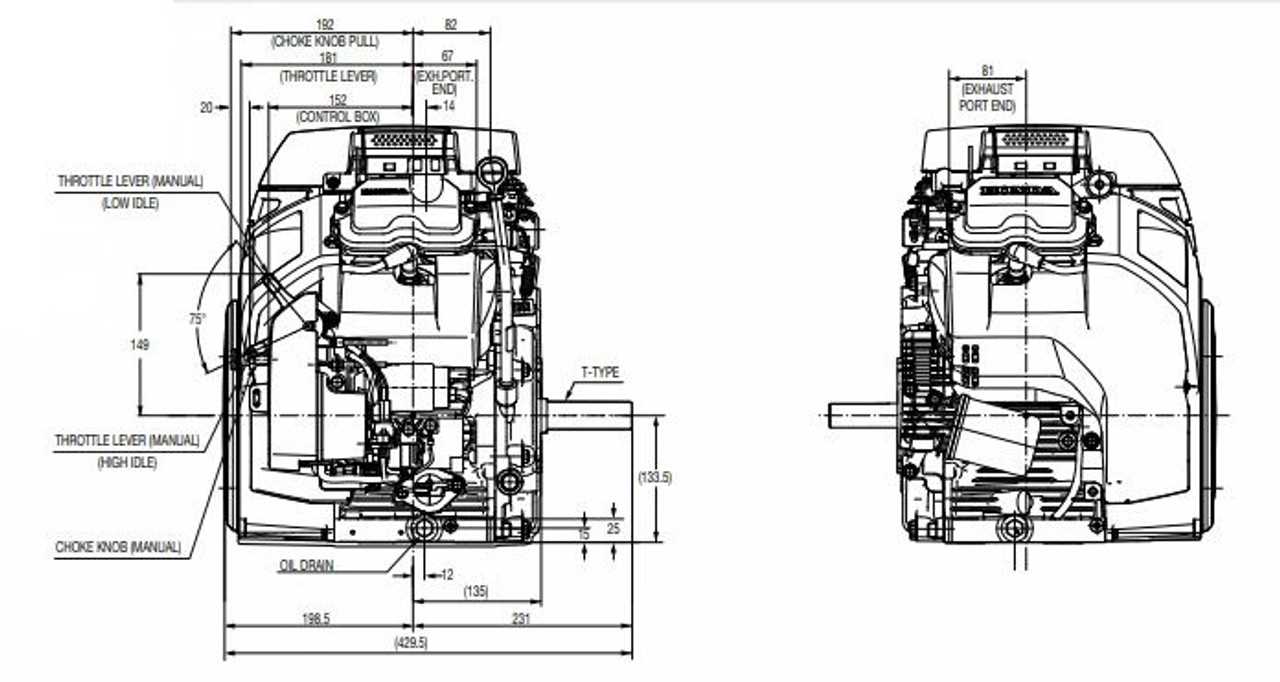

In the realm of small engine mechanics, comprehending the intricate layout of various components is essential for effective maintenance and repair. This section delves into the key elements that constitute a specific model of an engine, providing insight into their arrangement and functionality. Grasping the interconnections and roles of these components can significantly enhance your troubleshooting skills.

By exploring the structure of this engine, enthusiasts and technicians alike can gain valuable knowledge that aids in identifying potential issues and executing necessary repairs. This exploration will empower users to approach their maintenance tasks with confidence, ensuring that their machinery operates smoothly and efficiently. Understanding the configuration of engine elements is not just beneficial; it is a crucial step towards mastering engine care.

Engines, known for their reliability and performance, can encounter various challenges over time. Understanding these common problems can help owners maintain optimal functioning and prolong lifespan.

1. Fuel System Complications

One of the frequent issues arises within the fuel system. Problems may include:

- Clogged fuel filters, leading to restricted flow

- Old or contaminated fuel causing starting difficulties

- Fuel leaks from damaged lines

2. Electrical System Failures

Electrical components can also be a source of trouble. Common electrical issues include:

- Worn spark plugs affecting ignition

- Battery-related problems leading to starting issues

- Corroded wiring connections causing shorts

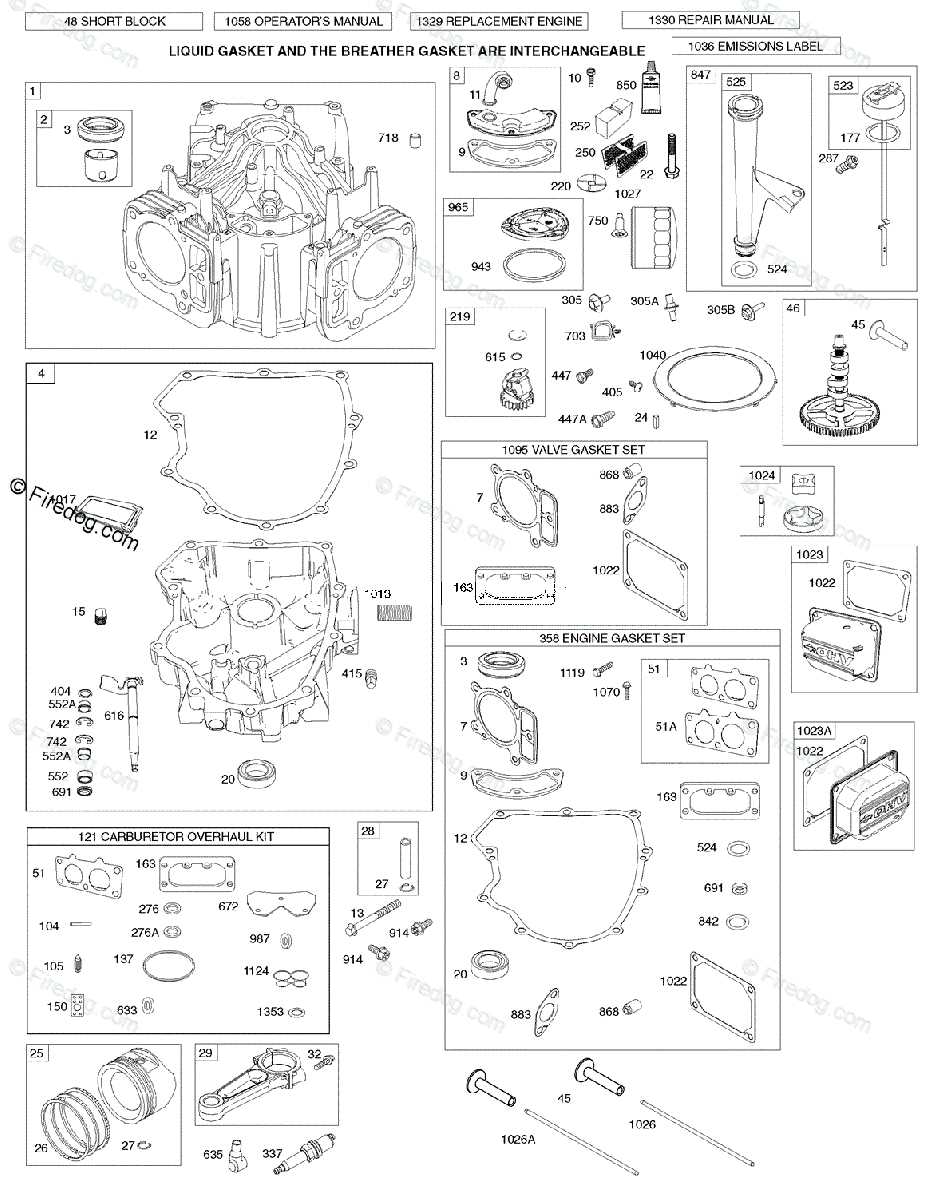

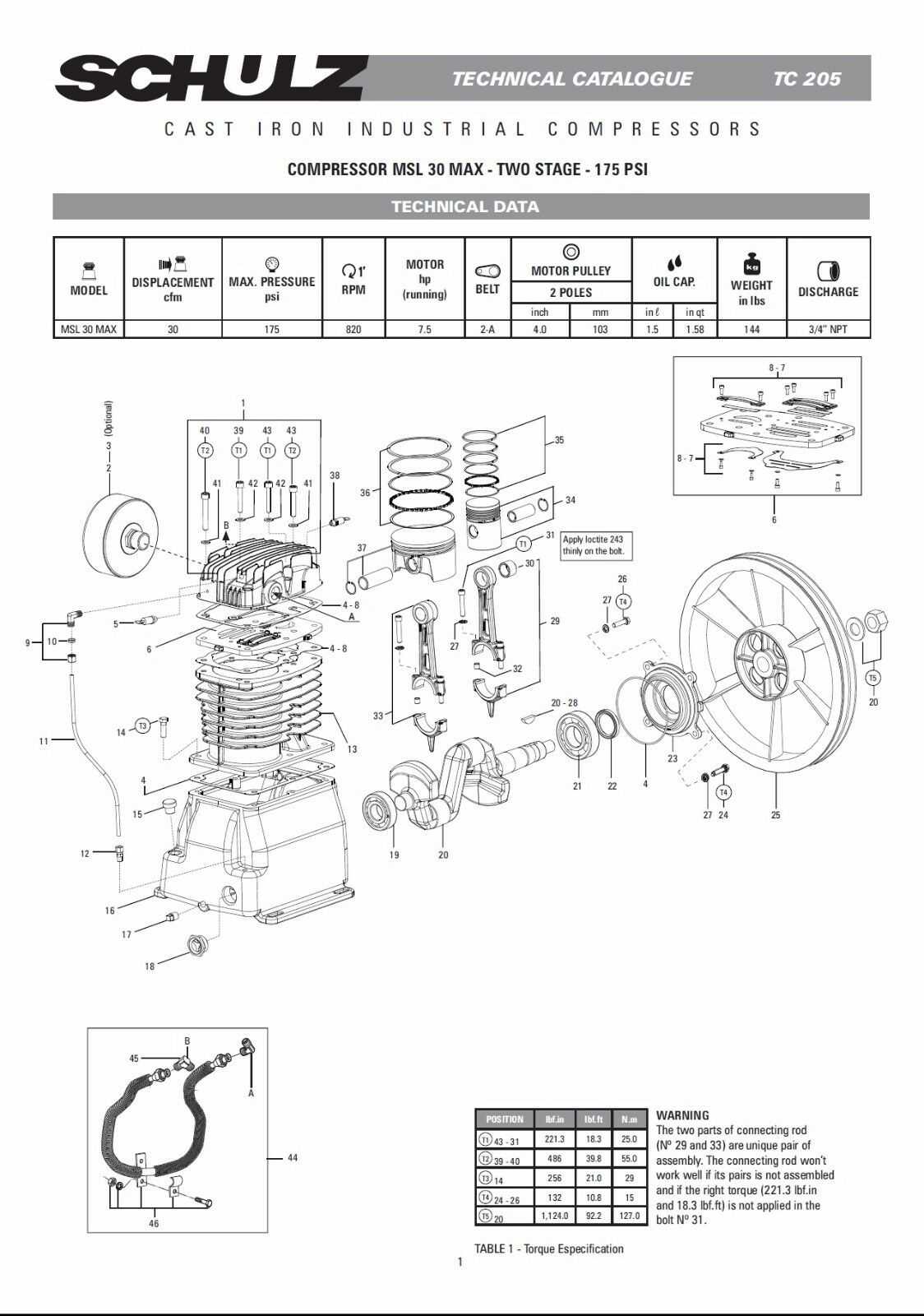

Parts Identification for Efficient Repair

Understanding the components of a machinery system is essential for effective maintenance and troubleshooting. By recognizing each element, one can streamline repair processes and ensure optimal performance. This section highlights the significance of identifying various components, promoting a more systematic approach to upkeep.

Importance of Accurate Recognition

Accurate identification of machine elements enables technicians to quickly diagnose issues and determine the necessary actions. Misunderstanding or misidentifying components can lead to delays and increased repair costs. Therefore, having a clear understanding of each part’s function is crucial for efficient operations.

Common Components Overview

| Component Name | Description | Function |

|---|---|---|

| Cylinder | Main housing for combustion process | Houses the piston for power generation |

| Piston | Moving element within the cylinder | Translates combustion pressure into mechanical energy |

| Crankshaft | Rod that converts linear motion to rotational | Transfers power to the output shaft |

| Fuel Injector | Delivers fuel into the combustion chamber | Ensures optimal fuel-air mixture for combustion |

Ordering Replacement Parts Effectively

When it comes to maintaining machinery, acquiring the correct components is crucial for optimal performance. Ensuring you have the right items can prevent unnecessary delays and additional costs. Here are some effective strategies to consider when placing orders for replacements.

- Identify the Specific Component: Before making a purchase, it’s essential to accurately determine the required item. Review your machinery’s manual or any available reference materials to confirm the specifications.

- Research Reliable Suppliers: Look for trusted vendors who specialize in the type of equipment you are working with. Customer reviews and ratings can provide insight into their reliability and service quality.

- Compare Prices: Once you have identified potential suppliers, compare their pricing for the same component. This can help you find the best deal while ensuring quality is not compromised.

- Check for Availability: Before finalizing your order, confirm that the component is in stock. Delays in shipping can impact your project timeline, so ensure prompt delivery options are available.

- Keep Records: Maintain a log of your orders, including part numbers and suppliers. This practice simplifies future orders and helps track your inventory effectively.

Implementing these strategies will not only streamline the ordering process but also enhance the efficiency of your maintenance tasks. Proper planning and organization can lead to significant time and cost savings.

Benefits of Genuine Honda Parts

Using authentic components from the manufacturer ensures optimal performance and longevity for your machinery. These elements are designed specifically to fit and function seamlessly, enhancing reliability and efficiency.

| Advantage | Description |

|---|---|

| Quality Assurance | Original components undergo rigorous testing to meet high standards, ensuring durability and effectiveness. |

| Perfect Fit | Designed to work flawlessly with your equipment, reducing the risk of malfunctions or compatibility issues. |

| Warranty Protection | Using genuine components helps maintain your warranty, providing peace of mind against unexpected repair costs. |

| Enhanced Performance | Authentic parts are engineered to maximize the efficiency and power of your engine, contributing to better overall performance. |

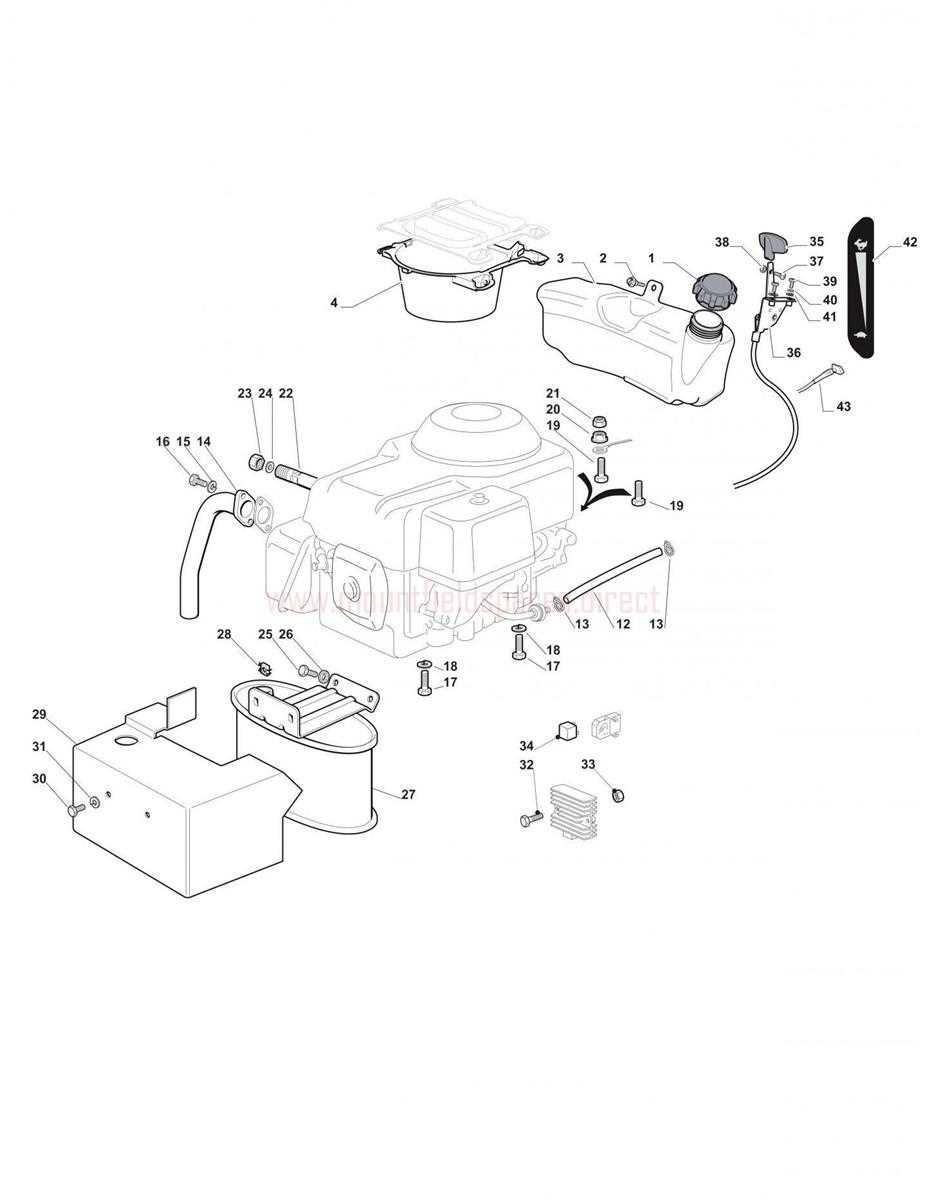

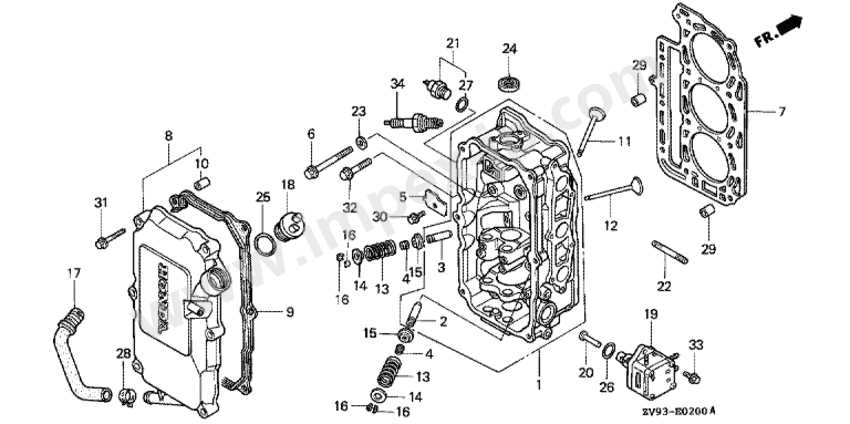

How to Read Parts Diagrams

Understanding visual representations of components can significantly aid in identifying and sourcing the necessary items for machinery. These illustrations typically provide a comprehensive overview of the various elements, their arrangement, and interconnections, enabling users to grasp the assembly more effectively.

Key Elements of Visual Representations

When examining these visuals, focus on the key features that are commonly present. These may include reference numbers, which correlate with a list of items, and various symbols indicating the nature of each component. Familiarizing yourself with these symbols and numbers is crucial for efficient navigation.

Utilizing Reference Lists

Alongside the illustrations, there is often a reference list that details each component. This list typically includes specifications such as size, material, and functionality, which can aid in making informed decisions during repairs or replacements. Ensure to compare the numbers from the illustration with those in the list for accurate identification.

| Component | Description | Reference Number |

|---|---|---|

| Item A | Connector piece for assembly | 001 |

| Item B | Sealing ring | 002 |

| Item C | Fastening screw | 003 |

Comparing Aftermarket vs. OEM Parts

When it comes to enhancing the performance and longevity of your engine, the choice between original components and alternative options is crucial. Understanding the differences between these categories can help in making informed decisions that affect both efficiency and maintenance costs.

Quality and Performance

Original equipment manufacturers (OEM) create components that are specifically designed for compatibility and optimal functionality with your engine. These components undergo rigorous testing to ensure they meet high standards of quality and performance. In contrast, aftermarket options can vary significantly in quality. While some may offer improved performance, others might not deliver the same reliability as their OEM counterparts.

Cost Considerations

One of the primary reasons for considering alternative options is cost. Aftermarket components are often more budget-friendly than original parts. However, it is essential to weigh the initial savings against potential long-term costs, such as increased maintenance or early replacements that may arise from lower-quality alternatives.

| Aspect | OEM Components | Aftermarket Components |

|---|---|---|

| Quality | High, consistent standards | Varies widely |

| Compatibility | Designed specifically for the engine | May require modifications |

| Price | Generally higher | Often lower |

| Warranty | Typically includes a warranty | Varies by manufacturer |

Tools Needed for Engine Repair

When undertaking engine maintenance, having the right tools is essential for effective and efficient repairs. Proper equipment not only simplifies the process but also ensures safety and precision while working on complex machinery.

Essential Hand Tools

Basic hand tools form the foundation of any repair toolkit. A set of wrenches and screwdrivers in various sizes is crucial for loosening and tightening components. Additionally, pliers and socket sets enhance versatility, allowing access to hard-to-reach areas.

Specialized Equipment

For more advanced tasks, certain specialized tools are necessary. An engine hoist is vital for lifting heavy components safely. A compression tester assists in diagnosing engine performance issues, while a multimeter is essential for electrical troubleshooting. Investing in quality tools will improve repair outcomes and prolong the lifespan of your engine.

Step-by-Step Repair Process

Repairing a small engine can seem daunting, but by following a systematic approach, the task becomes more manageable. This guide outlines a comprehensive method for addressing common issues, ensuring that each step is clearly defined and easy to follow.

- Preparation:

- Gather necessary tools such as wrenches, screwdrivers, and replacement components.

- Ensure you have a clean workspace to avoid losing small parts.

- Disassembly:

- Carefully remove the outer casing to access the internal components.

- Take note of the arrangement of parts as you remove them; consider taking photos for reference.

- Inspection:

- Examine each part for wear and damage.

- Look for cracks, rust, or any signs of failure that may need addressing.

- Replacement:

- Replace any damaged components with new ones, ensuring they are compatible.

- Follow manufacturer recommendations for specifications and part numbers.

- Reassembly:

- Carefully reattach all parts, following the reverse order of disassembly.

- Make sure all connections are secure and properly aligned.

- Testing:

- Once reassembled, perform a thorough test of the engine.

- Check for leaks, unusual noises, and ensure smooth operation.

By following this structured repair process, you can effectively address issues and extend the life of your engine. Regular maintenance and timely repairs will keep your equipment running smoothly.

Safety Precautions While Working

Ensuring a safe working environment is essential when performing maintenance or repairs on machinery. Adhering to proper safety protocols minimizes risks and protects both the individual and the equipment involved. This section outlines key safety measures that should be followed to maintain safety and prevent accidents.

Personal Protective Equipment (PPE)

Wearing appropriate personal protective equipment is crucial during any mechanical work. PPE helps shield individuals from potential hazards, including flying debris, chemical exposure, and electrical risks. Essential gear may include:

| Equipment | Purpose |

|---|---|

| Safety Goggles | Protects eyes from particles and chemicals. |

| Gloves | Prevents cuts and chemical contact. |

| Steel-Toed Boots | Provides foot protection against heavy objects. |

| Ear Protection | Reduces noise exposure during operation. |

Work Environment Safety

Maintaining a tidy and organized workspace is vital for safety. A cluttered area can lead to accidents and injuries. Ensuring that tools and materials are stored properly, and that the floor is free of obstacles will enhance safety. Furthermore, it is important to have proper ventilation when working with machinery that generates fumes or heat.

Frequently Asked Questions About Repairs

This section addresses common inquiries regarding maintenance and restoration processes for specific engine models. Understanding these frequently asked questions can help enhance the knowledge and skills required for effective troubleshooting and servicing.

One common question is about the best practices for regular maintenance. Ensuring that an engine operates smoothly often involves routine checks and timely replacements of essential components. Users frequently wonder how often these tasks should be performed to prevent unexpected failures.

Another area of concern is identifying signs of wear or malfunction. Recognizing symptoms early can significantly extend the life of an engine. Many individuals seek guidance on what indicators to watch for and how to respond appropriately to maintain optimal performance.

Finally, inquiries regarding compatibility and sourcing of replacement components are prevalent. Understanding which components can be substituted or upgraded is crucial for effective repairs. Many users also look for recommendations on reliable suppliers and resources for acquiring necessary items.