In the realm of agricultural machinery, comprehending the intricate elements that facilitate operational efficiency is paramount. Each machine is a complex assembly of parts that work in harmony to enhance productivity on the field.

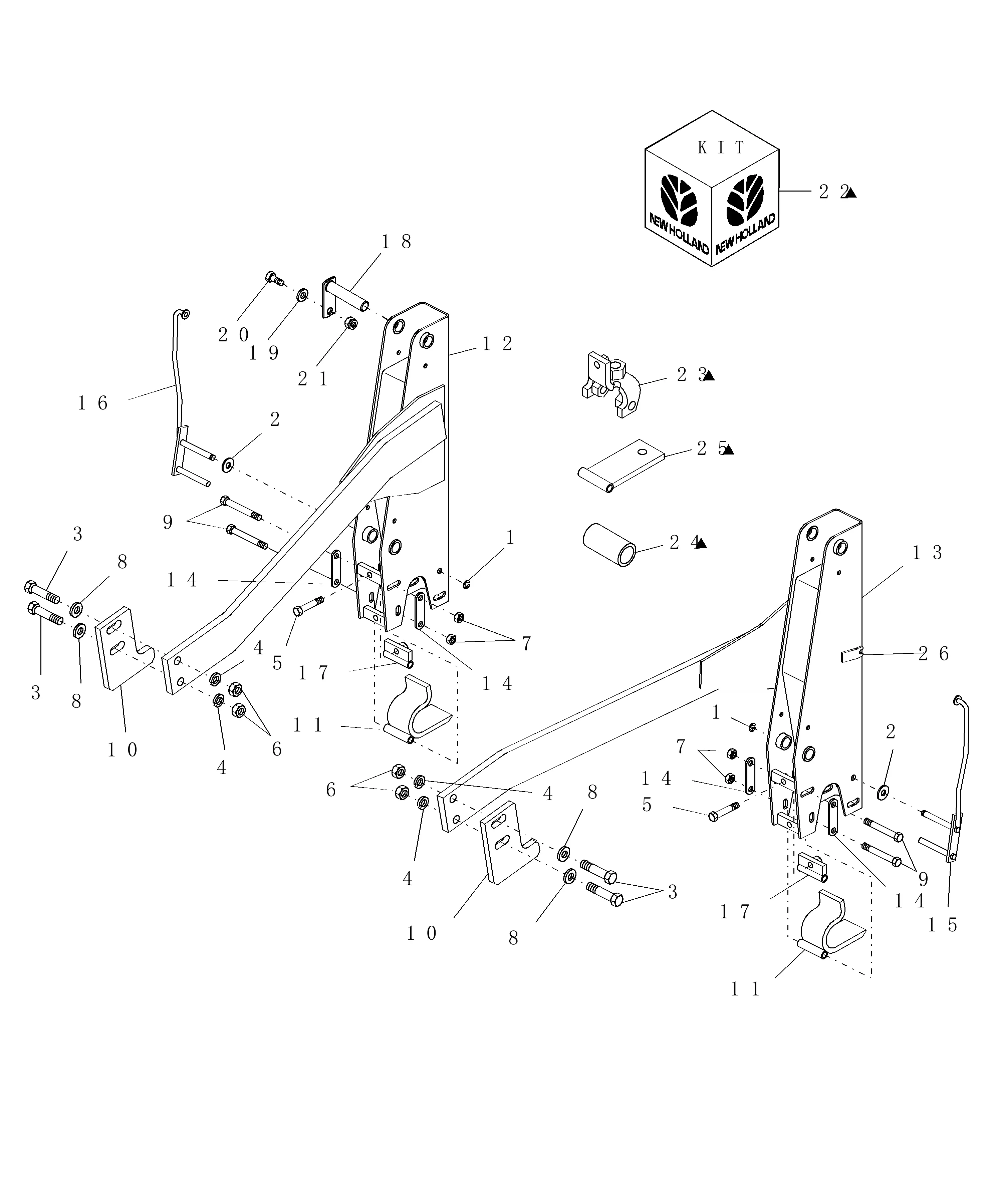

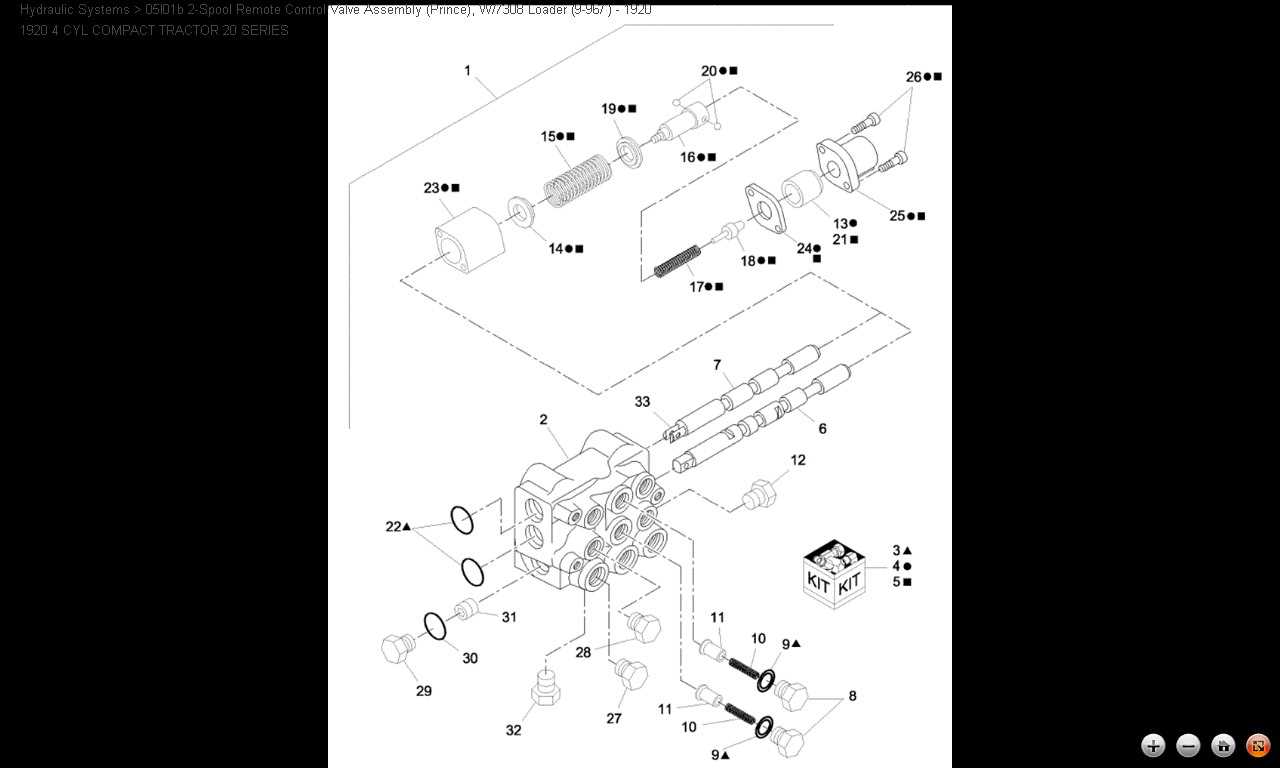

Visual aids can greatly assist in grasping the arrangement and functionality of these components. By exploring these illustrations, operators can identify specific sections, ensuring effective maintenance and repair practices.

For those seeking to optimize their machinery’s performance, an in-depth exploration of individual elements becomes the ultimate goal. Such knowledge not only fosters better troubleshooting but also prolongs the lifespan of the equipment.

Understanding New Holland Loaders

This section explores the essential features and components of agricultural and construction machinery, emphasizing their role in enhancing productivity and efficiency. Understanding these machines involves delving into their mechanisms, capabilities, and how they facilitate various tasks on job sites.

Key Components and Functionality

At the heart of these machines lies a robust structure designed to withstand demanding conditions. Key elements include hydraulic systems that enable smooth operation, powerful engines that provide the necessary force, and attachments that can be customized for specific tasks. Each component plays a vital role in ensuring optimal performance and versatility.

Importance of Maintenance and Support

Regular upkeep is crucial for longevity and reliable operation. Proper maintenance practices not only prevent breakdowns but also enhance safety for operators. Additionally, access to comprehensive support services ensures that any issues can be swiftly addressed, keeping the machinery in top condition and minimizing downtime.

Overview of Model 7308 Loader

This section provides a comprehensive examination of a specific piece of machinery designed for various agricultural and construction applications. Recognized for its reliability and efficiency, this equipment plays a crucial role in enhancing productivity across diverse tasks.

Equipped with advanced features, this model ensures optimal performance while maintaining ease of operation. Its robust construction allows it to handle heavy loads, making it an indispensable tool for professionals in the field. The versatility of this machinery is evident in its ability to adapt to different attachments, thereby expanding its range of uses.

Maintenance is straightforward, thanks to well-designed components that facilitate easy access for repairs and servicing. Understanding the configuration of the machinery can significantly aid users in maximizing its potential and longevity. Overall, this model stands out as a valuable asset in any fleet, contributing to efficient workflow and reduced operational downtime.

Importance of Loader Parts Diagrams

Understanding the intricacies of machinery components is essential for efficient maintenance and repair. Visual representations serve as crucial tools for technicians, enabling them to identify and manage various elements effectively. By utilizing these illustrations, users can streamline their workflow and enhance their problem-solving capabilities.

Enhanced Troubleshooting

When issues arise, having a visual guide can significantly improve the troubleshooting process. Technicians can quickly locate the malfunctioning component and assess its condition. This leads to more accurate diagnostics and faster resolutions, minimizing downtime and optimizing productivity.

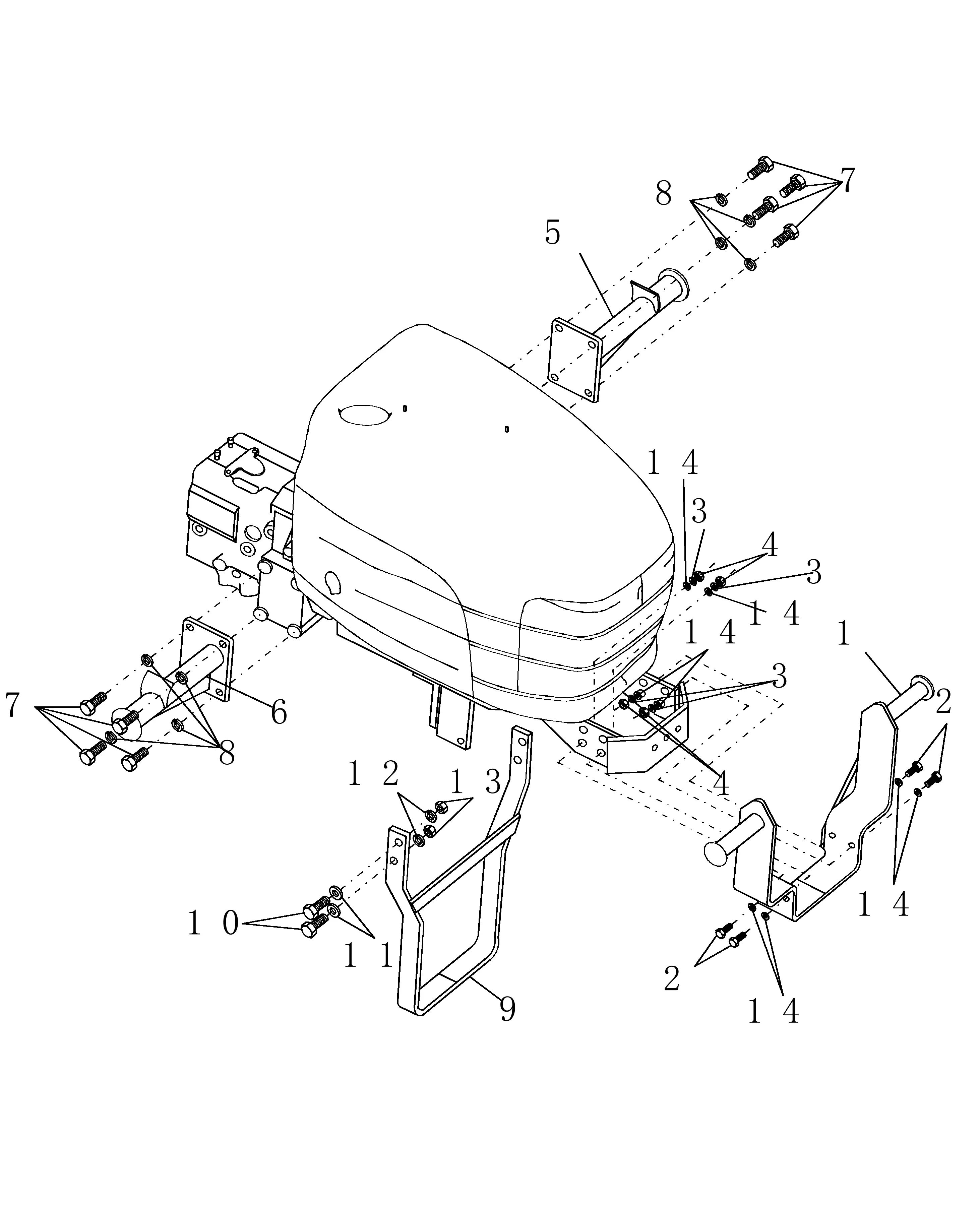

Efficient Assembly and Disassembly

Visual guides facilitate the assembly and disassembly of machinery. With a clear layout of components, users can follow a systematic approach, ensuring that each piece is correctly placed or removed. This not only simplifies the process but also reduces the risk of damage to delicate parts.

| Benefits | Description |

|---|---|

| Faster Repairs | Visual aids help technicians quickly identify issues. |

| Reduced Errors | Clear illustrations decrease the chances of mistakes. |

| Increased Knowledge | Users gain a better understanding of their equipment. |

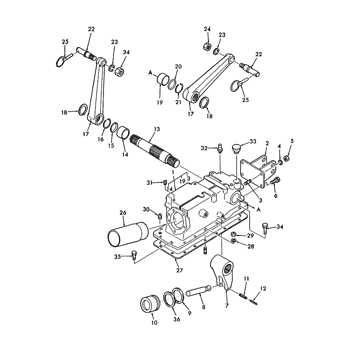

Key Components of the 7308

This section explores the essential elements that contribute to the functionality and efficiency of the equipment. Understanding these components is crucial for optimal performance and maintenance, ensuring longevity and reliability in various applications.

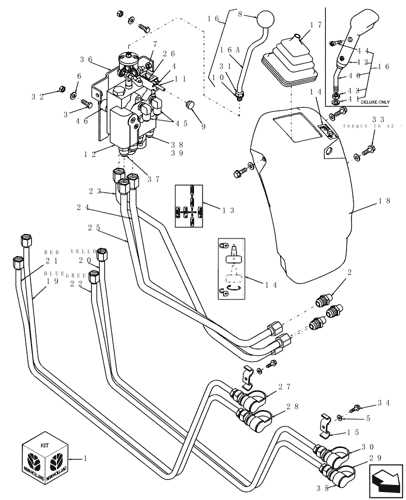

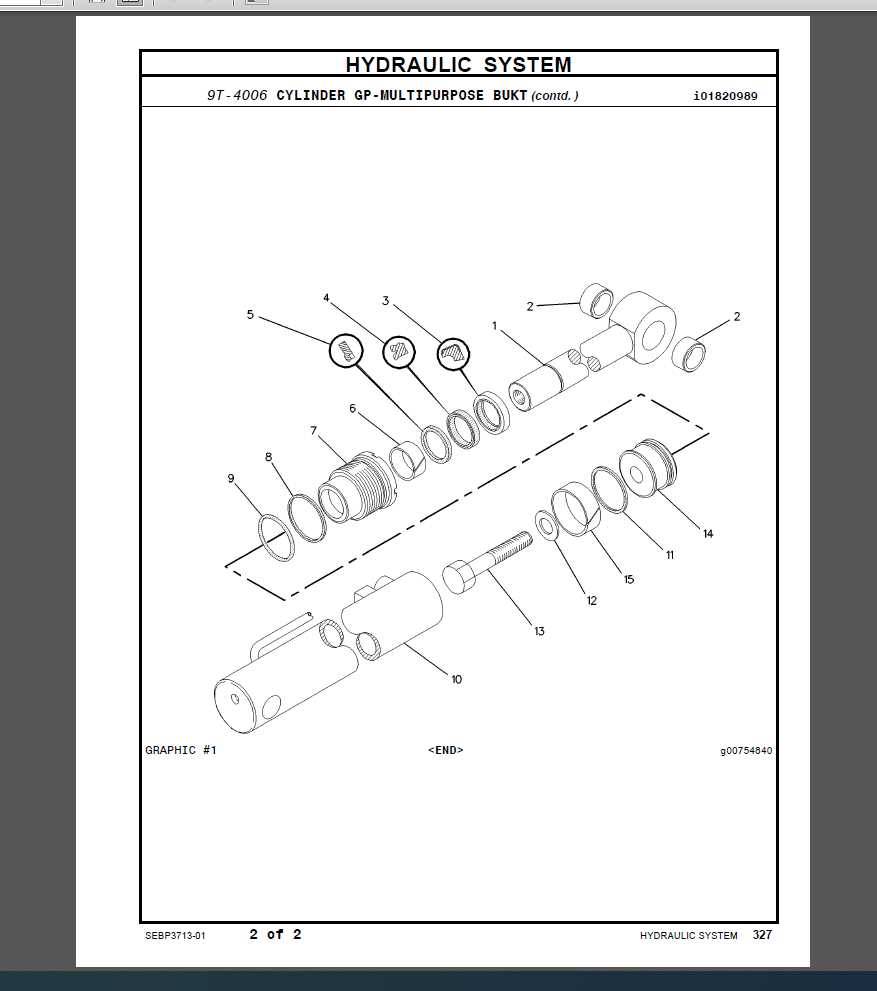

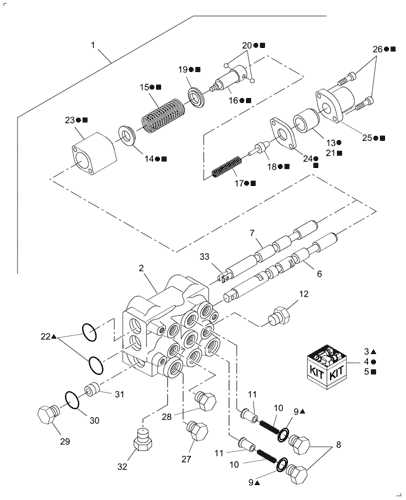

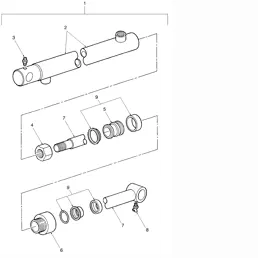

Hydraulic System

The hydraulic system plays a pivotal role in the operation, providing the necessary power to lift and move heavy loads. Key parts within this system include pumps, cylinders, and hoses, all of which work in harmony to facilitate smooth and effective movements.

Frame and Chassis

The frame and chassis provide the structural integrity required for robust performance. Constructed to withstand significant stress and strain, these components ensure stability and support during operation, making them vital for overall efficiency.

Common Issues with Loader Parts

Understanding the typical challenges faced with equipment components is crucial for maintaining optimal functionality. Various factors can lead to malfunctions, impacting performance and efficiency.

Wear and Tear

Frequent use can result in degradation of various components, leading to decreased performance. Regular inspections are essential to identify worn-out elements before they cause significant issues.

Hydraulic Problems

Hydraulic systems are vital for operation but can face issues such as leaks and pressure drops. Addressing these problems promptly is essential to avoid further complications.

| Issue | Symptoms | Solution |

|---|---|---|

| Wear and Tear | Reduced efficiency, unusual noises | Regular maintenance, timely replacements |

| Hydraulic Leaks | Fluid puddles, erratic movement | Seal replacements, system checks |

Finding Replacement Parts Effectively

Locating suitable components for machinery can often seem daunting, but with the right approach, it becomes a straightforward task. Understanding where to look and what resources are available is essential for ensuring your equipment operates smoothly and efficiently.

Begin by identifying the specific requirements of your equipment. Detailed knowledge about the model and specifications is crucial. This information can usually be found in user manuals or on the manufacturer’s website. Having a clear understanding of the necessary items will streamline your search significantly.

Utilizing online platforms is one of the most efficient methods for sourcing components. Numerous websites specialize in offering a wide array of options, including OEM and aftermarket solutions. Search for forums or communities related to your equipment type, where you can gain insights and recommendations from fellow users.

Additionally, consider contacting local suppliers or dealerships. They often have access to inventory that may not be listed online, and their expertise can help guide you toward the right choices. Don’t hesitate to ask questions regarding compatibility and availability, as this information can save you time and effort in the long run.

Lastly, keeping a detailed inventory of your machinery’s components can aid in anticipating future needs. By understanding what you have and what may need replacement, you can proactively seek out suitable alternatives before a breakdown occurs. This foresight can greatly enhance the longevity and performance of your equipment.

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations provide detailed insights into the various elements that make up machinery, helping users identify and source necessary items. Knowing how to interpret these visuals can significantly enhance your ability to manage equipment efficiently.

To effectively read these representations, follow these guidelines:

- Familiarize Yourself with Symbols:

- Each illustration often includes specific symbols that indicate different parts.

- Learn the common symbols used in the industry to streamline your understanding.

- Identify the Layout:

- Components are usually organized in a logical manner, often grouped by function.

- Observe how parts connect and interact with each other in the layout.

- Reference the Legend:

- Most visuals will include a legend or key explaining the symbols and numbering.

- Use this reference to clarify any uncertainties regarding the components.

- Look for Part Numbers:

- Part numbers are crucial for ordering replacements accurately.

- Note these numbers as you review the illustration for easy reference later.

- Understand the Flow:

- Recognize how parts work together and the flow of operation within the machinery.

- This comprehension can aid in troubleshooting and repairs.

By mastering these techniques, you will enhance your proficiency in interpreting these vital resources, ensuring that your equipment remains in optimal working condition.

Benefits of OEM vs. Aftermarket Parts

When considering replacements for equipment components, it’s essential to evaluate the advantages of original manufacturer products versus alternatives. Each option carries distinct characteristics that can significantly influence performance, longevity, and overall satisfaction.

Quality and Reliability

Original manufacturer items typically ensure a higher standard of quality, as they are designed specifically for the machinery. This dedication to precise engineering often translates to better reliability and durability, ultimately resulting in fewer maintenance issues over time.

Cost Considerations

While alternatives may present a more attractive price point initially, the long-term expenses can vary greatly. Often, investing in original components can lead to greater savings due to reduced frequency of replacements and repairs.

| Feature | OEM Parts | Aftermarket Parts |

|---|---|---|

| Quality | High | Variable |

| Cost | Higher | Lower |

| Compatibility | Guaranteed | May vary |

| Warranty | Often available | Limited or none |

Maintenance Tips for Loaders

Regular upkeep is essential for optimal performance and longevity of heavy machinery. Implementing effective maintenance practices can prevent costly repairs and ensure safety during operation.

1. Routine Inspections: Conduct frequent checks for wear and tear, focusing on critical components. Identifying issues early can save time and resources.

2. Lubrication: Ensure all moving parts are adequately lubricated to reduce friction and extend service life. Follow manufacturer guidelines for the type and frequency of lubrication.

3. Cleaning: Keep the machinery clean from dirt and debris. Regular cleaning helps maintain visibility and prevents corrosion.

4. Fluid Levels: Regularly monitor hydraulic fluid, oil, and coolant levels. Maintaining appropriate levels is vital for efficient operation and preventing overheating.

5. Tire Care: Inspect tires for proper inflation and tread wear. Well-maintained tires improve traction and stability, enhancing safety during use.

6. Operator Training: Ensure operators are well-trained in handling equipment. Proper training reduces the risk of accidents and promotes best practices.

Upgrading Your Loader’s Performance

Enhancing the functionality of your machinery can significantly improve productivity and efficiency. By implementing strategic upgrades, you can ensure that your equipment meets the demands of various tasks more effectively.

Consider the following enhancements:

- Improving hydraulic systems for better lifting capabilities.

- Upgrading the engine for increased power and fuel efficiency.

- Installing advanced control systems for precise maneuvering.

- Enhancing tire quality for better traction and stability.

By delving into these options, operators can achieve the ultimate balance between performance and reliability, ultimately benefiting their operations.

Safety Precautions While Operating Loaders

Ensuring safety during the operation of heavy machinery is paramount. Adhering to established guidelines helps prevent accidents and protects operators and bystanders alike. Understanding the essential measures is crucial for a secure working environment.

Pre-Operation Checks

Before commencing work, operators should conduct thorough inspections of the equipment. This includes checking fluid levels, brakes, and safety devices to ensure everything is in optimal condition. Proper maintenance is vital for both performance and safety.

Safe Operating Practices

While in use, it is essential to remain vigilant and follow best practices. Maintain a clear view of surroundings, avoid overloading, and use seat belts whenever available. Staying alert and cautious can significantly reduce the risk of incidents.

Resources for Parts and Repairs

Finding reliable resources for maintenance and replacement components is essential for optimal equipment performance. Whether you are looking for specialized suppliers or community-driven forums, numerous avenues exist to assist in securing the necessary items for upkeep.

Online Marketplaces: Numerous digital platforms offer a wide range of options for components, often at competitive prices. These sites allow you to compare products and read reviews, ensuring you make informed choices.

Local Dealers: Establishing a relationship with nearby dealerships can be beneficial. They often have access to quality components and can provide valuable insights on installation and compatibility.

Forums and Community Groups: Engaging with fellow enthusiasts and professionals through online forums can yield helpful advice and recommendations. These communities often share experiences and tips, making them a valuable resource.

Manuals and Guides: Accessing operation manuals and repair guides can enhance your understanding of the machinery. These documents frequently include illustrations and specifications crucial for proper maintenance.

Utilizing these resources can significantly streamline your repair process and prolong the lifespan of your equipment.

Expert Insights on Loader Efficiency

Enhancing operational effectiveness is crucial for maximizing productivity in any heavy machinery. Understanding the mechanisms and components involved can significantly impact performance, leading to improved results on the job site. This section provides valuable perspectives on optimizing equipment usage and maintenance.

Key Factors Influencing Performance

- Regular Maintenance: Scheduled checks can prevent breakdowns and ensure all parts are functioning optimally.

- Operator Training: Skilled personnel can make informed decisions that enhance efficiency and safety.

- Load Management: Properly distributing weight can prevent wear and tear, leading to longer lifespan.

Best Practices for Optimization

- Conduct routine inspections to identify potential issues early.

- Utilize the correct attachments for specific tasks to improve effectiveness.

- Monitor fuel consumption to identify any discrepancies that may indicate inefficiencies.

By focusing on these aspects, operators can significantly enhance the functionality and lifespan of their machinery, ultimately leading to greater productivity and reduced operational costs.