When working with robust off-road machines, it’s essential to have a comprehensive view of how various mechanical elements fit together to ensure optimal performance. Knowing the layout of key assemblies helps not only with repairs but also with regular maintenance, ensuring that your vehicle remains reliable over time. Every section, from the suspension system to the drive train, plays a crucial role in the machine’s functionality and resilience.

Each component is carefully designed to work in harmony, making it vital to understand how they interconnect. Whether you are upgrading specific elements or performing routine maintenance, having a clear visual reference can significantly streamline the process. This guide will help you navigate through the essential elements, providing

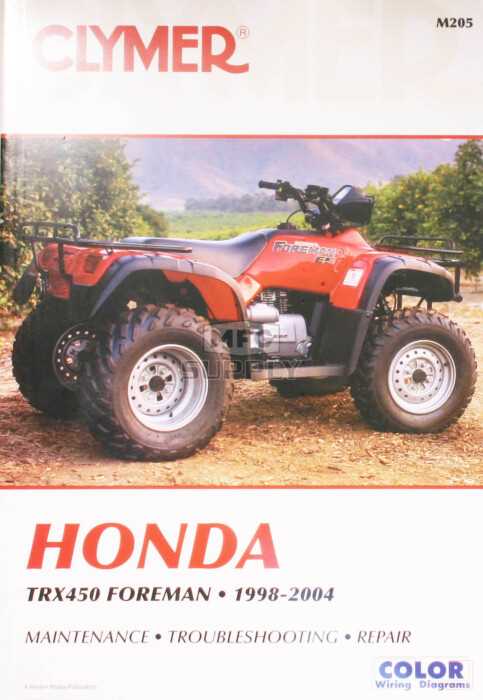

Comprehensive Breakdown of 2001 Honda Foreman 450 Components

In this section, we provide a detailed overview of the essential elements that make up the functionality and durability of this robust vehicle. By understanding the key features and how various components work together, you can ensure optimal performance and longevity. From the engine to the suspension system, each part plays a crucial role in delivering the reliability expected from a powerful all-terrain machine.

The mechanical structure is designed for rugged conditions, allowing users to tackle diverse terrains with ease. The core framework supports the engine’s strength, while the suspension and braking systems offer control and safety during challenging rides. These mechanisms, when maintained properly, ensure that the machine operates efficiently across varying environments.

Examining the individual systems, such as the transmission and electrical wiring

Key Systems of the 2001 Honda Foreman

The vehicle is equipped with a variety of essential mechanisms that work together to ensure reliable performance across various terrains. Each of these systems plays a critical role in maintaining balance, efficiency, and durability, making the machine suitable for heavy-duty tasks and outdoor activities.

Powertrain: The engine and transmission assembly deliver the necessary strength for off-road handling and carrying loads. The integration of an efficient gear system ensures smooth transitions, providing stability and control under diverse conditions.

Suspension: Built to absorb shocks and maintain comfort, the suspension system supports the frame during rugged journeys. It enhances maneuverability while safeguarding both the operator and the chassis from excessive wear.

Braking System: Designed for safety, the braking components provide controlled

Exploring the Engine Layout and Parts

The inner workings of this all-terrain vehicle’s engine involve a complex yet efficient system of components designed for durability and performance. Understanding the arrangement of these key elements is essential for maintaining optimal functionality and ensuring long-term reliability. By examining the core units, such as the combustion chamber and power transmission sections, we can gain insight into how each segment contributes to the vehicle’s overall capability.

One of the most significant aspects to consider is the interplay between the cylinder configuration, fuel system, and cooling mechanism. Each component has been engineered to handle rough terrain, heavy loads, and continuous operation. Together, they create a harmonious system that ensures the machine can withstand various challenges while delivering consistent power and performance.

Another crucial factor is the positioning of the engine’s key structural parts, which have been meticulously aligned to optimize airflow and heat dissipation. This not

Understanding the Suspension System

The suspension system plays a crucial role in ensuring a smooth and controlled ride. It absorbs the impact from uneven terrain and allows the vehicle to maintain stability. This mechanism is essential for both performance and comfort, as it reduces the strain on other components and minimizes the effects of rough surfaces on the operator.

To better comprehend how this system works, it’s important to explore the key elements that contribute to its overall function:

- Shock absorbers: These devices manage the energy from impacts, preventing excessive bouncing or jolts.

- Springs: They bear the weight of the vehicle and maintain the necessary clearance between the frame and the ground.

- Linkage components: These connect the suspension to the wheels and allow for flexible movement, ensuring proper wheel alignment during motion.

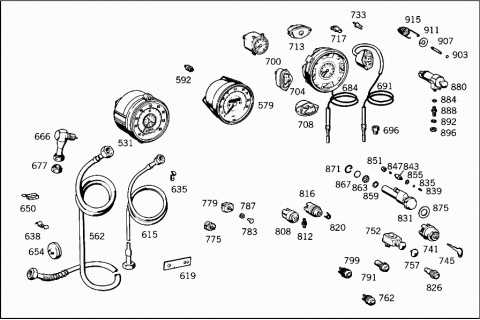

Detailed Look at the Electrical Components

The electrical system plays a crucial role in ensuring smooth operation and reliability. By understanding its individual elements, one can effectively manage maintenance and identify potential issues. This section focuses on breaking down the primary units that control power distribution and the related circuits.

Power Distribution Unit

The main hub responsible for delivering energy to various sections, this unit regulates the voltage and ensures proper allocation. It interacts with a network of fuses, relays, and wiring, each safeguarding specific functions within the system.

Lighting and Indicators

Lighting elements and signal indicators are essential not only for visibility but also for safety. The wiring responsible for these components is interconnected with switches and relays, allowing for seamless control of headlights, tail lights, and turn signals. Regular inspection of these circuits helps prevent unexpected failures.

Analyzing the Braking Mechanism

The functionality of a reliable stopping system is crucial for ensuring both safety and control during operation. Understanding how the braking system works involves exploring various components that interact to reduce motion, converting kinetic energy into heat through friction or pressure. This section breaks down the core elements of the system and how they work in harmony to deliver smooth, efficient deceleration.

Key Components

- Brake levers and controls, which initiate the braking process.

- The braking assembly that applies pressure to the wheels.

- Lines and cables that transfer force from the control mechanism to the braking assembly.

Understanding Friction and Pressure

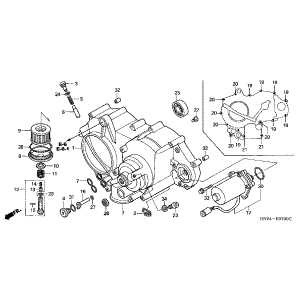

Transmission and Drivetrain Overview

The transmission system plays a crucial role in ensuring smooth power delivery to the wheels, allowing for efficient operation across different terrains. It seamlessly transfers engine energy to the drivetrain, adjusting torque and speed to suit various riding conditions. Understanding the key components involved in this process helps to ensure reliable performance and longevity.

The drivetrain works in tandem with the transmission to effectively transmit power from the engine to the wheels. It is designed to handle changes in speed and torque, ensuring optimal traction and stability. The components within this system are built to endure challenging environments, making maintenance and proper adjustment essential for continued functionality.

Chassis and Frame Structure Explained

The framework of a vehicle plays a crucial role in ensuring its stability, safety, and performance. This structure not only supports the weight of the various components but also absorbs shocks from the terrain. Understanding the intricacies of this foundational element is essential for any enthusiast or technician aiming to maintain or enhance vehicle functionality.

Importance of the Chassis

The chassis serves as the backbone of any automobile, providing a solid foundation for the body and engine. It is designed to withstand various forces and impacts, ensuring that all parts function harmoniously. A well-engineered framework contributes significantly to the overall durability and longevity of the vehicle, making it vital for off-road adventures and rugged terrains.

Frame Design Variations

There are several types of frame designs, each tailored for specific purposes. For instance, a tubular frame offers lightweight yet robust characteristics, ideal for performance-oriented models. On the other hand, a ladder frame provides enhanced rigidity, making it suitable for heavy-duty applications. Understanding these design differences can aid in selecting the right vehicle for your needs and optimizing its performance.

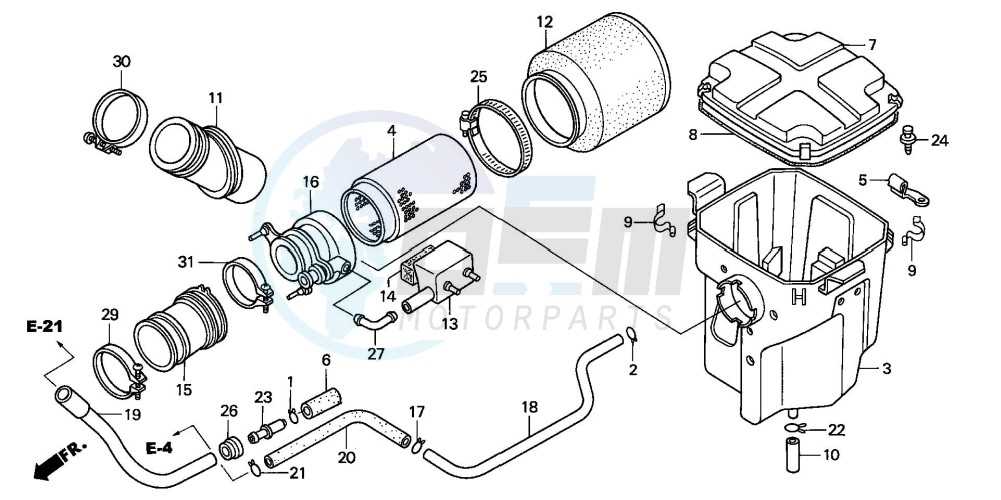

Fuel System Configuration in Detail

The fuel system in an all-terrain vehicle is crucial for its efficient operation and overall performance. This system is responsible for delivering the appropriate amount of fuel to the engine, ensuring optimal combustion and power generation. A thorough understanding of its components and their functions is essential for maintenance and troubleshooting.

Key Components of the Fuel System

The primary elements that constitute this system include the fuel tank, fuel pump, fuel filter, and carburetor. The fuel tank serves as the reservoir for storing the liquid energy source. It is designed to prevent leakage and withstand various environmental conditions. The fuel pump, typically located within or near the tank, is responsible for transporting fuel to the engine under pressure.

Fuel Delivery Process

Once the fuel is pumped from the tank, it passes through a fuel filter to remove impurities and debris that could potentially damage the engine components. The clean fuel then travels to the carburetor, where it is mixed with air to create an optimal air-fuel mixture for combustion. This process is vital for achieving efficient fuel consumption and maximizing power output.

In summary, a well-configured fuel system is fundamental for the reliable performance of the vehicle. Regular maintenance and understanding of its components can prevent operational issues and enhance the overall longevity of the engine.

Tires, Wheels, and Axle Assembly

The assembly of wheels, tires, and axles plays a crucial role in the overall performance and handling of an all-terrain vehicle. This component ensures that the vehicle maintains stability and traction across various terrains while also supporting its weight. Proper maintenance and understanding of each element within this assembly can enhance the longevity and efficiency of the vehicle.

The tire selection significantly influences grip and ride quality. Factors such as tread pattern, size, and material composition affect performance in diverse environments. The wheels must be compatible with the tire dimensions, as well as the vehicle’s axle specifications, to ensure a secure fit and optimal performance.

Component Description Function Tires Rubber coverings that provide traction and cushioning Support vehicle weight and enhance grip on surfaces Wheels Rims that hold the tires in place Allow rotation and transfer power from the axle Axles Rod-like structures connecting wheels Bear weight and facilitate wheel rotation Maintenance Tips for Key Parts

Ensuring the longevity and optimal performance of your vehicle involves regular upkeep of its essential components. This section will explore effective strategies to maintain critical elements, enhancing reliability and minimizing the need for costly repairs.

Engine Care

- Regularly check and change the oil to prevent sludge buildup and ensure smooth operation.

- Inspect the air filter frequently; replace it as needed to promote efficient airflow and engine performance.

- Monitor coolant levels and replace coolant at recommended intervals to avoid overheating issues.

Tire Maintenance

- Check tire pressure regularly to ensure optimal traction and fuel efficiency.

- Inspect tread depth and replace tires showing signs of excessive wear for improved safety.

- Rotate tires periodically to promote even wear and extend their lifespan.