When examining the internal configuration of electric heating systems, it’s essential to explore the various components that contribute to efficient temperature control. These devices are designed with a range of elements that work together to ensure consistent performance in maintaining warmth throughout a space. Gaining insight into the different sections of such systems can greatly enhance your understanding of how they operate and how to keep them functioning at their best.

The framework of these warming solutions often includes several key segments, each with its own role in the overall functionality

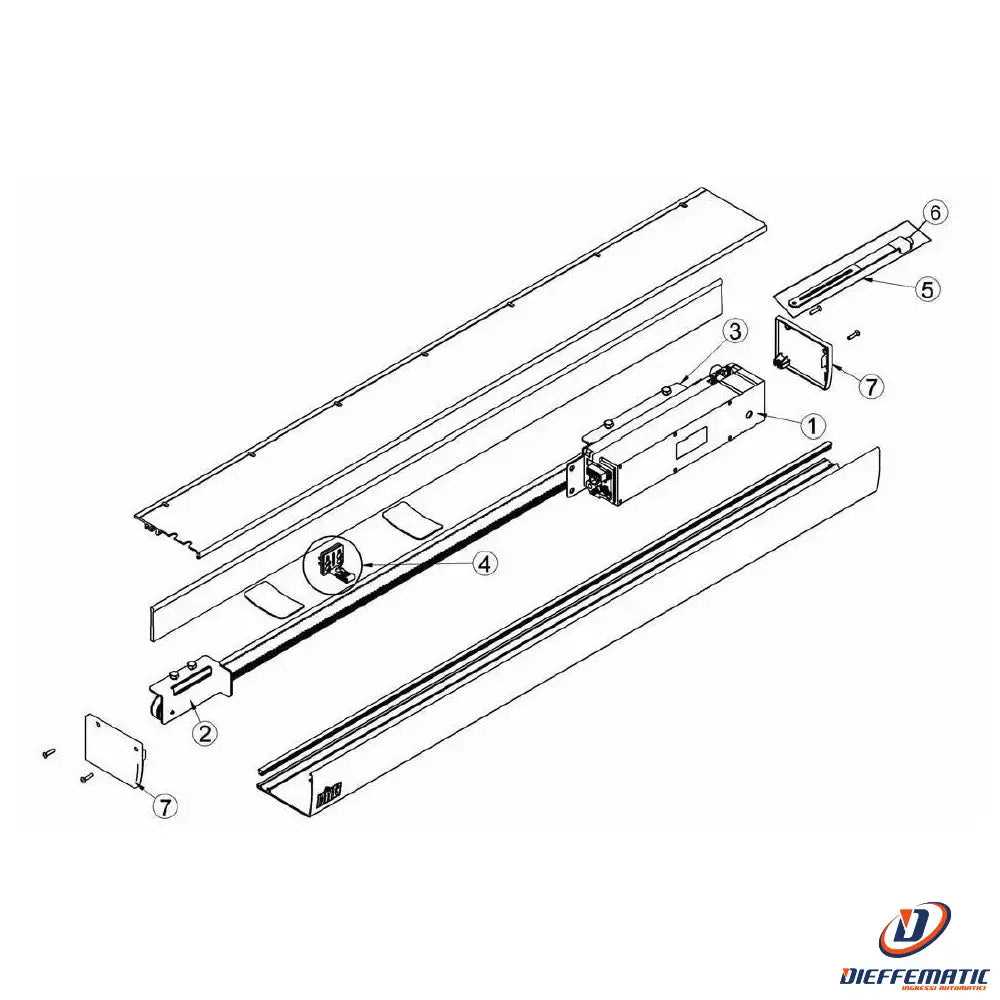

Baseboard Heating System Overview

In modern homes, one of the key methods for ensuring comfortable indoor temperatures is through a specific type of wall-mounted unit. These systems are designed to circulate warmth efficiently throughout living spaces, relying on the natural movement of air. The simplicity of the design makes it a popular choice for residential heating solutions.

Key components of this system work together to maintain optimal performance and energy efficiency. These elements typically include temperature regulators, piping for the circulation of fluids, and protective enclosures. Below is an outline of the primary features and their functions.

- Temperature Control: A critical element that allows users to adjust the warmth output according to their preferences.

- Heat Transfer Mechanism: This refers to the method by which warmth is distributed through the system, usually involving liquid or electrical elements.

- Protective Casing: Enclosures that safeguard the internal components and ensure safe operation within the home.

Understanding these key elements provides a foundation for further exploring how such systems contribute to home comfort and efficiency.

Understanding Key Components

When examining the structure of a typical thermal control system, it’s essential to identify the various elements that contribute to its functionality. Each element plays a critical role in ensuring efficient operation, from regulating warmth to managing energy flow. By breaking down these individual pieces, you can gain a clearer understanding of how the entire system works together.

Temperature Regulation Unit

The temperature regulation unit is a pivotal part of the system, designed to maintain the desired warmth level. It senses changes in the environment and adjusts accordingly, ensuring consistent thermal comfort. This element often works in tandem with other control mechanisms to optimize efficiency.

Energy Distribution Mechanism

The energy distribution mechanism is responsible for transferring power to different sections of the system. It ensures that energy is appropriately directed, allowing for smooth and even heat dispersal throughout the space. Understanding how this mechanism operates is key to troubleshooting and optimizing system performance.

How Electric Heating Elements Work

Electric heating elements function by converting electrical energy into heat. This process is driven by the movement of current through a conductor, which in turn produces thermal energy that is released into the surrounding environment. The efficiency of this conversion depends on various factors, including the material and design of the element.

Key aspects of how these systems work include:

- Resistance-based heating: When electricity flows through materials with specific resistance, the energy is

Exploring the Role of the Thermostat

The thermostat is an essential element in controlling temperature settings within a space. It functions by monitoring ambient conditions and regulating the power flow to ensure consistent warmth or coolness. Understanding its operation is crucial for optimizing energy efficiency and maintaining a comfortable environment.

A thermostat works by sensing the current climate and adjusting the system accordingly. Whether it’s a manual or programmable model, this device directly impacts how well the system maintains a steady level of comfort. Its effectiveness can significantly influence energy consumption and overall performance.

Heat Distribution and Airflow

Proper management of thermal energy is essential for maintaining consistent temperatures within a space. The circulation of warm air plays a key role in achieving uniform warmth throughout different areas. This process relies on the movement of air, which is affected by several factors, including the design of the system and the positioning of its elements.

Effective airflow ensures that heat reaches every corner of the room, preventing cold spots and improving overall comfort. By optimizing the flow of air, it is possible to enhance the efficiency of the entire setup. In addition, proper distribution can reduce energy consumption and maintain a steady environment.

To achieve balanced temperature control, attention must be given to the placement of components, as well as the way warm air moves and circulates. Improving these factors leads to a more effective system that meets the needs of diverse environments.

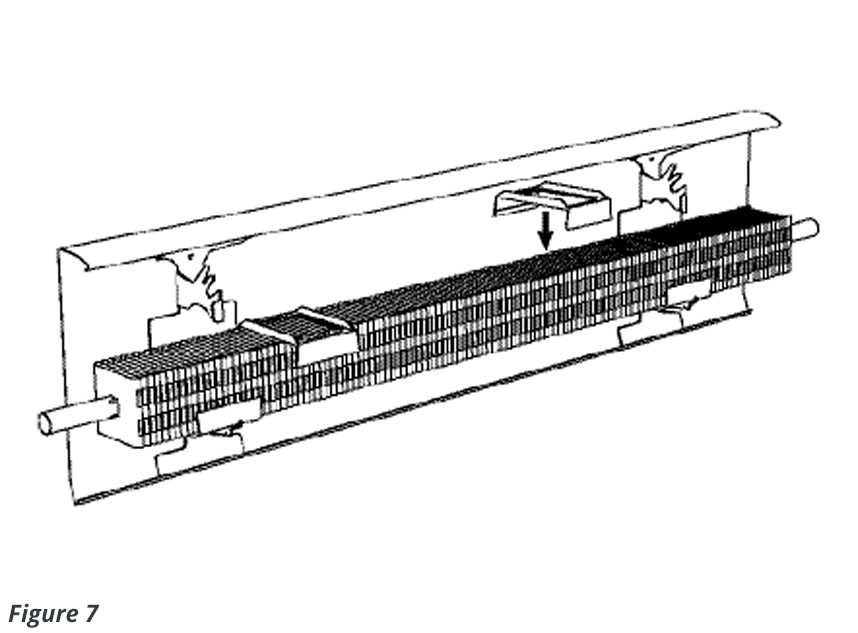

Importance of Fins in Heat Transfer

Fins play a crucial role in enhancing the efficiency of thermal exchange systems. By increasing the surface area available for heat dissipation, these components facilitate more effective energy transfer between the heating element and the surrounding environment. Their design and arrangement significantly impact overall performance, making them essential in various applications where temperature regulation is key.

Functionality of Fins

The primary function of fins is to maximize contact with the surrounding air, allowing for improved convection currents. As air flows over the fins, it absorbs heat, which helps to maintain a consistent temperature in the space. The materials used in fin construction also influence their effectiveness, with metals like aluminum and copper being popular choices due to their excellent thermal conductivity.

Factors Affecting Fin Efficiency

Several factors contribute to the overall effectiveness of fins in thermal systems. These include:

Factor Description Material The choice of material affects thermal conductivity and longevity. Design Fin shape and arrangement can optimize airflow and heat transfer. Surface Treatment Coatings can enhance corrosion resistance and improve heat exchange properties. Understanding these factors is vital for designing efficient thermal systems that deliver consistent performance while minimizing energy consumption.

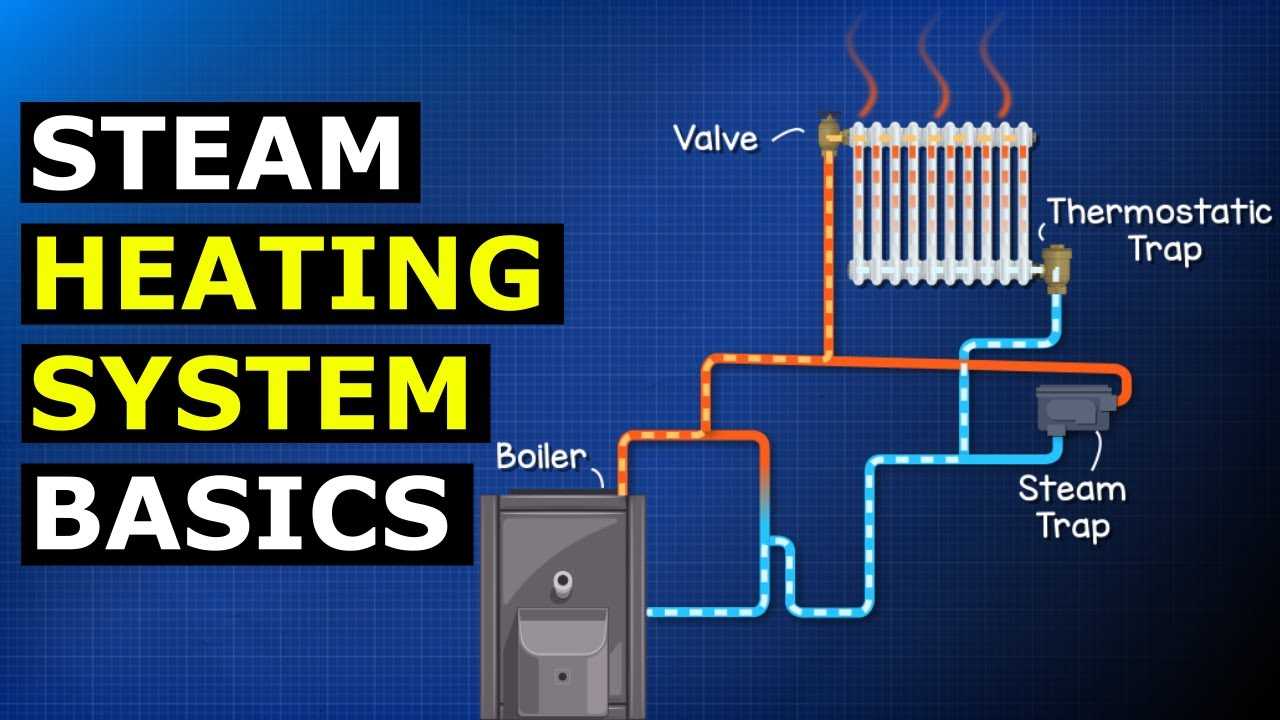

Wiring Connections in Baseboard Heaters

Understanding the electrical connections within heating units is crucial for efficient operation and safety. These components are designed to distribute warmth effectively throughout a space, relying on proper wiring configurations to ensure optimal functionality. Familiarity with the layout and connections will help in troubleshooting issues and performing necessary maintenance.

Types of Electrical Connections

There are several types of electrical connections that may be used in heating systems. Commonly, these include series and parallel arrangements. In a series setup, the electrical flow passes through each element sequentially, while in a parallel configuration, each unit operates independently, allowing for consistent heat distribution even if one unit fails.

Safety Considerations

When dealing with electrical components, it is essential to prioritize safety. Always ensure that the power is turned off before working on any connections. Additionally, using appropriate gauge wires and ensuring all connections are secure can prevent overheating and potential hazards. Regular inspections can also help maintain the integrity of the system.

Maintenance Tips for Long-lasting Performance

Ensuring the longevity and efficiency of your heating system involves regular upkeep and attention to detail. By following a few essential practices, you can enhance the performance and extend the life of your equipment.

Regular Inspections

Conducting periodic checks is crucial for identifying potential issues before they escalate. Here are some key areas to focus on:

- Examine the physical condition for signs of wear or damage.

- Ensure that all connections are secure and free from corrosion.

- Inspect the surrounding area for any obstructions that may hinder airflow.

Cleaning Practices

Maintaining cleanliness is vital for optimal functionality. Follow these cleaning tips:

- Dust and debris can accumulate over time, so regular cleaning of surfaces is essential.

- Remove any blockages in the vents to promote efficient airflow.

- Consider using a vacuum with a brush attachment for hard-to-reach areas.

By implementing these maintenance tips, you can ensure a reliable and efficient heating solution that lasts for years to come.

Replacing Worn-out Heating Parts

Over time, certain components of your heating system may wear out, leading to reduced efficiency and performance. It is essential to address these issues promptly to maintain optimal functioning. Regular inspection and timely replacement can ensure a steady supply of warmth in your living space.

Identifying which elements need replacement is the first step. Common signs of wear include:

- Inconsistent temperature output

- Unusual noises during operation

- Visible damage or corrosion

Once you have determined the faulty components, follow these steps for replacement:

- Turn off the power supply to ensure safety.

- Carefully remove the damaged component using appropriate tools.

- Install the new element, ensuring a secure fit.

- Restore the power and check for proper operation.

Regular maintenance, including periodic inspections and timely replacements, can significantly extend the lifespan of your heating system, keeping your environment comfortable year-round.

Identifying Common Issues in Heating Systems

One of the primary concerns in any warming setup is maintaining consistent operation. Over time, various problems can arise that affect functionality and efficiency. These issues often stem from wear, lack of maintenance, or faulty components. Understanding typical challenges can help prevent major malfunctions.

Electrical connectivity problems are a frequent cause of system failures. Issues with wiring or connections can lead to intermittent operation or complete shutdown. Regular inspection of the electrical components is essential to avoid unexpected breakdowns.

Another common issue is thermostat miscalibration, which can result in temperature inconsistencies. This can cause the system to run longer than necessary, leading to inefficiency and higher energy costs. Ensuring the control

Safety Considerations for Baseboard Heaters

Ensuring a safe environment when utilizing heating appliances is crucial for preventing accidents and maintaining comfort. Awareness of potential risks associated with these systems can help users take necessary precautions to mitigate hazards. Implementing safety measures not only protects individuals but also prolongs the lifespan of the equipment.

Regular Maintenance

Routine upkeep of heating appliances is vital for their efficient operation. Neglecting maintenance can lead to overheating, inefficiency, and increased energy costs. Regular inspections should be conducted to identify any signs of wear, corrosion, or obstructions that may impair performance.

Proper Installation

Correct installation is essential to ensure safety and efficiency. Follow all manufacturer guidelines and local building codes when setting up heating systems. Inadequate installation can result in serious safety issues, including fire hazards or improper airflow.

Safety Tip Description Clear Obstructions Ensure that the area around the unit is free of clutter to allow for proper airflow and heat distribution. Use Thermostats Utilizing thermostatic controls can help regulate temperature and prevent overheating. Emergency Shut-off Familiarize yourself with the emergency shut-off mechanism to quickly disable the system if necessary. Choosing the Right Replacement Components

When it comes to ensuring optimal performance and longevity of your heating system, selecting appropriate substitute elements is crucial. Understanding the specifics of what needs to be replaced and recognizing the compatibility of various components can significantly impact efficiency and functionality.

Assessing Compatibility and Quality

Before purchasing new elements, it’s essential to evaluate compatibility with your existing setup. Look for components that match the specifications of the originals, including size, voltage, and material. Investing in high-quality replacements is vital; inferior parts may lead to inefficiencies or even damage to the overall system.

Understanding Manufacturer Recommendations

Consulting the manufacturer’s guidelines can provide valuable insights into suitable replacements. Often, manufacturers offer specific suggestions that ensure performance and reliability. Using components that meet these recommendations can enhance the system’s effectiveness and extend its lifespan.