In the realm of all-terrain vehicles, grasping the intricate layout of individual elements is essential for both enthusiasts and casual users. A thorough understanding of these components not only enhances maintenance but also improves overall performance. This section delves into the specifics of the assembly, providing insight into the interrelations among various parts.

Every machine is a marvel of engineering, where each component plays a pivotal role in ensuring seamless operation. From the engine to the suspension system, the complexity of these vehicles demands careful attention. By familiarizing oneself with the arrangement and function of each part, owners can better appreciate their ride and tackle repairs more effectively.

Additionally, visual aids serve as valuable resources for identifying and sourcing replacements. These illustrations facilitate a clearer comprehension of how each section fits into the larger picture, enabling users to make informed decisions regarding upgrades and repairs. Understanding these diagrams can empower vehicle owners to enhance the longevity and efficiency of their beloved machines.

Understanding the Honda Rincon 680

The vehicle in question represents a remarkable blend of power, versatility, and innovative engineering. Designed for those who seek adventure and capability in rugged terrains, it offers a unique riding experience that stands out in its category. This machine is built not only for performance but also for reliability, making it a favored choice among enthusiasts.

Key Features: At its core, this model is equipped with a robust engine that ensures impressive torque and acceleration. The advanced suspension system enhances stability, allowing riders to navigate through various landscapes with ease. Additionally, the ergonomic design of the seating provides comfort during long journeys, making it suitable for both leisure and utility purposes.

Maintenance and Customization: Understanding the components and their functions is crucial for proper upkeep. Familiarity with the internal structure aids in troubleshooting and enhances the overall longevity of the vehicle. Customization options are also plentiful, allowing owners to tailor their ride to meet specific needs or personal preferences.

In conclusion, this exceptional vehicle encapsulates the spirit of exploration. Its engineering excellence and user-friendly design make it a valuable asset for anyone looking to embark on new adventures.

Key Features of the 2007 Model

This model stands out in its category due to a combination of advanced technology and robust design. It showcases a harmonious blend of performance, comfort, and versatility, making it suitable for various terrains and activities. Enthusiasts appreciate its reliability and user-friendly features, which enhance both leisure and work experiences.

| Feature | Description |

|---|---|

| Engine Performance | Equipped with a powerful engine that delivers excellent torque and horsepower, ensuring smooth operation in diverse conditions. |

| Suspension System | Advanced suspension technology offers superior handling and stability, providing a comfortable ride over rough surfaces. |

| Ergonomic Design | Thoughtfully designed seating and controls enhance comfort, making it ideal for long rides or demanding tasks. |

| Durability | Constructed with high-quality materials to withstand challenging environments, ensuring longevity and minimal maintenance. |

| Utility Features | Includes multiple storage options and towing capabilities, making it practical for a range of applications, from work to recreation. |

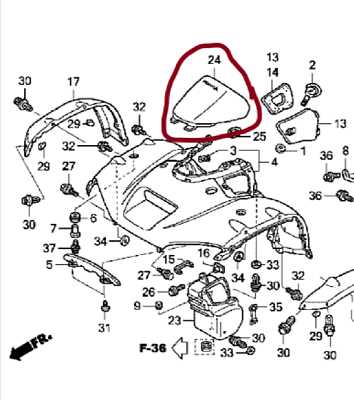

Common Parts in the Parts Diagram

This section focuses on frequently encountered components within the visual representation of the machine’s assembly. Understanding these elements is essential for maintenance and repair, ensuring optimal performance and longevity.

- Engine Assembly: The heart of the vehicle, responsible for power generation.

- Transmission System: This unit manages power distribution to the wheels.

- Suspension Components: These parts enhance stability and comfort during rides.

- Braking System: Critical for safety, these components ensure effective stopping power.

- Fuel System: This assembly is vital for delivering the necessary energy to the engine.

Each of these elements plays a pivotal role in the overall functionality and reliability of the vehicle. Familiarity with these components can greatly assist in troubleshooting and repairs.

- Inspect the engine assembly for signs of wear or damage.

- Ensure the transmission system operates smoothly without slipping.

- Check the suspension components for any signs of wear that may affect handling.

- Regularly test the braking system for responsiveness and efficiency.

- Monitor the fuel system for leaks or blockages.

By regularly reviewing and maintaining these key components, users can ensure a safe and enjoyable riding experience.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring your vehicle operates smoothly and efficiently. By following a structured maintenance routine, you can enhance performance and extend the lifespan of your machine. Here are some key strategies to keep in mind.

- Fluid Checks: Regularly inspect and replace essential fluids, including engine oil, coolant, and brake fluid. Clean fluids are crucial for optimal performance.

- Tire Maintenance: Ensure tires are properly inflated and tread is within safe limits. Rotate them periodically to promote even wear.

- Air Filter Replacement: Replace the air filter as recommended to maintain proper airflow to the engine, enhancing combustion efficiency.

- Belt and Chain Inspection: Check drive belts and chains for wear and tension. Replace any components that show signs of damage.

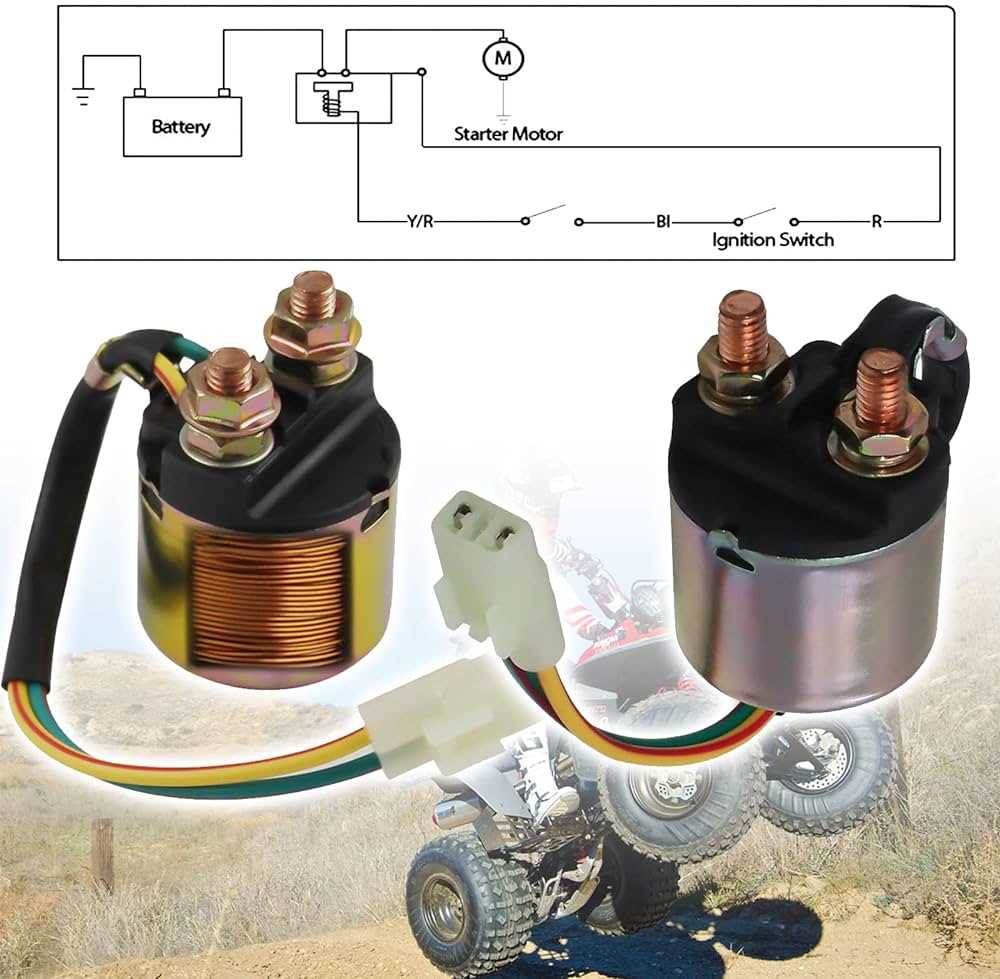

- Battery Care: Keep the battery terminals clean and check the charge regularly. A well-maintained battery is vital for reliable starts.

By implementing these practices, you can ensure that your machine remains in peak condition, providing you with a reliable and enjoyable experience every time you take it out.

Identifying Essential Components Easily

Understanding the crucial elements of a vehicle can significantly enhance maintenance and repair efforts. Familiarity with these components not only streamlines the troubleshooting process but also empowers owners to make informed decisions regarding their machines.

Key Elements to Recognize

- Engine Assembly

- Transmission System

- Suspension Components

- Electrical System

- Braking Mechanism

Steps for Identification

- Consult the owner’s manual for a comprehensive overview.

- Utilize online resources to view detailed illustrations.

- Label each component during inspection for easier reference.

- Join forums or communities for shared insights and tips.

By systematically approaching the identification of vital parts, owners can ensure their vehicles operate at peak performance while reducing the likelihood of costly repairs.

Where to Find Replacement Parts

Locating the right components for your vehicle can be a straightforward process if you know where to look. Whether you need specific items for maintenance or upgrades, several avenues offer quality solutions. Below are some effective resources to help you source the necessary components.

- Authorized Dealerships: Visiting official dealerships ensures you receive genuine items designed for your model. They often have a comprehensive inventory and knowledgeable staff to assist you.

- Online Retailers: Numerous e-commerce platforms specialize in automotive equipment. Websites like Amazon, eBay, and dedicated automotive sites provide a vast selection, often with customer reviews to guide your choices.

- Local Auto Parts Stores: Neighborhood shops can be a convenient option for immediate needs. Many offer a range of components and can often order specific items on request.

- Salvage Yards: For budget-conscious individuals, salvage yards can be a treasure trove. You might find gently used items at a fraction of the cost, but ensure to check their condition carefully.

- Specialty Forums and Communities: Engaging with online forums or local clubs dedicated to your vehicle type can provide valuable insights. Members often share recommendations for reliable suppliers and may even sell parts directly.

- Manufacturer Websites: Many manufacturers offer online catalogs where you can search for specific components. This can help you identify compatible items and provide direct purchasing options.

lessCopy code

By exploring these various sources, you can confidently find the components you need, ensuring your vehicle remains in optimal condition.

Comparing Models: 2007 vs. Others

When evaluating different models from a specific year against their contemporaries, it’s essential to consider various aspects that influence performance, design, and usability. Each variant offers unique features and specifications that cater to specific user needs, which can significantly affect the overall experience. This comparison sheds light on how these variations stack up against each other.

Performance and Features

Different models often showcase a range of performance metrics, including engine output, handling, and technological advancements. These characteristics can lead to varying experiences for users, particularly in off-road settings where agility and power are crucial.

Specifications Overview

| Model | Engine Type | Horsepower | Weight | Suspension |

|---|---|---|---|---|

| Model A | Single Cylinder | 50 hp | 700 lbs | Independent Front |

| Model B | V-Twin | 65 hp | 750 lbs | Dual A-Arm |

| Model C | Single Cylinder | 55 hp | 720 lbs | Independent Rear |

By analyzing these specifications, users can make informed decisions based on their preferences and intended use. Ultimately, understanding the differences among various models enhances the buying experience and ensures satisfaction in the long run.

Assembly and Disassembly Guidelines

Proper techniques for assembling and disassembling mechanical components are essential for maintaining functionality and longevity. Following systematic steps can prevent damage and ensure a smooth process. This section outlines key practices to follow when handling parts.

Preparation Steps

- Gather all necessary tools and equipment before starting the procedure.

- Ensure a clean and organized workspace to minimize the risk of losing components.

- Review the service manual or reference materials for specific instructions related to the assembly or disassembly process.

Disassembly Procedure

- Begin by disconnecting the power source to ensure safety.

- Carefully remove outer covers and shields, taking note of any fasteners or clips used.

- Label and store components systematically to facilitate reassembly.

- Inspect parts for wear or damage during removal, noting any necessary replacements.

By adhering to these guidelines, you can effectively manage the assembly and disassembly of mechanical systems, ensuring optimal performance and reliability.

Tools Needed for Repairs

Performing maintenance and repairs on your vehicle requires the right set of instruments to ensure efficiency and effectiveness. Proper tools not only facilitate the process but also contribute to the longevity of the machine. Below is a list of essential equipment you should consider having on hand.

- Basic Hand Tools:

- Wrenches (various sizes)

- Screwdrivers (flathead and Phillips)

- Plier sets

- Socket Set:

- Metric and SAE sockets

- Ratchet handle

- Extension bars

- Torque Wrench: A crucial tool for applying the correct amount of force on bolts and nuts.

- Diagnostic Tools:

- OBD-II scanner

- Multimeter

- Fluid Change Tools:

- Oil filter wrench

- Fluid transfer pump

- Safety Gear:

- Gloves

- Safety glasses

Having these tools ready will not only make your repair tasks easier but also enhance your overall experience, allowing for a more thorough and confident approach to vehicle maintenance.

Owner Experiences and Feedback

This section focuses on the collective insights and opinions of individuals who have owned and operated a specific all-terrain vehicle. Through their feedback, potential buyers can gain valuable understanding regarding performance, reliability, and maintenance aspects of their machines.

Common Praise

- Performance: Many users highlight the exceptional handling and power, making it suitable for various terrains.

- Comfort: Riders appreciate the ergonomic design, which provides a smooth and comfortable experience during long rides.

- Durability: Owners frequently mention the robust construction, which withstands challenging conditions and extensive use.

Areas for Improvement

- Fuel Efficiency: Some users express a desire for better mileage, particularly during extended outings.

- Parts Availability: A few owners have noted challenges in sourcing specific components, especially for older models.

- Maintenance Requirements: While most find the upkeep manageable, some suggest that certain tasks could be simplified for ease of access.

Overall, the feedback from users provides a balanced view, helping prospective owners make informed decisions while also highlighting areas where improvements could enhance future iterations of the vehicle.

Frequently Asked Questions about Parts

This section aims to address common inquiries related to components and their maintenance for your all-terrain vehicle. Understanding the various elements and their functions can enhance your experience and ensure longevity.

What should I consider when purchasing replacements?

When looking for substitutes, always check for compatibility with your specific model. Quality and durability are crucial, so opt for reputable brands to avoid premature wear.

How can I find a reliable source for components?

Research authorized dealers and trusted online retailers. Customer reviews and ratings can guide you in selecting a trustworthy source.

Is it necessary to use original equipment for replacements?

While original equipment can guarantee perfect fit and performance, aftermarket options can also be effective. Evaluate your needs and budget before making a decision.

How often should I inspect my vehicle’s components?

Regular inspections are essential, particularly before and after intense usage. Keeping an eye on wear and tear helps in preventing potential breakdowns.

What signs indicate that a component needs replacement?

Look for unusual noises, vibrations, or performance issues. Additionally, visual inspections can reveal cracks, rust, or significant wear, signaling the need for a new part.