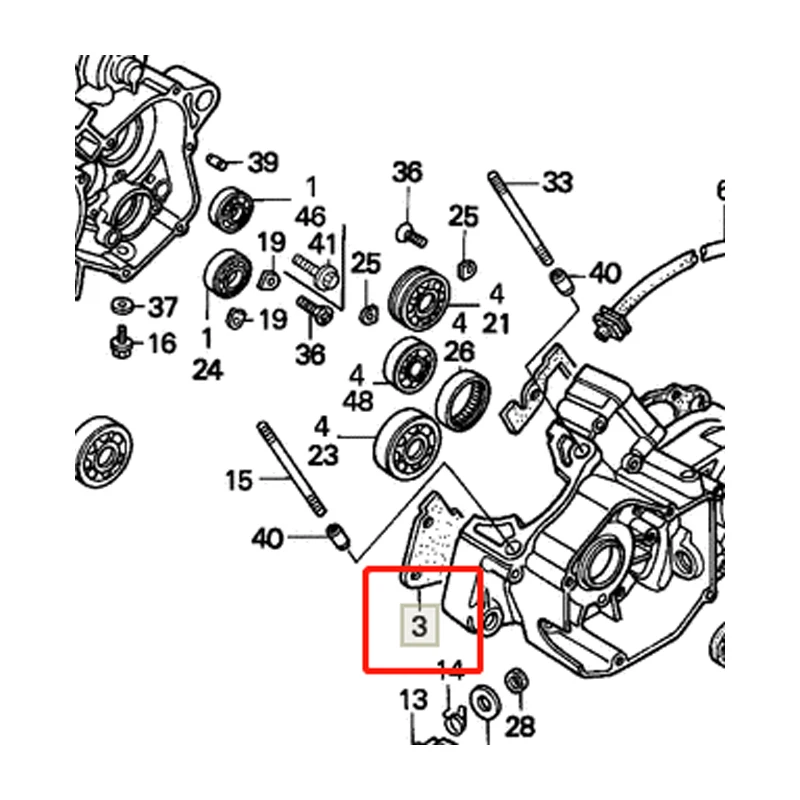

Understanding how different elements fit together in a complex mechanical system is crucial for anyone looking to maintain or improve the performance of their vehicle. By visualizing how each element interacts with the rest, one can gain a deeper appreciation for the design and ensure every piece functions as intended.

In this section, we’ll explore how various components come together to form a cohesive whole. You’ll find detailed representations that illustrate the connections and roles of each element, helping you navigate the intricacies of the system with ease.

Clear and concise visual aids will guide you through the structure, providing insight into the layout and function of every piece. Whether you’re troubleshooting or upgrading, these insights can offer valuable assistance in understanding the core of the system.

Overview of Honda CR125 Components

The structure of this off-road bike consists of a variety of essential elements that work together to ensure smooth performance and durability. These units are designed to enhance the bike’s handling, engine efficiency, and overall riding experience. Understanding the key sections of the bike helps in maintaining its reliability and optimizing its functionality during rides on challenging terrains.

Key Mechanical Units

- Engine assembly, which drives the power output

- Transmission system for shifting gears efficiently

- Exhaust system to manage waste gases

- Suspension components for absorbing shock impacts

- Braking system ensuring rider safety and control

Frame and Structural Elements

- Main frame supporting the entire setup

- Subframe providing additional structural stability

- Wheels and tires for grip and traction

- Handlebars and controls for steering and maneuvering

- Seat providing comfort for the rider

Key Engine Parts for CR125

The engine consists of several crucial components that work together to ensure smooth operation and optimal performance. Each part plays a vital role in the overall function, contributing to the power and reliability of the vehicle. Understanding these elements is essential for both maintenance and potential upgrades.

Crankshaft and Connecting Rod

The crankshaft is responsible for converting linear motion into rotational energy. This piece is paired with the connecting rod, which transmits the force from the piston. Together, they create the movement necessary for the engine’s power output. Proper maintenance of these components ensures efficient energy transfer and longevity.

Cylinder and Piston

The cylinder houses the piston, a critical part that moves up and down, compressing air and fuel to generate combustion. This combination is key to producing the engine’s power, and any wear or damage to these parts can significantly impact performance. Regular inspection and cleaning help maintain their functionality.

Suspension System Breakdown

The suspension system is a crucial component that ensures a smooth and stable ride across various terrains. By absorbing shocks and maintaining balance, it provides better control and comfort for the rider. Understanding the structure and key elements of the suspension is essential for optimal performance and longevity.

Main Components of the Suspension

- Shock Absorbers: These play a central role in dampening vibrations and maintaining stability on rough surfaces.

- Forks: A vital part of the front suspension, they help in controlling the front wheel’s movement.

- Springs: These provide resistance and help the system recover its original position after compression.

Common Issues and Maintenance

- Leakage: Over time, seals may wear out, causing oil leaks and reducing performance.

- Wear and Tear: Regular inspection and replacement of worn-out components are necessary for a smooth ride.

- Adjustment: Proper tuning based on rider weight and terrain is essential for maximizing the efficiency of the system.

Frame and Chassis Design

The structure and design of the chassis play a crucial role in ensuring optimal performance and durability. The overall framework is engineered to provide balance, stability, and control during various riding conditions, making it a fundamental component of any off-road experience. This section explores the construction and features that contribute to its agility and reliability.

Materials and Construction

The frame is crafted from high-strength materials, which offer a balance between lightweight handling and durability. These materials are carefully chosen to withstand intense conditions while minimizing overall weight, allowing for improved maneuverability.

- Lightweight materials for better agility

- Reinforced sections for durability

- Corrosion-resistant coatings

Geometry and Handling

The geometry of the chassis is designed to provide precise control and stability, ensuring a smooth ride across different terrains. The angles and dimensions are fine-tuned to enhance the rider’s ability to navigate challenging environments with ease.

- Optimized angle for stability

- Well-balanced weight distribution

- Enhanced suspension integration

Electrical System and Wiring Layout

The electrical system plays a crucial role in ensuring the efficient operation of various components within a vehicle. Proper understanding of the wiring layout allows for seamless integration of electrical functions, ensuring reliability and safety during usage. This section provides an overview of how the system is structured, highlighting the main connections and circuits involved in powering the essential features.

Main Components

- Battery – Supplies energy to the entire electrical system.

- Ignition System – Responsible for starting the engine through electrical impulses.

- Lighting – Ensures visibility and signaling for the operator.

- Fuse Box – Protects the electrical circuits from overloads.

Wiring Layout Overview

The wiring layout is designed to connect each component systematically, ensuring efficient energy distribution. The cables are organized to minimize interference and ensure smooth operation of all systems.

- Primary wiring runs from the power source to the ignition and lighting systems.

- Secondary wiring connects smaller components such as sensors and switches.

- Ground wires ensure the safe discharge of electrical cur

Fuel Delivery System Components

The fuel delivery system is crucial for the efficient operation of any two-wheeled vehicle. It ensures the proper supply of fuel to the engine, optimizing performance and ensuring smooth operation. Understanding its components is essential for effective maintenance and troubleshooting.

- Fuel Tank: Stores the fuel and provides it to the system.

- Fuel Pump: Transfers fuel from the tank to the engine, creating the necessary pressure.

- Fuel Filter: Cleans the fuel, removing impurities and debris that could harm the engine.

- Carburetor or Fuel Injector: Mixtures the fuel with air to create a combustible mixture for the engine.

- Throttle Body: Controls the amount of air entering the engine, affecting power and efficiency.

- Fuel Lines: Connect various components, allowing fuel to flow from the tank to the engine.

Maintaining these components is vital for ensuring optimal fuel delivery and overall engine performance.

Brake System Parts Overview

The braking mechanism is a crucial aspect of any vehicle’s functionality, ensuring safety and control during operation. Understanding the components that contribute to this system is essential for effective maintenance and optimal performance. Each element plays a distinct role, working harmoniously to deliver reliable stopping power.

Component Description Brake Lever A device that the rider operates to engage the braking system, providing control over deceleration. Master Cylinder The component responsible for converting the lever’s mechanical force into hydraulic pressure, activating the brake system. Brake Line A flexible or rigid conduit that transports hydraulic fluid from the master cylinder to the calipers. Caliper A crucial part that houses the brake pads and exerts pressure on the brake disc to slow down or stop the vehicle. Brake Pads Friction materials that press against the brake disc, creating the necessary force to halt the motion of the vehicle. Brake Disc A metal rotor that the brake pads clamp onto, facilitating the reduction of speed through friction. Transmission and Gearbox Parts Guide

This section provides an overview of the essential components found within the transmission and gearbox systems of a two-wheeled vehicle. Understanding these elements is crucial for maintaining optimal performance and ensuring smooth operation during rides. Each part plays a significant role in the overall functionality of the machinery, influencing factors such as gear shifting and power transfer.

Key Components

- Gears

- Shafts

- Clutch Assembly

- Bearings

- Transmission Case

Maintenance Tips

- Regularly check for wear and tear on gears and shafts.

- Ensure the clutch assembly operates smoothly to prevent slippage.

- Lubricate all moving parts to reduce friction.

- Inspect bearings for signs of damage or misalignment.

- Keep the transmission case free from contaminants and leaks.

Cooling System and Radiator Components

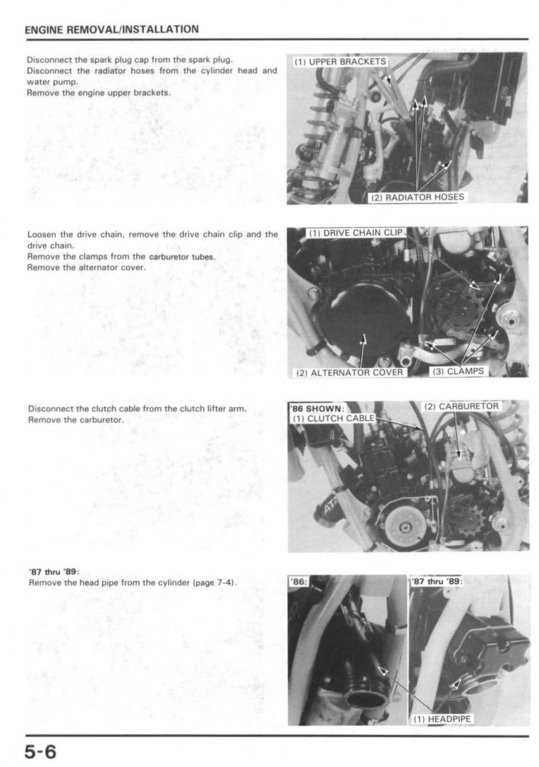

The efficiency of a motorcycle’s engine heavily relies on its cooling system, which plays a crucial role in maintaining optimal operating temperatures. This system prevents overheating and ensures that the engine runs smoothly by circulating coolant through various components. Understanding the key elements of this system is essential for proper maintenance and performance enhancement.

Key Components of the Cooling System

The cooling mechanism consists of several vital parts that work together seamlessly. These components include the radiator, water pump, hoses, and thermostat. Each plays a significant role in the flow and regulation of coolant, contributing to the overall functionality of the engine’s temperature management.

Component Description Radiator A heat exchanger that dissipates heat from the coolant into the air. Water Pump Circulates coolant throughout the system to maintain flow. Hoses Flexible tubes that transport coolant between components. Thermostat Regulates the coolant flow based on temperature. Maintenance Tips for Optimal Performance

Regular maintenance of the cooling system is essential for ensuring the longevity and efficiency of the engine. Checking the coolant levels, inspecting hoses for leaks, and cleaning the radiator can significantly enhance performance. Timely replacement of worn-out components also plays a critical role in preventing overheating and maintaining smooth operation.

Exhaust System Parts and Functions

The exhaust system is a crucial component of any vehicle, responsible for directing gases away from the engine and minimizing noise. It consists of various elements that work in harmony to enhance performance, reduce emissions, and ensure optimal functioning. Understanding these components and their roles can help in maintaining and troubleshooting the overall system effectively.

Main Components of the Exhaust System

This section highlights the key elements of the exhaust setup, detailing their functions and contributions to the overall system.

Component Function Header Collects exhaust gases from the engine cylinders and directs them into the exhaust system. Exhaust Pipe Transports exhaust gases from the header to the muffler. Muffler Reduces engine noise produced by exhaust gases before they exit the system. Catalytic Converter Converts harmful gases into less harmful emissions before they are released into the atmosphere. Tailpipe Releases exhaust gases into the environment, completing the exhaust flow. Importance of Each Element

Each part of the exhaust setup plays a vital role in ensuring the efficiency and effectiveness of the entire system. Proper functioning of these components not only enhances vehicle performance but also contributes to environmental protection by minimizing harmful emissions. Regular maintenance and checks can help in identifying potential issues early, ensuring longevity and reliability of the exhaust system.

Wheels and Tires Setup

Achieving optimal performance and handling requires careful attention to the wheel and tire configuration of your motorcycle. The right selection and adjustment of these components can significantly enhance stability, traction, and overall ride quality. Understanding the various options and setups available is essential for any rider looking to improve their experience on the track or trail.

Choosing the Right Tires

Selecting appropriate tires is crucial for maximizing grip and control. Different terrains demand specific tread patterns and rubber compounds to ensure optimal performance. Consider factors such as weather conditions and riding style when making your choice.

Wheel Alignment and Maintenance

Proper alignment of the wheels is vital for ensuring smooth operation and preventing uneven wear. Regular maintenance, including checking for any damage and ensuring spokes are tight, contributes to the longevity of the wheels and tires.

Tire Type Terrain Benefits Knobby Off-road Excellent traction in loose surfaces Slick Street Improved grip on paved roads Dual-purpose Mixed Versatile performance on various terrains Handlebar and Control Systems

The handlebar and control systems play a crucial role in the overall functionality and maneuverability of a motorcycle. These components provide the rider with the necessary means to steer and manage various functions, ensuring a smooth and responsive experience while navigating different terrains. A well-designed setup enhances comfort and control, allowing the rider to focus on the road ahead.

At the core of these systems are the handlebars, which not only facilitate steering but also house essential controls for braking, throttle, and other vital functions. The design and positioning of these elements are critical for ergonomic handling, enabling riders to maintain a natural posture during operation. Furthermore, the integration of grips, switches, and cables ensures seamless communication between the rider and the motorcycle, contributing to a safer and more enjoyable ride.

Maintenance of the handlebar and control systems is vital for optimal performance. Regular inspections and adjustments can prevent potential issues, such as sticking controls or misalignment, which can significantly affect riding dynamics. By keeping these components in good condition, riders can enhance their overall experience and prolong the life of their motorcycle.

Air Intake and Filtration System

The air intake and filtration system is a crucial component in ensuring optimal performance and efficiency in two-stroke engines. This system facilitates the flow of clean air into the combustion chamber, which is vital for achieving the right air-fuel mixture necessary for effective combustion. A well-designed intake system not only enhances power output but also improves the overall durability of the engine.

Functionality of the Intake Mechanism

The primary function of the intake mechanism is to draw in ambient air and channel it towards the engine. This process typically involves various components, including air filters, ducts, and manifold designs, which work together to minimize contaminants and maintain airflow. By optimizing this airflow, the engine can perform more efficiently, leading to improved throttle response and acceleration.

Importance of Air Filtration

Effective air filtration is essential to protect the engine from harmful particles that can cause wear and damage over time. High-quality filters are designed to trap dirt, dust, and other impurities while allowing a sufficient volume of air to pass through. Regular maintenance of the filtration system ensures that the engine runs smoothly and extends its lifespan, highlighting the importance of this component in overall vehicle performance.