Understanding the intricate structure of machinery is crucial for efficient maintenance and repair. A clear view of how each element fits together allows for precise troubleshooting and proper servicing. By studying the assembly of key vehicle systems, operators can gain better control over the performance and longevity of their equipment.

Detailed insights into each section help ensure that every component is correctly placed and functions as intended. These visual guides offer a comprehensive reference, aiding both experienced technicians and those new to the field in recognizing individual pieces and their roles.

With the right reference materials, anyone can confidently perform repairs and replacements, minimizing downtime and maximizing operational efficiency. Proper documentation and understanding of these mechanical structures are the foundation of long-term reliability and safe usage.

Exploring the New Holland Rustler 125 Parts

Understanding the key components of an off-road utility vehicle is crucial for maintaining its performance and longevity. This section delves into the various elements that make up the vehicle’s structure, focusing on the most important systems and their functions. From the engine to the wheels, each piece plays a vital role in ensuring smooth operation and durability in demanding conditions.

Core Elements of the Vehicle

- Engine system: The powerhouse that drives the vehicle forward.

- Transmission: Transfers the engine’s power to the wheels, enabling movement.

- Suspension: Ensures stability and comfort by absorbing shocks and bumps.

- Braking system: Provides stopping power, ensuring safety during operation.

Maintenance and Upkeep

- Regular inspection of the engine and fluids to ensure optimal performance.

- Periodic checks on the suspension and wheels to prevent wear and tear.

- Cleaning and replacing filters to maintain air and fuel quality.

- Brake system checks to avoid any issues with stopping power.

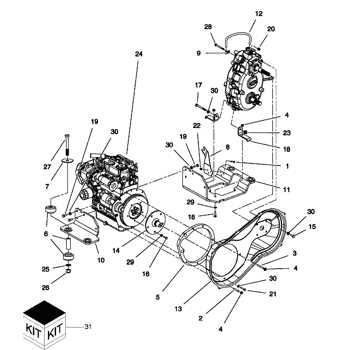

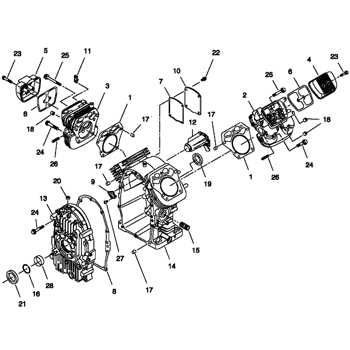

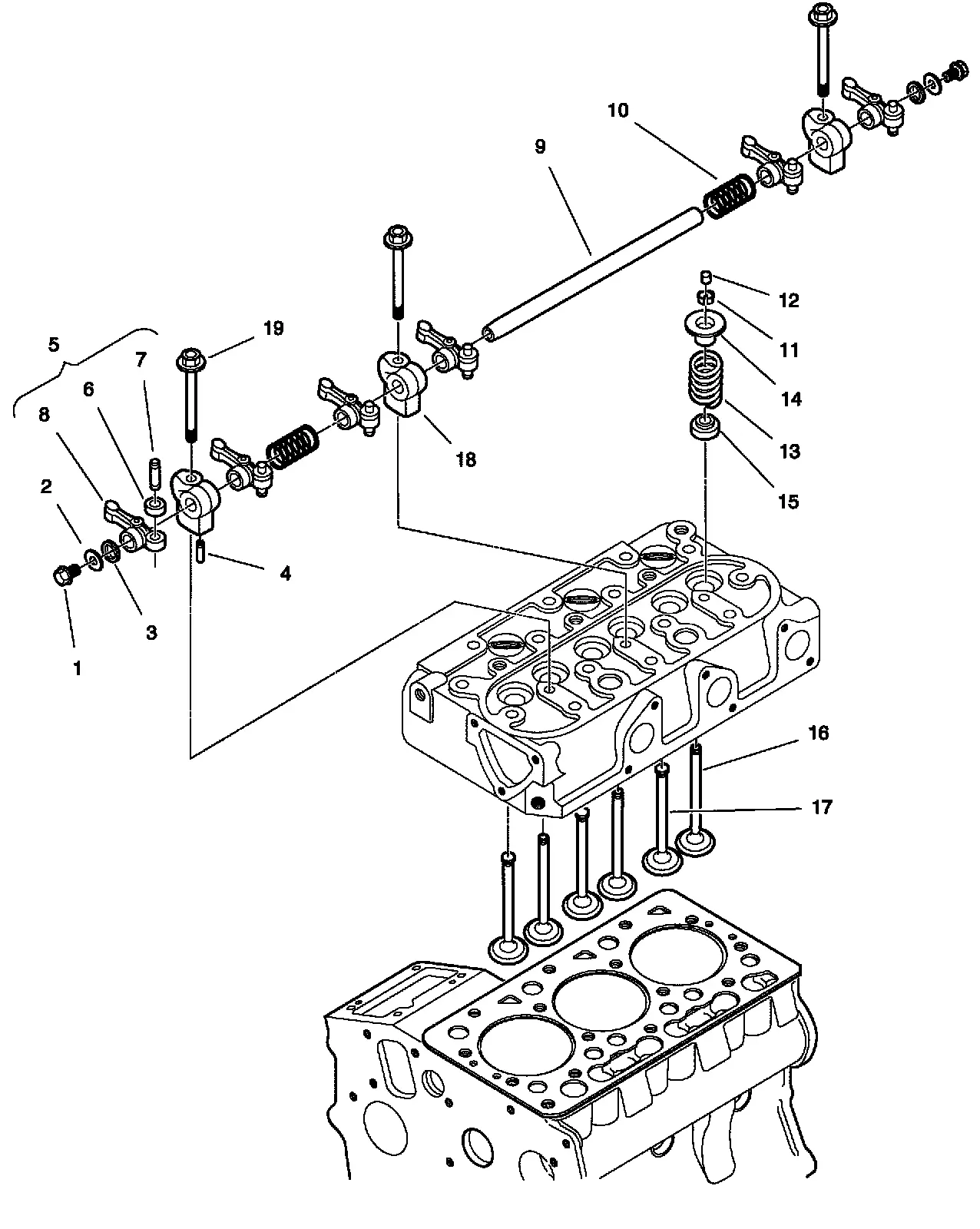

Understanding the Engine Components of Rustler 125

The engine of a utility vehicle plays a crucial role in ensuring optimal performance and longevity. Each component within the engine has a specific function that contributes to the vehicle’s overall efficiency and power output. Familiarity with these key elements helps in maintaining the engine and troubleshooting any potential issues that may arise.

Key Engine Elements: The primary components include the cylinder block, which houses the pistons and other moving parts, and the cylinder head, which ensures proper air intake and exhaust flow. Additionally, the crankshaft is vital for converting the up-and-down motion of the pistons into rotational energy.

Maintaining these engine components in peak condition is essential for ensuring the vehicle operates smoothly, with maximum power and fuel efficiency. Each part must be inspected and serviced regularly to prevent wear and tear that could lead to costly repairs or decreased performance.

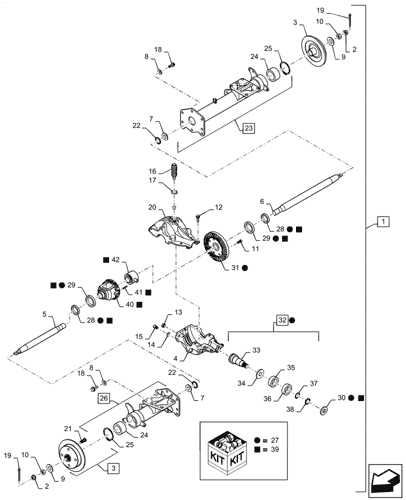

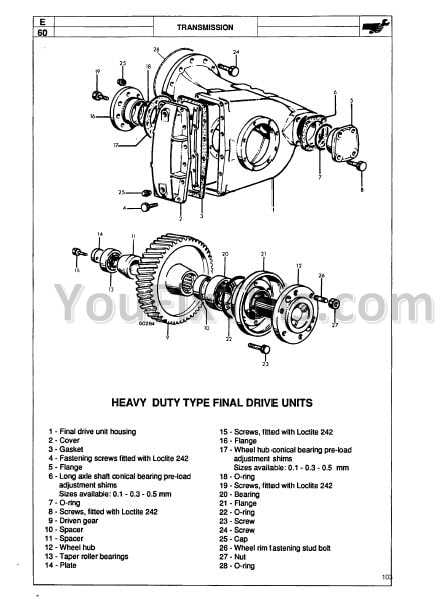

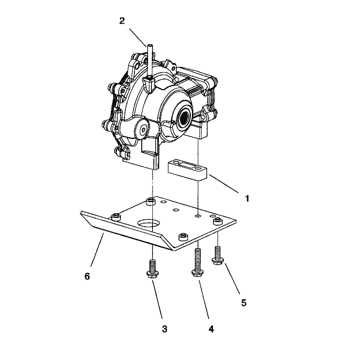

Key Features of New Holland Rustler’s Transmission

The transmission system of this utility vehicle is designed to offer optimal power delivery and smooth operation across various terrains. Key attributes include precision engineering, durability, and ease of use, ensuring the vehicle performs efficiently under diverse conditions.

- Multi-Speed Options: Multiple gear ratios provide flexibility in speed control, allowing operators to adjust performance based on the workload.

- Automatic Transmission: Facilitates seamless gear shifting without manual intervention, improving driving comfort and reducing operator fatigue.

- Heavy-Duty Components: The transmission is built with robust materials to withstand heavy loads, offering extended service life even in challenging environments.

- Efficient Power Transfer: The system ensures that engine power is transferred efficiently to the wheels, enhancing acceleration and overall performance.

- Enhanced Traction Control: A feature that optimizes wheel engagement for better control on slippery or uneven surfaces.

Importance of Electrical System in Rustler 125

The electrical setup plays a crucial role in ensuring the optimal operation of agricultural equipment. It powers various components such as lights, sensors, and control systems, which are essential for efficient functionality. A well-maintained electrical system contributes to the longevity and smooth performance of the machinery, reducing downtime and enhancing productivity on the field.

Key Functions of the Electrical System

- Power supply for ignition and starter mechanisms

- Operation of lighting and signaling systems for safety

- Control of sensors for monitoring engine and mechanical performance

- Ensures efficient communication between various system components

Maintenance and Troubleshooting

- Regular inspections to identify signs of wear or damage

- Prompt replacement of worn-out wires, connectors, and fuses

- Use of proper diagnostic tools for identifying electrical faults

How to Maintain the Suspension System

Proper maintenance of the suspension system is essential for ensuring a smooth ride and enhancing the vehicle’s overall stability. Regular checks and timely repairs help in extending the lifespan of the system and improve its performance under various conditions.

Start by inspecting the shock absorbers and struts for any signs of wear or damage. Leaking fluid or excessive rust on these components may indicate a need for replacement. Additionally, ensure that all bushings, joints, and mounts are intact and free from cracks or excessive play.

Lubrication of the suspension parts is crucial to reduce friction and avoid premature wear. Use high-quality grease and follow the manufacturer’s recommendations for the right intervals. Keep an eye on the alignment and balance of the vehicle, as misalignment can lead to uneven tire wear and compromised handling.

Finally, check the condition of the springs, as they bear the load of the vehicle and help in absorbing shocks. If they appear weak or sagging, replacing them can restore the system’s effectiveness and comfort.

Rustler 125: Brake and Steering Parts

In this section, we will explore the essential components responsible for controlling both the braking and steering systems of your vehicle. These mechanisms ensure smooth operation, safety, and precision during your rides, making their maintenance critical for optimal performance.

The braking system is designed to bring your vehicle to a stop efficiently, while the steering system provides the necessary control over direction. Each element in these systems plays a vital role in maintaining the balance and responsiveness of the vehicle.

Brake System Components

- Brake pads: Crucial for generating friction and slowing down the wheels.

- Brake discs: The surface against which the brake pads apply pressure to halt the motion.

- Calipers: The part that holds the brake pads and squeezes them against the discs.

- Brake fluid reservoir: Stores the hydraulic fluid necessary for brake pressure.

Steering System Components

- Steering wheel: The primary control used to direct the vehicle.

- Steering column: Connects the steering wheel to the rest of the steering mechanism.

- Rack and pinion: A key component that converts rotational motion into linear motion for steering.

- Power steering pump: Provides hydraulic pressure to assist in turning the wheels.

Wear and Tear in New Holland Rustler 125

Over time, every vehicle experiences natural degradation due to constant use and environmental factors. Understanding where this wear occurs and how to manage it is crucial for maintaining the vehicle’s performance and longevity. In the case of utility vehicles like this, certain components are more prone to wear and need regular attention to ensure smooth operation.

Common Areas of Wear

- Wheels and Tires: Constant contact with the ground leads to gradual wear. Uneven terrain accelerates this process, causing tires to lose grip and efficiency.

- Engine Components: Regular use can lead to the degradation of key engine parts such as belts, spark plugs, and filters.

- Transmission: The transmission undergoes significant stress, especially when used for towing or heavy-duty tasks.

- Suspension: The shocks and struts in the suspension system absorb impacts, leading to gradual wear and reduced ride quality over time.

- Brakes: Brake pads and discs wear down with every stop, demanding timely replacement to maintain safety.

Maintaining Performance

- Regular inspections and servicing will prevent excessive damage.

- Routine replacement of worn-out components ensures the vehicle continues to operate efficiently.

- Investing in high-quality parts can help extend the lifespan of the vehicle.

Upgrading the Wheels and Tires for Rustler

Enhancing the performance and appearance of your utility vehicle often begins with modifying its wheels and tires. This upgrade can provide better traction, improved durability, and a smoother ride, especially when navigating off-road terrains. Selecting the right combination of wheels and tires is essential for achieving optimal results, and it involves careful consideration of factors such as terrain type, vehicle weight, and driving conditions.

Choosing the Right Wheels

When selecting new wheels, it’s crucial to focus on factors like size, material, and design. Alloy wheels, for example, offer a lightweight option that can boost both acceleration and fuel efficiency. On the other hand, steel wheels are known for their strength and durability, making them ideal for heavy-duty use. Matching the wheels to your vehicle’s specifications ensures compatibility and enhances overall performance.

Selecting the Appropriate Tires

Tires play a critical role in handling and comfort, especially when driving over uneven or rugged surfaces. All-terrain tires are a versatile option that provides a balance between off-road grip and on-road comfort. Mud tires, with their deep treads, offer superior traction in challenging conditions, such as muddy or sandy areas. The right

Replacement Guides for Off-Road Utility Vehicle

Maintaining an off-road utility vehicle requires regular check-ups and occasional replacement of key components. Understanding the steps to identify and replace these essential parts is crucial for ensuring the longevity and performance of the machine. Below, we outline some common replacement processes that can help owners keep their vehicles in optimal condition.

Engine and Transmission Components

One of the most critical areas to monitor is the engine and transmission system. Regular maintenance and timely replacement of worn-out elements can prevent significant damage. Ensuring that these parts are inspected periodically can avoid unexpected failures during operation.

Suspension and Steering System

The suspension and steering system plays a vital role in handling and comfort. Replacing worn-out bushings, tie rods, and shock absorbers is essential for smooth rides, especially in rough terrain conditions. Pay attention to any unusual noises or handling issues, as these may signal the need for replacement.

| Component | Recommended Replacement Interval |

|---|---|

| Engine Filter | Every 50

Lubrication and Fluid Maintenance for Utility Vehicle

Proper lubrication and fluid management are essential for ensuring the longevity and efficient performance of any utility vehicle. Regular maintenance of all moving parts, as well as timely fluid changes, plays a critical role in reducing wear and tear, preventing breakdowns, and maintaining optimal functionality. Attention to these details will enhance the durability of the machine. Engine Oil and Filter MaintenanceOne of the key aspects of vehicle upkeep is checking and replacing the engine oil and filters at regular intervals. Keeping the oil clean and ensuring proper lubrication helps maintain engine performance, prevents overheating, and reduces internal friction. Always follow manufacturer-recommended intervals for oil changes to avoid unnecessary strain on the engine. Transmission and Hydraulic Fluid Check

In addition to engine oil, transmission and hydraulic fluids are critical to the smooth operation of the vehicle. These fluids should be regularly inspected for contamination and replaced when necessary. Adequate fluid levels ensure that the transmission system operates smoothly and that hydraulic components function without unnecessary wear. Common Repairs and Troubleshooting Tips

Maintaining any utility vehicle requires addressing common issues that may arise during regular use. Proper diagnosis of problems and applying appropriate fixes can significantly extend the life of the machine and prevent future breakdowns. Below are some frequent mechanical problems and solutions that can help identify and repair faults effectively. Engine TroublesEngine not starting: If the vehicle struggles to start, the problem may stem from the fuel system, battery, or ignition. First, ensure that the fuel lines are clear, and the fuel tank is filled. Check the battery for any signs of corrosion or low charge. Finally, inspect the ignition system for any loose connections or faulty components. Overheating: When the engine runs hotter than usual, it can indicate a coolant system issue. Make sure that the radiator is not clogged and the coolant levels are adequate. Additionally, examine the thermostat for proper functioning and replace it if needed. Electrical System IssuesLights malfunctioning: When lights flicker or fail to work, it is often due to a faul |