The functionality of agricultural machinery is deeply reliant on its individual elements. A comprehensive grasp of these components is essential for effective operation and maintenance. This section delves into the intricate details of a specific model’s structure, illustrating the significance of each part in ensuring optimal performance.

Recognizing the Layout of the machinery can significantly enhance the efficiency of repairs and upgrades. By familiarizing oneself with the arrangement of various elements, operators can quickly identify any issues that may arise. This knowledge not only aids in troubleshooting but also promotes a proactive approach to equipment care.

Moreover, understanding the relationship between different components can lead to better decision-making when it comes to replacements or enhancements. Fostering this knowledge empowers users to maximize their investment in agricultural technology, ensuring longevity and reliability in the field.

This section outlines the essential characteristics of the cutting equipment, focusing on its design and functionality. Understanding these attributes helps users optimize performance and ensure effective operation during harvesting.

The following table summarizes the primary features that enhance the efficiency and reliability of the machinery:

| Feature | Description |

|---|---|

| Robust Construction | Durable materials ensure longevity and withstand harsh field conditions. |

| Adjustable Height | Customizable cutting height allows for adaptability to various crop types. |

| Efficient Cutting Mechanism | Precision blades provide clean cuts, minimizing crop loss and damage. |

| Easy Maintenance | Accessible design simplifies routine checks and repairs, ensuring optimal performance. |

| Compatibility | Designed to integrate seamlessly with various harvesting equipment for enhanced versatility. |

Maintenance Tips for Longevity

Ensuring the durability and efficiency of agricultural machinery requires regular upkeep and attention. By following essential maintenance practices, operators can extend the lifespan of their equipment while maximizing performance.

- Regular Inspections: Frequently check all components for signs of wear or damage. This proactive approach helps identify potential issues before they escalate.

- Lubrication: Keep moving parts well-lubricated to minimize friction and prevent premature wear. Consult the manufacturer’s guidelines for recommended lubrication intervals.

- Cleanliness: Maintain a clean working environment. Remove debris and dirt that can interfere with operations and lead to equipment malfunctions.

- Adjustments: Periodically adjust settings to ensure optimal performance. Properly calibrated machinery operates more efficiently and reduces the risk of damage.

- Storage: Store equipment in a dry, sheltered area when not in use. This protects it from environmental factors that can cause deterioration.

- Parts Replacement: Replace worn or damaged components promptly. Using quality replacements will help maintain performance and reliability.

Implementing these maintenance strategies will enhance the functionality of your equipment, ensuring it serves you well for years to come.

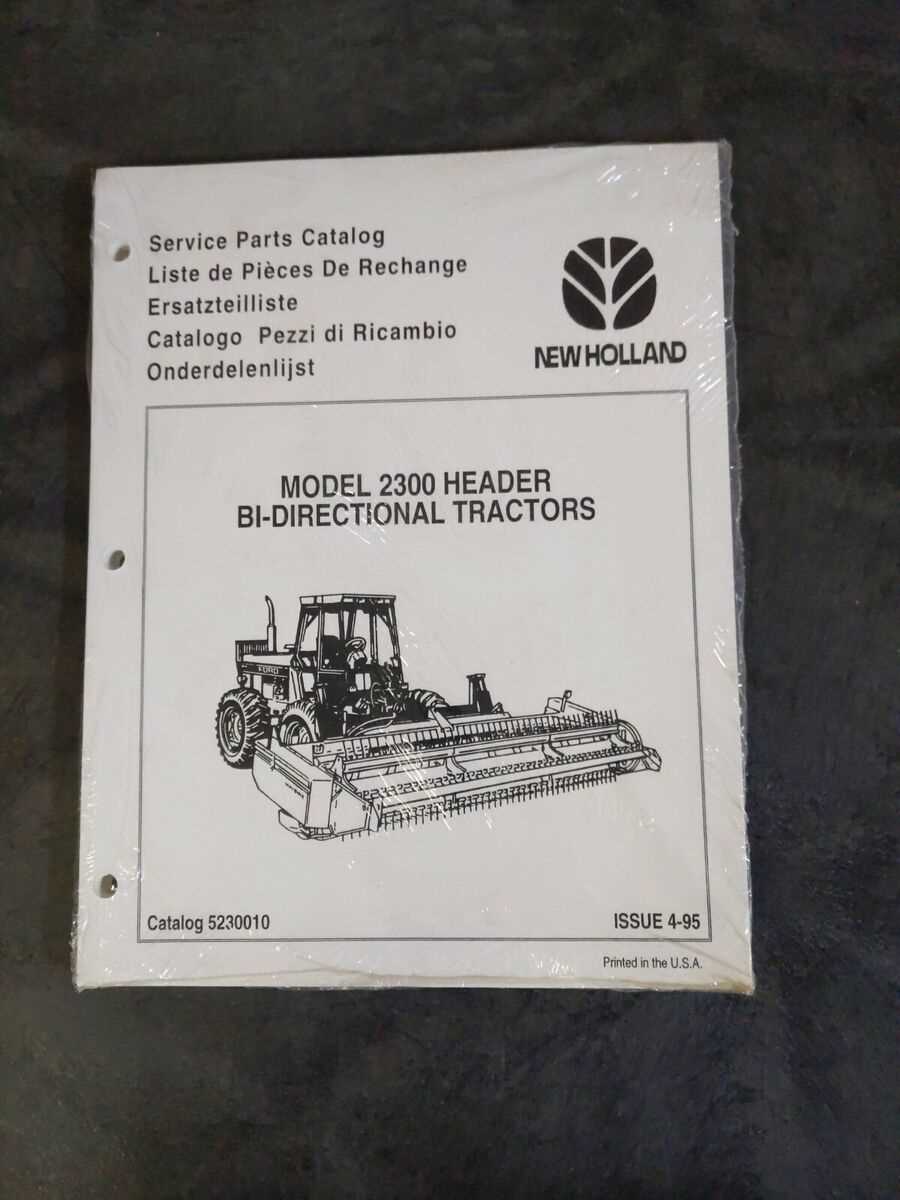

Common Issues with the 2300 Header

When working with agricultural machinery, it’s crucial to understand the frequent challenges that can arise. Identifying and addressing these complications early can enhance efficiency and prolong the lifespan of the equipment. Various factors may contribute to operational difficulties, often linked to design or wear over time.

Mechanical Failures

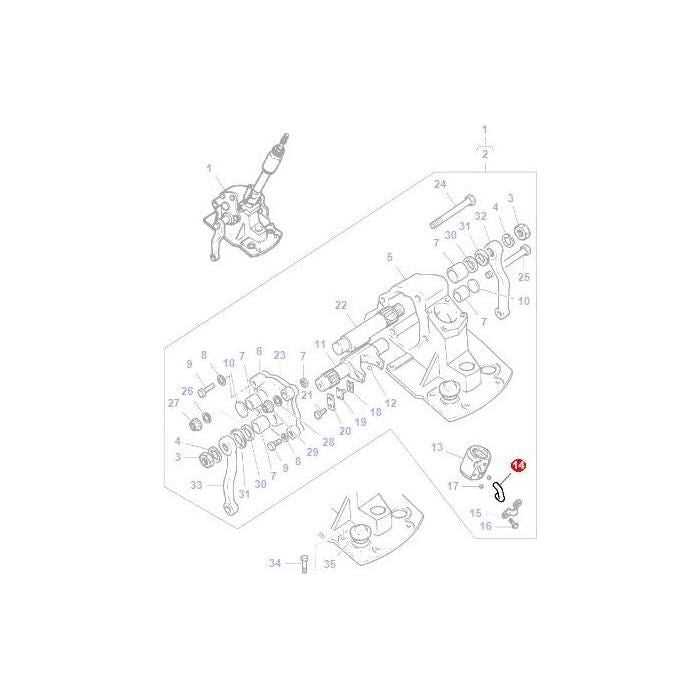

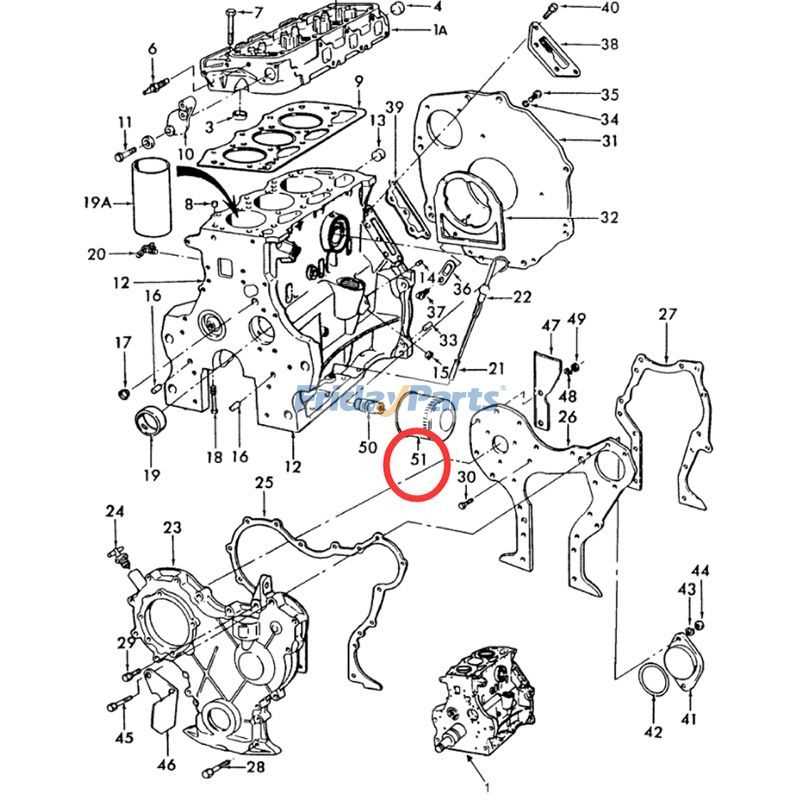

One prevalent concern involves mechanical malfunctions. Over time, components may wear down or become misaligned, leading to decreased performance. Regular maintenance and inspections can help detect these issues before they escalate.

Hydraulic System Problems

Another significant area of concern is the hydraulic system. Issues such as leaks or insufficient pressure can disrupt functionality, making it challenging to operate effectively. Ensuring that all hydraulic connections are secure and well-maintained is vital for optimal operation.

Parts Replacement Guidelines

When maintaining agricultural machinery, it is essential to follow specific procedures for swapping out components to ensure optimal performance and longevity. Understanding the appropriate methods for replacing elements can help in minimizing downtime and enhancing efficiency in operations.

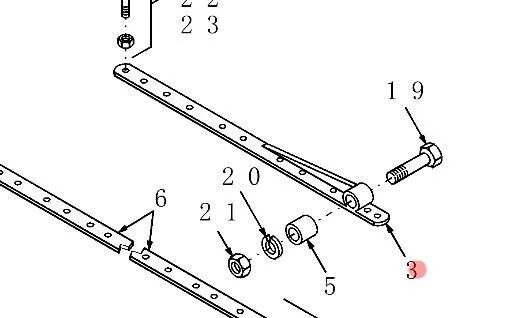

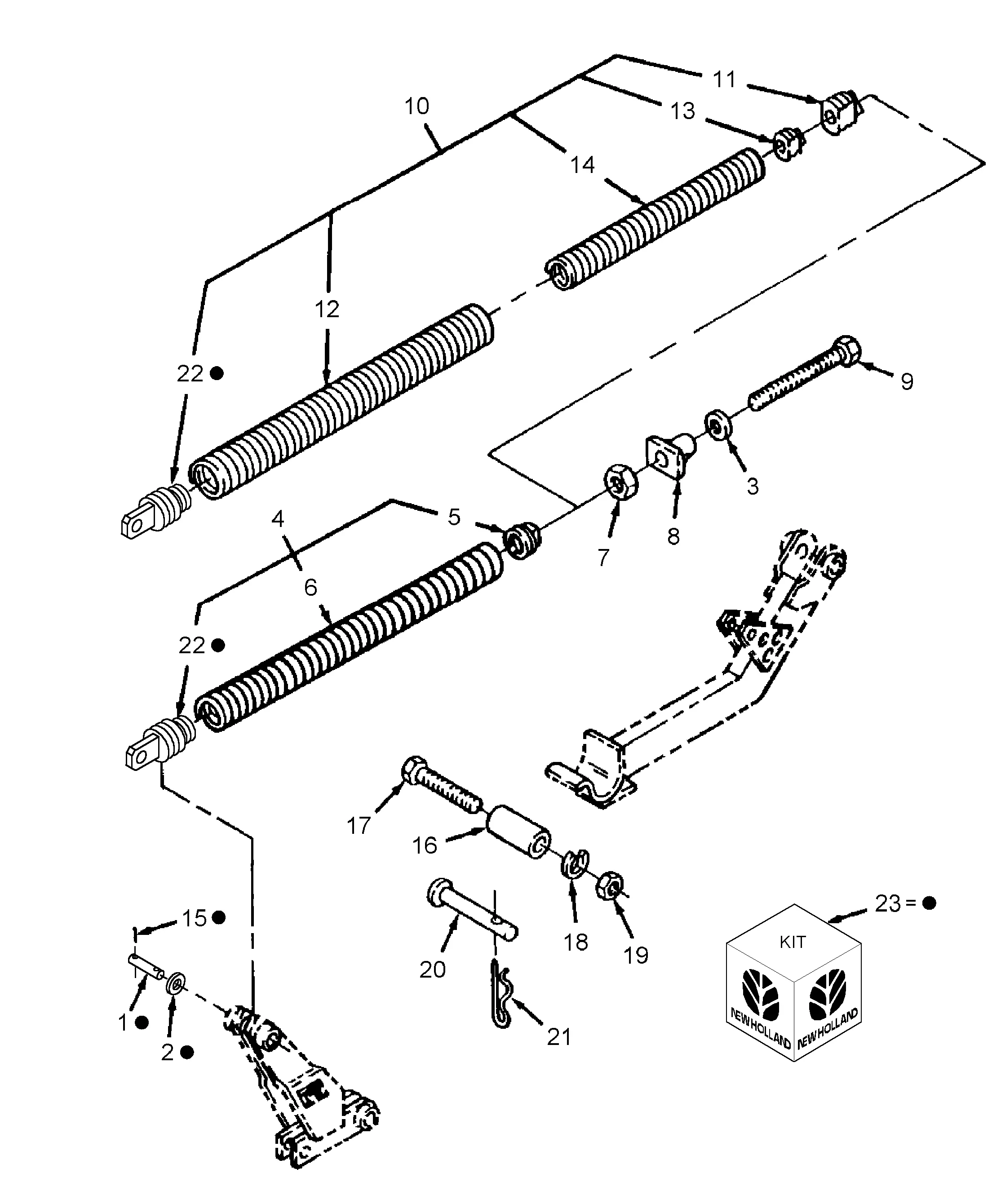

Identifying Components

Before initiating the replacement process, it is crucial to accurately identify the components requiring attention. This includes assessing wear and tear, as well as ensuring that the correct replacements are sourced to maintain compatibility with the machinery.

Replacement Procedure

During the replacement process, safety precautions must be prioritized. Ensure that the machinery is powered down and secured. Following the manufacturer’s guidelines for disassembly and reassembly is vital to avoid any potential damage. Proper tools should be utilized to facilitate a seamless transition between old and new components.

Where to Find Replacement Parts

Locating suitable components for your machinery can be a straightforward process if you know where to look. Whether you are in need of original equipment or aftermarket solutions, various resources can help you track down the items necessary to keep your equipment running smoothly.

Authorized Dealers and Retailers

One of the most reliable options is to visit authorized dealers who specialize in your equipment brand. These establishments often provide genuine components and can assist in ensuring compatibility with your model. Additionally, they may have knowledgeable staff who can answer any questions regarding installation and maintenance.

Online Marketplaces

The internet offers a wealth of options for finding components. E-commerce platforms and specialized websites often feature a vast selection of items, including both new and refurbished options. When purchasing online, it is advisable to check the seller’s reputation and reviews to ensure quality and reliability. Furthermore, always verify that the specifications match your requirements before making a purchase.

Technical Specifications of the Header

This section outlines the essential attributes and features of the cutting implement utilized in agricultural machinery. Understanding these specifications is crucial for optimizing performance and ensuring compatibility with various models.

Key Features

- Overall dimensions: Length, width, and height specifications for proper fitment.

- Weight: Total mass of the unit affecting transport and handling.

- Material composition: Quality and type of materials used for durability.

- Cutting width: Maximum swath that can be efficiently processed.

- Drive type: Description of the mechanism used to power the implement.

Performance Metrics

- Operating speed: Recommended velocity for optimal cutting efficiency.

- Power requirements: Engine specifications needed for proper operation.

- Maintenance intervals: Suggested timelines for routine checks and servicing.

Comparing Different Header Models

When evaluating various cutting implements used in agricultural machinery, it is essential to understand the unique features and specifications that each model offers. These designs can significantly influence performance, efficiency, and suitability for specific tasks. By examining the differences among models, operators can make informed decisions tailored to their operational needs.

Key Features to Consider

- Construction Material: Different models may utilize varied materials, impacting durability and maintenance.

- Cutting Width: Assessing the width can determine the efficiency of harvesting operations.

- Weight: The weight of each model can affect compatibility with different machinery.

- Adjustability: Features that allow for modification based on crop type or conditions can enhance versatility.

Performance Metrics

- Speed: Comparing the operational speed can reveal which models provide faster processing times.

- Fuel Efficiency: Evaluating fuel consumption can lead to cost savings over time.

- Maintenance Requirements: Understanding the upkeep needed for each model ensures proper long-term operation.

User Reviews and Feedback

This section aims to highlight the perspectives and experiences of users who have interacted with the specified machinery. Their insights can provide valuable information for potential buyers and existing owners looking to enhance their understanding of the product’s functionality and performance.

Many users appreciate the efficiency and reliability of the equipment, noting that it significantly improves productivity in various agricultural tasks. Feedback often highlights the durability of the components, with several customers mentioning that they have experienced minimal wear and tear even after extensive use.

Conversely, some reviews indicate challenges related to maintenance and availability of specific components. Users have expressed a desire for more accessible support and resources, which would help streamline the repair process. Overall, the feedback offers a balanced view, showcasing both strengths and areas for improvement.