For efficient maintenance and smooth operation of machinery, it is essential to have a clear overview of how various elements fit and function together. This guide aims to help users visualize the placement of essential elements, ensuring both familiarity with their configuration and the ability to identify specific components when needed.

Knowing how systems are interconnected plays a crucial role in troubleshooting and regular upkeep. By recognizing the structure and arrangement, users can easily perform replacements, adjustments, and repairs with confidence.

This resource provides a comprehensive look at how each piece works in harmony, making it easier to maintain peak performance and avoid potential

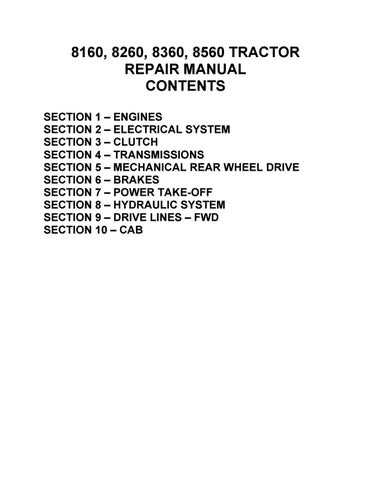

Understanding the New Holland TC30 System

The machinery’s system is designed to offer efficiency and performance for various tasks. Its mechanical components work together to ensure smooth operation, allowing users to manage a wide range of functions with ease. Every part within the system plays a crucial role in maintaining overall functionality, whether for everyday tasks or more demanding operations.

Key areas of focus within the equipment’s system include essential moving components that provide power, stability, and precision. Understanding how these sections are interconnected allows operators to optimize their use and address any potential issues efficiently.

When properly maintained, this machinery ensures consistent operation, making it a reliable choice for diverse applications. The balance between power and control in the system contributes to its effectiveness in various work environments.

Key Components in the TC30 Tractor

The core elements of this versatile machine are designed to ensure efficient performance in various agricultural and maintenance tasks. These fundamental parts work in harmony to provide a balance of power, control, and durability, enabling the tractor to handle different terrains and loads with ease.

Engine and Transmission

The engine, paired with a robust transmission system, plays a critical role in delivering the necessary power for both fieldwork and transport. The transmission offers multiple gear options, allowing for smooth adjustments based on speed and terrain requirements.

Hydraulic System and PTO

The hydraulic setup is essential for operating attachments and implements, providing the force needed for lifting and maneuvering tools. The power take-off (PTO) enables the tractor to drive various equipment, making it adaptable to a wide range of tasks.

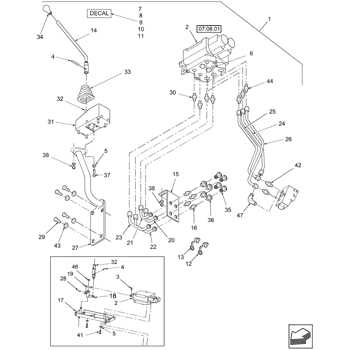

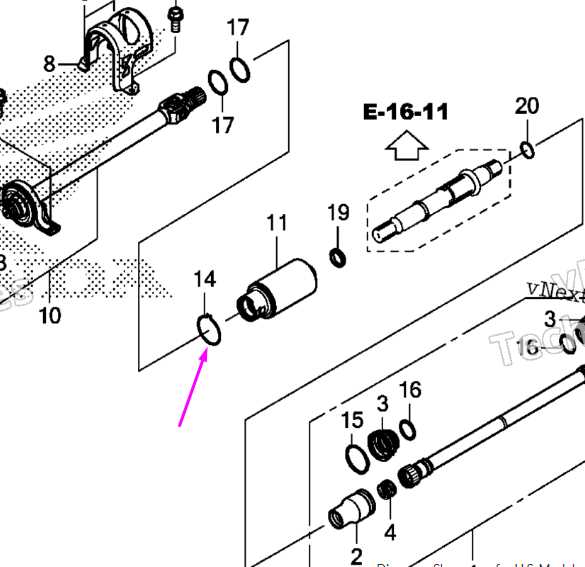

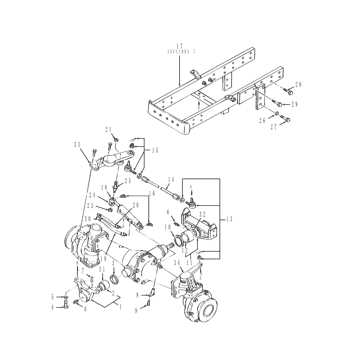

Hydraulic System Layout and Parts

The hydraulic system plays a critical role in ensuring the efficient operation of various components. Its design enables smooth movement, power transfer, and control, making it essential for the overall functionality of the equipment. Understanding how the elements are connected and how they interact is key to maintaining and troubleshooting the system.

Key Components Overview

At the heart of the system are several essential components that work together to manage fluid flow and pressure. These elements include the pump, control valve, cylinders, and various hoses and fittings. Each part is designed to handle specific pressures and ensure seamless power delivery to the corresponding mechanisms.

Component Connections

Proper connection and placement of each component ensure the system operates without issues. The layout generally follows a logical path

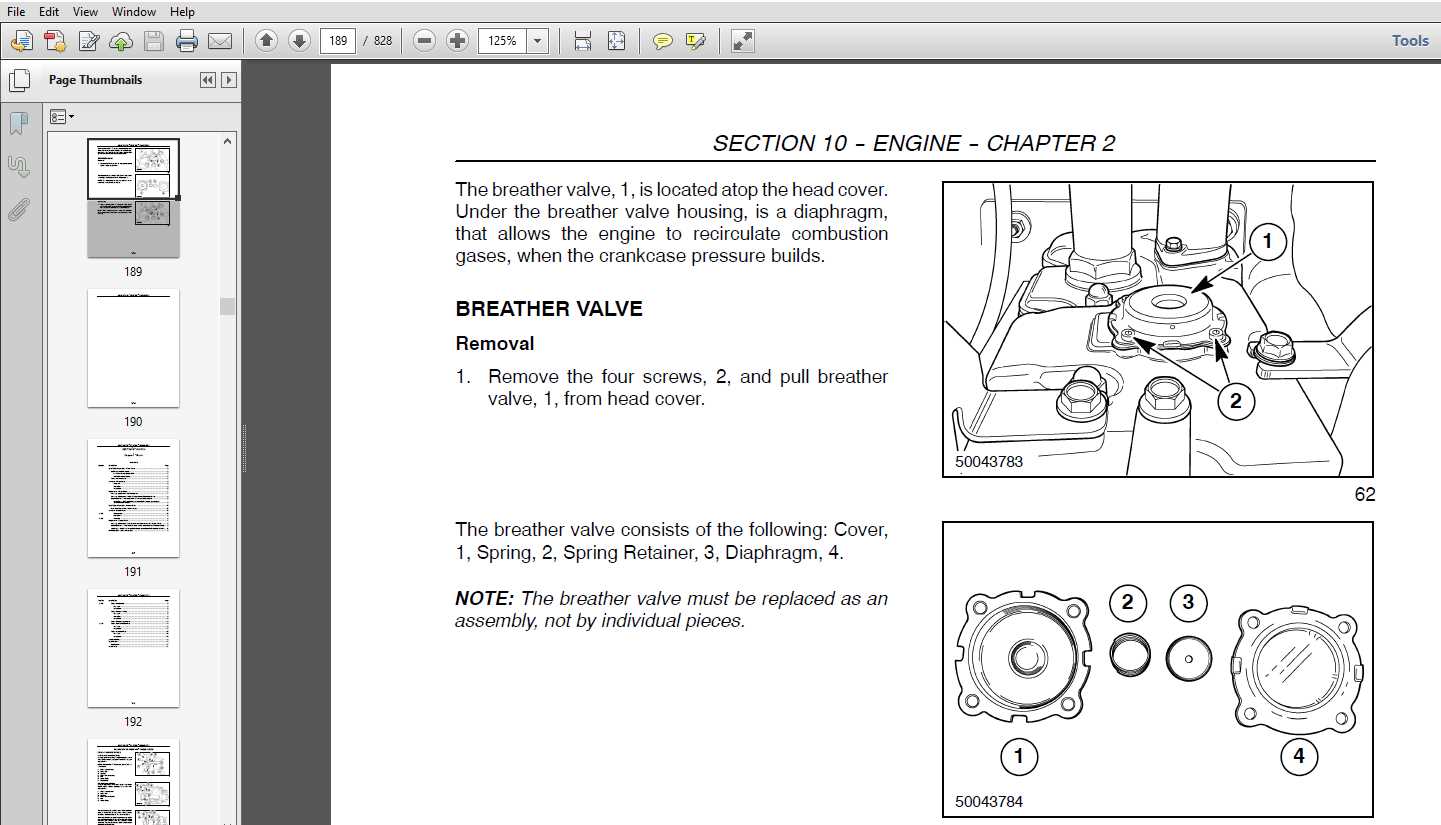

Engine Parts Overview for TC30

The engine in this model is a critical component that requires attention to several key elements for optimal performance. Understanding the structure and organization of these elements helps in maintaining and repairing the engine more effectively.

| Component | Description | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Cylinder Head | The upper part of the engine where combustion occurs. It contains vital components like valves and spark plugs. | ||||||||

| Pistons | These move within the cylinder, transforming fuel combustion into mechanical power. | ||||||||

| Crankshaft | Responsible for

Transmission Parts BreakdownThe transmission system plays a critical role in transferring power from the engine to the wheels, ensuring smooth and efficient movement. Understanding its components and how they work together is essential for maintaining peak performance. In this section, we’ll explore the main elements involved in this complex mechanism. Main Components

Maintenance Tips

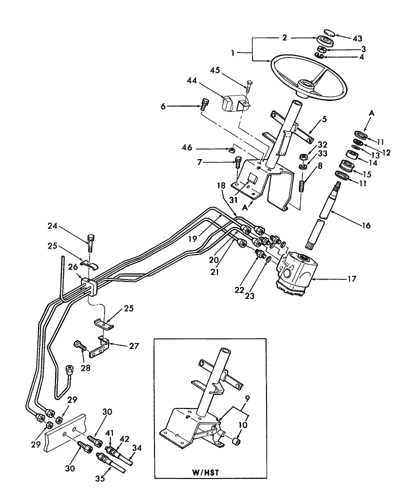

Steering Mechanism and Parts DiagramThis section provides an overview of the steering system, highlighting its essential components and their functions. Understanding this assembly is crucial for efficient operation and maintenance, ensuring optimal maneuverability and control. The steering system plays a vital role in directing the vehicle, making it indispensable for effective navigation across various terrains. Key ComponentsThe steering assembly consists of several integral elements, each serving a unique purpose. The steering wheel is the primary control interface, allowing the operator to dictate the direction of movement. Connecting rods transmit the rotational motion from the wheel to the steering gear, facilitating precise adjustments. Additionally, the gear mechanism converts the wheel’s motion into the desired angle of the front wheels, enabling smooth transitions during turns. Functionality Overview

Efficient operation of the steering assembly relies on the harmonious interaction between its components. As the operator turns the steering wheel, the connecting rods engage the gear mechanism, which, in turn, adjusts the angle of the front wheels. This seamless process ensures accurate steering control, enhancing the overall driving experience. Regular inspections and maintenance of these components are essential to prevent wear and ensure reliable functionality. Electrical System ComponentsThe electrical system is a crucial aspect of modern machinery, playing a vital role in the overall functionality and efficiency of the equipment. It encompasses various elements that work together to ensure proper operation, providing power to essential components and facilitating communication between different systems. Understanding these components is key to maintaining and troubleshooting any issues that may arise. Wiring Harness

The wiring harness serves as the central nervous system of the electrical framework, connecting all components and allowing for the distribution of electrical signals. It consists of multiple wires bundled together, designed to withstand harsh environments while providing reliable connectivity. Proper maintenance of the wiring harness is essential for preventing electrical failures. Switches and RelaysSwitches and relays play a pivotal role in controlling electrical circuits within the system. Switches enable users to manually operate various functions, while relays act as automated switches, allowing low-power signals to control high-power circuits. Understanding the function and operation of these devices is critical for effective troubleshooting and ensuring optimal performance. Front Axle and Suspension Components

This section focuses on the critical elements associated with the front axle and suspension system, essential for maintaining stability and control in various terrains. Understanding these components is crucial for ensuring optimal performance and longevity of the machinery. Proper maintenance and timely replacement of these elements can significantly enhance operational efficiency. Key Elements of the Axle System

The axle system consists of several integral components that work together to provide support and enable smooth movement. Each part has a specific role, contributing to the overall functionality of the vehicle.

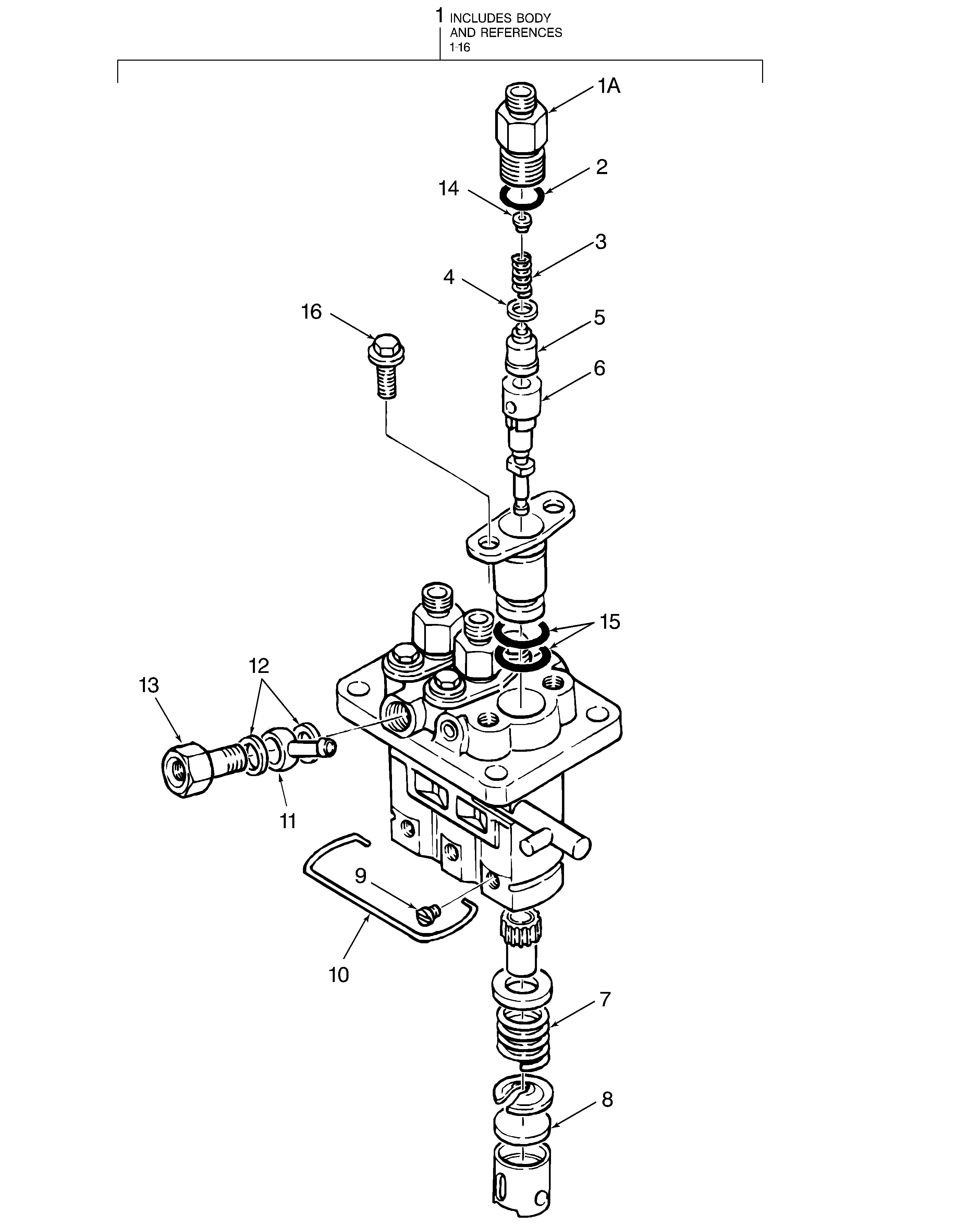

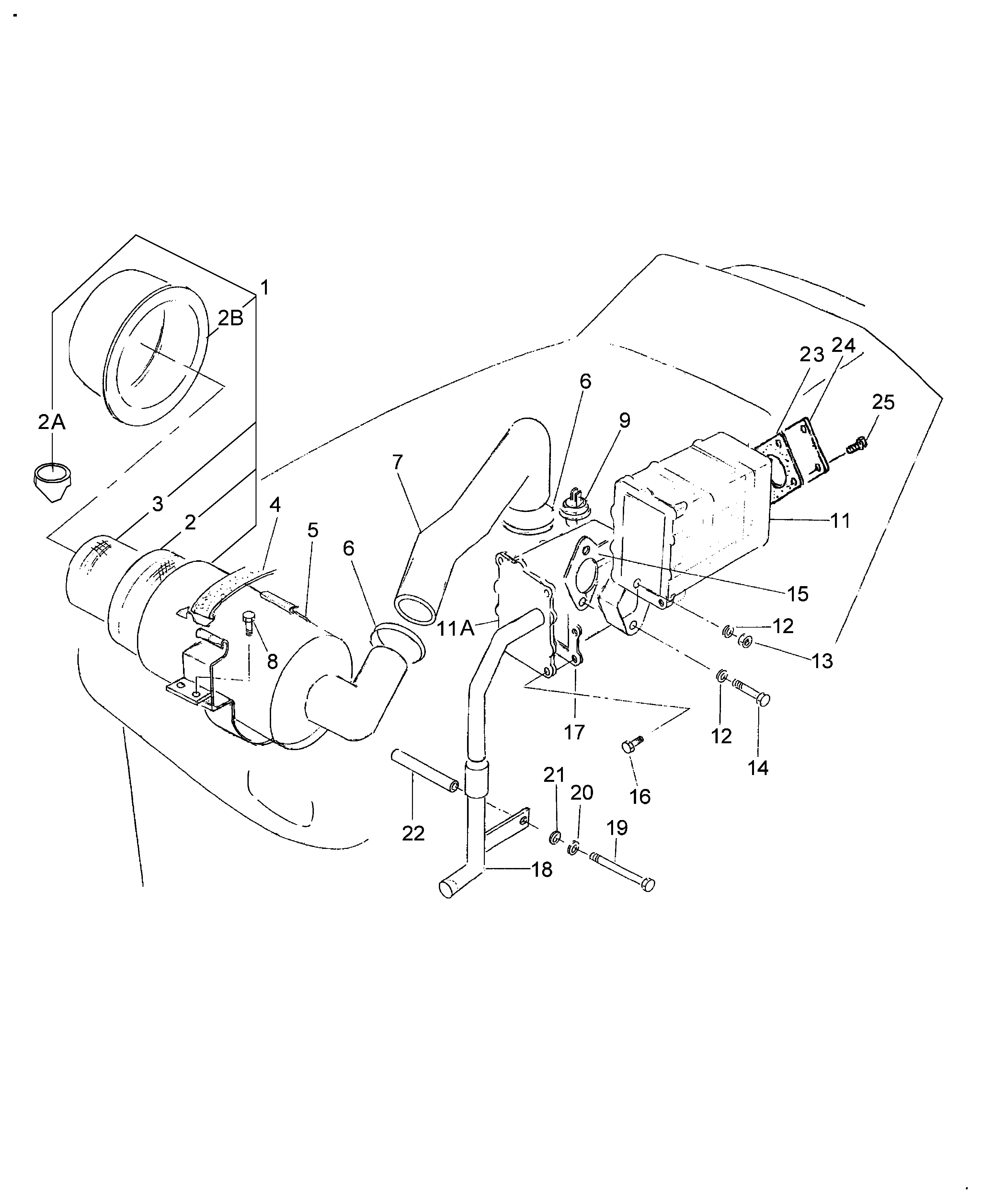

Importance of Regular InspectionRegular checks and maintenance of the front axle and suspension components are vital for safety and performance. Neglecting these components can lead to severe issues, affecting overall operation. By staying proactive in maintenance, one can prevent unnecessary repairs and extend the machinery’s lifespan. Cooling System Parts and FunctionThe cooling mechanism is essential for maintaining optimal operating temperatures in machinery. This system effectively regulates engine heat, preventing overheating and ensuring smooth performance. By understanding the components involved, one can appreciate their roles in enhancing the efficiency and longevity of the equipment. Radiator: The radiator plays a crucial role in dissipating heat from the coolant. It facilitates the transfer of heat to the surrounding air, thereby lowering the temperature of the fluid before it circulates back to the engine. Water Pump: This component is responsible for circulating coolant throughout the system. It ensures a steady flow, which is vital for maintaining consistent engine temperatures and preventing local hot spots. Thermostat: The thermostat regulates the flow of coolant based on temperature readings. By opening and closing as needed, it maintains an ideal operating temperature, optimizing performance. Coolant Hoses: These flexible tubes transport coolant between various system components. Their design allows for the necessary expansion and contraction as temperatures change, ensuring a secure and efficient flow. Cooling Fan: The fan assists in airflow across the radiator, enhancing heat dissipation. It is particularly important during low-speed operations or when the engine is under load, where natural airflow may be insufficient. Each of these elements works synergistically to ensure that the machinery operates within safe temperature limits, ultimately contributing to its reliability and performance. Fuel System Components LayoutThe layout of the fuel system is essential for ensuring optimal performance and efficiency in machinery. This system comprises various elements that work together to deliver fuel from the tank to the engine, Rear Axle Assembly and PartsThe rear axle assembly is a crucial component of any agricultural machinery, playing a vital role in the overall performance and stability of the equipment. This section will explore the various components that comprise this assembly, highlighting their functions and importance in maintaining operational efficiency. Understanding the intricate details of the rear axle system can significantly enhance the longevity and reliability of the machinery. Key components of the rear axle assembly include the axle housing, differential, wheel hubs, and drive shafts. Each part serves a specific purpose, working in harmony to ensure smooth transmission of power from the engine to the wheels. The axle housing provides structural support and houses essential elements, while the differential allows for effective power distribution during turns. Wheel hubs connect the wheels to the axle, facilitating movement, and drive shafts transmit torque from the engine. Regular inspection and maintenance of the rear axle assembly are essential for preventing wear and tear. Issues such as leaks, unusual noises, or difficulty in steering may indicate a problem within the assembly. Addressing these concerns promptly can help avoid more significant repairs down the line, ensuring that the machinery continues to operate at peak performance. Braking System Components OverviewThe braking mechanism is crucial for ensuring safety and control during operation. It consists of various elements that work in harmony to facilitate effective stopping power and stability. Understanding the functionality of these components can enhance maintenance and performance. Brake Pedal: The user engages the system through this interface, initiating the braking process. It translates the operator’s input into hydraulic pressure, enabling the system to function effectively. Hydraulic Actuator: This component converts the force from the brake pedal into hydraulic pressure, which then activates the brakes. It is essential for achieving consistent stopping performance. Brake Lines: These conduits carry hydraulic fluid from the actuator to the braking units. They must be in good condition to ensure reliable transmission of pressure. Brake Calipers: Positioned at the wheels, these devices clamp down on the braking surfaces to create friction, slowing down the machine. Proper maintenance is vital for optimal performance. Friction Discs: These components provide the surface against which the calipers press. Their condition directly affects the overall braking efficiency, making regular inspections important. Understanding the intricacies of these components is essential for effective troubleshooting and maintenance, ensuring safe operation over time. Understanding PTO Parts and Mechanism

The Power Take-Off (PTO) system is crucial in various agricultural machinery, enabling the transfer of engine power to different attachments and implements. Understanding its components and functionality is essential for efficient operation and maintenance. This section delves into the primary elements of the PTO mechanism, highlighting their roles and significance. The main components of a PTO system typically include:

Proper maintenance and understanding of these components can lead to improved performance and longevity of the machinery. Regular checks can help identify wear and tear, ensuring the system functions smoothly. In conclusion, familiarity with the PTO mechanism not only enhances operational efficiency but also contributes to the safety and reliability of agricultural equipment. Knowing each part’s role fosters better decision-making in maintenance and troubleshooting. |