Understanding the intricate details of agricultural machinery is essential for efficient operation and maintenance. Visual representations of various elements serve as invaluable tools for identifying parts and their functions within the overall system.

By examining these illustrations, users can gain insights into the assembly and arrangement of components, enhancing their ability to perform repairs and replacements. This knowledge ultimately contributes to improved machinery performance and longevity.

Utilizing these resources empowers operators to navigate complex systems with confidence, ensuring that each element operates harmoniously within the machinery. Such understanding fosters a proactive approach to maintenance, leading to optimal productivity in agricultural tasks.

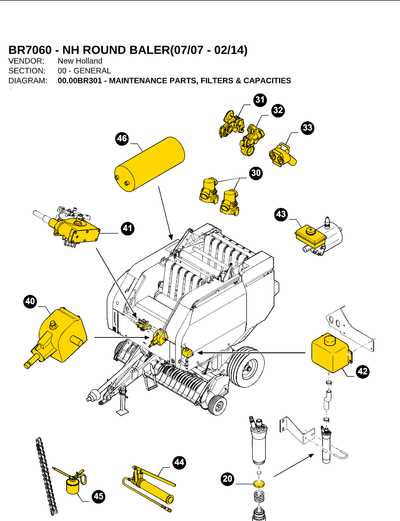

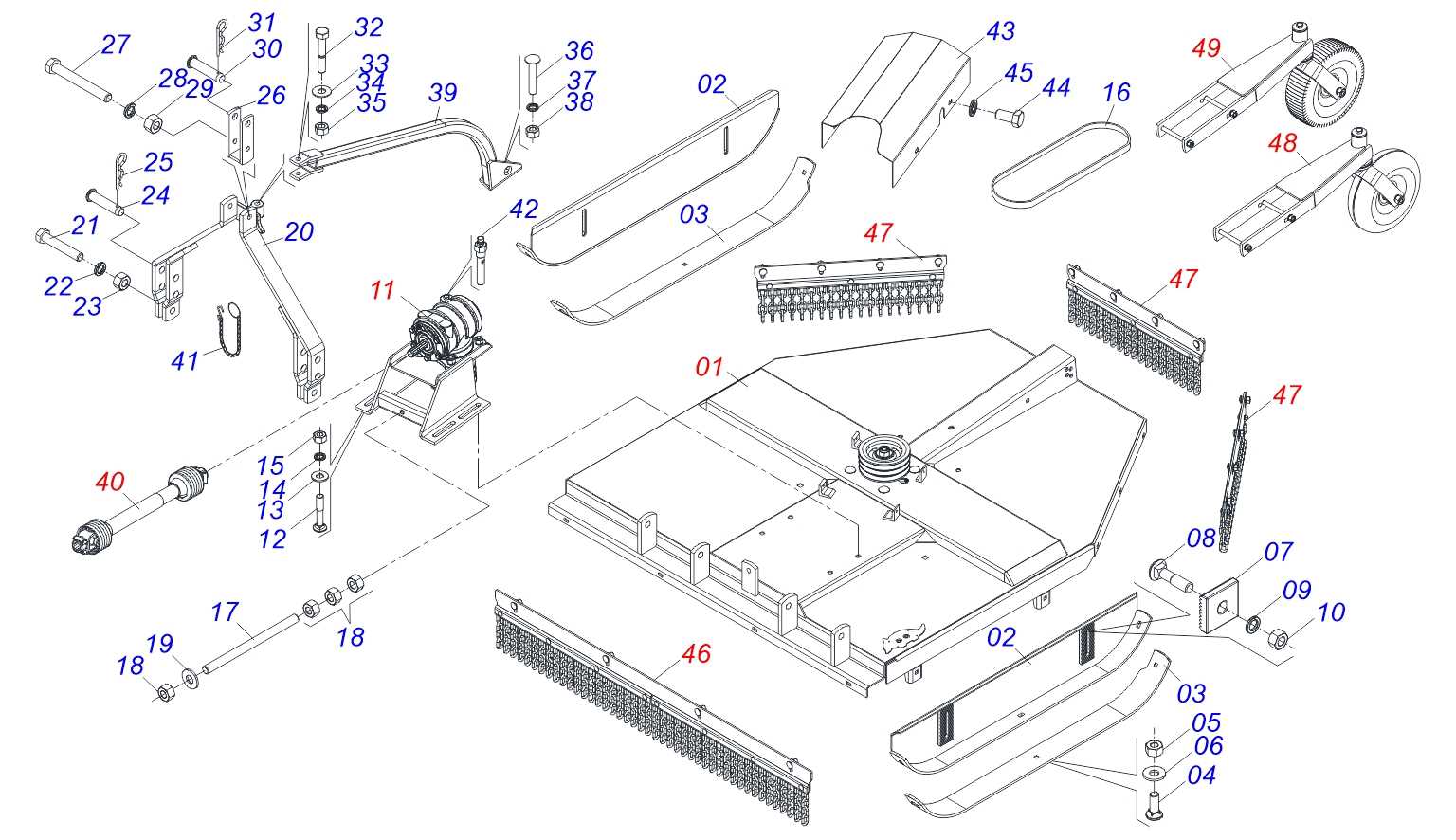

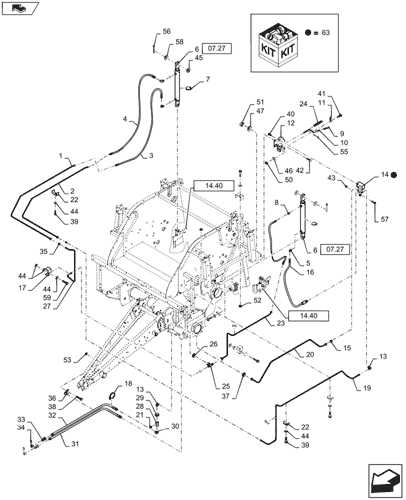

Understanding the BR7060 Parts Diagram

Grasping the layout of essential components in agricultural machinery is crucial for effective maintenance and operation. This section aims to provide insights into the intricate design and relationships between various elements within the equipment, enhancing user familiarity and efficiency.

Key Components Overview

The assembly includes numerous integral elements, each serving a specific function. Familiarity with these components helps in troubleshooting and ensuring optimal performance, contributing to the longevity of the machinery.

Importance of Familiarity

Recognizing how each part interacts can prevent operational issues and reduce downtime. A thorough understanding empowers users to carry out necessary repairs and replacements confidently, ultimately leading to improved productivity in the field.

Importance of Accurate Parts Identification

Precise identification of components plays a crucial role in maintaining machinery efficiency and reliability. When each element is correctly recognized, it leads to smoother operations and reduces the risk of costly errors.

Benefits of accurate identification include:

- Enhanced Performance: Proper components ensure optimal functioning of the equipment.

- Reduced Downtime: Quick and accurate identification minimizes delays in repairs.

- Cost Savings: Prevents unnecessary purchases of incorrect items.

- Improved Safety: Accurate components reduce the risk of malfunctions that could lead to accidents.

In conclusion, understanding the significance of recognizing each element contributes greatly to the overall effectiveness and longevity of the machinery.

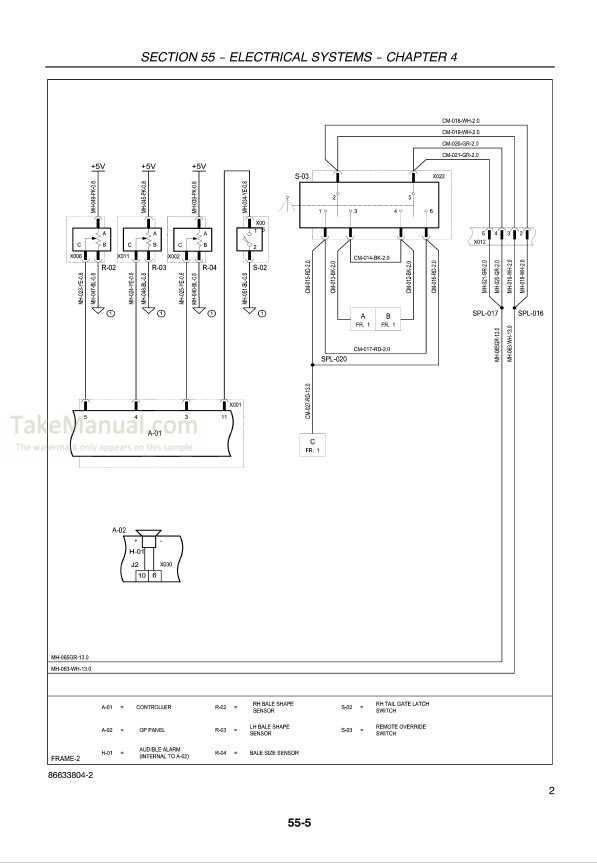

Common Issues with BR7060 Components

Components of agricultural machinery often face various challenges that can affect their performance and longevity. Understanding these common problems can help operators maintain efficiency and prevent costly repairs.

Frequent Mechanical Failures

Mechanical parts may suffer from wear and tear due to regular use. This can lead to misalignment or breakdown, impacting overall functionality.

Hydraulic System Concerns

Hydraulic components can experience leaks or pressure drops, which might hinder operational capabilities. Timely inspection and maintenance are essential to address these issues.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Wear and Tear | Reduced efficiency, unusual noises | Regular maintenance, timely replacements |

| Hydraulic Leaks | Fluid loss, decreased pressure | Check seals, replace faulty components |

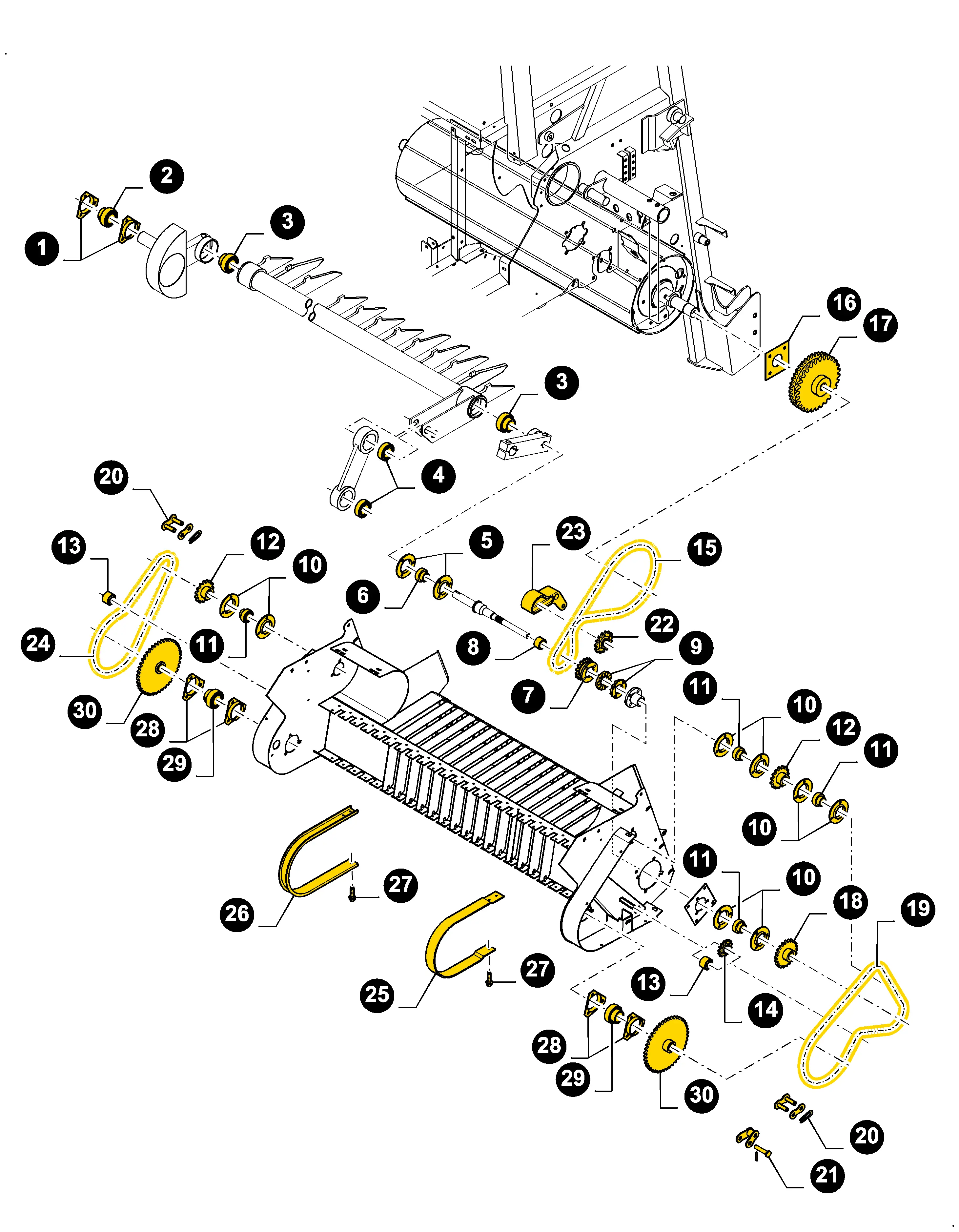

How to Read Parts Diagrams

Understanding visual representations of components is crucial for effective maintenance and repairs. These illustrations provide a detailed overview, allowing users to identify various elements and their relationships within a system.

To grasp these visuals, consider the following steps:

- Familiarize Yourself with the Layout: Start by observing the overall structure. Recognize the different sections and how they relate to one another.

- Identify Key Symbols: Learn the meanings of common symbols used in these representations, as they often indicate specific types of components or actions.

- Refer to Labels: Pay attention to any annotations or labels that provide additional information about the elements displayed.

- Use a Legend: If available, consult a legend to decode any unfamiliar markings or notations.

- Follow the Flow: Analyze the flow of connections and interactions among various components to understand the complete picture.

By mastering these techniques, users can effectively navigate and interpret complex visual guides, facilitating smoother repairs and maintenance tasks.

Key Components of the BR7060

This section focuses on the essential elements that contribute to the functionality and efficiency of the machine in agricultural operations. Understanding these components is crucial for maintaining optimal performance and reliability.

- Chassis: The robust framework that supports all other elements, ensuring stability and strength.

- Engine: The powerhouse that drives the entire system, providing the necessary energy for operations.

- Harvesting Mechanism: The assembly responsible for cutting and collecting crops, vital for efficient harvesting.

- Transmission: The system that transfers power from the engine to the wheels or belts, facilitating movement and operation.

- Control Panel: The interface for operators, allowing for adjustments and monitoring of machine functions.

Each of these components plays a significant role in ensuring the effectiveness of agricultural tasks, making them integral to overall productivity.

Maintenance Tips for Longevity

Ensuring the durability of machinery involves regular upkeep and attention to detail. Implementing effective maintenance practices can significantly enhance performance and extend the lifespan of equipment. By prioritizing certain tasks, operators can prevent common issues and avoid costly repairs.

Regular Inspections: Conduct frequent checks on key components to identify any signs of wear or damage. Early detection can prevent larger problems from developing.

Proper Lubrication: Maintain smooth operation by using appropriate lubricants on moving parts. This reduces friction and minimizes the risk of overheating.

Cleanliness: Keep machinery clean from debris and contaminants. Regular cleaning prevents build-up that can lead to mechanical failures.

Follow Manufacturer Guidelines: Adhere to recommended service intervals and procedures. Utilizing proper maintenance schedules is crucial for optimal performance.

Training and Knowledge: Equip operators with the necessary skills and understanding of equipment functions. A knowledgeable team is key to effective maintenance.

Replacing Worn-Out Parts Effectively

Ensuring optimal performance of machinery requires timely replacement of components that have lost their effectiveness. Addressing wear and tear proactively not only enhances efficiency but also extends the lifespan of the equipment. This section explores strategies for effectively managing the replacement of degraded components.

Identifying Signs of Wear

Regular inspections are crucial in recognizing when components are nearing the end of their useful life. Some common indicators include unusual noises, decreased performance, and visible damage. Monitoring these signs allows for timely interventions, preventing further complications.

Replacement Procedure

Once worn components are identified, a systematic approach to replacement should be followed. This ensures that the process is efficient and minimizes downtime. Below is a guide outlining the steps involved:

| Step | Description |

|---|---|

| 1 | Gather necessary tools and new components. |

| 2 | Ensure the machinery is turned off and secure. |

| 3 | Remove the old component carefully, taking note of its installation. |

| 4 | Install the new component, following proper alignment and specifications. |

| 5 | Test the machinery to confirm proper operation. |

Where to Find Quality Spare Parts

Finding reliable components for agricultural machinery is crucial for ensuring optimal performance and longevity. Various sources offer an array of options, making it essential to identify trustworthy suppliers to meet your needs effectively.

One effective approach is to explore authorized dealers who specialize in equipment. These establishments typically provide genuine components that guarantee compatibility and reliability. Additionally, they often have knowledgeable staff who can assist in selecting the appropriate items.

Another option is to check online marketplaces, which can offer a wide selection of alternatives. When utilizing these platforms, it’s important to pay attention to seller ratings and reviews to ensure the quality of the products being purchased. Comparing prices across different sites can also help in finding the best deals.

Local repair shops may also have spare components available or can guide you in sourcing them. Establishing a relationship with these professionals can lead to valuable recommendations and insights into maintaining your equipment efficiently.

Lastly, consider joining online forums or communities focused on agricultural machinery. These platforms allow users to share experiences and suggestions regarding where to obtain quality replacements, fostering a network of support among enthusiasts and professionals alike.

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components offers numerous advantages that can significantly enhance performance and longevity. These elements are specifically designed to meet the exact specifications of machinery, ensuring optimal compatibility and functionality.

| Advantage | Description |

|---|---|

| Quality Assurance | OEM components are manufactured to high standards, ensuring durability and reliability. |

| Perfect Fit | Designed to match exact specifications, they guarantee seamless integration into the system. |

| Warranty Protection | Using original parts often maintains warranty coverage, providing peace of mind for users. |

| Enhanced Performance | These components contribute to improved efficiency and overall machine performance. |

| Long-Term Savings | Investing in quality parts can reduce the frequency of repairs and replacements, leading to cost savings over time. |

DIY Repairs vs. Professional Help

When it comes to addressing mechanical issues, individuals often face a choice between tackling repairs themselves or seeking assistance from experts. Each option has its advantages and disadvantages, which can significantly impact both the outcome and the overall cost of the repair process.

Self-repairs can be a rewarding experience, offering the satisfaction of solving problems independently. Engaging in do-it-yourself work can also save money, as it eliminates labor costs associated with hiring a technician. However, this approach requires a certain level of skill and access to appropriate tools. Mistakes during the repair process can lead to further complications, potentially increasing expenses in the long run.

On the other hand, professional services provide peace of mind, as trained technicians bring expertise and specialized knowledge to the table. Their experience allows for quicker diagnostics and often more efficient repairs. While this option may come at a higher upfront cost, it can save time and reduce the risk of further damage, making it a viable choice for those unfamiliar with mechanical work.

Ultimately, the decision between self-repair and hiring a professional depends on factors such as individual skill level, the complexity of the issue, and available resources. Weighing these considerations carefully can help ensure the most effective solution is chosen.

Resources for Further Information

Exploring comprehensive materials can significantly enhance your understanding of machinery components and their functionalities. Numerous platforms offer valuable insights and detailed visuals, catering to both enthusiasts and professionals in the field.

Online Forums and Communities

Participating in dedicated online communities provides access to firsthand experiences and advice from fellow users. Engaging in discussions can uncover practical tips and troubleshooting techniques that are often shared by those with extensive hands-on experience.

Manufacturer’s Manuals and Guides

Accessing official manuals and guides from manufacturers can provide in-depth knowledge about various mechanisms and maintenance protocols. These documents often include clear illustrations and descriptions, helping users to better understand assembly and repair processes. Consulting these resources can be invaluable for ensuring optimal performance and longevity.