In the realm of agricultural technology, the efficiency of machinery plays a crucial role in the productivity of farming operations. A comprehensive grasp of the various elements that comprise these machines can significantly enhance their functionality and longevity. Whether for harvesting or other essential tasks, knowing how each component interacts is vital for optimal performance.

For those who work closely with specific models, familiarization with the structural layout and individual components is indispensable. This knowledge not only aids in maintenance and repairs but also empowers operators to troubleshoot issues effectively. A well-structured overview of these mechanisms can serve as a valuable resource for both novice and experienced users alike.

By delving into the intricate details of machinery design, one can better appreciate the engineering behind agricultural tools. An organized representation of these elements can simplify the understanding of their roles and interrelations, ensuring that every operation runs smoothly and efficiently. Proper insights into these constructs ultimately lead to enhanced agricultural practices and improved yield outcomes.

Understanding the New Holland 644 Baler

This section aims to provide insights into a vital piece of agricultural machinery used for efficient crop handling. By exploring its functionality, users can appreciate the design and engineering behind this equipment.

Key features include:

- Robust construction for durability.

- Efficient crop collection and compression.

- Adjustable settings for various materials.

Common applications involve:

- Hay production.

- Straw collection.

- Silage preparation.

Understanding the inner workings enhances operational efficiency and maintenance practices.

Key Features of the 644 Model

This model boasts a range of exceptional characteristics designed to enhance efficiency and productivity in agricultural operations. With its robust construction and advanced engineering, it delivers reliable performance even under demanding conditions.

Durability: Built with high-quality materials, the unit is engineered to withstand heavy use, ensuring a long lifespan.

Efficiency: The design promotes optimal operation, reducing downtime and maximizing output.

Versatility: Capable of handling various types of materials, it adapts seamlessly to different farming needs.

User-Friendly Features: Intuitive controls and easy maintenance contribute to a hassle-free experience for operators.

Innovative Technology: Incorporating cutting-edge advancements, this model enhances performance and provides real-time feedback for improved management.

Importance of Baler Maintenance

Regular upkeep of agricultural equipment is essential for optimal performance and longevity. Neglecting maintenance can lead to unexpected breakdowns, reduced efficiency, and costly repairs. Ensuring that all components are in good working condition is crucial for smooth operation during critical harvesting periods.

Enhanced Efficiency

Proper care of machinery ensures that it operates at peak efficiency. Routine inspections and timely replacements of worn-out components minimize downtime and enhance productivity. Efficient machines consume less fuel and complete tasks faster, contributing to overall operational success.

Increased Longevity

Consistent maintenance practices extend the lifespan of equipment significantly. By addressing minor issues before they escalate, operators can avoid major repairs and ensure that their machinery remains reliable for many seasons. This proactive approach ultimately leads to better return on investment.

Common Parts for Replacement

In agricultural machinery, certain components are frequently subject to wear and tear, necessitating timely replacement to ensure optimal performance. Understanding which elements require attention can significantly enhance efficiency and longevity of the equipment.

Key Components

Rollers and belts are among the most commonly replaced items. These parts endure substantial stress during operation, making them prone to deterioration. Regular checks and timely replacements can prevent further damage.

Other Essential Elements

Additionally, bearings and pulleys often require maintenance. Their failure can lead to operational disruptions, so monitoring their condition is crucial for maintaining smooth functionality.

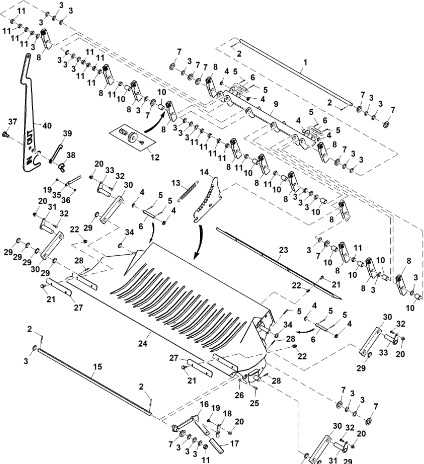

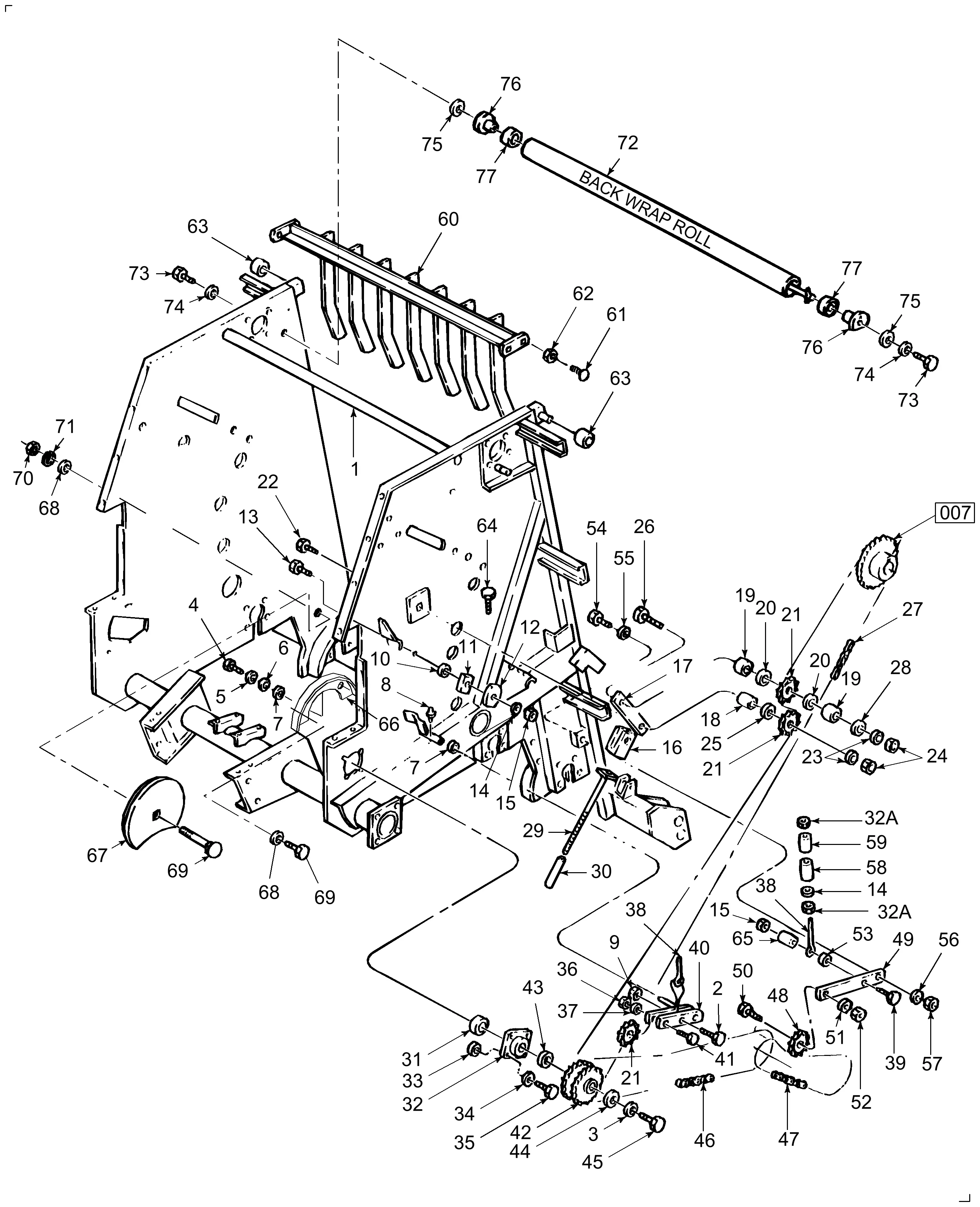

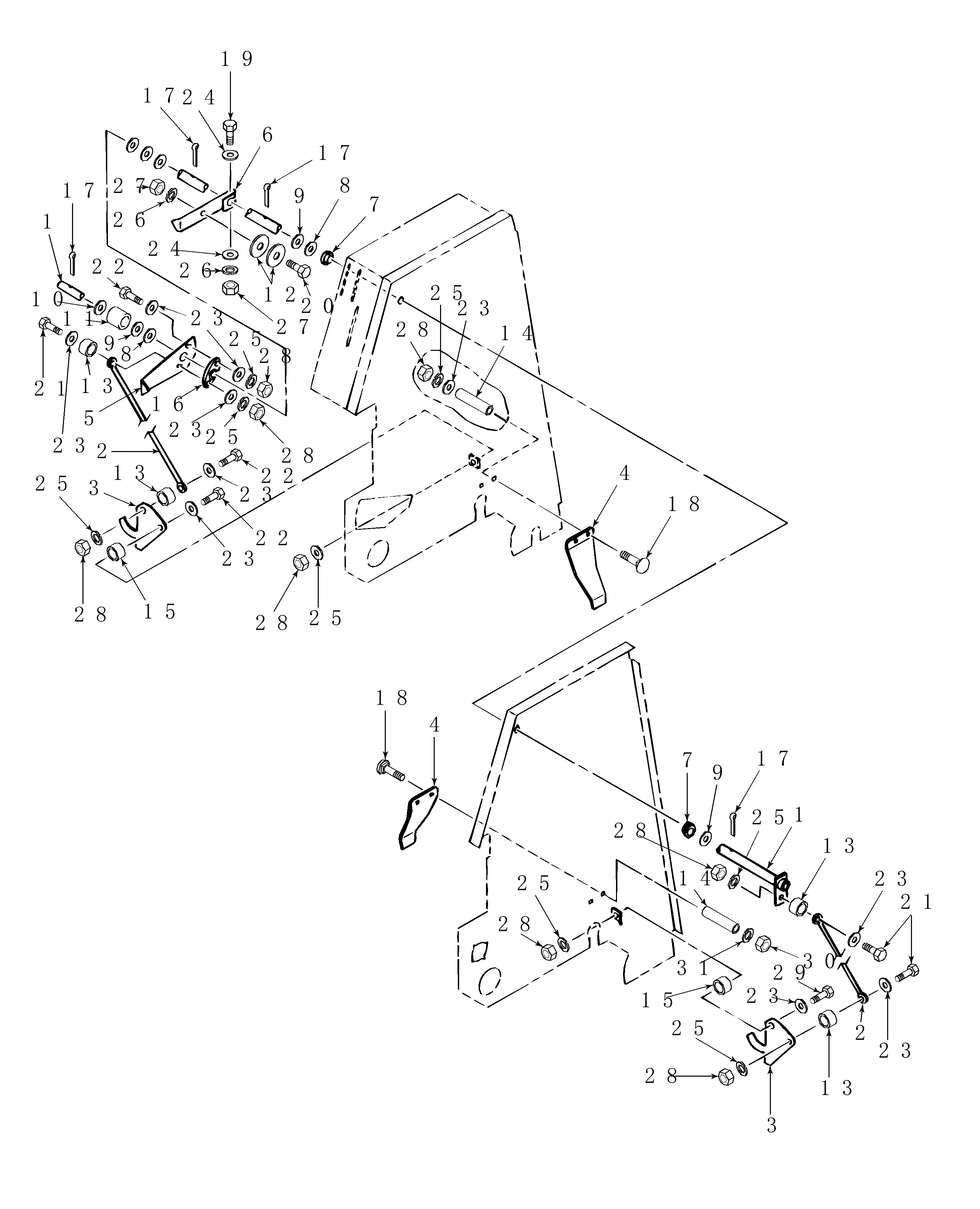

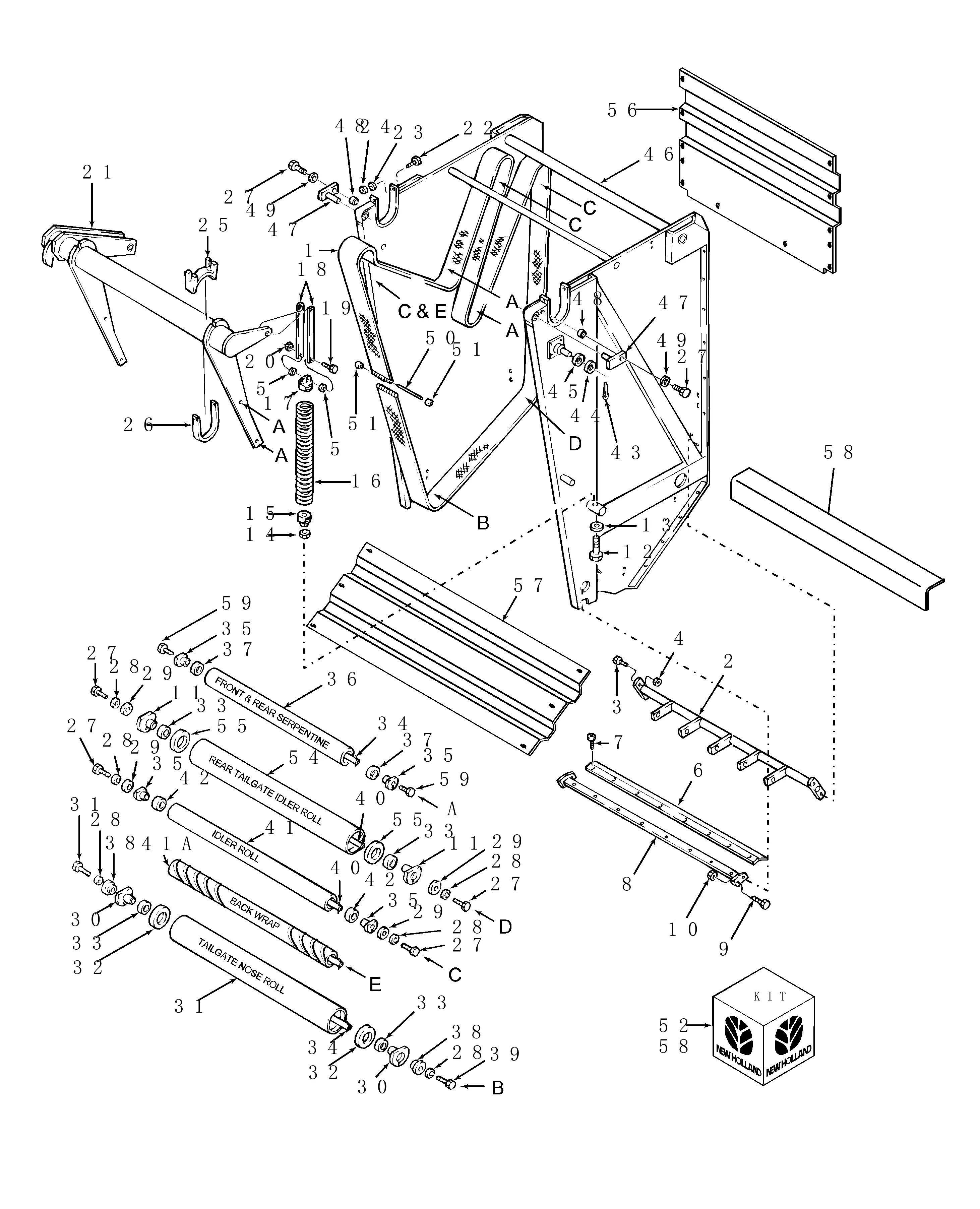

How to Read a Parts Diagram

Understanding an assembly illustration is crucial for effective maintenance and repair of equipment. These visual representations provide essential information about components, their arrangement, and how they interact with one another. By familiarizing yourself with the symbols and layout, you can streamline your repair processes and ensure that you are using the correct components.

Identifying Components

The first step in interpreting an assembly illustration is to identify each individual piece. Most diagrams will label components with unique reference numbers or letters, which correspond to a list of items. Pay attention to these identifiers, as they help you locate the correct part when sourcing replacements. Additionally, note the shape and size of each item, as these characteristics can aid in distinguishing similar components.

Understanding Connections and Assembly

Next, examine how the various components connect to one another. Lines or arrows in the illustration often indicate the direction and method of attachment. Understanding these connections is vital for proper assembly or disassembly. Some diagrams may also include exploded views, which provide a clearer perspective on how parts fit together, making it easier to visualize the assembly process.

Identifying Critical Components

Understanding the essential elements of agricultural machinery is vital for efficient operation and maintenance. Recognizing these components helps in ensuring optimal performance and longevity of the equipment.

Key elements to focus on include:

- Drive system: Facilitates the transfer of power throughout the machine.

- Feeding mechanism: Ensures smooth intake of materials for processing.

- Wrapping unit: Secures the baled material for protection and preservation.

- Control system: Manages functionality and allows for adjustments during operation.

By familiarizing yourself with these crucial parts, you can enhance both the effectiveness and reliability of your machinery.

Where to Find Genuine Parts

Locating authentic components for agricultural machinery is crucial for maintaining optimal performance and durability. Quality parts ensure that equipment operates efficiently and reduces the risk of unexpected failures. This section will explore various avenues for sourcing genuine replacements that guarantee reliability.

Authorized dealers are often the best source for original equipment. They provide not only genuine products but also expert advice and support tailored to your specific model. Additionally, these retailers may offer warranties that ensure peace of mind with every purchase.

Another excellent option is manufacturer websites, where you can find comprehensive catalogs and online ordering systems. These platforms often include detailed specifications, ensuring you select the right component for your needs.

Online marketplaces also host a range of suppliers offering authentic items. It’s essential to verify the reputation of the seller and read reviews to ensure the quality of the components. Look for listings that specify original parts to avoid counterfeit options.

Lastly, joining agricultural forums or community groups can connect you with fellow operators who share insights on where to find reliable components. Recommendations from experienced users can lead you to trustworthy sources and potential savings.

Tools Required for Baler Repairs

Proper maintenance and repairs require a specific set of tools to ensure efficiency and effectiveness. Having the right equipment on hand can significantly ease the process of troubleshooting and fixing various issues that may arise during operation.

Essential Tools

To effectively conduct repairs, a mechanic should possess various essential tools. These include hand tools for disassembly, diagnostic equipment for identifying problems, and safety gear to protect against potential hazards.

| Tool | Purpose |

|---|---|

| Wrenches | Loosening and tightening bolts |

| Screwdrivers | Removing screws and panels |

| Diagnostic Scanner | Identifying electronic issues |

| Safety Goggles | Protecting eyes from debris |

Specialized Equipment

In addition to basic tools, specialized equipment may be necessary for more complex repairs. Hydraulic jacks, alignment tools, and torque wrenches can greatly enhance the repair process, ensuring that everything is properly aligned and secured.

Step-by-Step Repair Process

When tackling machinery maintenance, a systematic approach is essential for ensuring efficiency and longevity. This section outlines a comprehensive procedure to guide you through the necessary steps for effective repairs, minimizing downtime and optimizing performance.

Begin by gathering all required tools and resources, including manuals and any replacement components. Thoroughly inspect the equipment to identify specific issues and areas requiring attention.

Next, carefully disassemble the relevant sections, taking care to document each step. This will help in reassembly and ensure that no parts are misplaced.

After dismantling, clean all components to remove dirt and debris. Examine each piece for wear or damage, replacing any faulty items as needed. It’s crucial to adhere to manufacturer specifications during this phase.

Once repairs are completed, reassemble the equipment systematically. Double-check all connections and ensure everything is secured properly.

Finally, conduct a thorough testing phase to confirm that the machine operates as intended. This step is vital for validating the effectiveness of the repairs and identifying any remaining issues.

Common Issues with the 644 Baler

In the world of agricultural machinery, understanding typical challenges is crucial for maintaining efficiency and productivity. Operators often encounter a range of mechanical problems that can hinder performance. Familiarity with these issues allows for timely interventions and proper maintenance, ensuring smooth operation in the field.

Frequent Mechanical Failures

One of the most prevalent concerns involves the mechanical components. These can wear down over time due to constant use and exposure to harsh conditions. Problems such as bearing failures and chain issues can lead to significant downtime. Regular inspections and timely replacements are essential to avoid severe disruptions during peak seasons.

Feeding and Tension Problems

Another common challenge arises with the feeding system. Blockages can occur, causing uneven compression and leading to improper bales. Additionally, maintaining the correct tension is vital; too tight or too loose settings can result in productivity losses and excessive wear on parts. Operators should consistently check and adjust these settings to maintain optimal performance.

Upgrading Components for Better Performance

Enhancing the functionality of your machinery can lead to significant improvements in efficiency and productivity. By focusing on specific elements of the equipment, you can optimize its operation and ensure it meets the demands of various tasks. This section explores the benefits of upgrading key components to achieve superior results.

When considering enhancements, it is essential to identify which parts will provide the most noticeable improvements. Below is a table outlining common upgrades and their potential advantages:

| Component | Upgrade Option | Benefits |

|---|---|---|

| Feed Mechanism | High-Efficiency Roller | Improved material handling and reduced downtime |

| Drive System | Heavy-Duty Gearbox | Enhanced power transfer and durability |

| Control System | Digital Monitor | Better performance tracking and ease of use |

| Cutting Assembly | Premium Blades | Increased cutting efficiency and longevity |

| Chassis | Reinforced Structure | Improved stability and reduced wear |

Investing in these enhancements not only boosts overall performance but also contributes to the longevity of the equipment, making it a wise choice for any operator aiming to maximize their operational capabilities.

Resources for Baler Owners

Maintaining agricultural equipment effectively requires access to a variety of resources. Whether you’re seeking repair guides, user manuals, or community forums, the right tools can enhance your experience and prolong the life of your machinery. This section aims to provide valuable information to assist operators in troubleshooting, maintenance, and overall care.

1. User Manuals: Obtaining the original user manual is crucial. It offers detailed information on operation, maintenance schedules, and troubleshooting tips. Many manufacturers provide digital versions on their websites.

2. Online Forums: Engaging with online communities can provide insights from fellow operators. These platforms allow users to share experiences, solutions, and advice on common issues, making them a valuable source of support.

3. Video Tutorials: Video resources can visually guide you through repairs and maintenance tasks. Platforms like YouTube have numerous channels dedicated to agricultural machinery, offering step-by-step demonstrations.

4. Local Dealerships: Establishing a relationship with local equipment dealers can be beneficial. They often provide parts, service, and expert advice tailored to specific models and their common issues.

5. Maintenance Workshops: Participating in workshops can enhance your understanding of equipment maintenance. These sessions, often conducted by experienced professionals, cover various topics and practical techniques.