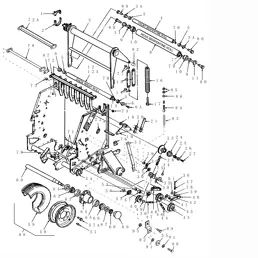

Exploring the intricate layout of machinery components is essential for effective maintenance and repair. A comprehensive visual representation can significantly enhance the understanding of how various elements interact within a system. This knowledge not only aids technicians in troubleshooting but also ensures that equipment operates at peak efficiency.

When dealing with agricultural or industrial machinery, familiarity with each segment’s role and placement can prevent costly errors. An organized schematic provides insights into assembly and disassembly processes, which are vital for anyone involved in servicing these powerful machines.

By delving into a detailed representation of the system, users can identify key elements that require attention or replacement. This approach empowers operators and mechanics to make informed decisions, ultimately prolonging the lifespan of the equipment while optimizing performance.

Understanding New Holland 688 Parts

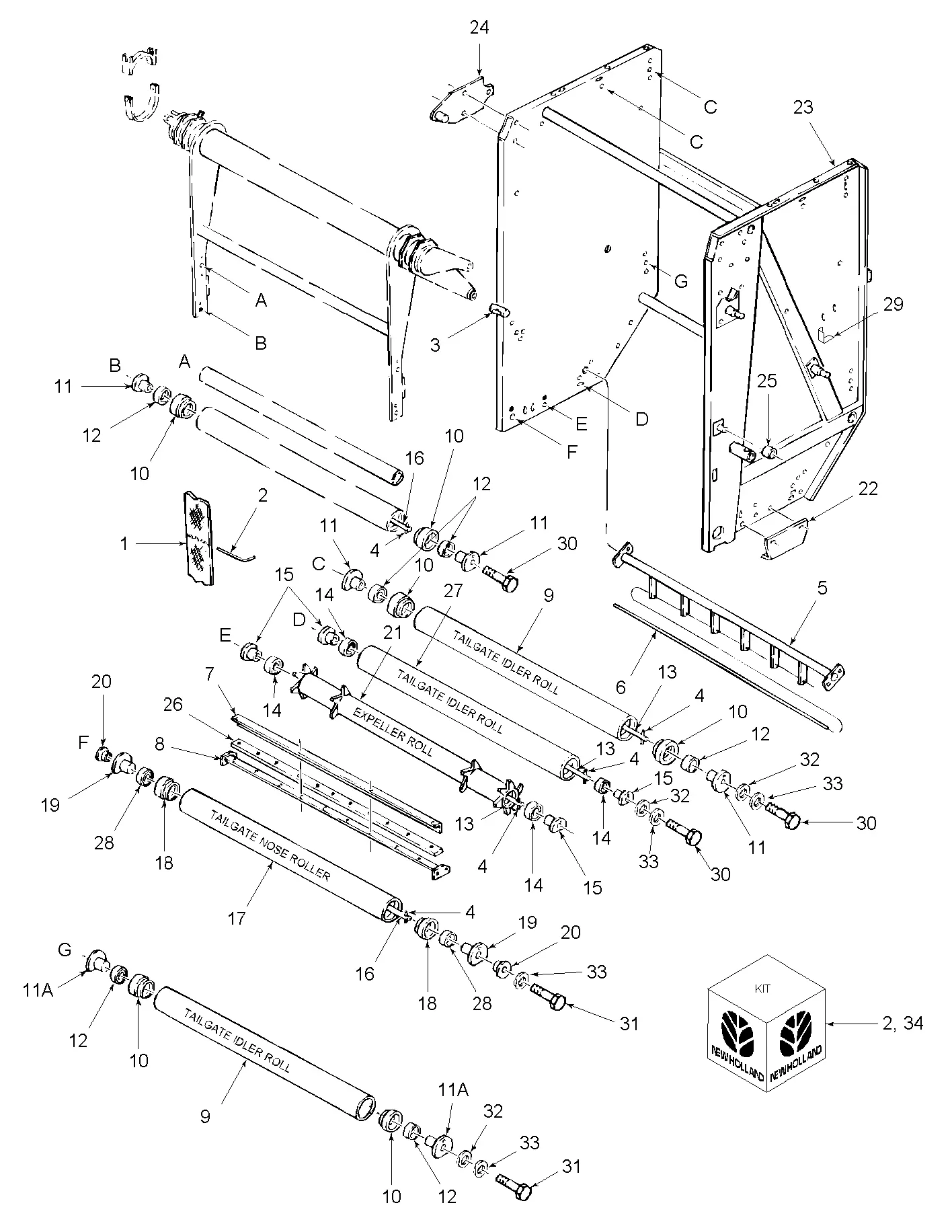

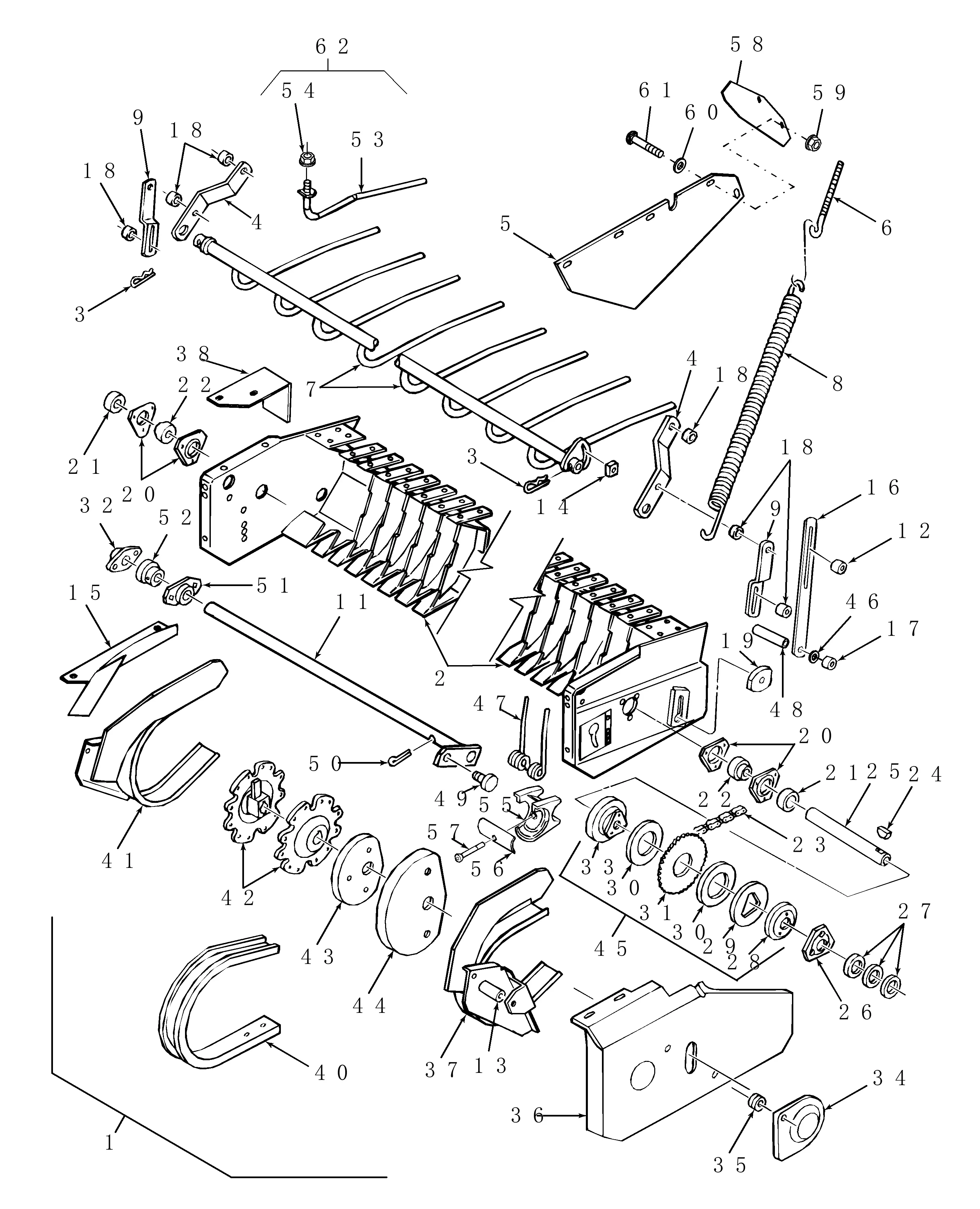

Comprehending the components of agricultural machinery is essential for efficient maintenance and operation. Each element plays a pivotal role in the overall functionality of the equipment, contributing to its performance and longevity. By familiarizing oneself with these essential units, users can enhance their troubleshooting skills and optimize machine upkeep.

Identifying Key Components is crucial for anyone involved in the maintenance of these machines. Each segment, from the engine to hydraulic systems, must be well understood to ensure proper operation. Detailed knowledge allows for timely interventions and reduces the risk of major breakdowns.

Common Issues and Solutions arise when components wear out or malfunction. Understanding the signs of wear can help in early detection, potentially saving time and costs associated with extensive repairs. Regular inspections and familiarity with the individual functions of each unit contribute to a smoother operational experience.

In summary, an in-depth grasp of the machinery’s essential units enhances not only operational efficiency but also the overall lifespan of the equipment. By prioritizing this understanding, users can ensure their machines run optimally, thereby maximizing productivity on the field.

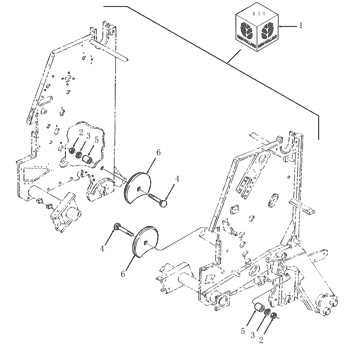

Importance of Parts Diagrams

Understanding the intricate layout of machinery components is crucial for effective maintenance and repair. Visual representations serve as invaluable tools for technicians and operators, allowing them to identify, locate, and assess individual elements with ease. This clarity not only enhances efficiency but also minimizes the risk of errors during servicing.

Clarity in visual guides fosters a deeper comprehension of the assembly, enabling users to navigate complex systems without ambiguity. When individuals can easily recognize each section, it significantly reduces the time required for troubleshooting.

Additionally, these illustrations play a vital role in inventory management. By clearly displaying the various components, they assist in tracking what is available and what needs to be ordered, thereby streamlining the repair process. This proactive approach ultimately leads to reduced downtime and improved productivity.

In essence, well-structured visual guides empower users, ensuring they have the necessary knowledge to maintain machinery effectively, thereby prolonging its lifespan and enhancing overall performance.

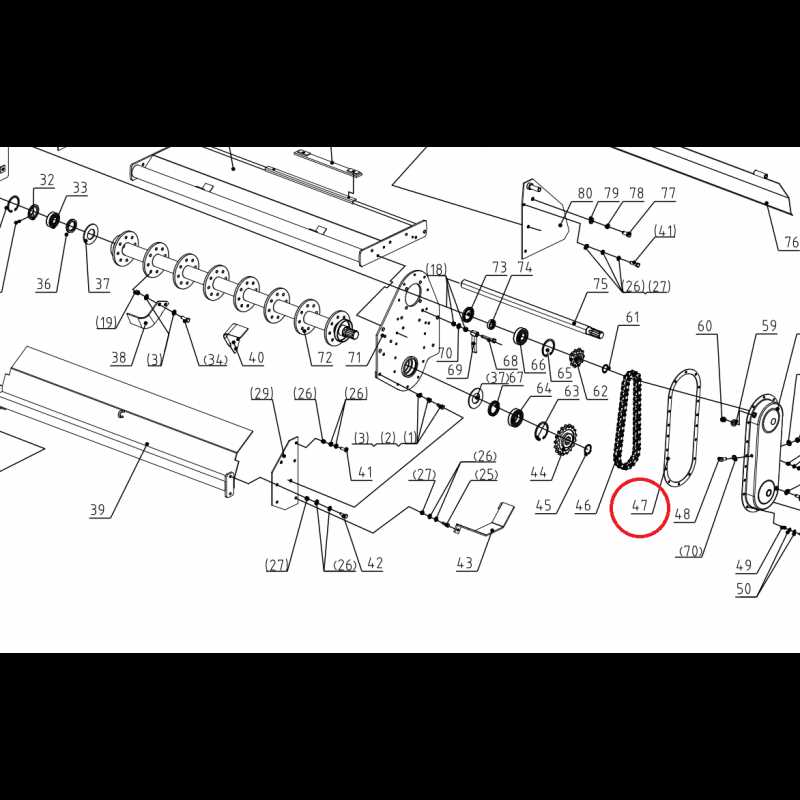

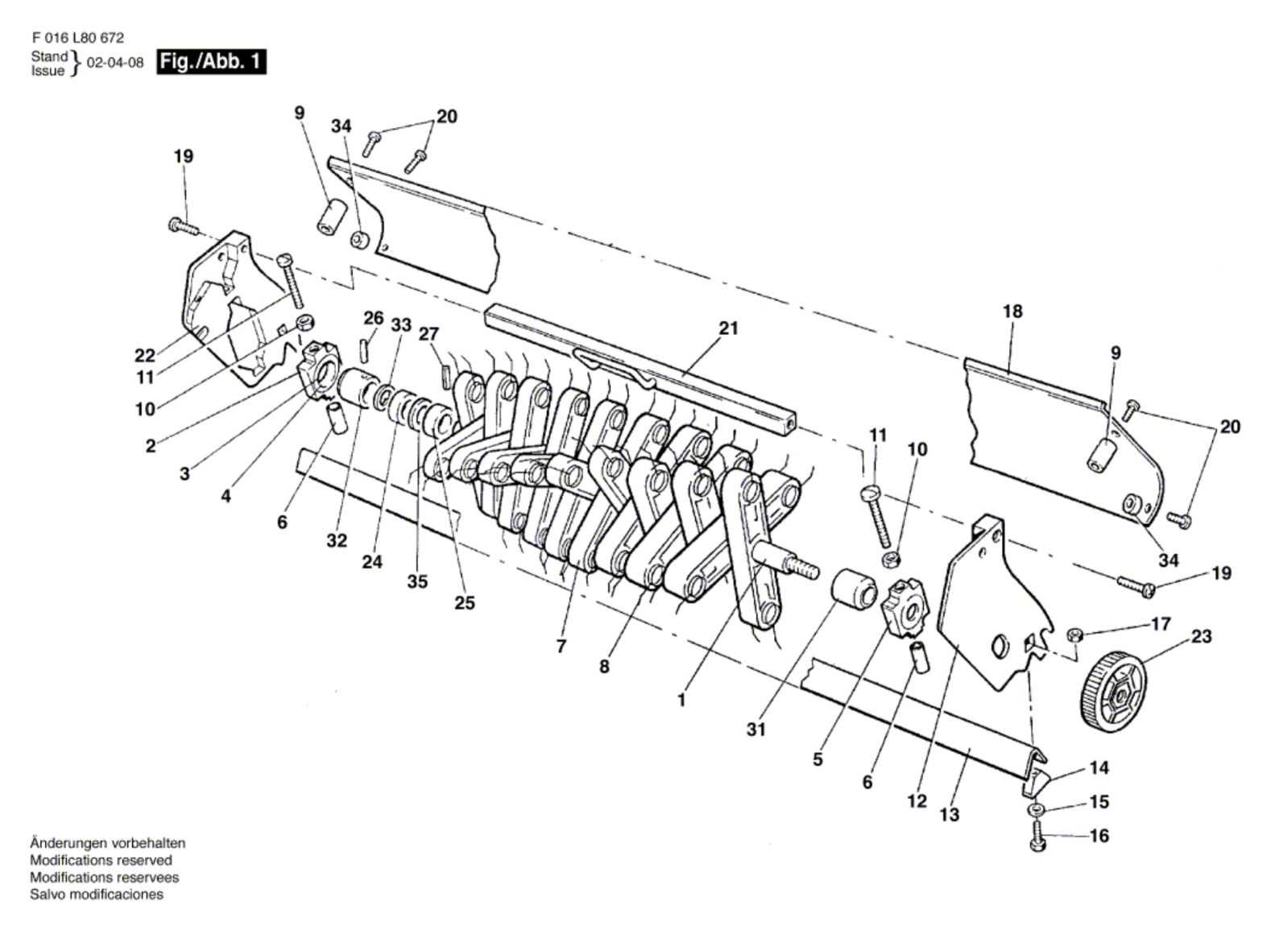

Key Components of the 688 Model

The essence of any agricultural machinery lies in its fundamental elements, each playing a pivotal role in overall functionality and efficiency. Understanding these core parts is crucial for maximizing performance and ensuring longevity. This section delves into the primary components that define this particular model, highlighting their significance and interrelation.

Engine and Powertrain

The powerhouse of the equipment is its engine, designed for robust performance under various conditions. Coupled with a reliable powertrain, it delivers the necessary torque and speed to handle demanding tasks. Together, these components ensure seamless operation and adaptability in diverse agricultural settings.

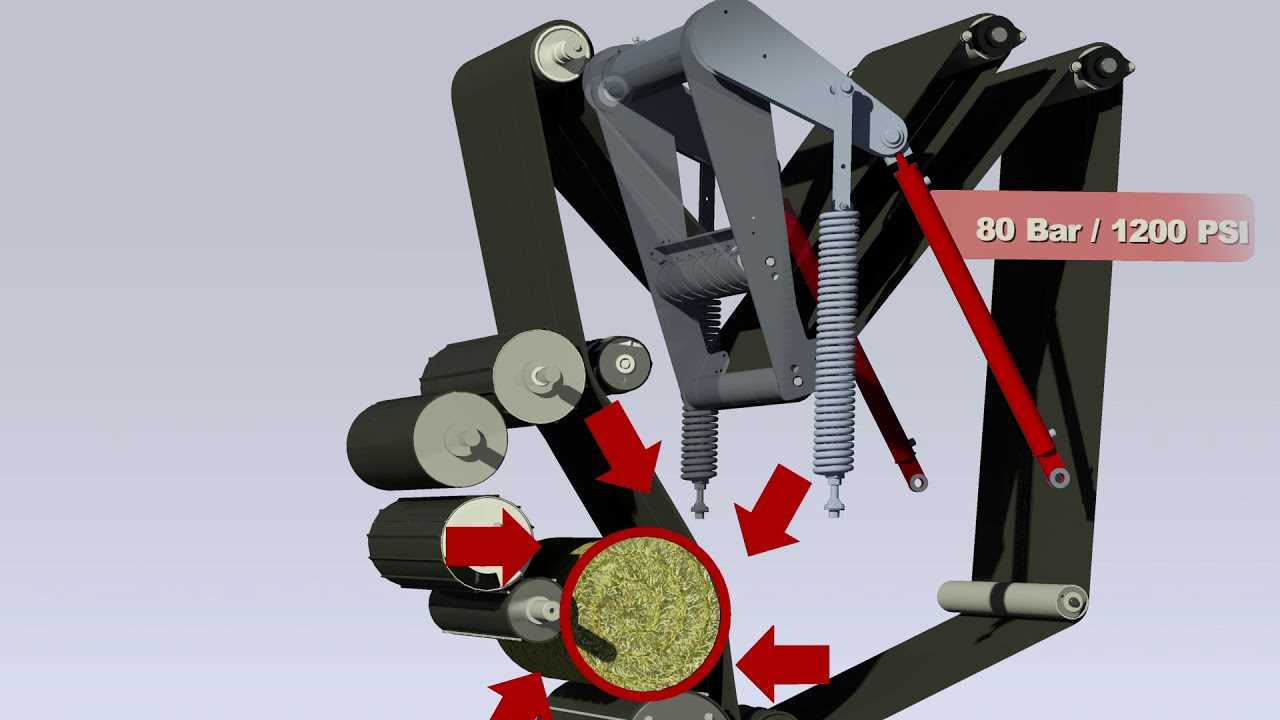

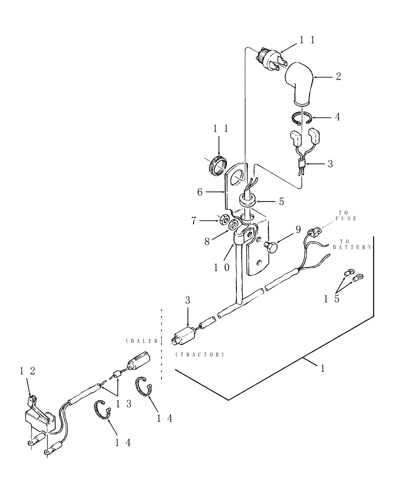

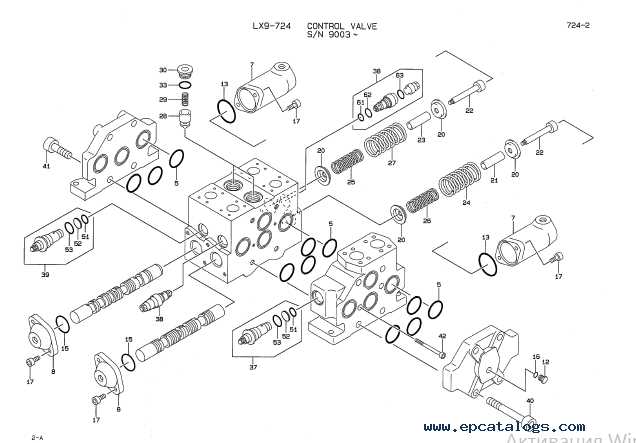

Hydraulic System

Another vital aspect is the hydraulic system, which facilitates the movement of attachments and enhances operational capabilities. This system not only allows for precise control but also maximizes efficiency during fieldwork. Proper maintenance of the hydraulic components is essential for sustained performance and productivity.

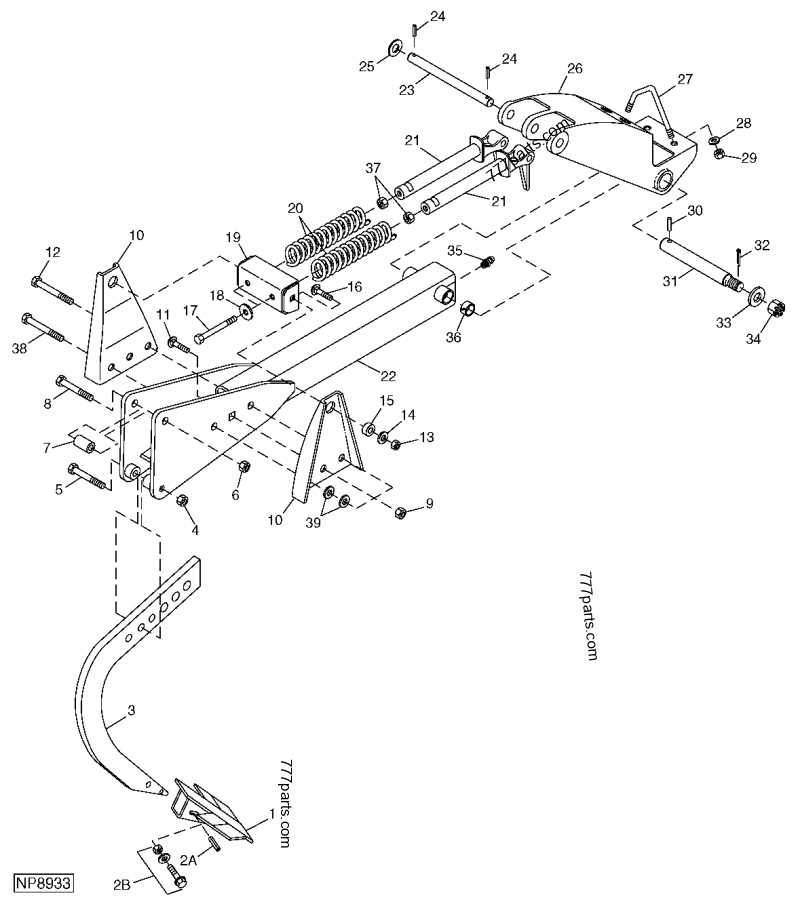

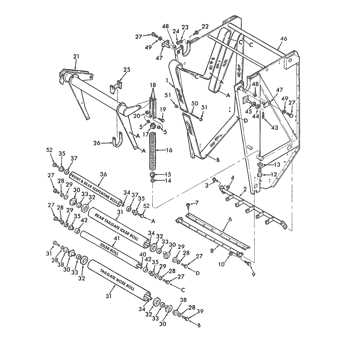

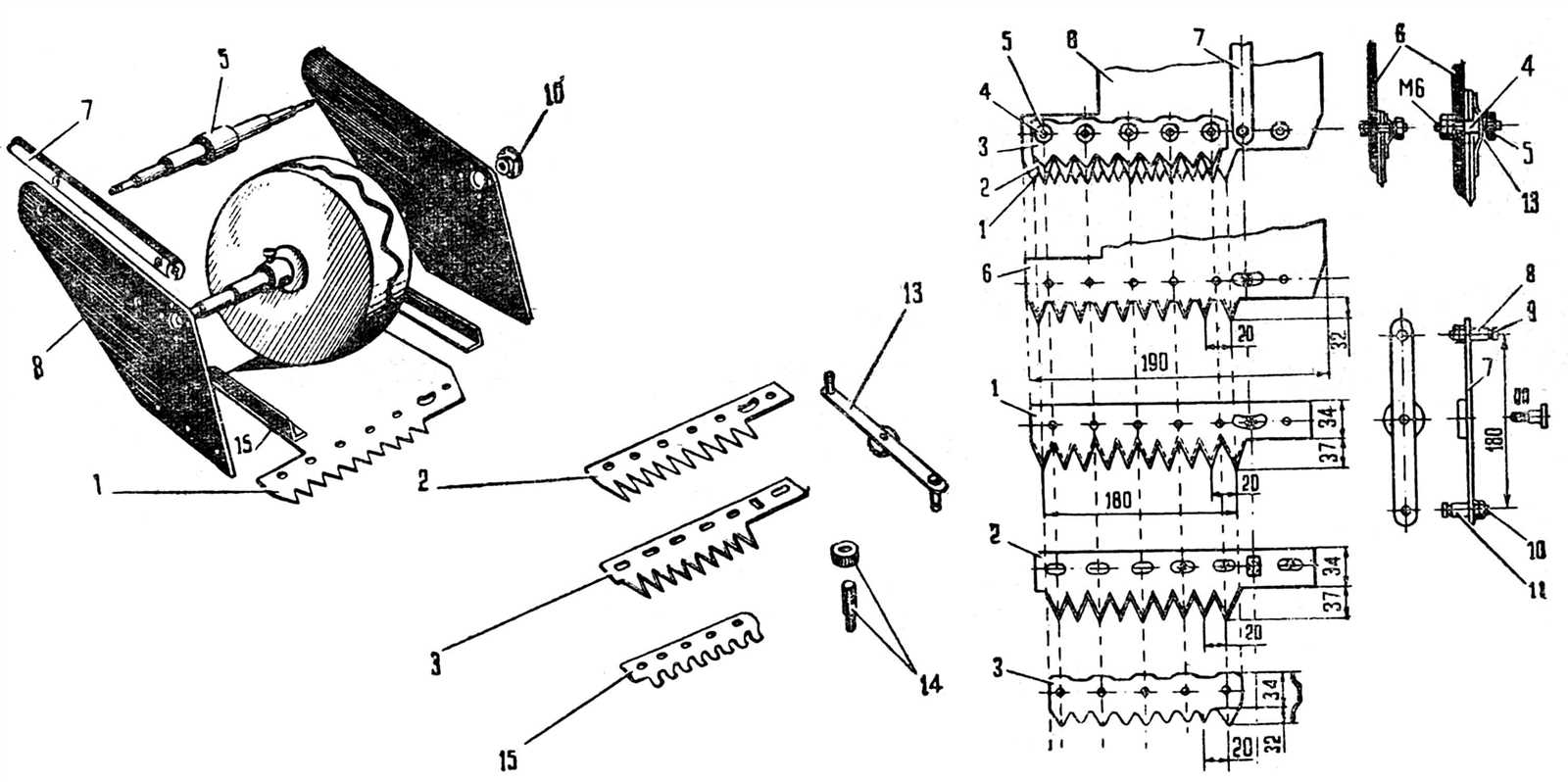

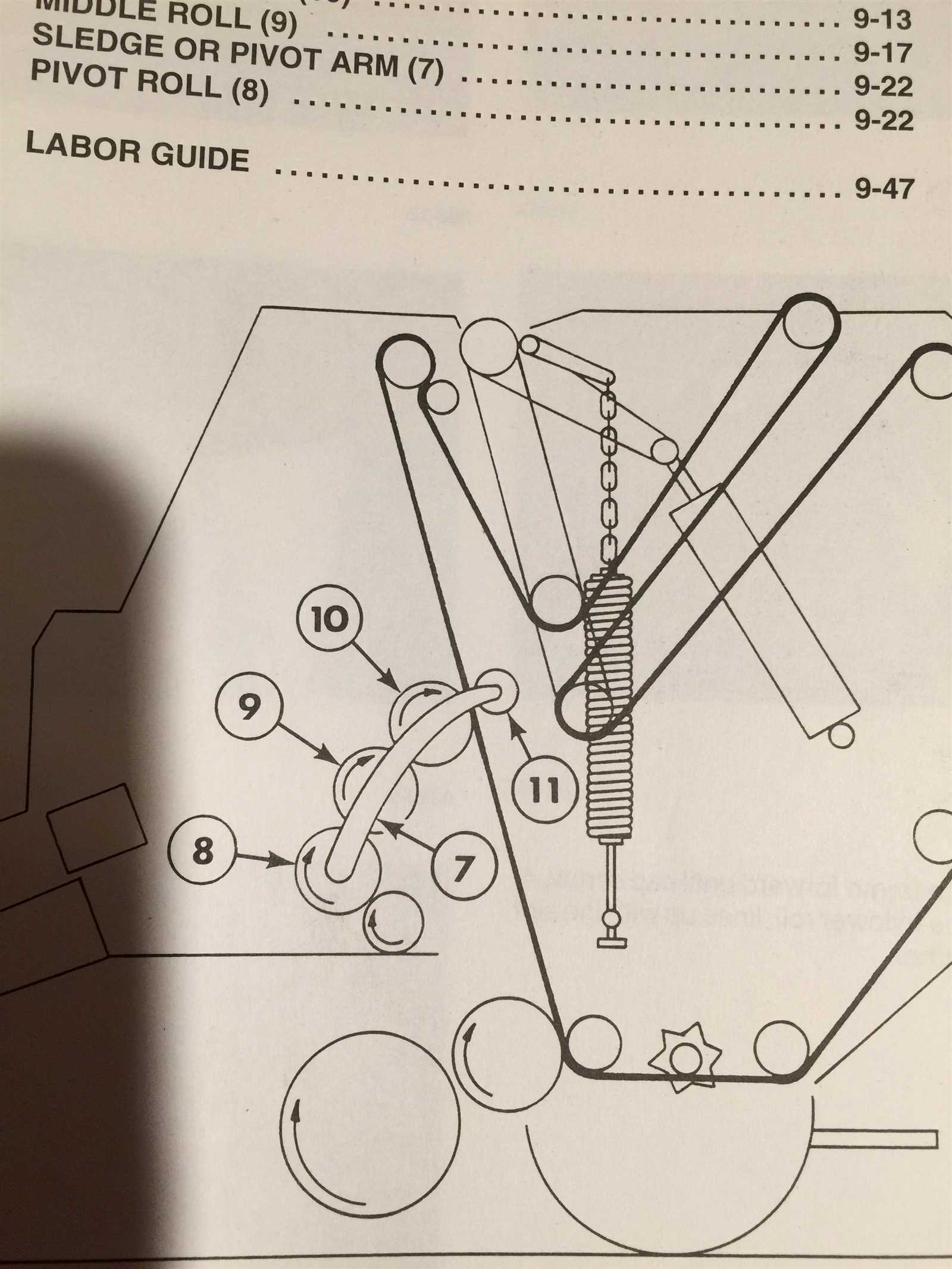

How to Read Parts Diagrams

Understanding visual schematics is essential for effective maintenance and repair. These illustrations provide a clear representation of components and their relationships within machinery. By grasping the structure of these visuals, one can identify specific elements and comprehend their functions, making troubleshooting more efficient.

Key Elements to Focus On

When examining a schematic, pay attention to the following components:

| Element | Description |

|---|---|

| Labels | These indicate the names and numbers of components, providing clarity on what each part is. |

| Lines | Connecting lines show relationships and pathways between various components, illustrating how they interact. |

| Symbols | Standardized icons often represent specific functions or types of components, aiding in quick identification. |

Steps to Interpret the Visuals

To effectively interpret these visuals, follow these steps:

- Identify all labeled components to familiarize yourself with the terminology used.

- Trace the connections to understand how parts work together and the flow of operations.

- Refer to the accompanying documentation for detailed descriptions and specifications of each component.

Common Issues with New Holland 688

Every machine can encounter difficulties over time, and this model is no exception. Understanding the prevalent challenges can help owners and operators maintain optimal performance and prolong the lifespan of their equipment.

- Engine Performance

- Difficulty starting

- Inconsistent power delivery

- Overheating issues

- Hydraulic System

- Slow response times

- Fluid leaks

- Pressure fluctuations

- Transmission Concerns

- Shifting difficulties

- Unusual noises during operation

- Vibration issues

- Electrical Problems

- Faulty wiring connections

- Malfunctioning gauges

- Battery drain

Addressing these common issues promptly can prevent more serious complications, ensuring efficient operation and reducing repair costs.

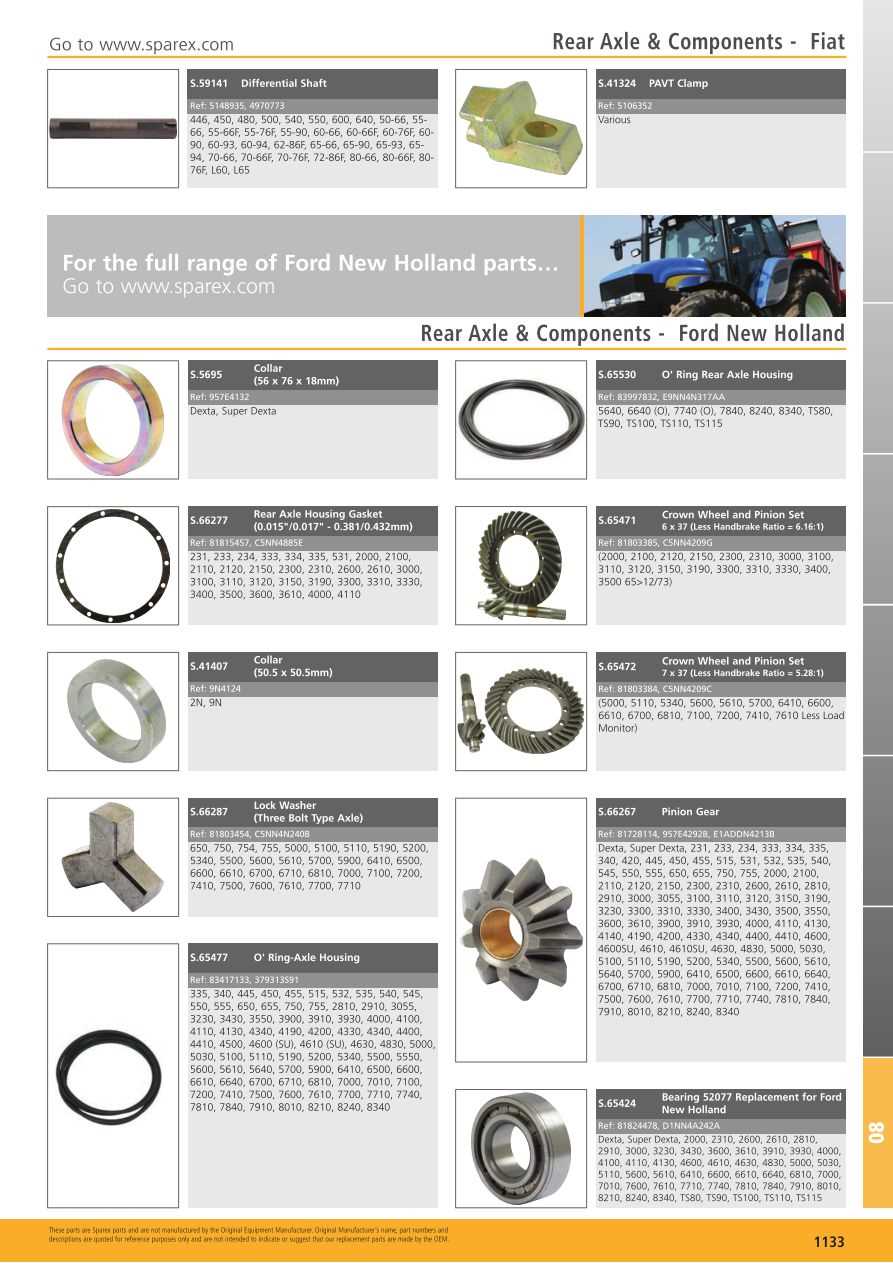

Where to Find Replacement Parts

Locating suitable components for machinery can be a challenging task, yet understanding where to search can significantly simplify the process. Various resources, both online and offline, offer a plethora of options for obtaining the necessary items to ensure optimal functionality and longevity of your equipment.

| Source Type | Description |

|---|---|

| Authorized Dealers | Official distributors often carry high-quality items that meet manufacturer specifications, providing peace of mind regarding compatibility and performance. |

| Online Marketplaces | Websites such as eBay, Amazon, and specialized platforms can be excellent for finding both new and used components, often at competitive prices. |

| Local Repair Shops | These establishments frequently stock essential items and may offer expert advice on installation and maintenance. |

| Manufacturer’s Website | Visiting the official site can provide direct access to catalogs, specifications, and purchasing options for specific items. |

| Forums and Community Groups | Online communities can be valuable for recommendations on where to find rare components and for tips on installation. |

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of your machinery. Regular attention to key components not only enhances performance but also reduces the likelihood of unexpected breakdowns. By adopting a systematic approach to maintenance, you can ensure that your equipment remains reliable and efficient over time.

Here are some effective strategies to maintain your machinery:

| Tip | Description |

|---|---|

| Regular Inspections | Conduct thorough inspections at scheduled intervals to identify wear and tear before they escalate. |

| Fluid Checks | Monitor and replace fluids as necessary, ensuring that all systems operate smoothly and efficiently. |

| Cleaning | Keep the machinery clean to prevent debris accumulation, which can lead to overheating and mechanical failure. |

| Lubrication | Apply lubricants to moving parts regularly to minimize friction and prevent premature wear. |

| Follow Manufacturer Guidelines | Adhere to the maintenance schedule provided by the manufacturer to optimize performance and longevity. |

Implementing these practices can significantly contribute to the durability and reliability of your equipment, ensuring it performs at its best for years to come.

Comparing Models: 688 vs Others

This section explores the differences and similarities among various agricultural machines, focusing on one specific model and its competitors. By examining features, performance, and user experiences, we aim to provide insights that will help potential buyers make informed decisions.

Key Features Comparison

- Engine Power: Assessing the horsepower and torque available in each model.

- Capacity: Evaluating the load and operational capacity for efficiency in various tasks.

- Durability: Comparing build quality and materials used for longevity.

Performance in the Field

- Fuel Efficiency: How each model performs in terms of fuel consumption.

- Handling: Analyzing maneuverability and ease of operation across different terrains.

- Maintenance Requirements: Understanding the upkeep needed for optimal performance.

By considering these aspects, users can better understand which model aligns with their specific agricultural needs and operational preferences.

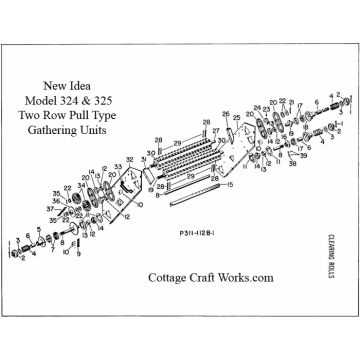

DIY Repairs Using Parts Diagrams

Understanding the components of machinery can significantly enhance the efficiency of your repair tasks. By utilizing visual representations of the various elements, you can simplify the process of identifying and sourcing the necessary replacements. This approach not only saves time but also empowers you to tackle repairs with confidence.

Here are some key benefits of using these visual guides:

- Clarity: Visual aids provide a clear view of where each component fits and how it interacts with others.

- Efficiency: Identifying the correct parts quickly reduces downtime during repairs.

- Cost-effectiveness: Understanding what you need allows for better budget management by avoiding unnecessary purchases.

- Learning opportunity: Familiarizing yourself with the components enhances your overall knowledge of the equipment.

To make the most of these visual resources, follow these steps:

- Gather tools: Assemble the necessary tools before starting any repair.

- Refer to the visual guide: Identify the parts you need to replace or repair.

- Order replacements: Use the information to find the correct components from reliable suppliers.

- Follow instructions: Use the visual guide to help you with the installation or repair process.

By leveraging these resources, you can confidently embark on DIY repairs, ensuring your machinery remains in optimal working condition.

Cost Considerations for Replacement Parts

When it comes to maintaining machinery, evaluating the financial implications of component replacements is crucial. The investment in high-quality substitutes can significantly affect both performance and longevity, while opting for cheaper options might lead to higher costs in the long run due to frequent failures or inefficiencies.

Budgeting for replacements involves assessing not only the purchase price but also installation fees, potential downtime, and the impact on overall operations. Quality assurance plays a vital role; higher-priced items often come with warranties and better reliability, which can reduce future expenditures. Additionally, understanding the availability of aftermarket alternatives versus original equipment can influence costs and sourcing strategies.

Lastly, considering the long-term value of replacements is essential. While initial costs may seem daunting, investing in durable and efficient components can lead to savings in maintenance and increased productivity over time. Therefore, a comprehensive analysis of all financial aspects is necessary for informed decision-making.

Expert Recommendations for 688 Users

For individuals utilizing this specific agricultural equipment model, there are several best practices that can enhance performance and longevity. Following expert insights can lead to improved efficiency and reduced downtime, ensuring that the machinery operates at its peak capabilities.

- Regular Maintenance: Schedule consistent check-ups to identify wear and tear early. This includes inspecting fluids, belts, and filters.

- Quality Parts: Invest in high-quality components that meet or exceed the manufacturer’s specifications. This choice can greatly affect the reliability of your machinery.

- Operator Training: Ensure that all users are well-trained on the equipment’s features and functions. Proper operation minimizes the risk of damage and enhances productivity.

- Documentation: Keep a detailed log of maintenance and repairs. This information can be invaluable for troubleshooting and resale value.

- Environment Considerations: Be mindful of the working environment. Conditions such as dust, moisture, and extreme temperatures can impact the performance and lifespan of the equipment.

By adhering to these recommendations, users can ensure that their machinery remains in optimal condition, resulting in greater operational success.

Resources for New Holland Owners

Owning agricultural machinery can be a rewarding experience, but it often comes with its own set of challenges. Access to reliable resources is essential for maintaining efficiency and ensuring longevity. Whether you’re looking for manuals, community support, or supplier contacts, having the right information at your fingertips can make a significant difference.

Manuals and Documentation: A comprehensive manual is crucial for understanding the operation and maintenance of your equipment. Many manufacturers provide downloadable resources on their websites, including user guides and maintenance schedules. These documents offer valuable insights into troubleshooting and routine care.

Online Forums and Communities: Engaging with fellow owners through online platforms can provide practical advice and shared experiences. Many forums are dedicated to specific models or brands, allowing users to exchange tips, solve common problems, and discuss upgrades. This sense of community can be an invaluable resource.

Parts Suppliers: Finding a reliable source for replacement components is vital. Numerous suppliers specialize in agricultural machinery, offering both OEM and aftermarket options. Researching and comparing prices and availability can help ensure that you get the best deal for your needs.

Local Dealerships: Establishing a relationship with local dealerships can provide access to expert knowledge and assistance. These establishments often have trained staff who can offer advice on repairs, upgrades, and general maintenance, making them a valuable asset for any owner.

Instructional Videos: Many platforms, such as YouTube, feature tutorials and walkthroughs created by enthusiasts and professionals. These videos can be a great way to visualize processes, learn new techniques, and gain confidence in handling repairs.

Utilizing these diverse resources can empower owners to maximize the performance and lifespan of their agricultural equipment, ensuring that it remains a reliable asset in their operations.