In the realm of farming machinery, grasping the intricate details of various implements is essential for optimal performance and maintenance. Each piece of equipment plays a vital role in enhancing efficiency during the harvesting and processing stages. Understanding how these components interact can ultimately lead to improved productivity and longevity of the machines.

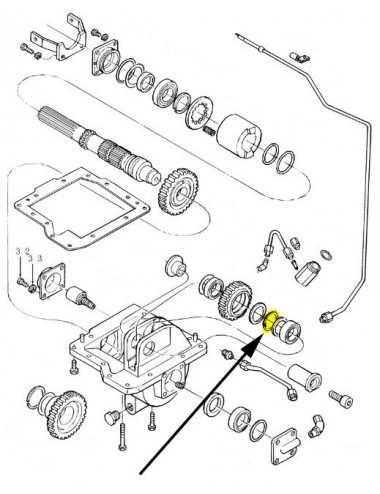

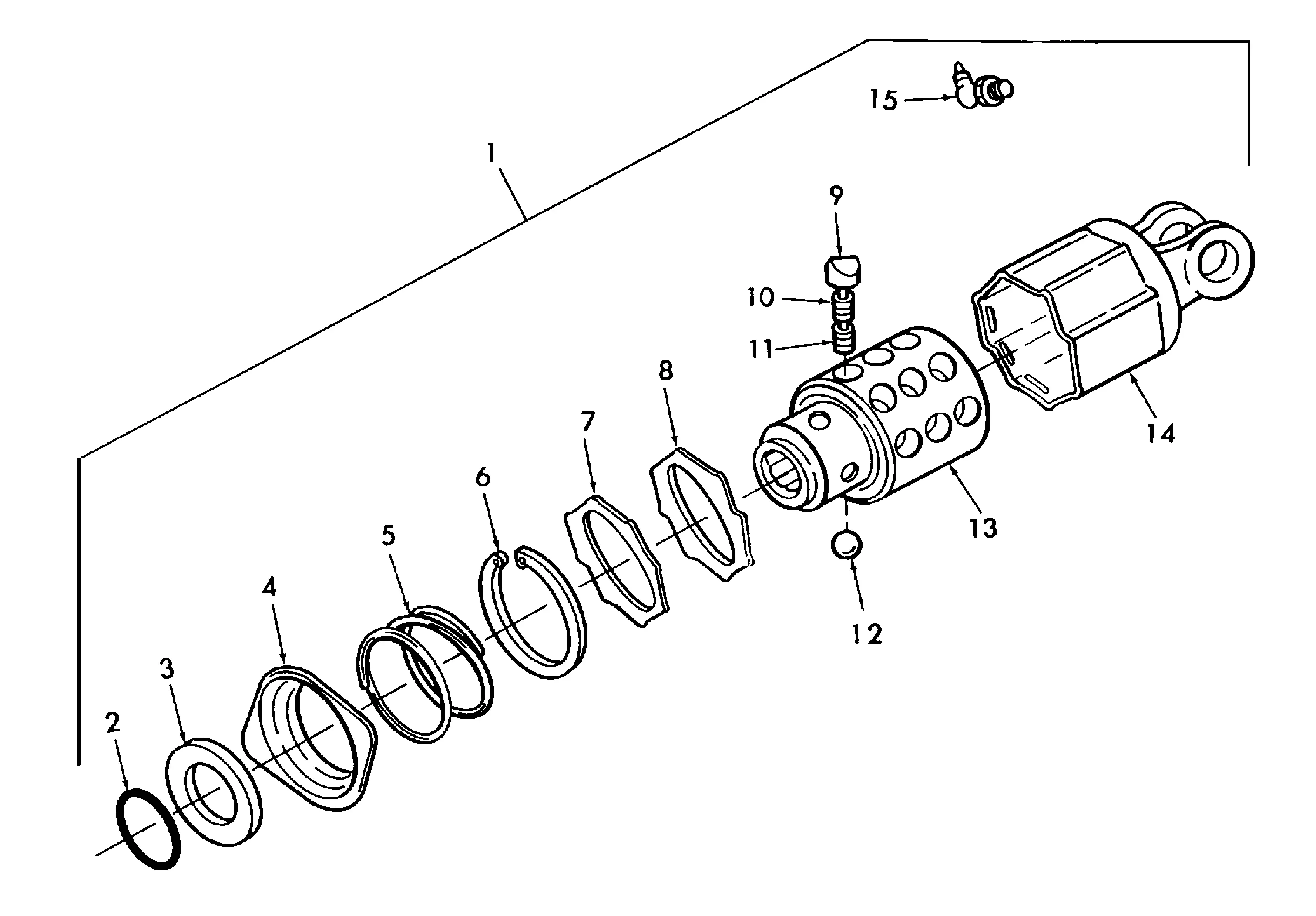

Visual aids that illustrate the configuration of essential elements offer invaluable insights for operators and technicians alike. By delving into these representations, one can easily identify crucial segments, ensuring timely repairs and replacements when necessary. This understanding fosters a proactive approach to machinery care.

Equipping oneself with knowledge about specific models enhances operational effectiveness. Whether you’re a seasoned professional or a novice in the field, familiarity with these mechanisms is the ultimate key to unlocking the full potential of your agricultural investments.

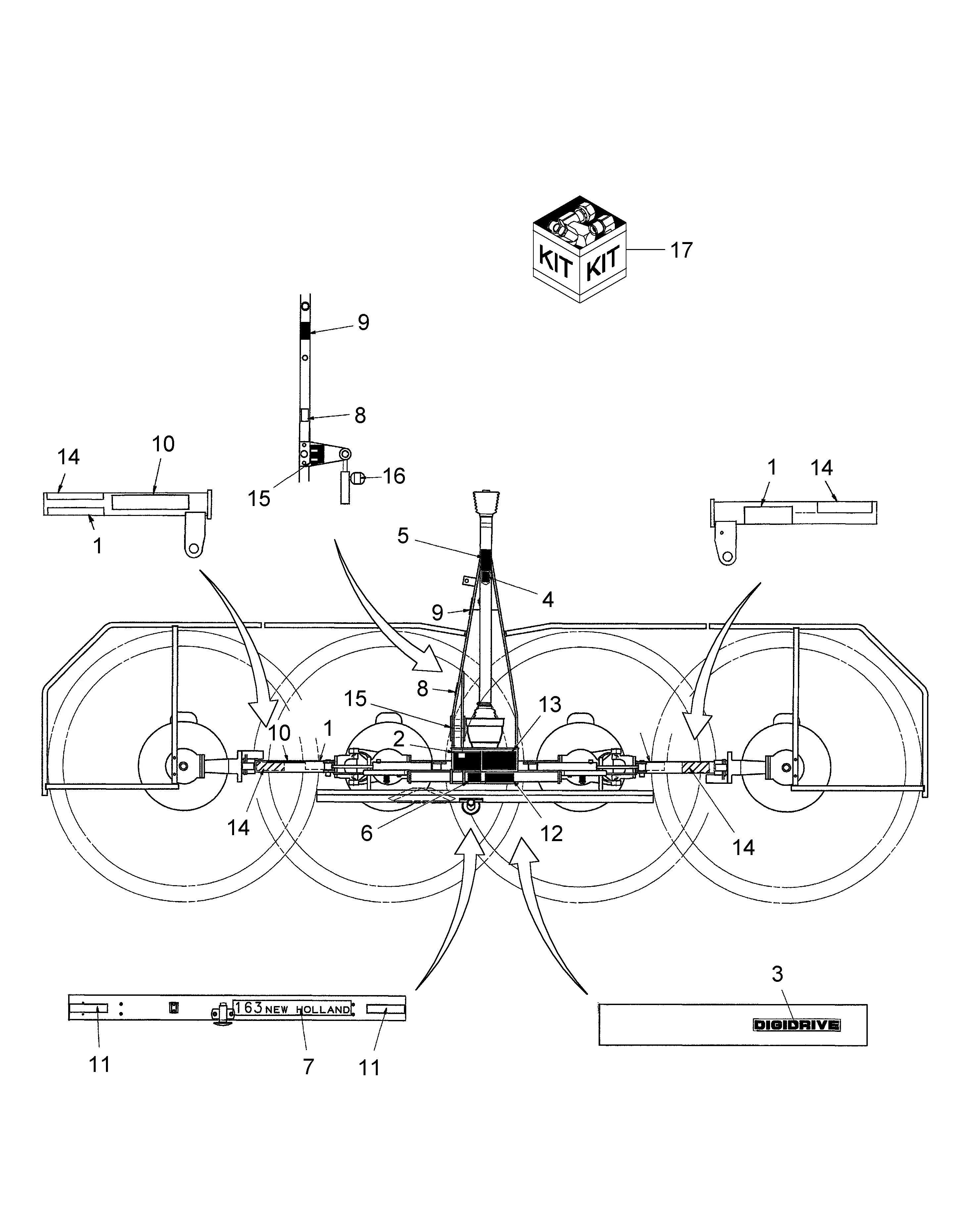

Understanding the New Holland 163 Tedder

This section aims to explore a specific type of agricultural equipment designed for efficient crop management. By examining its design, functionality, and components, users can gain insights into its operation and maintenance.

Key Features

- Efficient drying of forage

- Durable construction for longevity

- User-friendly operation

Maintenance Tips

- Regular inspection of moving parts

- Lubrication to prevent wear

- Ensuring proper alignment for optimal performance

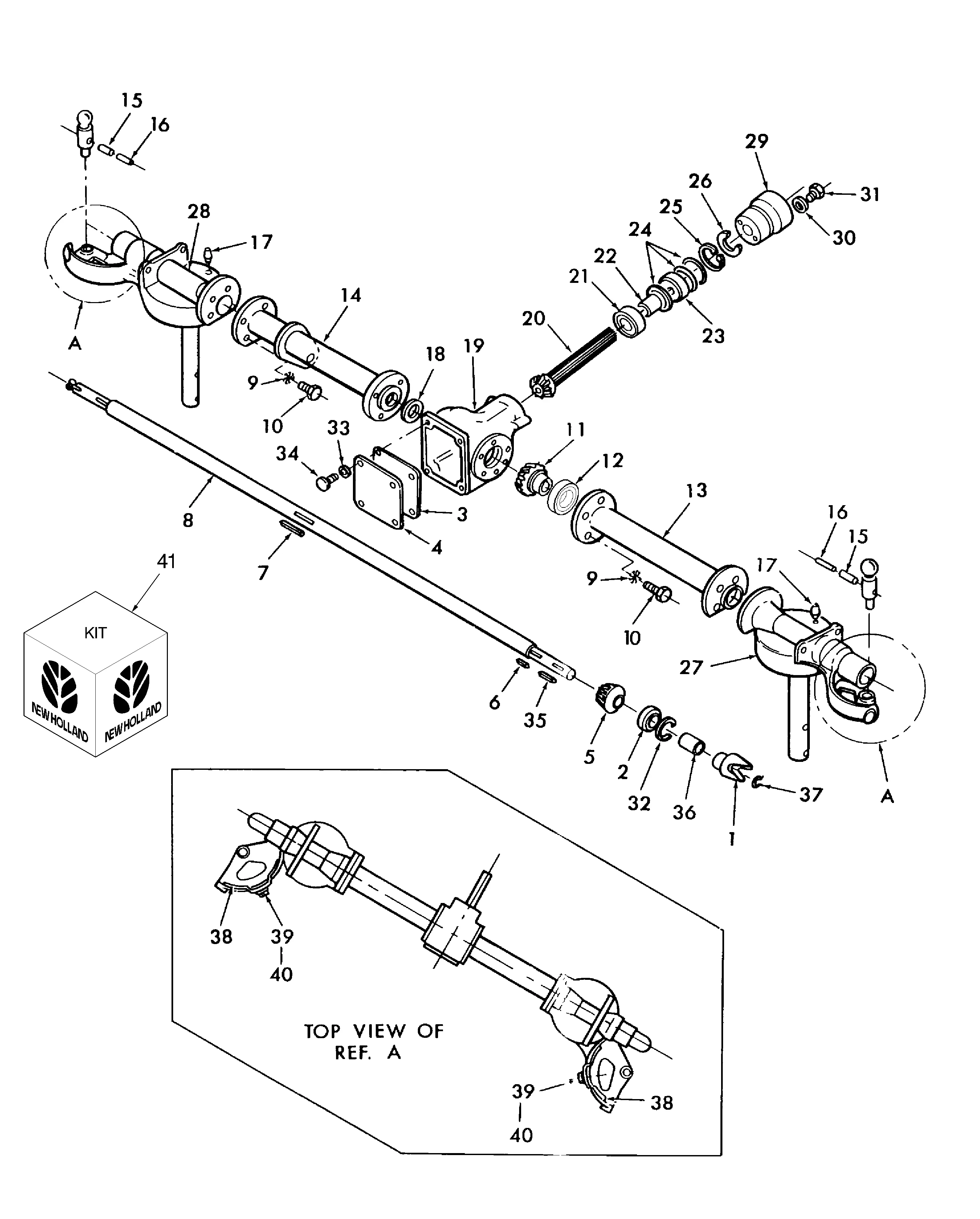

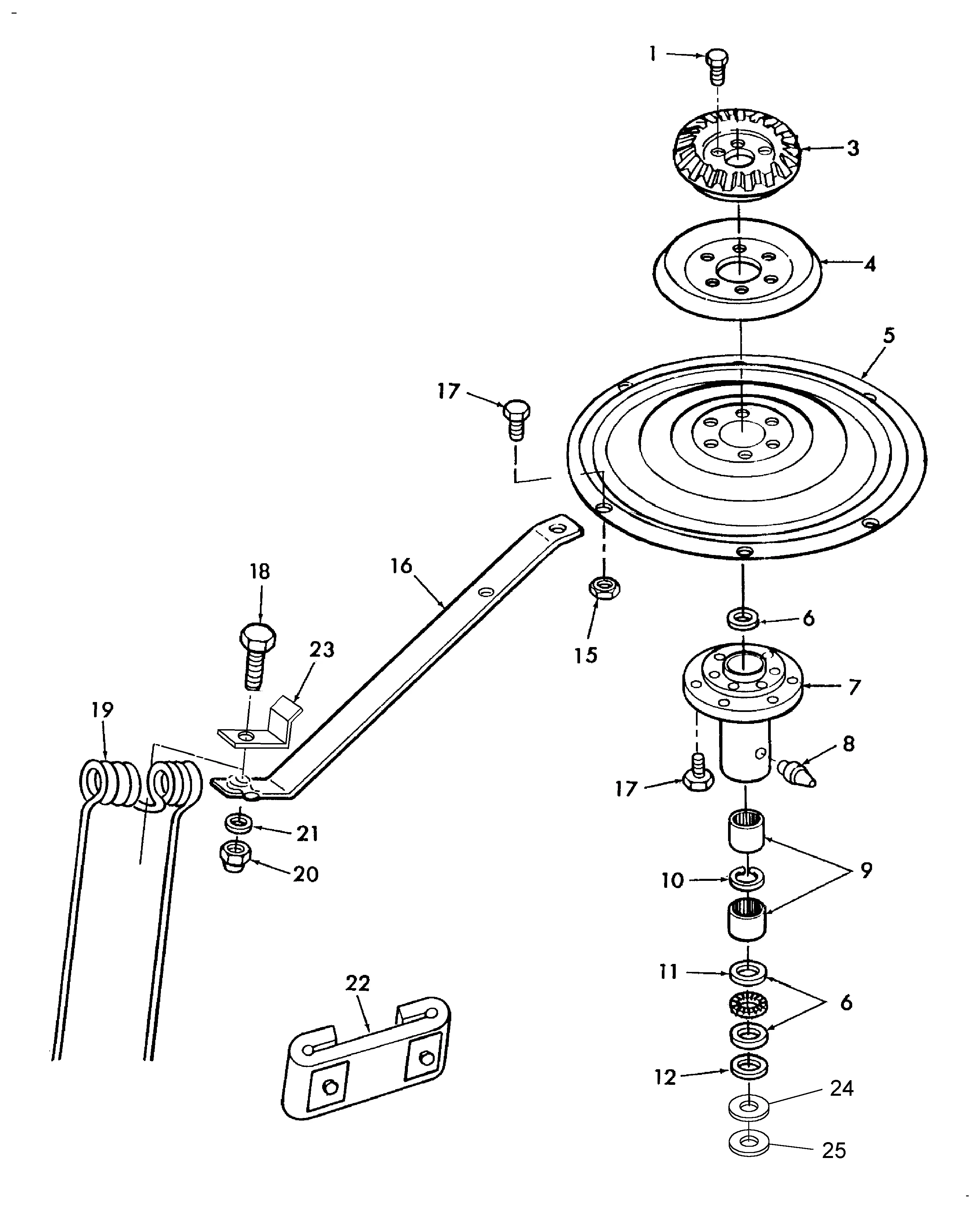

Key Components of the Tedder

Understanding the essential elements of a haymaking machine is crucial for efficient operation and maintenance. These components work together to ensure optimal performance in the field.

- Frame: The sturdy structure that supports all other components.

- Rotors: These spinning arms effectively lift and aerate the crop.

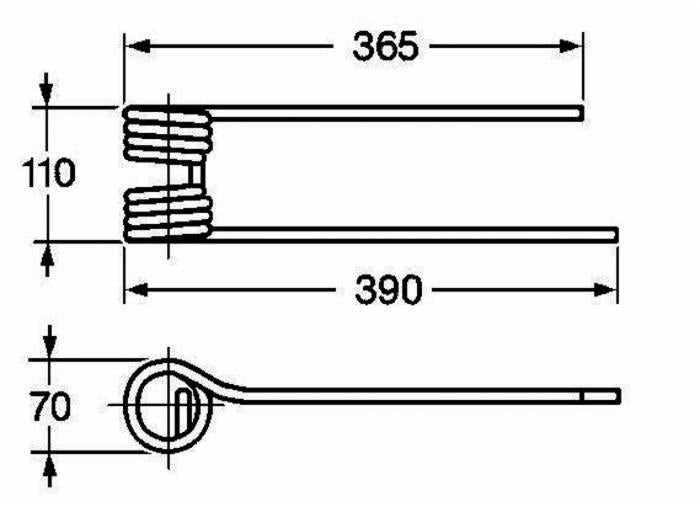

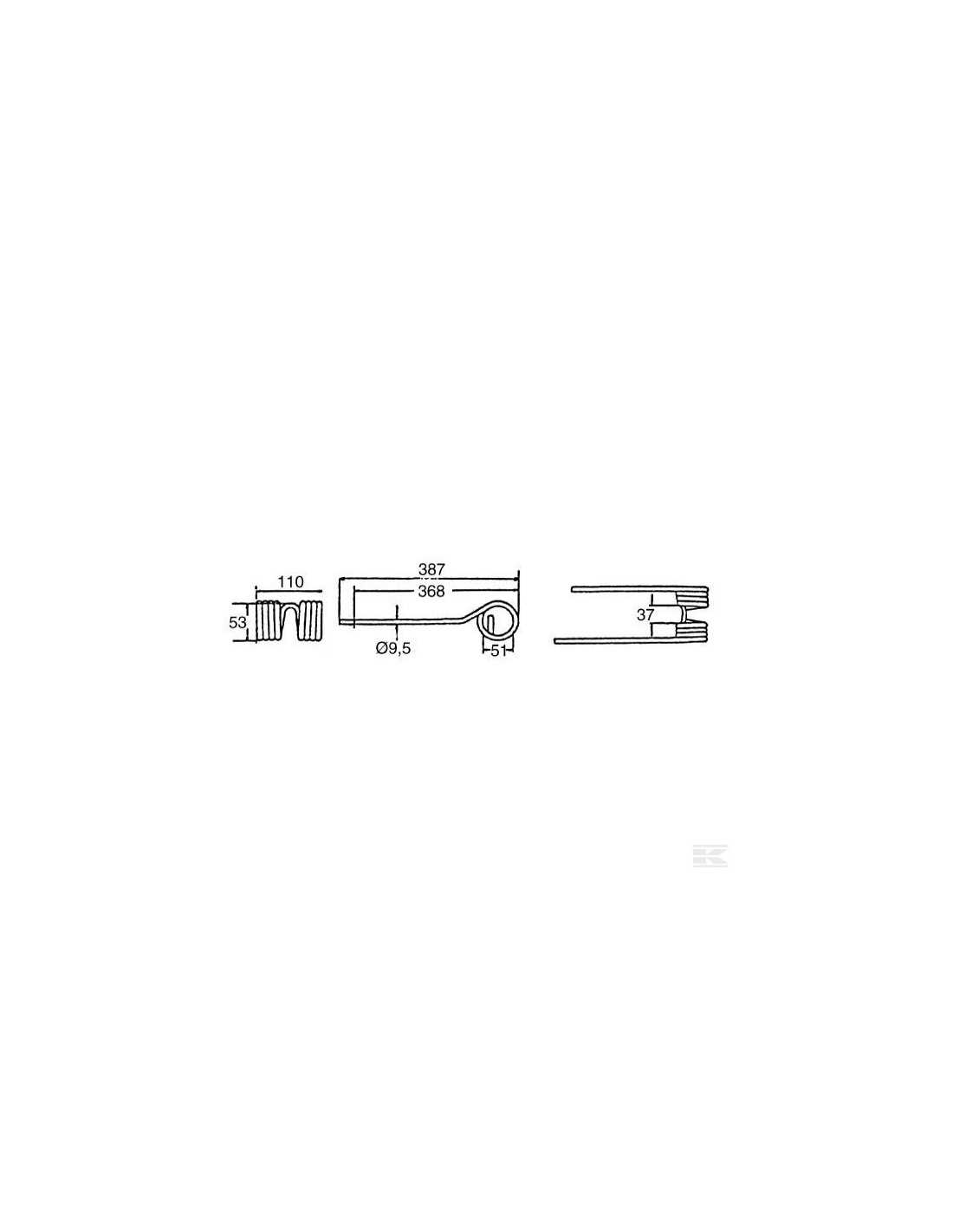

- Tines: Flexible prongs that help to rake and spread the material.

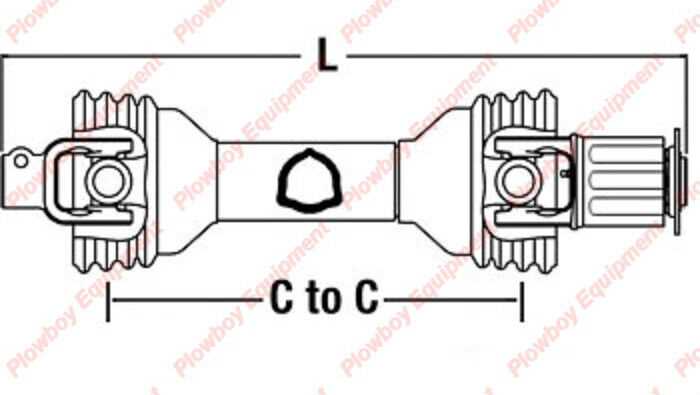

- Gearbox: Transfers power from the tractor to the machine, enabling movement.

- Hitch: Connects the implement to the tractor for towing.

Each of these parts plays a vital role in achieving the ultimate goal of efficient hay production.

Importance of Regular Maintenance

Routine upkeep is essential for the longevity and efficiency of agricultural machinery. By ensuring that equipment is consistently serviced, operators can prevent unexpected failures and extend the lifespan of their tools. This proactive approach not only enhances performance but also contributes to overall productivity in farming operations.

Timely inspections and repairs are crucial for identifying potential issues before they escalate into significant problems. Regular maintenance allows for the early detection of wear and tear, ensuring that components function optimally. This not only minimizes downtime but also reduces repair costs in the long run.

Additionally, consistent care fosters safety for operators and workers. Well-maintained equipment is less likely to malfunction, thereby decreasing the risk of accidents on the field. Prioritizing maintenance helps create a safer working environment, ultimately benefiting everyone involved in agricultural activities.

In conclusion, committing to regular maintenance is a wise investment that yields substantial returns. It ensures reliability, enhances safety, and promotes efficient farming practices, making it an indispensable part of any successful agricultural operation.

How to Identify Worn Parts

Recognizing the signs of deterioration in agricultural machinery components is essential for maintaining efficiency and prolonging the lifespan of your equipment. Regular inspections can help pinpoint issues before they escalate, ensuring smooth operation and reducing repair costs.

Visual Inspection Techniques

Conduct a thorough visual examination of the machinery. Look for any signs of rust, cracks, or unusual wear patterns. Pay close attention to areas that experience high levels of stress or friction, as these are often the first to show signs of fatigue. Noticing a change in color or texture can also indicate that a component is nearing the end of its useful life.

Functional Assessments

Evaluate the performance of the equipment while in use. Listen for unusual sounds such as grinding or clattering, which may suggest that certain elements are failing. Additionally, monitor the overall efficiency; a decrease in productivity can be a clear signal that maintenance is required. Regularly checking fluid levels and operating temperatures can also provide insights into the condition of various components.

Benefits of OEM Replacement Parts

When it comes to maintaining machinery, the choice of replacement components can significantly impact performance and longevity. Utilizing original manufacturer replacements ensures that each piece fits seamlessly and functions as intended, leading to optimal efficiency and reduced downtime.

One of the primary advantages of these components is their guaranteed compatibility. Designed specifically for your equipment, they minimize the risk of malfunctions that can occur with generic alternatives. This precise engineering not only enhances functionality but also contributes to overall safety.

Furthermore, original components often come with warranties that provide peace of mind. In the event of a failure, the assurance of coverage can save time and money, making them a wise investment. Additionally, the use of high-quality materials in these replacements results in improved durability, meaning less frequent replacements and lower long-term costs.

Choosing OEM replacements also supports the manufacturer’s reputation for quality. By opting for these components, users can trust that they are upholding the standards set by the original design, ultimately leading to better overall performance of their machinery.

In conclusion, the decision to utilize authentic replacements is one that pays dividends in reliability, safety, and efficiency, ensuring your equipment remains in peak condition for years to come.

Common Issues with Tedder Operation

Operational difficulties can often arise during the use of grass spreading machinery, impacting efficiency and output quality. Understanding these challenges is essential for maintaining optimal performance and ensuring a successful harvest.

Mechanical Failures

Wear and tear on components can lead to unexpected breakdowns. Regular inspections are crucial to identify potential issues before they escalate, ensuring smooth operation throughout the season.

Improper Adjustments

Incorrect settings can significantly affect the effectiveness of the machinery. It’s vital to follow manufacturer guidelines for adjustments, as this ensures the equipment operates at its ultimate efficiency, maximizing crop yield and quality.

Assembly Instructions for New Holland 163

This section provides a comprehensive guide for the assembly process of the equipment, ensuring that each component is correctly positioned and secured. Proper assembly is crucial for optimal performance and longevity.

Follow these steps to achieve a successful setup:

| Step | Description |

|---|---|

| 1 | Begin by organizing all components and tools required for assembly. Ensure everything is clean and free from debris. |

| 2 | Refer to the manual to identify all major components. Familiarize yourself with the layout to streamline the assembly. |

| 3 | Assemble the frame first, ensuring all bolts and nuts are tightened to the recommended torque specifications. |

| 4 | Attach the necessary attachments, making sure they are aligned correctly and securely fastened. |

| 5 | Perform a thorough inspection of all connections and moving parts to ensure functionality and safety before operation. |

By adhering to these instructions, you can achieve a smooth and efficient assembly process, readying the equipment for effective use.

Exploring Parts Compatibility Options

Understanding the compatibility of various components is crucial for maintaining and optimizing agricultural machinery. When assessing available choices, it’s important to consider not only direct replacements but also alternative options that can enhance functionality and longevity. A well-informed approach ensures that equipment operates at its best while minimizing downtime.

Evaluating Alternatives

When seeking compatible elements, evaluating alternatives can provide significant advantages. Identifying aftermarket solutions or cross-compatible components can lead to enhanced performance and reduced costs. Researching specifications and user reviews helps in making informed decisions that align with specific operational needs.

Maintenance and Upgrades

Regular maintenance and strategic upgrades can extend the lifespan of machinery. Compatibility options should be explored not only for replacements but also for enhancements that improve efficiency and effectiveness. Consulting with experts and accessing detailed resources will aid in selecting the most suitable components for optimal operation.

Essential Tools for Repairs

When maintaining agricultural equipment, having the right tools is crucial for effective and efficient repairs. Proper tools not only ensure safety but also enhance the longevity of machinery, allowing for optimal performance in the field.

Basic Tool Requirements

- Wrenches (various sizes)

- Screwdrivers (flathead and Phillips)

- Pliers (needle-nose and standard)

- Socket set

Specialized Equipment

- Torque wrench for precise fittings

- Impact wrench for stubborn bolts

- Grease gun for lubrication

- Diagnostic tools for troubleshooting

Safety Tips During Maintenance

Ensuring a safe environment during upkeep tasks is crucial for preventing accidents and injuries. Proper procedures and precautions can significantly enhance both the effectiveness of the work and the safety of those involved. Here are some essential guidelines to follow.

Proper Equipment Usage

Always utilize the appropriate tools and protective gear when performing maintenance. Wearing gloves, goggles, and sturdy footwear can safeguard you from potential hazards. Ensure all tools are in good condition and suitable for the job at hand.

Work Environment Management

Maintain a clean and organized workspace to reduce the risk of slips and falls. Keep the area free from clutter and ensure adequate lighting to facilitate visibility. It’s essential to be aware of your surroundings and any moving machinery during the process.

Where to Find Replacement Parts

Finding components for agricultural machinery can be a daunting task, but several resources make the process more manageable. Whether you are looking to restore functionality or improve efficiency, knowing where to source these essential items is crucial for seamless operations.

Authorized Dealers are often the best starting point. They provide genuine items that ensure compatibility and reliability. Many dealerships also offer maintenance services, making them a one-stop shop for your needs.

Online Marketplaces have become increasingly popular for sourcing machinery components. Websites such as eBay and Amazon feature a vast selection of options, often at competitive prices. However, always check seller ratings and reviews to avoid potential pitfalls.

Local Repair Shops can be invaluable resources as well. They frequently stock commonly needed items and can provide expert advice on which parts are best suited for your equipment. Building a relationship with a trusted local technician can lead to better insights and faster service.

Specialty Suppliers focus exclusively on agricultural equipment and may offer a broader range of specific components. These suppliers often have knowledgeable staff who can assist in identifying the right items for your machinery.

Lastly, online forums and communities dedicated to farming and machinery often have members who share their experiences and recommendations. Engaging with these communities can lead to discovering lesser-known suppliers or even used components that are still in great condition.