Online Forums | Community discussions providing insights and troubleshooting tips from experienced users. | Join Forums |

| Video Tutorials | Step-by-step guides demonstrating repairs and setups through visual content. | Watch Videos |

| Parts Suppliers | Websites offering a range of replacement components and accessories. | Find Parts |