When it comes to ensuring optimal performance of portable energy solutions, a thorough comprehension of their internal structures is essential. A detailed overview of the individual components not only aids in maintenance but also enhances overall functionality. By familiarizing oneself with the arrangement and interconnectivity of these elements, users can troubleshoot issues more effectively and extend the lifespan of their equipment.

Exploring the intricate details of each segment provides insights into how they work together to produce reliable power. This knowledge empowers users to identify which areas may require attention or replacement over time. Understanding these relationships fosters a proactive approach to upkeep, ultimately leading to greater efficiency and reduced downtime.

Furthermore, having access to a comprehensive visual representation of these components serves as a valuable resource. Such illustrations can demystify the setup, making it easier to grasp how each piece functions within the whole. This not only enhances user confidence but also simplifies the process of repairs and enhancements, paving the way for a more sustainable and dependable experience.

Understanding the Honda EU3000is Generator

Exploring the intricacies of this portable power source reveals a well-engineered device designed for efficiency and reliability. Its compact nature and versatile applications make it an ideal choice for various scenarios, from recreational use to emergency situations.

Key Features

- Quiet operation for peaceful surroundings

- Fuel efficiency that maximizes runtime

- Lightweight design for easy transport

- Advanced technology ensuring stable power delivery

Maintenance Tips

- Regularly check and change the oil.

- Inspect air filters to maintain airflow.

- Keep the fuel system clean and topped up.

- Test the device periodically to ensure functionality.

Understanding these elements can help users maximize the potential of this remarkable machine.

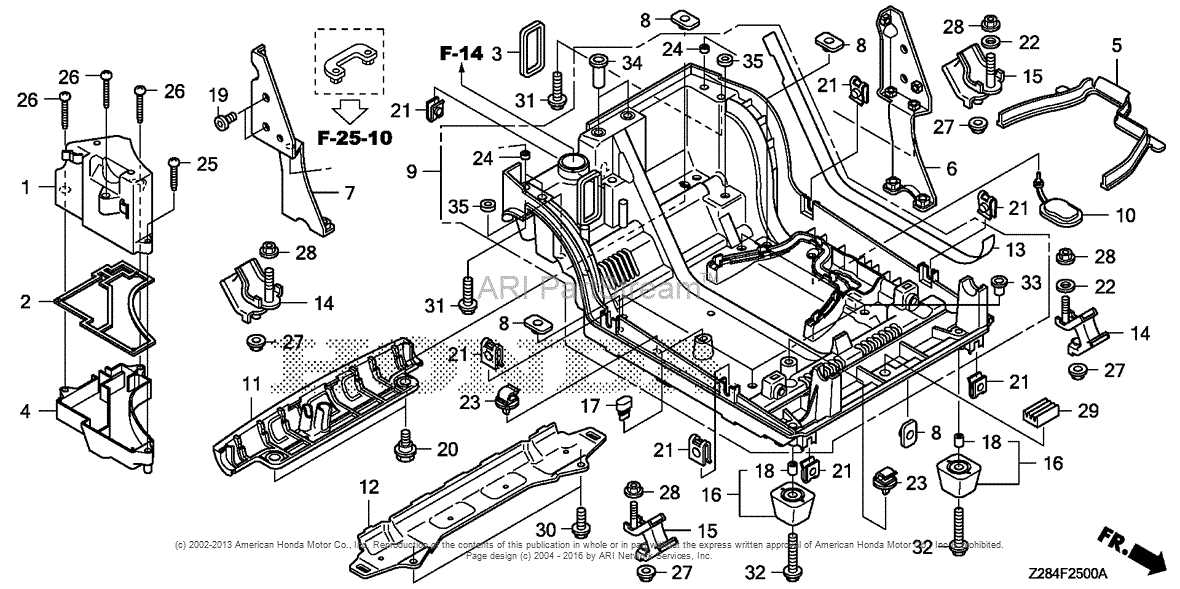

Overview of Generator Parts

This section provides a comprehensive understanding of the various components that make up a portable energy source. Each element plays a crucial role in ensuring efficient operation, reliability, and safety. Recognizing these individual sections can enhance maintenance practices and troubleshooting skills.

| Component | Description |

|---|---|

| Engine | Drives the system, converting fuel into mechanical energy. |

| Alternator | Transforms mechanical energy into electrical energy. |

| Fuel System | Stores and delivers fuel to the engine for combustion. |

| Cooling System | Maintains optimal operating temperatures to prevent overheating. |

| Exhaust System | Directs harmful gases away from the unit and users. |

| Control Panel | Allows users to manage operations and monitor performance. |

| Frame | Provides structural integrity and protects internal components. |

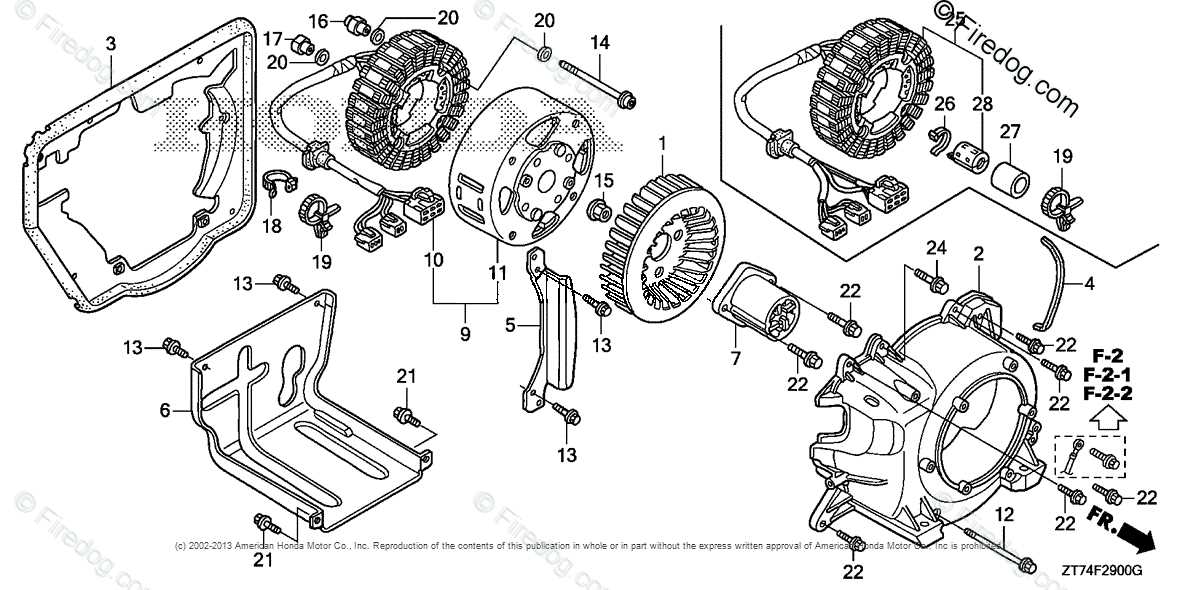

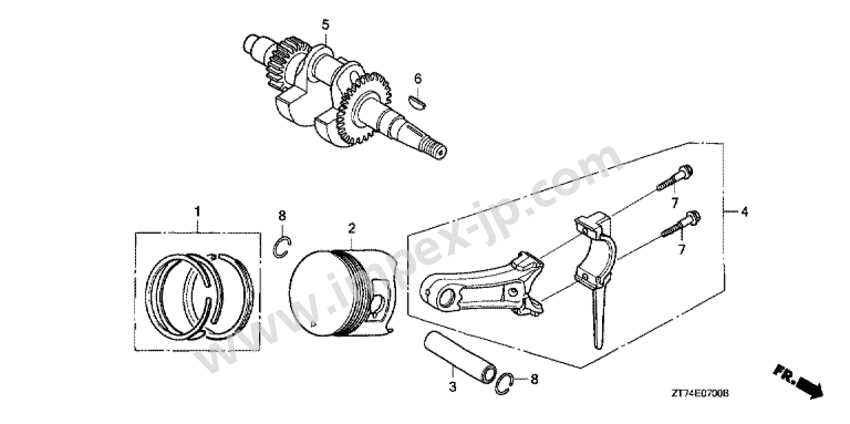

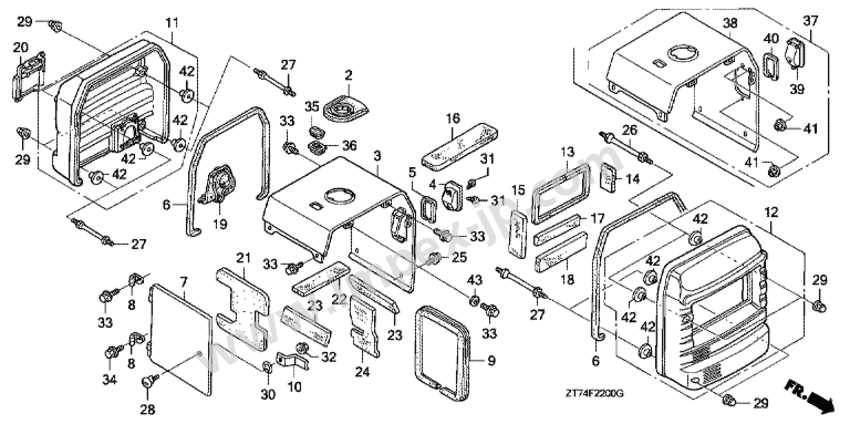

Importance of a Parts Diagram

Understanding the components of machinery is crucial for effective maintenance and repair. A visual representation of these elements not only simplifies the identification of each section but also aids in troubleshooting. When users can easily reference how various pieces fit together, it enhances their overall experience and efficiency.

Enhanced Clarity

Having a visual guide provides enhanced clarity when dealing with complex systems. Users can quickly locate specific items, ensuring that they know exactly what they need when making repairs. This minimizes confusion and potential errors during the reassembly process.

Facilitates Maintenance

Regular upkeep is essential for optimal performance. A clear visual representation helps users to delve into maintenance routines, identifying wear and tear more effectively. This proactive approach can ultimately extend the lifespan of the equipment.

Key Components of EU3000is

Understanding the essential elements of this portable power unit is crucial for both users and technicians. Each component plays a significant role in ensuring efficient operation and reliability. Here, we delve into the main parts that make this device a preferred choice for many.

Essential Elements

- Engine: The powerhouse that drives the entire system, providing the necessary energy output.

- Fuel Tank: This reservoir holds the energy source, enabling extended operation without frequent refueling.

- Control Panel: The interface for users, allowing them to monitor performance and manage power distribution.

- Exhaust System: Responsible for directing exhaust gases away from the unit, ensuring safety and compliance with regulations.

- Air Filter: This component protects the engine from debris and contaminants, promoting longevity and efficiency.

Supporting Components

- Chassis: The structural framework that supports and houses all other components.

- Cooling System: Maintains optimal operating temperatures, preventing overheating during prolonged use.

- Battery: Provides the necessary power to start the engine and supports electronic functions.

- Voltage Regulator: Ensures consistent voltage output, protecting connected devices from fluctuations.

- Noise Reduction Features: These elements minimize operational sound, enhancing user experience and compliance with noise regulations.

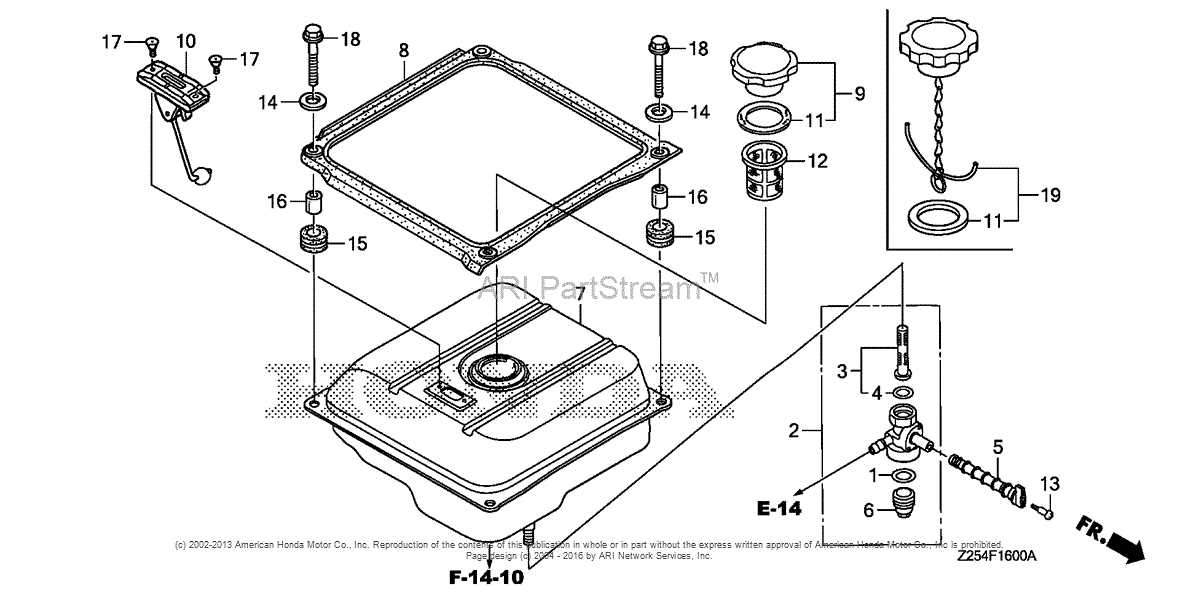

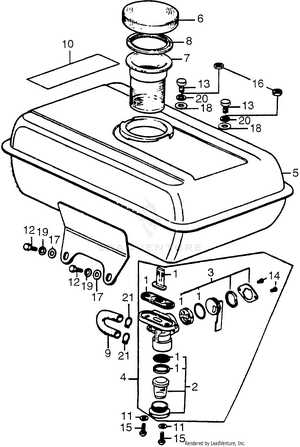

Fuel System Elements Explained

The functionality of any energy-producing device relies heavily on its liquid delivery components. Understanding how these elements interact is crucial for optimal performance and longevity. This section delves into the various components that facilitate the flow and management of fuel, ensuring efficient operation and reliability.

Components Overview

Key parts of the liquid delivery system include the tank, pump, and filter. The tank stores the fuel, providing a reservoir for easy access. The pump is responsible for transferring the liquid from the tank to the engine, while the filter ensures that any impurities are removed before the fuel reaches the combustion area.

Fuel Delivery Process

The process begins with the extraction of liquid from the tank, driven by the pump. As the fuel moves through the filter, it is cleansed of debris, promoting a smoother flow to the combustion chamber. This sequence is vital for maintaining efficiency and preventing potential damage caused by contaminants.

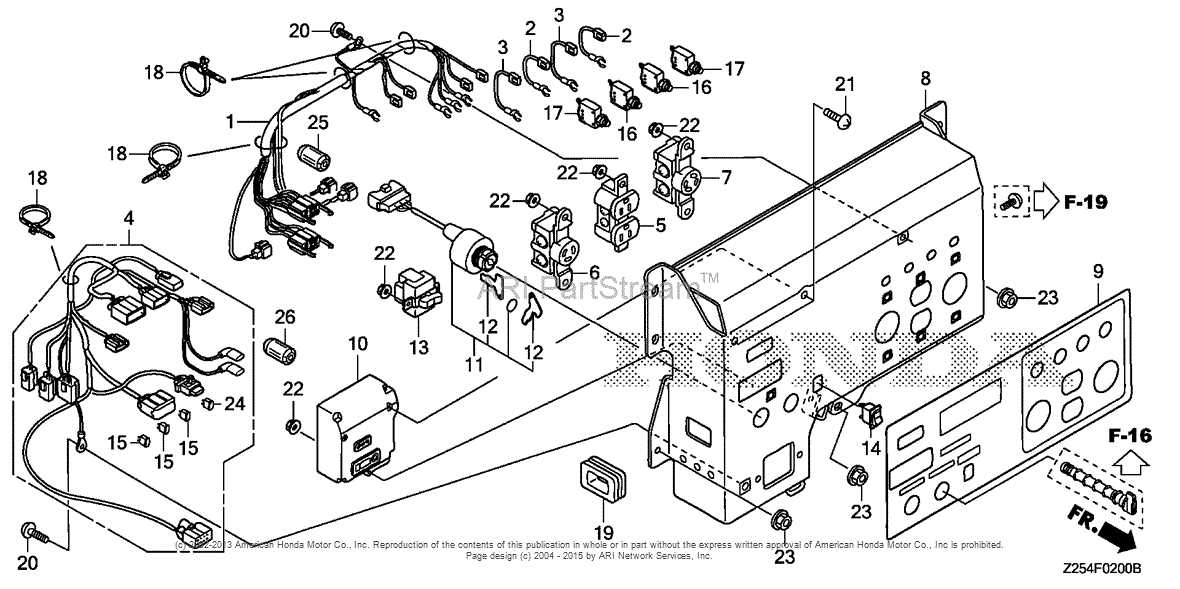

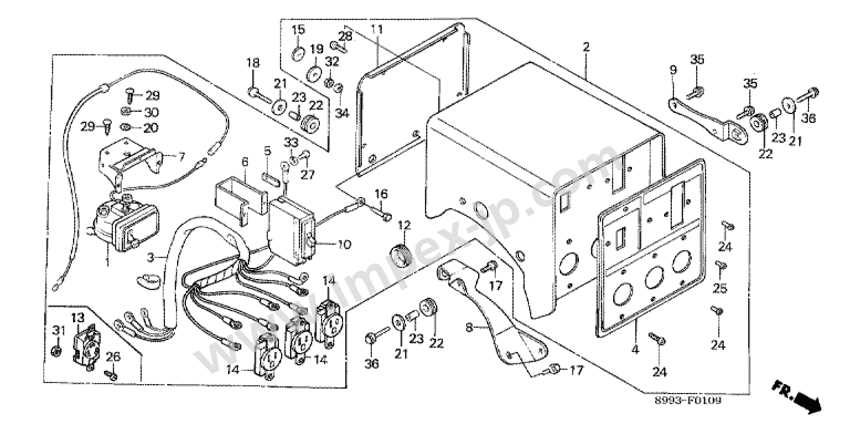

Electrical System Components Overview

This section delves into the essential elements that constitute the power distribution framework, vital for efficient operation. Understanding these components is crucial for maintenance and troubleshooting.

Main Components

- Battery: Serves as the energy reservoir, supplying power to start the unit.

- Alternator: Converts mechanical energy into electrical energy, ensuring a continuous supply.

- Voltage Regulator: Maintains consistent voltage levels to protect devices from fluctuations.

Wiring and Connectors

Proper wiring and robust connectors are critical for seamless electricity flow. Each connection must be secure to prevent disruptions.

- Wiring Harness: Organizes and channels electrical paths effectively.

- Connectors: Facilitate easy assembly and disassembly, ensuring quick repairs.

Cooling Mechanism and Its Function

Effective temperature regulation is essential for the optimal performance and longevity of machinery. The cooling system plays a crucial role in dissipating excess heat generated during operation, ensuring that components function smoothly and efficiently.

This mechanism typically employs various methods to manage thermal levels, including:

- Air circulation: Utilizing fans or vents to enhance airflow.

- Liquid cooling: Circulating a coolant to absorb heat from critical components.

- Heat exchangers: Transferring heat from one medium to another to lower temperatures.

Each of these methods contributes to maintaining an ideal operating temperature, which helps prevent overheating and subsequent damage. Proper functioning of the cooling system ultimately enhances reliability and performance.

Maintenance Parts for Longevity

Ensuring the extended life of any machinery relies heavily on the regular replacement and upkeep of essential components. By prioritizing these vital elements, users can significantly enhance performance and reliability. This approach not only safeguards the investment but also minimizes the likelihood of unexpected breakdowns.

Key Components for Optimal Functioning

Critical elements such as filters, spark plugs, and oil can greatly influence the overall efficiency of the system. Filters play a crucial role in maintaining clean air and fuel flow, while spark plugs ensure smooth ignition. Regular inspection and timely replacement of these items can prevent costly repairs and extend operational life.

Scheduling Regular Maintenance

Establishing a routine for checking and replacing worn-out components is essential. Creating a maintenance schedule that includes regular inspections of key elements will help in identifying potential issues before they escalate. By adhering to this practice, users can enjoy consistent performance and reliability throughout the lifespan of the equipment.

Common Issues and Replacement Parts

In any mechanical device, certain challenges may arise over time, leading to a need for specific components to be replaced. Understanding these common problems can significantly enhance the lifespan and efficiency of your equipment. Regular maintenance and timely replacements can prevent minor issues from escalating into major repairs.

Frequent Malfunctions

Users often encounter issues such as difficulty in starting, irregular operation, or excessive noise. These symptoms may indicate wear on essential elements like the ignition system or the fuel delivery mechanism. Addressing these problems promptly can restore optimal function and reliability.

Essential Components for Replacement

When dealing with performance issues, certain components are commonly replaced. For instance, filters, spark plugs, and fuel lines are critical to maintaining smooth operation. Having these replacement items readily available ensures quick fixes and minimizes downtime, allowing for consistent performance.

Using the Diagram for Repairs

Employing a visual reference for maintenance tasks can significantly enhance the repair process. It provides a clear overview of components and their connections, aiding in identifying any issues quickly. With a comprehensive illustration, users can effectively understand the layout and functionality of various elements.

When troubleshooting, this reference allows for pinpointing malfunctioning sections and determining the necessary replacements. Thorough analysis of each part helps ensure that repairs are conducted efficiently, minimizing downtime and restoring optimal performance. Additionally, following the visual guide facilitates a structured approach to disassembly and reassembly, making the entire procedure smoother.

Finding Authentic Honda Parts

When it comes to maintaining and repairing your equipment, sourcing genuine components is crucial for optimal performance and longevity. Understanding how to identify authentic replacements can save you time and ensure reliability.

Recognizing Genuine Components

Genuine replacements often come with specific identifiers such as serial numbers and manufacturer branding. These markers can usually be found on packaging or the item itself. Always verify these details before making a purchase to avoid counterfeit products.

Where to Purchase

Reputable retailers and authorized dealers are the best sources for acquiring original replacements. Online platforms and local shops that specialize in equipment can also be reliable, but it’s essential to check their credibility and reviews. Investing in authentic components not only guarantees quality but also enhances the overall functionality of your equipment.

Upgrading Parts for Better Performance

Enhancing the components of your equipment can significantly improve its efficiency and longevity. By selecting superior materials or advanced technology, you can elevate functionality and ensure a smoother operation. Whether it’s boosting power output or optimizing fuel consumption, upgrades can lead to impressive results.

| Component | Upgrade Option | Benefits |

|---|---|---|

| Fuel System | High-Performance Carburetor | Improved fuel efficiency and power response |

| Air Filter | High-Flow Air Filter | Enhanced airflow and engine breathing |

| Exhaust | Performance Exhaust System | Reduced back pressure and increased torque |

Safety Considerations with Generators

When utilizing portable power sources, it’s essential to prioritize safety to prevent accidents and injuries. Awareness of potential hazards and following best practices can significantly reduce risks associated with improper use.

Key Safety Tips

- Always operate in well-ventilated areas to prevent carbon monoxide buildup.

- Keep the unit dry and away from water sources to avoid electrical shock.

- Use appropriate extension cords rated for the load to prevent overheating.

- Regularly inspect equipment for any signs of damage or wear.

Emergency Preparedness

- Have a fire extinguisher nearby to handle any unforeseen fires.

- Familiarize yourself with the operation manual for emergency procedures.

- Inform others nearby about the use of the equipment to ensure collective safety.