High-Strength All

Fuel System Design and Functionality

The design and functionality of a fuel delivery system play a crucial role in the overall performance of a vehicle. This system is engineered to ensure efficient combustion by managing the flow and distribution of fuel to the engine. A well-designed fuel delivery mechanism enhances power output, optimizes fuel efficiency, and reduces emissions.

The components involved in this system are intricately connected, working together to achieve optimal performance. Key elements include the fuel tank, fuel pump, fuel filter, and fuel injectors. Each component serves a specific purpose, contributing to the seamless operation of the entire system.

| Component |

Function |

| Fuel Tank |

Stores the fuel until needed by the engine. |

| Fuel Pump |

Delivers fuel from the tank to the engine. |

| Fuel Filter |

Removes impurities from the fuel before it reaches the engine. |

| Fuel Injectors |

Spray fuel into the combustion chamber for optimal mixing with air. |

Understanding the interplay of these components is essential for diagnosing issues related to fuel delivery. Regular maintenance and inspection can prevent problems that may arise from wear and tear, ensuring the longevity and reliability of the system.

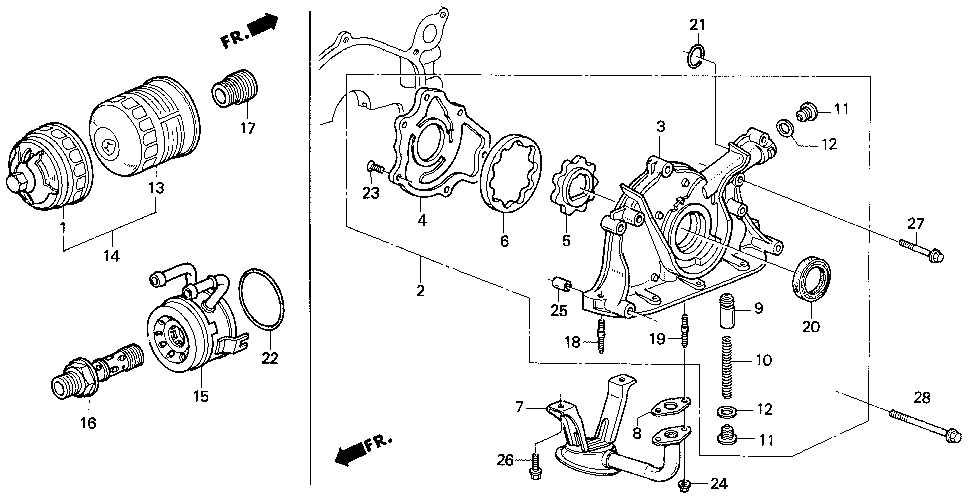

Transmission and Drivetrain Configuration

The arrangement of power transfer and motion in vehicles plays a crucial role in their performance and efficiency. This section explores the fundamental components that contribute to the seamless operation of these systems, ensuring optimal power delivery from the engine to the wheels.

Key Components

- Transmission: Responsible for adjusting the engine’s power to provide the appropriate speed and torque.

- Drive Shaft: Transfers power from the transmission to the differential, enabling the vehicle’s movement.

- Differential: Allows the wheels to rotate at different speeds, especially during turns.

- Axles: Connect the differential to the wheels, transmitting power while supporting the vehicle’s weight.

Functionality Overview

The drivetrain system works in harmony to optimize the vehicle’s capabilities. The transmission modulates engine output based on driving conditions, while the drive shaft efficiently channels this power to the differential. This setup ensures that each wheel receives the necessary force for smooth operation, enhancing both maneuverability and stability.

Cooling Mechanism and Radiator Placement

The effectiveness of an engine’s thermal management system is crucial for optimal performance and longevity. A well-designed cooling system ensures that the engine maintains an ideal operating temperature, preventing overheating and associated damage. Central to this system is the component responsible for dissipating heat, which plays a significant role in regulating engine temperature.

Functionality of the Cooling System

This mechanism primarily relies on the circulation of coolant to absorb heat from the engine. The heated fluid is then directed to the radiator, where it releases heat into the atmosphere. The process not only protects the engine but also enhances efficiency by maintaining the appropriate temperature range for combustion.

Radiator Location and Design

The placement of the heat dissipation unit is strategically designed to maximize airflow. Typically positioned at the front of the vehicle, it ensures that the incoming air effectively cools the fluid as it passes through the radiator’s fins. This layout is essential for maintaining efficient cooling, particularly during high-performance scenarios.

| Component |

Function |

| Coolant |

Transfers heat from the engine to the radiator |

| Radiator |

Dissipates heat from the coolant into the air |

| Thermostat |

Regulates coolant flow based on temperature |

| Cooling Fans |

Enhance airflow through the radiator during low-speed conditions |

Detailed View of Brake System Parts

The braking system is crucial for ensuring safety and control in any vehicle. Understanding its components helps in maintaining performance and addressing potential issues effectively. This section provides an in-depth look at the essential elements involved in the braking mechanism.

- Brake Pads: These are the friction materials that press against the rotor to create the necessary stopping force. Regular inspection and replacement are vital for optimal braking efficiency.

- Brake Rotors: Attached to the wheel hub, these circular metal discs receive pressure from the brake pads. They can become warped over time, affecting performance.

- Calipers: This component houses the brake pads and pistons. When the brake pedal is pressed, the calipers exert pressure, pushing the pads against the rotors.

- Brake Lines: These flexible tubes carry brake fluid from the master cylinder to the calipers. They must be inspected for leaks or damage to ensure the system functions properly.

- Master Cylinder: This hydraulic device generates pressure in the brake fluid, facilitating the movement of the brake components. Its functionality is critical for effective braking.

Regular maintenance and timely replacement of these components can significantly enhance the vehicle’s safety and reliability. Understanding each element’s role is essential for anyone looking to ensure their braking system operates efficiently.

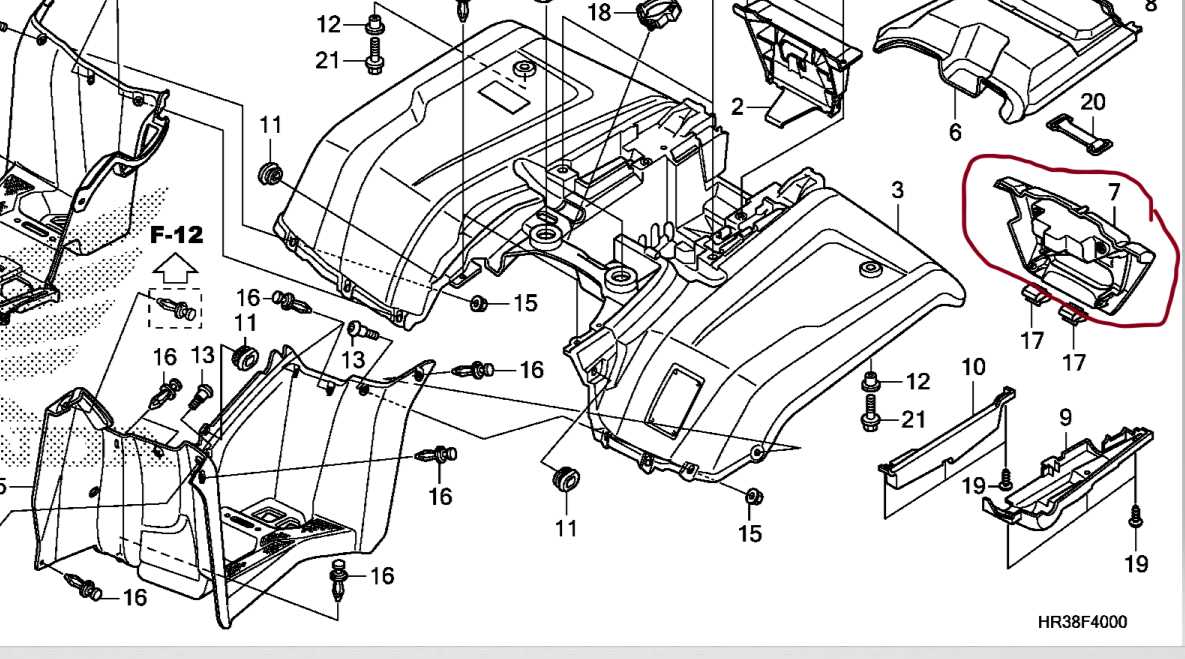

Handlebar and Control Elements Mapping

This section focuses on the arrangement and functionality of the various controls located on the handlebar of all-terrain vehicles. Understanding the layout and purpose of these components is essential for safe and effective operation. Each element plays a crucial role in the rider’s interaction with the machine, influencing handling and overall riding experience.

Key Components and Their Functions

At the forefront are the throttle and brake controls, vital for managing speed and stopping the vehicle. The throttle is typically located on the right side, allowing the rider to accelerate smoothly. In contrast, the brake lever, found on the left, provides immediate stopping power. Additionally, the presence of switches for lights and indicators enhances visibility and communication with other road users, promoting safety.

Ergonomics and User Comfort

The design of the handlebars is not only functional but also tailored for user comfort. Proper positioning ensures that riders can maintain control without strain. Features like adjustable grips and lever placements contribute to a more personalized riding experience, accommodating various preferences and hand sizes. Ultimately, a well-mapped handlebar setup allows for a more intuitive and enjoyable ride.

Wiring Harness Connections and Routing

This section focuses on the connections and routing of electrical systems within the vehicle. Properly managing the wiring harness is crucial for ensuring that electrical signals are transmitted efficiently throughout the various components. Understanding the layout and organization of these connections can help diagnose issues and maintain optimal performance.

When working with electrical systems, it is essential to follow the designated routing paths to prevent damage to the wiring. The connections should be secured and insulated to protect against environmental factors and wear. Here are some key aspects to consider:

| Connection Type |

Purpose |

Routing Considerations |

| Ground Connections |

Establish a reference point for the electrical system |

Avoid corrosion by ensuring they are clean and securely attached |

| Power Connections |

Supply voltage to various components |

Route away from heat sources to prevent insulation damage |

| Signal Connections |

Transmit data between sensors and control units |

Keep away from high-current wires to reduce interference |

Regular inspections of the wiring harness and connections can identify wear or damage early, allowing for timely repairs. This proactive approach not only enhances reliability but also extends the lifespan of the electrical components.