In the realm of agricultural equipment, having a comprehensive understanding of machinery layouts is crucial for efficient operation and maintenance. This knowledge enables operators to identify various components and their functions, ensuring optimal performance in the field.

For those engaged in agricultural practices, familiarity with specific machinery configurations can greatly enhance productivity. By exploring the intricate details of each element, users can effectively troubleshoot issues and implement timely repairs, minimizing downtime.

Delving into these configurations not only aids in immediate problem-solving but also contributes to long-term equipment care. Whether you’re an experienced farmer or a novice, mastering the ultimate aspects of machinery design empowers you to make informed decisions regarding maintenance and upgrades.

Understanding New Holland 570 Baler

This section explores the intricacies of a specific type of agricultural machinery designed for efficient harvesting. By examining its components and operational principles, we aim to provide valuable insights for users and technicians alike.

Key Features

- Robust construction for durability

- High capacity for efficient processing

- Advanced technology for optimal performance

Common Components

- Feed mechanism for material intake

- Compression chamber for bundling

- Discharge system for finished products

Understanding these elements is crucial for effective maintenance and operation, ensuring the ultimate productivity of your equipment.

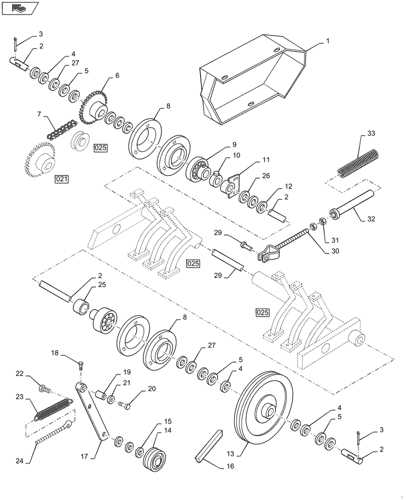

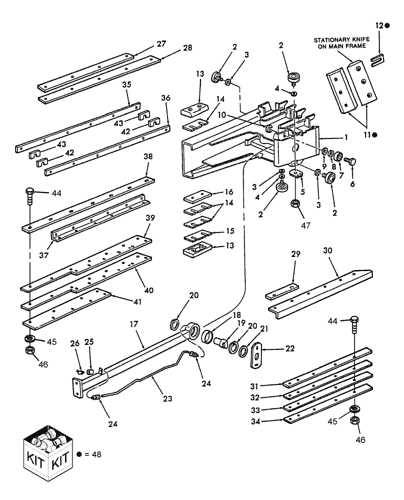

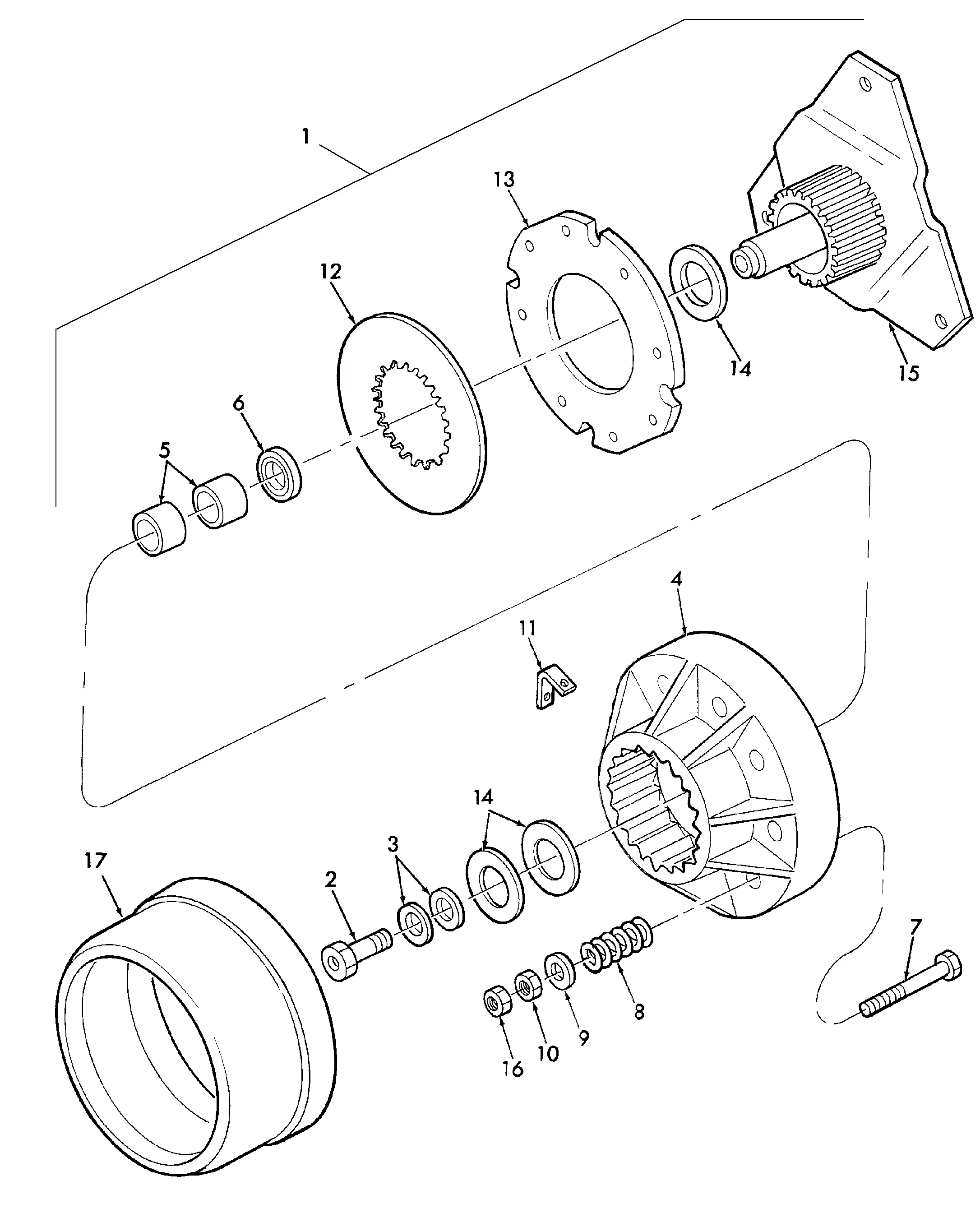

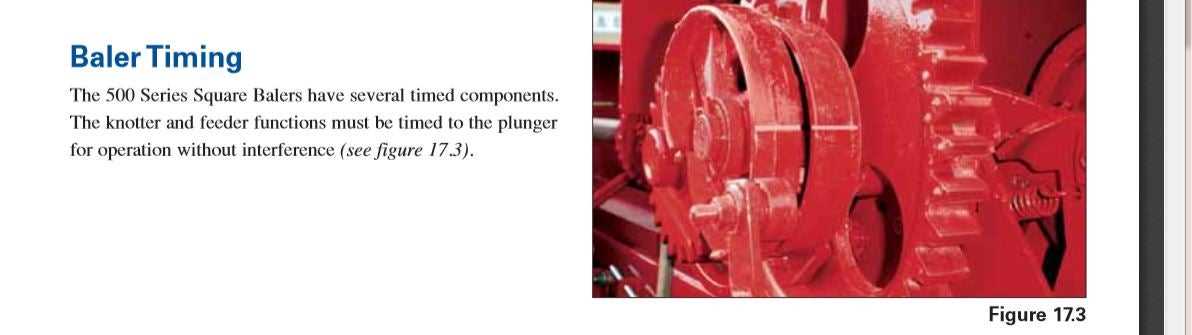

Key Components of the Baler

The efficiency of a machine designed for compressing and bundling materials relies on several crucial elements. Each component plays a significant role in ensuring optimal performance and durability. Understanding these features is essential for maintaining functionality and maximizing output.

The feed mechanism is responsible for guiding the raw material into the system, ensuring a steady flow for processing. The compression chamber is where the materials are compacted into manageable sizes, while the tying system secures the bundles for easy handling and transport. Additionally, the drivetrain transmits power, enabling the seamless operation of the entire assembly.

Importance of Maintenance for Longevity

Regular upkeep is crucial for the extended life of machinery and equipment. By implementing consistent maintenance practices, operators can ensure optimal performance and reduce the likelihood of unexpected breakdowns.

Enhancing Performance

Proper maintenance significantly improves efficiency. When components are regularly checked and serviced, the overall functionality of the equipment is enhanced, leading to better productivity during operation.

Cost-Effectiveness

Investing time and resources in maintenance can lead to substantial savings. Preventative measures help avoid costly repairs and replacements, ultimately maximizing the value of the investment over time.

Common Issues and Solutions

When operating agricultural machinery, users often encounter a range of challenges that can hinder efficiency and productivity. Understanding these frequent problems and their solutions is crucial for maintaining optimal functionality and ensuring smooth operation.

1. Jamming: One of the most prevalent issues is jamming, which can occur due to a variety of reasons, such as overloaded material or foreign objects. Regularly inspecting the feed area and ensuring proper loading techniques can significantly reduce the likelihood of this problem.

2. Poor Compression: Inadequate compression may lead to loose bales, affecting storage and transport. Checking and adjusting the tension settings can help achieve the desired compactness. Additionally, maintaining the integrity of the compression chamber is vital.

3. Hydraulic Failures: Hydraulic system issues, such as leaks or pressure drops, can disrupt operations. Regular maintenance, including checking hoses and connections, is essential. If a problem arises, identifying the source promptly can prevent more significant damage.

4. Electrical Malfunctions: Faulty wiring or blown fuses may lead to erratic machine behavior. Conducting routine electrical inspections and ensuring all connections are secure can minimize these risks. Keeping a stock of spare fuses and wiring can also expedite repairs.

5. Worn Components: Over time, certain elements may wear out, affecting performance. Regularly monitoring wear indicators and replacing parts as necessary can enhance longevity. Investing in high-quality replacements ensures reliability and reduces downtime.

By being proactive and addressing these common challenges, users can enhance the reliability and efficiency of their machinery, ultimately leading to improved agricultural operations.

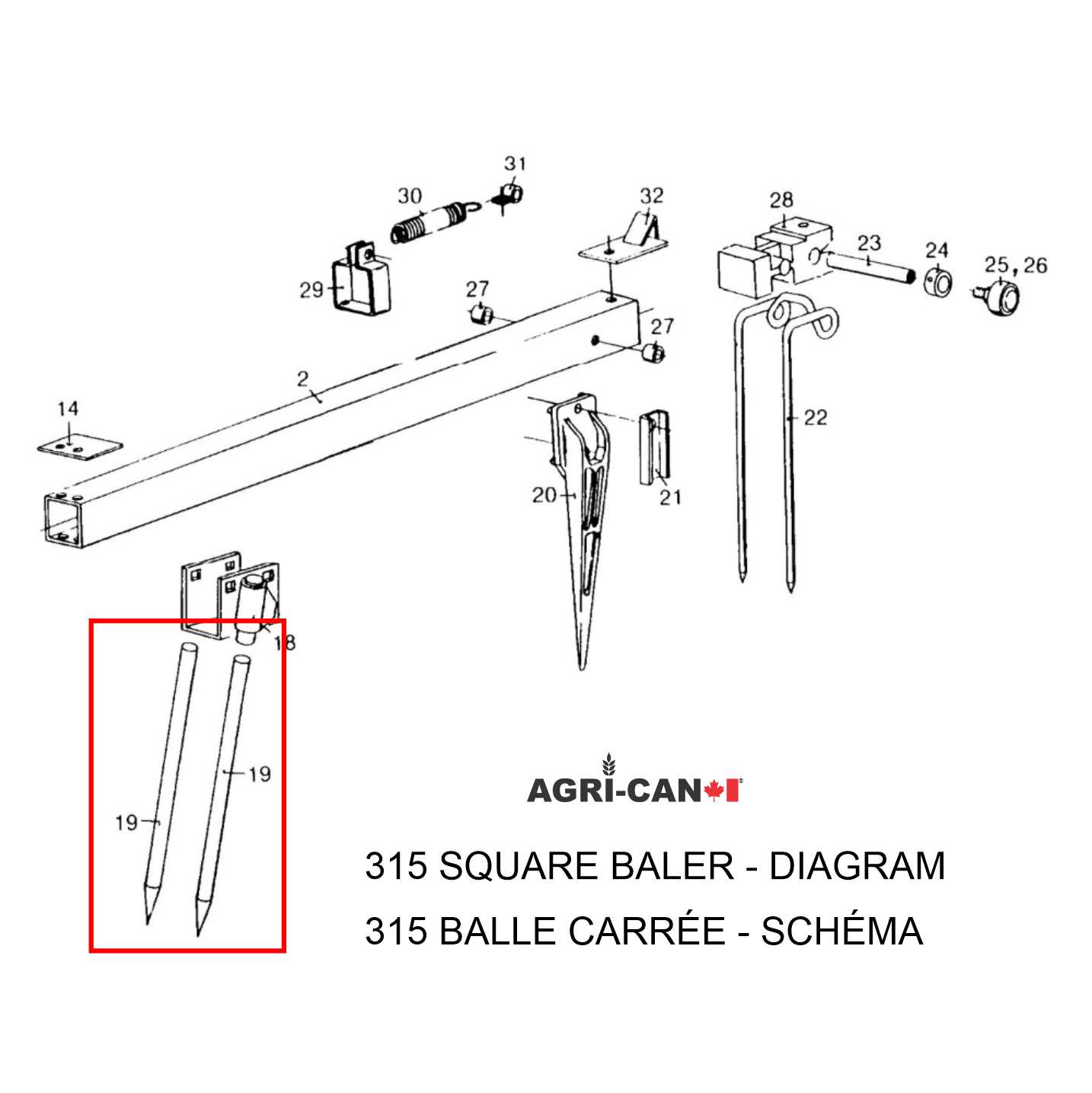

How to Read Parts Diagrams

Understanding component illustrations is essential for efficient maintenance and repair. These visuals provide a detailed overview of the various elements within a machine, allowing users to identify, locate, and replace specific components. Mastering the art of interpreting these representations can significantly enhance your ability to troubleshoot and service equipment effectively.

Familiarize Yourself with the Legend

Every illustration typically includes a legend or key that explains the symbols and markings used throughout the image. Take the time to study this section carefully, as it will clarify what each symbol represents. Knowing the terminology and designations used in the diagram will streamline your understanding and help you navigate the illustration with ease.

Identify Key Components

Once you’re acquainted with the legend, focus on the main elements depicted in the visual. Look for numbered items or labeled sections that correspond to the legend. By systematically going through each component, you can build a comprehensive understanding of how everything fits together and operates, making it easier to spot potential issues or necessary replacements.

Where to Find Replacement Parts

When it comes to maintaining agricultural machinery, sourcing the right components is crucial for optimal performance. Several avenues exist for locating high-quality replacements, ensuring that your equipment remains functional and efficient.

One of the most reliable methods is to reach out to authorized dealers. These professionals typically offer genuine components that meet manufacturer specifications, providing peace of mind regarding quality and compatibility. Additionally, they often have access to detailed information on the specific requirements of your equipment.

Online marketplaces have also gained popularity for their convenience and extensive selections. These platforms allow you to compare prices, read customer reviews, and find both original and aftermarket components. However, it’s essential to verify the credibility of the sellers and the quality of the items.

Lastly, local salvage yards can be a treasure trove of affordable options. Many of these facilities have dismantled machines, allowing you to find used parts that are still in good condition. This route is particularly beneficial for older models where new components may be harder to find.

| Source | Advantages | Considerations |

|---|---|---|

| Authorized Dealers | Genuine quality, expert advice | Higher cost, limited availability |

| Online Marketplaces | Wide selection, competitive pricing | Quality varies, check seller ratings |

| Local Salvage Yards | Cost-effective, unique finds | Condition may vary, limited warranty |

Upgrades for Enhanced Performance

Improving machinery efficiency can significantly boost productivity and reduce operational costs. Implementing various enhancements not only increases output but also prolongs the lifespan of equipment. This section explores key modifications that can lead to superior functionality and reliability.

High-Quality Components: Investing in premium elements can lead to better durability and less frequent breakdowns. Upgrading wear parts ensures that the machine operates smoothly under various conditions.

Advanced Technology: Integrating modern technology can provide real-time data analytics, enabling operators to make informed decisions and optimize performance. Features like automated controls and monitoring systems can enhance user experience.

Improved Maintenance Practices: Regular maintenance upgrades, such as enhanced lubrication systems or efficient cleaning processes, can greatly affect overall performance. Keeping the machinery in top shape minimizes downtime and maximizes efficiency.

Customization Options: Tailoring modifications to specific operational needs allows for a more tailored approach to performance. Adjusting settings for different materials can lead to significant improvements in handling and output quality.

Safety Features of the 570 Model

This model is equipped with various mechanisms designed to ensure the protection of operators and enhance overall functionality. Emphasizing safety helps to prevent accidents and prolong the lifespan of the machine, making it essential for effective operation in agricultural settings.

Emergency Stop Systems

Integrated emergency stop systems allow for immediate halting of operations in case of unexpected incidents. This feature provides peace of mind, enabling users to react swiftly to any hazardous situation.

Protective Shields and Guards

Strategically placed shields and guards protect users from moving parts and debris. These barriers not only safeguard the operator but also contribute to the efficient functioning of the equipment.

Comparing Models: 570 vs. Others

In the realm of agricultural machinery, evaluating various models is essential for maximizing efficiency and productivity. This section delves into the strengths and weaknesses of a specific machine in comparison to its peers, helping users make informed decisions based on their operational needs.

Performance Characteristics

When examining the performance of this specific model alongside its counterparts, factors such as durability, speed, and output capacity come into play. Users often find that the unique design elements enhance performance in challenging conditions, setting it apart in the competitive landscape.

Cost-Effectiveness

Another crucial aspect is the overall value proposition. While some alternatives may present lower initial costs, the long-term efficiency and maintenance needs of this particular machine often yield a more favorable return on investment. Evaluating operational expenses is key to determining the ultimate choice for any agricultural enterprise.

Tips for Efficient Operation

Maximizing the effectiveness of your equipment requires careful attention to several key practices. By implementing these strategies, you can enhance productivity, minimize downtime, and ensure consistent performance throughout the working season.

Regular Maintenance

Maintaining your machinery in optimal condition is essential. Regularly inspect and service critical components to prevent wear and tear. This proactive approach not only extends the lifespan of your equipment but also boosts efficiency. Make it a habit to check lubricants, belts, and tensioners before each use.

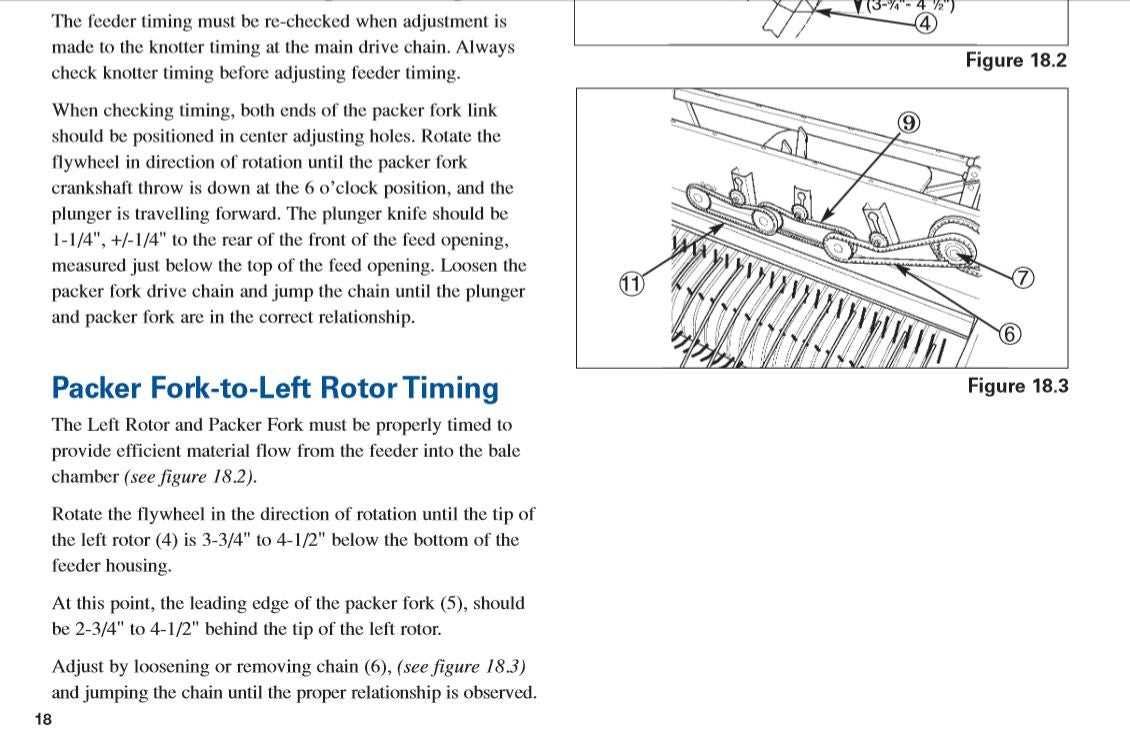

Proper Settings and Adjustments

Ensure that your machine is correctly calibrated for the specific task at hand. Adjusting settings such as pressure and speed according to the type of material being processed can greatly impact the quality of the output. Take the time to familiarize yourself with the recommended settings in the user manual to achieve the best results.

Additionally, monitoring environmental conditions can help in fine-tuning operations. Adapting to changes in moisture levels or crop density can significantly enhance overall performance.