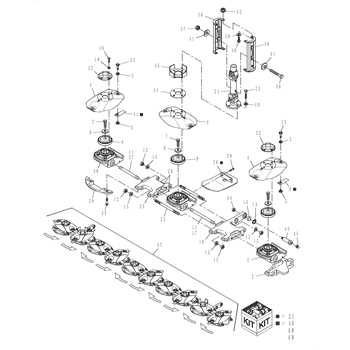

A comprehensive understanding of the components involved in a mower conditioner can greatly enhance efficiency and maintenance. This section delves into the various elements that constitute this essential agricultural equipment, providing clarity on their functions and interrelationships.

Recognizing the layout of these crucial components not only aids in the proper assembly and disassembly of the machine but also facilitates troubleshooting and repair processes. By exploring the intricate details, users can ensure optimal performance and longevity of their equipment.

Whether you are a seasoned operator or a newcomer, familiarizing yourself with the schematic representation of these parts can empower you to make informed decisions regarding upkeep and modifications. This knowledge is instrumental in maximizing productivity and minimizing downtime during the harvesting season.

The functionality of this specialized agricultural machinery relies on several crucial elements that work together seamlessly. Understanding these components can enhance maintenance practices and improve overall efficiency in field operations.

- Cutter Bar: The cutting mechanism is essential for achieving a clean cut of the crop. It features sharp blades designed to slice through vegetation effectively.

- Roller System: This system assists in conditioning the crop after cutting, facilitating faster drying and improving forage quality.

- Frame Structure: The robust frame provides stability and durability, ensuring the machine can withstand various field conditions.

- Drive Mechanism: This component transfers power from the tractor to the machine, enabling all functions to operate efficiently.

Each of these parts plays a vital role in the overall operation, making it essential for operators to be familiar with their functions and maintenance requirements.

Importance of Regular Maintenance

Consistent upkeep of agricultural machinery plays a vital role in ensuring optimal performance and longevity. By adhering to a routine maintenance schedule, operators can prevent unexpected breakdowns and extend the life of their equipment. Regular inspections and servicing not only enhance efficiency but also contribute to the overall safety of the machinery.

Benefits of Routine Upkeep

Performing maintenance tasks on a regular basis offers numerous advantages. Firstly, it helps identify potential issues before they escalate into significant problems, thereby saving time and costs associated with major repairs. Secondly, well-maintained equipment operates more efficiently, leading to improved productivity and reduced fuel consumption.

Enhancing Operational Safety

Another crucial aspect of routine maintenance is the enhancement of safety standards. Regular checks ensure that all components are functioning correctly, reducing the risk of accidents caused by equipment failure. This not only protects the operator but also promotes a safer working environment for everyone involved in agricultural operations.

Identifying Wear and Tear

Understanding the signs of deterioration is essential for maintaining optimal performance in agricultural machinery. Regularly inspecting equipment for wear and damage can prevent unexpected failures and costly repairs. By recognizing key indicators of wear, operators can ensure the longevity and reliability of their machinery.

Common Signs of Deterioration

Look for visible signs such as cracks, fraying, or unusual noise during operation. Components may exhibit discoloration or uneven surfaces, indicating that they are nearing the end of their functional lifespan. Addressing these issues promptly can enhance efficiency and reduce downtime.

Importance of Routine Checks

Implementing a schedule for routine inspections is crucial. Regular maintenance not only prolongs the life of the equipment but also maximizes productivity. Operators should familiarize themselves with the common wear points and incorporate systematic checks into their maintenance routines.

Common Replacement Parts Overview

The efficiency of agricultural machinery relies heavily on the regular upkeep and timely replacement of essential components. Understanding the most frequently replaced items can greatly enhance the longevity and performance of the equipment. This section provides insights into the key elements that often require attention to maintain optimal functionality.

Wear Components: Various elements experience significant wear and tear during operation. These include cutting edges and other surfaces that come into contact with crops, necessitating regular inspection and replacement to ensure effective performance.

Drive Mechanisms: The drive systems are crucial for the machinery’s operation. Gears and belts often endure stress, leading to potential malfunctions. Regular checks can prevent breakdowns and ensure smooth operation.

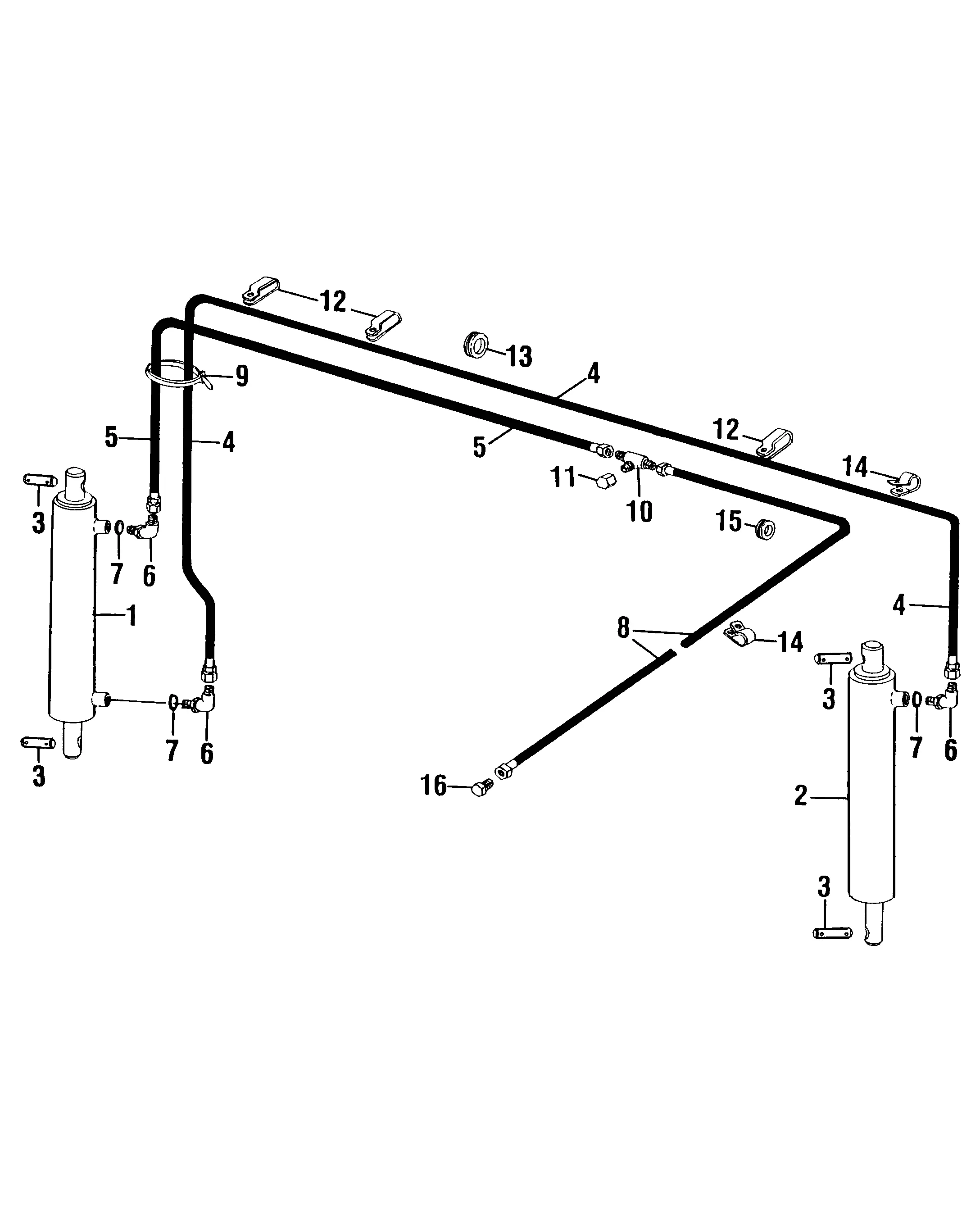

Hydraulic Systems: Components within the hydraulic systems are vital for movement and functionality. Seals and hoses may degrade over time, so monitoring their condition is essential for maintaining pressure and performance.

Frames and Support Structures: The structural integrity of the equipment is paramount. Frames can suffer from fatigue and damage, making it necessary to evaluate and replace any compromised sections to maintain stability and safety.

Parts Sourcing for the Discbine

Sourcing components for agricultural machinery is a crucial step in ensuring optimal performance and longevity. Access to reliable suppliers can significantly impact the efficiency of maintenance and repair tasks. Understanding the variety of sources available can help operators make informed decisions when seeking replacements or upgrades.

When looking for components, it is essential to explore multiple avenues. Local dealers often provide original equipment options, ensuring compatibility and quality. Additionally, aftermarket suppliers can offer a range of alternatives, often at competitive prices. Online platforms have also become invaluable resources, allowing users to compare options and read reviews before making a purchase.

Before committing to a purchase, it is advisable to verify the specifications and compatibility of the selected component. Consulting manuals or expert advice can help prevent issues related to improper fit or functionality. In summary, a strategic approach to sourcing can enhance the overall reliability of the equipment.

How to Read the Parts Diagram

Understanding the layout of a machinery component chart is essential for effective maintenance and repairs. This guide will help you interpret the various elements illustrated in such a chart, enabling you to identify specific elements and their relationships to one another.

Typically, the chart will be organized into sections, each representing different aspects of the assembly. Familiarizing yourself with the symbols and numbering system used can greatly enhance your ability to locate and reference individual components.

| Symbol | Description | Reference Number |

|---|---|---|

| ⚙️ | Gear | 1 |

| Bolt | 2 | |

| ️ | Tool | 3 |

| Measuring Device | 4 |

Assembly Instructions for Key Parts

This section provides a comprehensive guide on how to assemble essential components effectively. Understanding the assembly process is crucial for maintaining optimal functionality and ensuring longevity. Follow the outlined steps carefully to achieve the best results.

Before starting the assembly, gather all necessary tools and components. This preparation will streamline the process and help avoid unnecessary interruptions.

-

Step 1: Prepare the Components

- Inspect each component for any damage or defects.

- Organize parts by type to facilitate easy access during assembly.

-

Step 2: Initial Assembly

- Begin by aligning the primary structure with the supporting elements.

- Use bolts and fasteners to secure the connection, ensuring they are tightened to the specified torque.

-

Step 3: Attach Auxiliary Components

- Install the secondary parts, ensuring each is aligned properly.

- Double-check all connections for security and stability.

-

Step 4: Final Inspection

- Conduct a thorough check of the assembled unit to ensure everything is in place.

- Test the functionality to confirm that all components operate smoothly.

By following these instructions carefully, the assembly process will be efficient, resulting in a well-functioning unit ready for operation.

Safety Considerations When Servicing

Ensuring safety during maintenance is essential for both personnel and equipment. Proper precautions can prevent accidents and promote a secure working environment. It is important to be aware of potential hazards and implement appropriate safety measures before starting any servicing tasks.

Preparation and Personal Protective Equipment

Before beginning any maintenance work, it’s crucial to prepare adequately and use the right protective gear. Consider the following steps:

- Wear safety goggles to protect your eyes from debris.

- Use gloves to prevent cuts and abrasions.

- Ensure that sturdy footwear is worn to provide ankle support and protection.

- Have a first-aid kit accessible for emergencies.

Proper Equipment Handling

Handling equipment correctly is vital to avoid accidents. Follow these guidelines:

- Always turn off and disconnect power sources before servicing.

- Use tools that are suitable for the task at hand.

- Ensure all parts are secure and in good condition before operating.

- Be mindful of your surroundings and ensure the workspace is free from clutter.

Upgrading Parts for Improved Performance

Enhancing components can significantly elevate the efficiency and productivity of your agricultural machinery. By carefully selecting advanced alternatives, operators can ensure that their equipment performs at its peak capacity, adapting to the challenges of modern farming. This section explores various upgrades that can lead to better operational outcomes.

| Component | Upgrade Option | Benefits |

|---|---|---|

| Cutter Bar | High-Strength Steel | Increased durability and reduced maintenance needs. |

| Drive System | Heavy-Duty Gearbox | Enhanced torque transmission and longevity. |

| Hydraulic System | High-Performance Pump | Improved responsiveness and efficiency in operations. |

| Frame | Reinforced Chassis | Better stability and resistance to wear. |

Common Troubleshooting Tips

When dealing with equipment challenges, identifying and resolving issues efficiently is crucial for optimal performance. Understanding common problems and their potential solutions can save time and improve functionality.

Identifying Common Issues

- Inspect the cutting mechanism for any obstructions or damage.

- Check for fluid leaks around the hydraulic system.

- Monitor the drive system for unusual noises or vibrations.

Effective Solutions

- Clear any debris that may be interfering with operation.

- Replace worn-out components to restore efficiency.

- Regularly service the hydraulic fluid to ensure proper function.

Consulting the User Manual

Referring to the instructional guide is essential for effective operation and maintenance of the equipment. This document contains valuable information that helps users understand the functionality, assembly, and care of the machine. By following the guidelines provided, operators can ensure optimal performance and longevity of their machinery.

The manual typically includes detailed instructions on usage, troubleshooting tips, and maintenance schedules. Familiarizing oneself with this resource can prevent potential issues and enhance the overall efficiency of the equipment. It is advisable to keep the manual accessible for quick reference whenever questions arise during operation.

Resources for Parts and Service

Accessing reliable resources for maintenance and repair is essential for ensuring optimal performance of agricultural machinery. Whether you’re seeking components, service manuals, or expert guidance, the right tools can significantly enhance your operational efficiency.

Official Manufacturer Support

Many manufacturers provide comprehensive support, including online catalogs and technical documentation. Utilizing these resources can help you identify compatible components and understand service procedures effectively.

Online Forums and Communities

Participating in specialized forums can be incredibly beneficial. Here, you can delve into discussions with experienced users, share insights, and discover ultimate solutions to common challenges faced during maintenance.