When maintaining any machine, having a clear visual reference for its components is essential. This section delves into the various elements that make up the intricate systems of a particular engine model. By providing a detailed illustration of the key components, users can gain insight into how these parts interact and function together to ensure optimal performance.

For anyone involved in repair or servicing, being familiar with the specific arrangement of these elements can greatly enhance the efficiency of maintenance tasks. This resource aims to simplify the complexity of engine mechanics by presenting a straightforward representation of the essential pieces. With a solid understanding of these components, users can approach repairs with confidence and precision.

Moreover, knowing the layout of an engine can assist in troubleshooting issues that may arise during operation. By recognizing where each part is located and how it connects to others, users can effectively diagnose problems and implement appropriate solutions. This guide serves as a valuable tool for both novice and experienced individuals seeking to deepen their knowledge of engine systems.

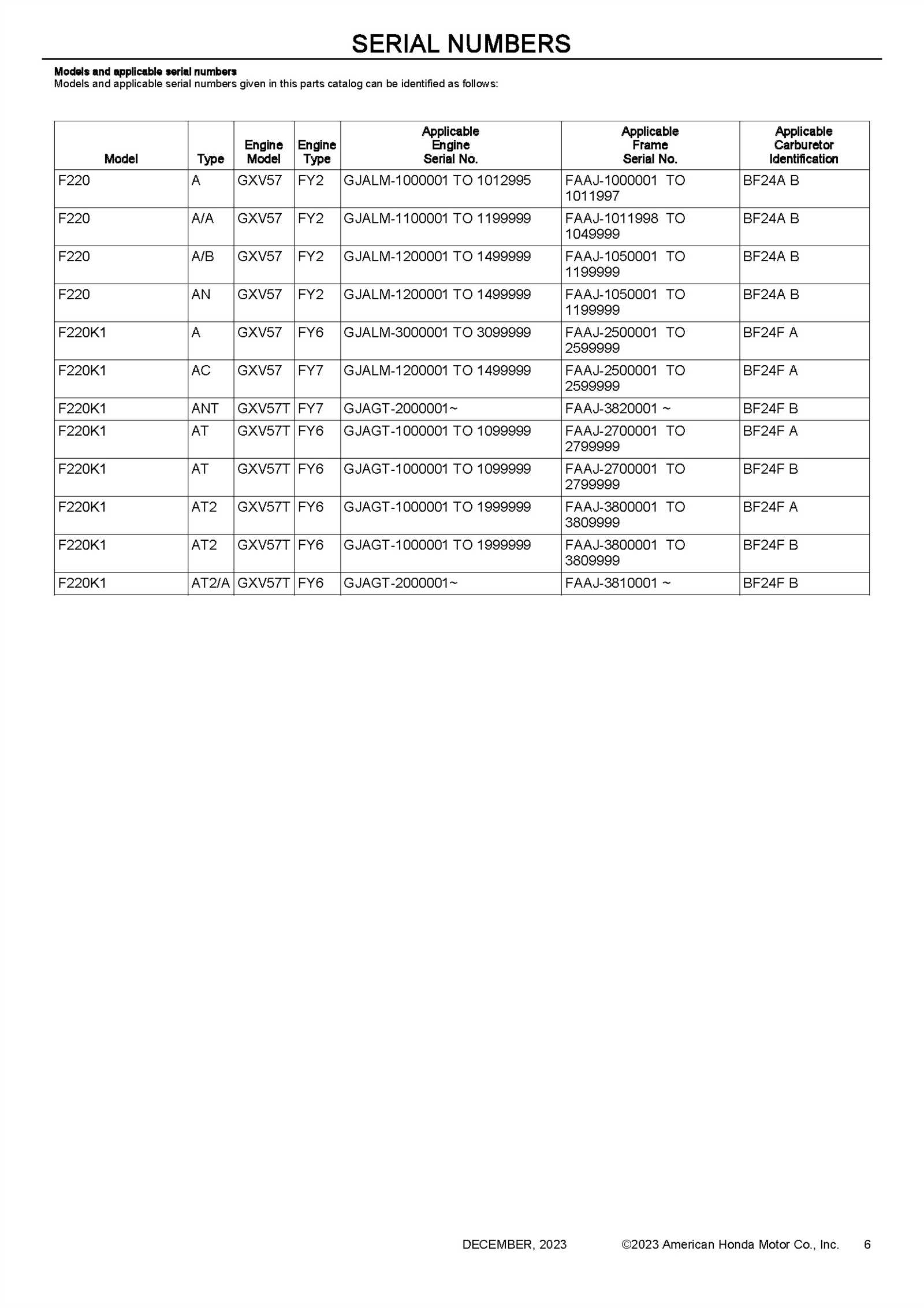

This section aims to provide an organized overview of the components and mechanisms that make up a specific engine model. Understanding the assembly and function of each part is crucial for effective maintenance and troubleshooting. By examining the various elements, users can gain insights into the overall operation and care of the machinery.

The following table outlines the primary components and their corresponding functions, offering a comprehensive view of the engine’s architecture.

| Component | Description |

|---|---|

| Block | The main structure housing the internal components. |

| Piston | Moves up and down within the cylinder to create power. |

| Cylinder Head | Covers the top of the cylinders, containing valves and spark plugs. |

| Crankshaft | Converts linear motion of the pistons into rotational motion. |

| Camshaft | Controls the opening and closing of the engine valves. |

| Fuel System | Delivers fuel to the engine for combustion. |

| Cooling System | Maintains optimal operating temperature by dissipating heat. |

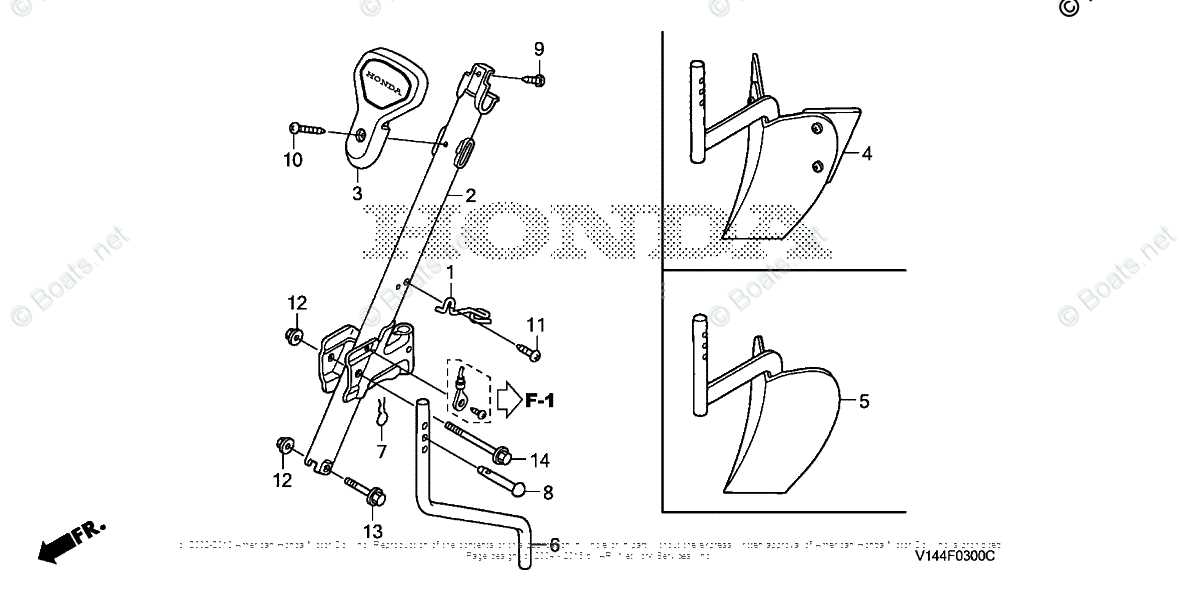

Key Components of the F220

This section focuses on the essential elements that contribute to the functionality and performance of the machinery in question. Understanding these components is crucial for effective maintenance and optimal operation.

Essential Elements

- Engine: The powerhouse that drives the entire unit, converting fuel into mechanical energy.

- Transmission: This component facilitates the transfer of power from the engine to the wheels, ensuring smooth operation.

- Chassis: The framework that supports the machine, providing stability and strength during use.

- Cooling System: Prevents overheating by regulating the temperature of the engine.

- Fuel System: Responsible for storing and supplying fuel to the engine efficiently.

Additional Components

- Exhaust System: Directs harmful gases away from the engine and reduces emissions.

- Electrical System: Powers various electronic components, ensuring proper functioning of lights and ignition.

- Steering Mechanism: Allows the operator to control the direction of the unit with precision.

- Braking System: Ensures safety by providing reliable stopping power.

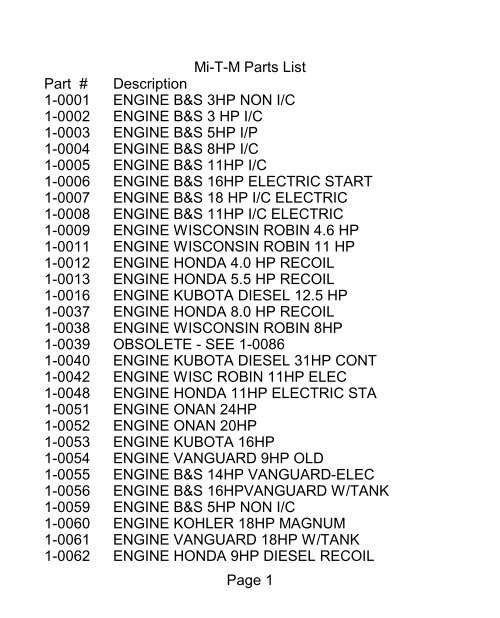

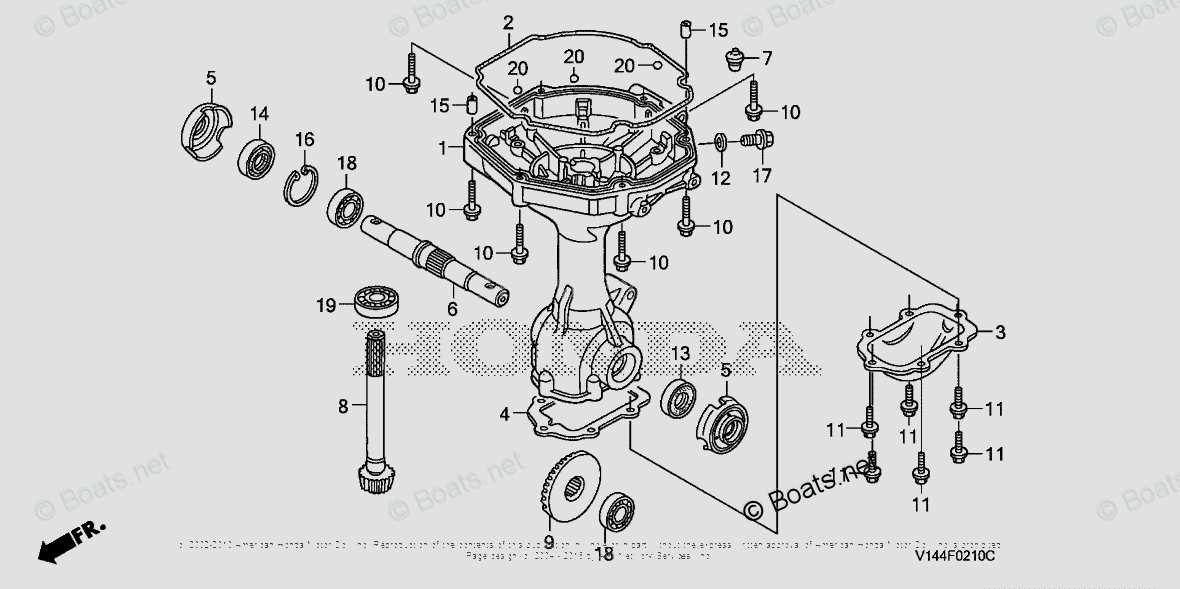

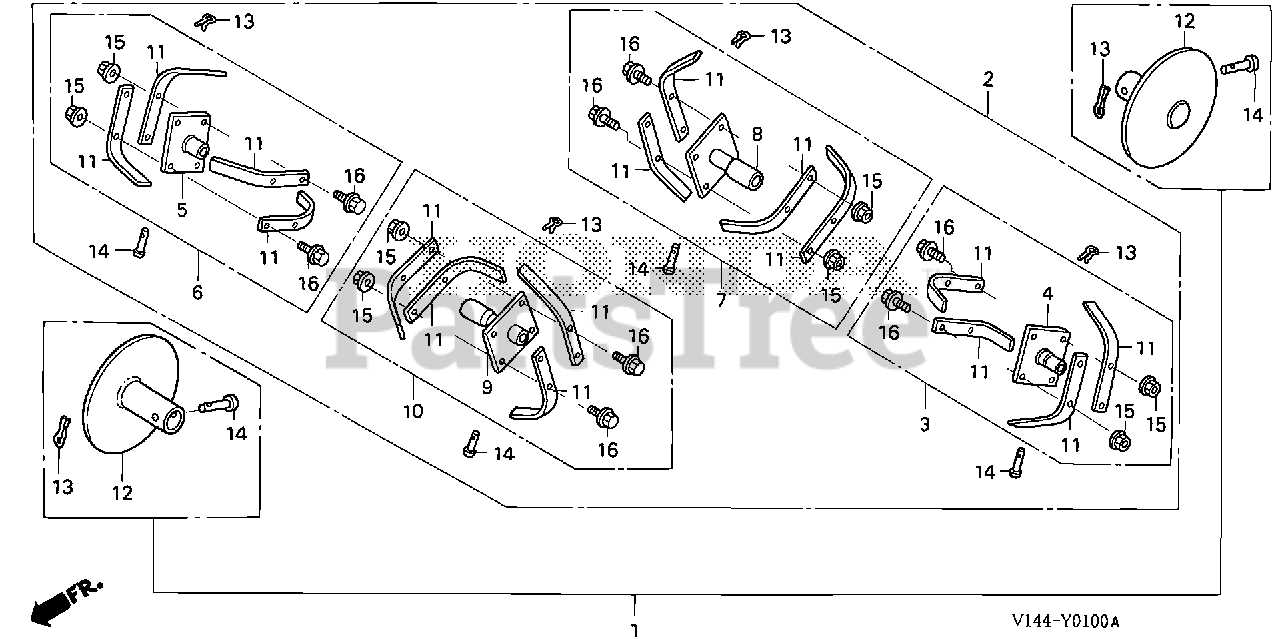

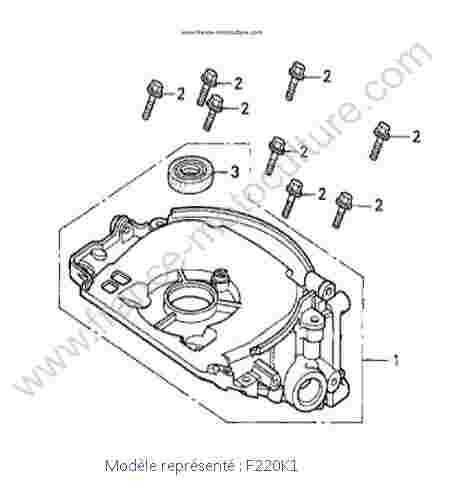

Visual Representation of Parts

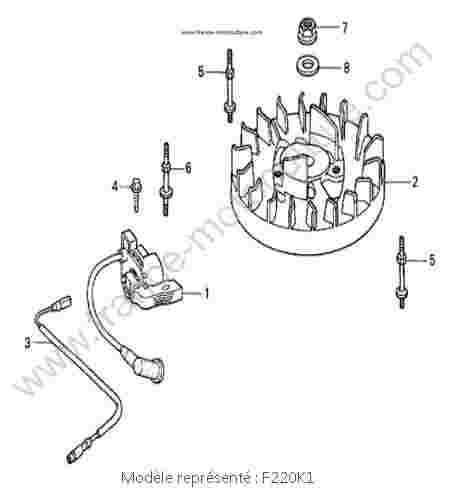

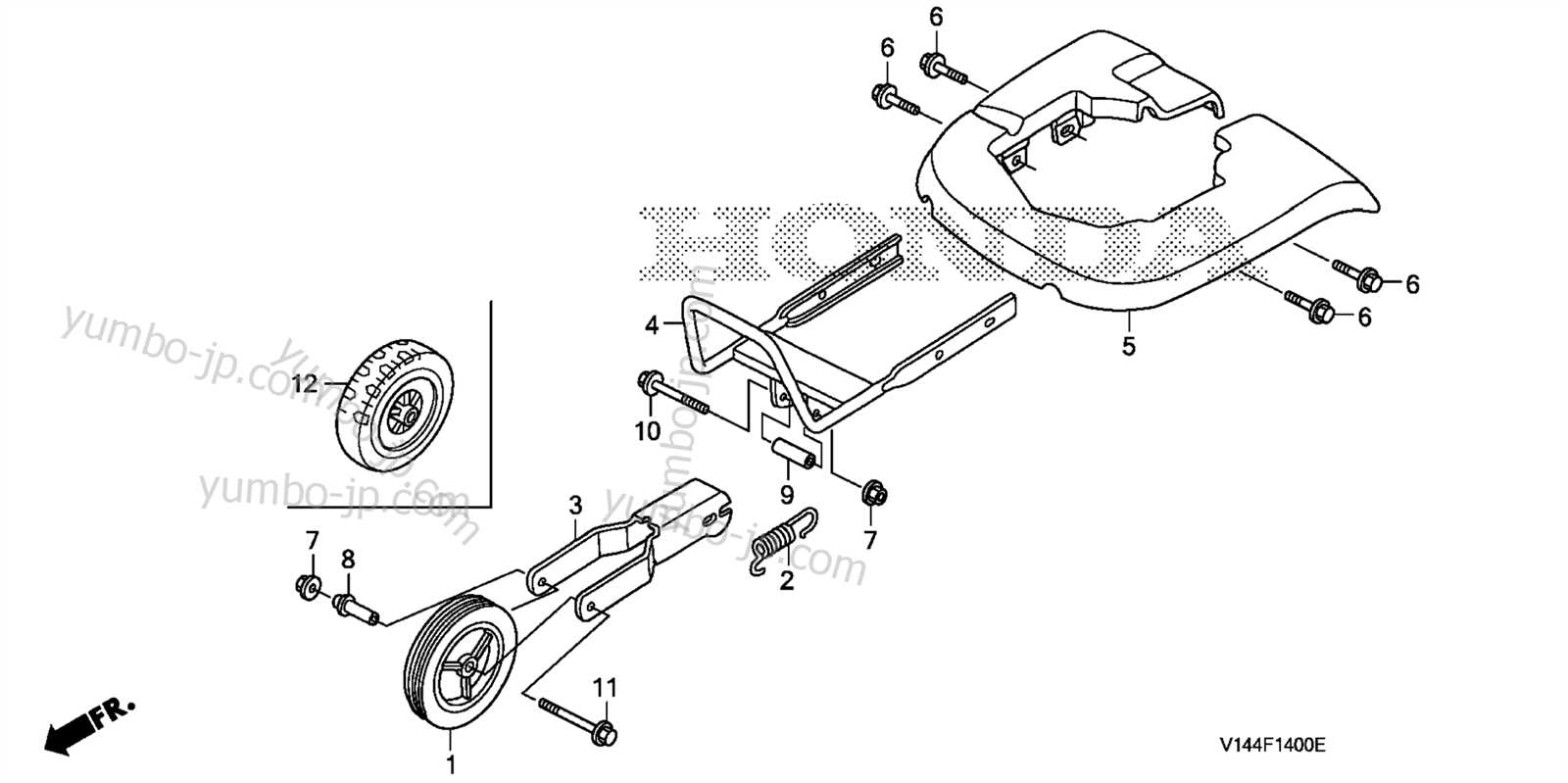

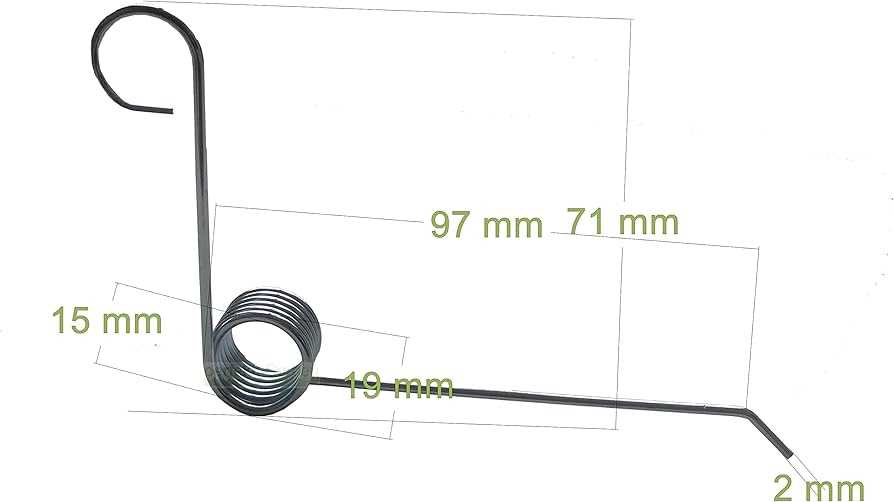

This section focuses on the graphical depiction of components, highlighting their arrangement and function within the machinery. Such illustrations serve as valuable tools for understanding the intricate relationships between each element, facilitating easier identification and maintenance.

Illustrative materials play a crucial role in showcasing how various elements interact. By examining these visual guides, users can gain insights into the assembly and disassembly processes, ensuring efficient handling and repairs. Furthermore, these representations aid in comprehending the overall structure and mechanics, allowing for informed decision-making during maintenance activities.

Utilizing detailed visuals enhances the learning experience, making complex systems more accessible. Whether for educational purposes or practical application, these graphical tools simplify the understanding of functionality and connectivity, ultimately contributing to improved operational effectiveness.

How to Use the Diagram

This section aims to guide users in effectively interpreting and utilizing visual representations of components for better understanding and maintenance. Familiarizing yourself with these illustrations can greatly enhance your ability to identify individual elements and their functions.

Understanding the Key Elements

Start by identifying the labeled sections within the visual guide. Each segment typically represents a specific component or assembly, allowing you to grasp how they interact within the overall system. Pay attention to any accompanying annotations, as they often provide valuable insights into functionality and compatibility.

Practical Applications

Once you have a good grasp of the visual guide, you can apply this knowledge when performing maintenance or repairs. Use the illustrations to locate parts that require attention, ensuring that you have the correct tools and replacements on hand. This approach not only streamlines the process but also minimizes the risk of errors during assembly or disassembly.

Common Issues and Solutions

When operating outdoor machinery, users may encounter several recurring challenges that can hinder performance and efficiency. Understanding these common issues and their corresponding fixes can significantly enhance the longevity and reliability of the equipment.

Frequent Problems

- Starting Difficulties: Many users report trouble starting their equipment, which may stem from fuel delivery issues or electrical system malfunctions.

- Overheating: Excessive heat can lead to engine damage if not addressed promptly, often caused by low coolant levels or clogged air filters.

- Poor Performance: A noticeable drop in efficiency might be attributed to worn components or improper adjustments.

Possible Solutions

- For starting difficulties, check the fuel system for clogs and ensure the battery is fully charged.

- To combat overheating, regularly inspect and replenish coolant levels, and clean any blockages in the air intake.

- For performance issues, conduct routine maintenance to replace worn parts and make necessary calibrations to the system.

Maintenance Tips for Longevity

To ensure the extended lifespan of your machinery, regular upkeep is essential. Implementing a routine maintenance schedule can prevent unexpected failures and enhance performance efficiency. Attention to detail during servicing can lead to a more reliable and durable unit, ultimately saving both time and money in the long run.

Regular Inspection

Frequent checks of various components can help identify wear and tear before it becomes problematic. Look for signs of rust, cracks, or loose fittings, and address any issues promptly. Keeping the equipment clean from dirt and debris will also contribute to its overall health and functionality.

Fluid Levels and Changes

Maintaining proper fluid levels is critical for optimal operation. Regularly check and replace lubricants and other fluids as recommended in the user manual. Using the right type of fluids not only enhances performance but also reduces friction, which can lead to premature wear.

Replacement Parts Availability

When it comes to maintaining equipment, the availability of essential components is crucial for ensuring optimal performance and longevity. Users often seek reliable sources for high-quality replacements that can seamlessly integrate with their machinery. Understanding where to find these components can greatly enhance the maintenance process, allowing for swift repairs and minimal downtime.

Sources for Components

Various avenues exist for acquiring replacement items. Authorized dealers typically offer genuine products that meet manufacturer specifications. Online retailers have also become increasingly popular, providing a wide array of options that cater to different needs and budgets. Local repair shops may also stock commonly required components, making them convenient for quick fixes.

Comparison of Availability

| Source | Availability | Quality Assurance |

|---|---|---|

| Authorized Dealers | High | Guaranteed |

| Online Retailers | Varies | Mixed |

| Local Repair Shops | Moderate | Variable |

Benefits of Genuine Components

Using authentic components for machinery and equipment is essential for ensuring optimal performance and longevity. Genuine items are specifically designed to fit perfectly and function effectively within the system, providing peace of mind for users. By choosing original products, owners can avoid potential issues associated with inferior alternatives, ultimately leading to a more reliable operation.

Enhanced Durability

Original components are manufactured to meet rigorous quality standards, ensuring they withstand the demands of regular use. Their robust construction minimizes the risk of premature failure, offering a longer lifespan compared to counterfeit or generic options.

Improved Performance

Utilizing genuine items significantly enhances the overall functionality of the equipment. These components are engineered to work harmoniously with the existing system, leading to better efficiency, increased power output, and reduced wear and tear. In contrast, using non-authentic parts may compromise performance, resulting in higher maintenance costs and potential breakdowns.

Assembly Process Explained

The assembly process of machinery involves a systematic approach to putting together various components to create a functional unit. Understanding this procedure is crucial for ensuring efficiency and longevity of the equipment.

Here’s a step-by-step breakdown of the assembly procedure:

- Preparation: Gather all necessary components and tools required for the assembly.

- Inspection: Examine each part for defects or irregularities before beginning the assembly.

- Base Assembly: Start by constructing the main frame or base, ensuring stability and alignment.

- Component Integration: Sequentially add components such as engines, transmission systems, and other critical parts.

- Fastening: Secure each part using appropriate fasteners, ensuring they are tightened to the recommended specifications.

- Connections: Establish connections for electrical, hydraulic, or fuel systems as required by the design.

- Final Inspection: Conduct a thorough check of the assembled unit, ensuring all components are properly installed and functioning.

Following these steps meticulously enhances the reliability of the equipment and optimizes its performance in the long run.

Tools Required for Repairs

To carry out effective maintenance and restoration tasks on outdoor power equipment, it’s essential to have the right set of instruments. This ensures not only efficiency but also safety during the repair process. A well-equipped toolkit can significantly streamline procedures and help achieve desired results.

| Tool | Description |

|---|---|

| Socket Set | Essential for loosening and tightening various fasteners, offering versatility in sizes. |

| Screwdriver Set | Used for removing and securing screws, available in multiple types such as flathead and Phillips. |

| Wrench | Helps in gripping and turning nuts and bolts, crucial for assembly and disassembly tasks. |

| Pliers | Useful for gripping, bending, and cutting wires, providing excellent control in tight spaces. |

| Torque Wrench | Ensures fasteners are tightened to the manufacturer’s specifications, preventing damage. |

| Safety Goggles | Protects the eyes from debris and potential hazards during the repair process. |

| Work Gloves | Provides hand protection and enhances grip while handling tools and equipment. |