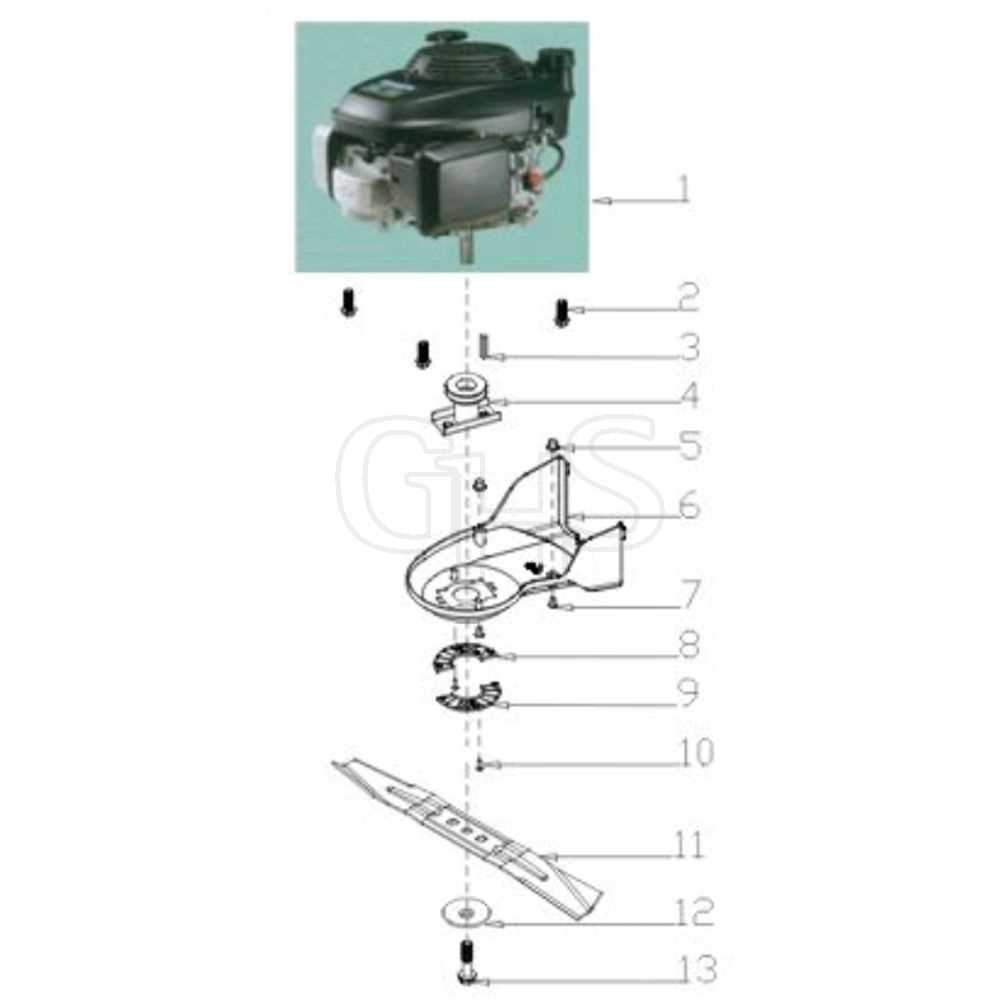

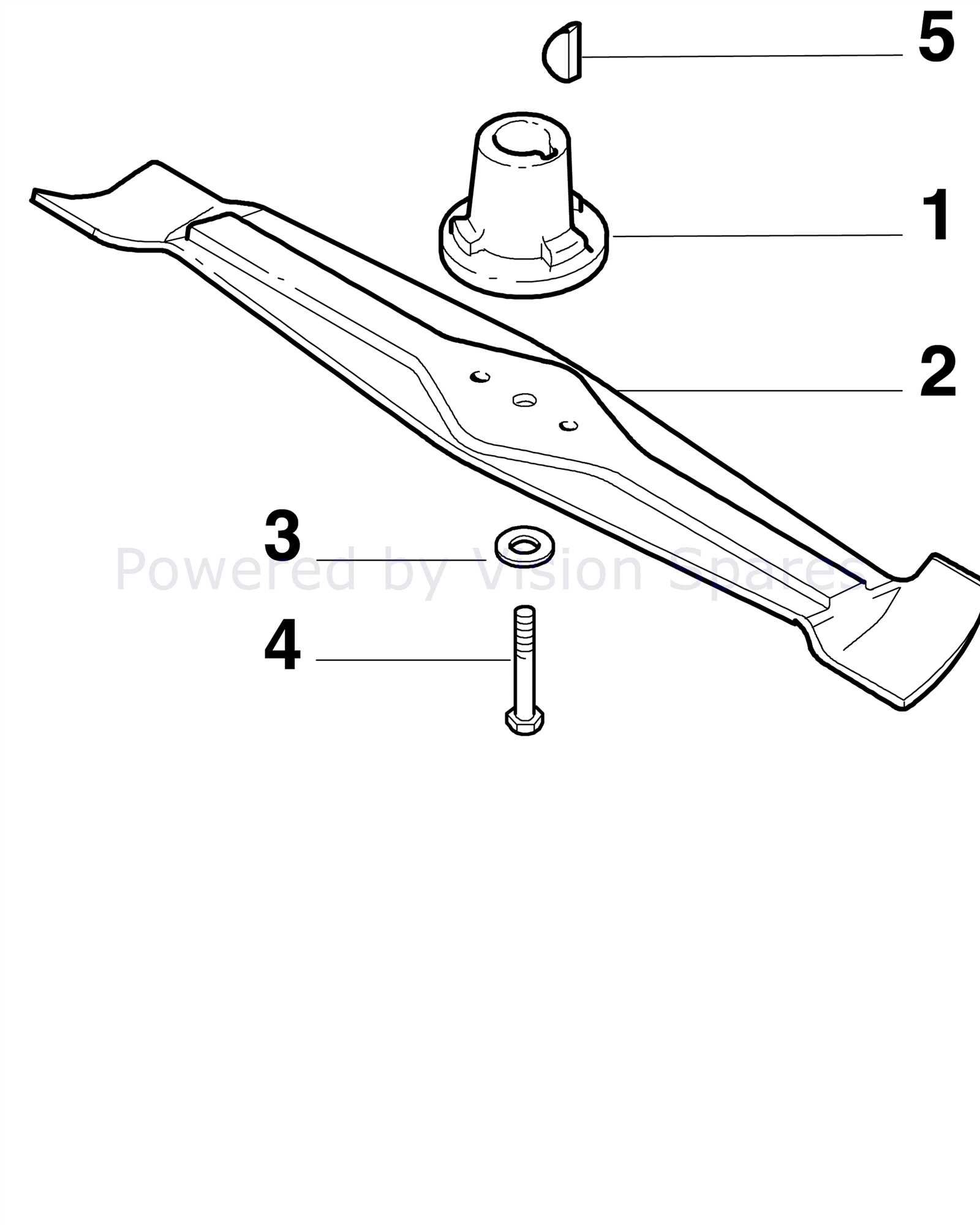

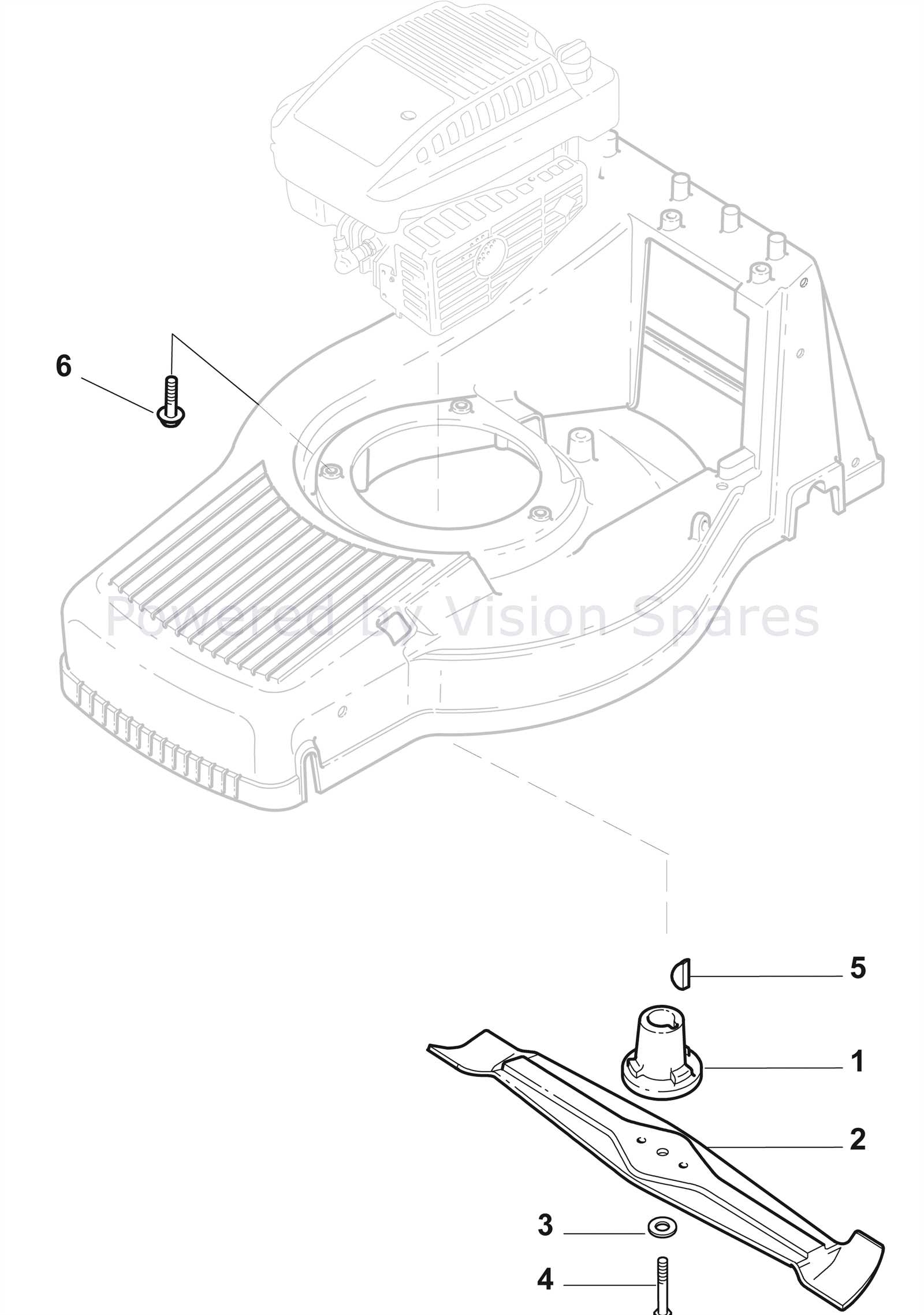

When it comes to maintaining or repairing engines, one of the key elements is understanding the layout of its individual components. Each element of the system works in harmony, and knowing how they are positioned relative to each other can be critical for effective troubleshooting and assembly.

For those looking to replace or inspect specific parts, having a clear view of the entire setup can simplify the process. Whether you are focusing on internal mechanisms or external elements, an organized view of all pieces can help streamline your maintenance efforts.

In this section, we will explore the arrangement of various components, providing a clear overview that helps in re

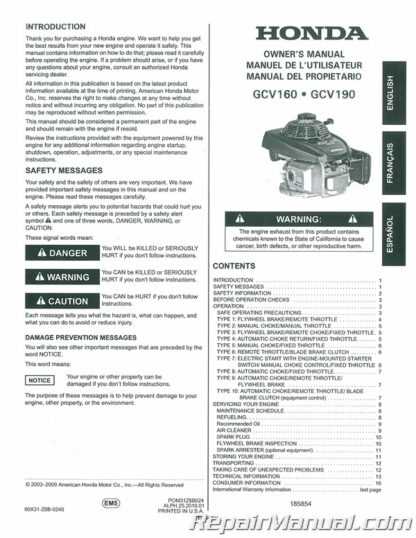

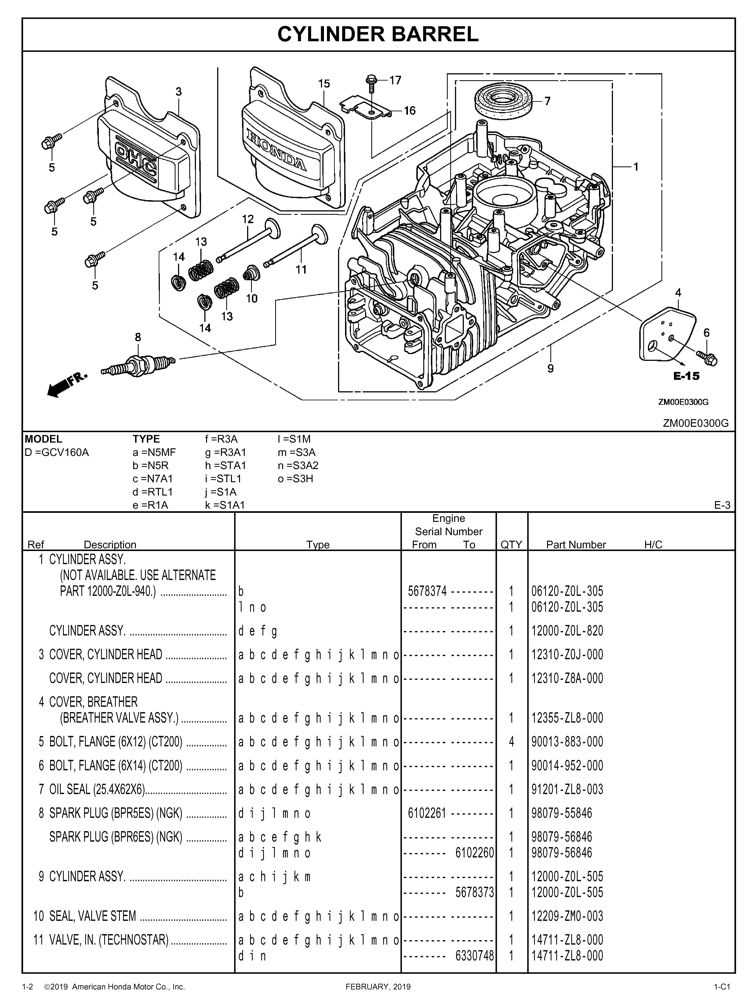

Honda GVC160 Parts Overview

This section provides an insight into the key components of a widely-used small engine, highlighting its structure and functional elements. Understanding these components is essential for maintaining the device in good working condition and ensuring efficient performance over time.

Key Functional Components

- Air filtration system: Ensures clean airflow to the internal mechanisms, preventing debris from entering the core parts.

- Fuel delivery components: These manage the proper mix of fuel and air, allowing the engine to run smoothly.

- Ignition system: Initiates the engine’s operation by creating the necessary spark for combustion.

Maintenance Points

- Regular cleaning of the air filtration section to prevent clogging.

- Inspection of fuel delivery elements to ensure proper functionality.

Main Components of Honda GVC160 Engine

The internal structure of this small-scale engine is built to ensure both durability and efficient operation. It consists of several key elements that work in harmony to convert fuel into mechanical power, making the machine suitable for various applications. Each component plays a vital role in maintaining optimal performance and reliability over time.

Cylinder and Piston

At the core of the engine lies the cylinder, housing the piston. These elements are essential for generating the compression needed for ignition. The movement of the piston within the cylinder creates the necessary force to drive the entire mechanism, transforming fuel energy into motion.

Carburetor and Fuel System

The carburetor is responsible for mixing air and fuel in the proper ratio before combustion occurs. This system ensures that the engine receives the correct amount of fuel, contributing to efficient operation and reducing emissions. Proper functioning of this system is critical to the overall power output and fuel economy.

Air Filter and Maintenance Tips

Regular upkeep of the air filter is essential for ensuring smooth and efficient performance of any equipment with an engine. A clean filter helps in maintaining airflow, which improves the machine’s overall efficiency and prevents the buildup of dust and debris that can affect its operation.

How to Maintain the Air Filter

To keep the filter in good condition, it’s important to clean it regularly. Depending on the environment, the frequency of cleaning may vary. In dusty or high-debris areas, consider cleaning it more frequently. Always check for any damage or excessive wear during inspection.

Prolonging the Lifespan of Your Filter

Replacing the filter when needed is crucial to maintaining optimal performance. Always ensure you’re using compatible parts and following manufacturer guidelines for replacement intervals. Proper care and timely

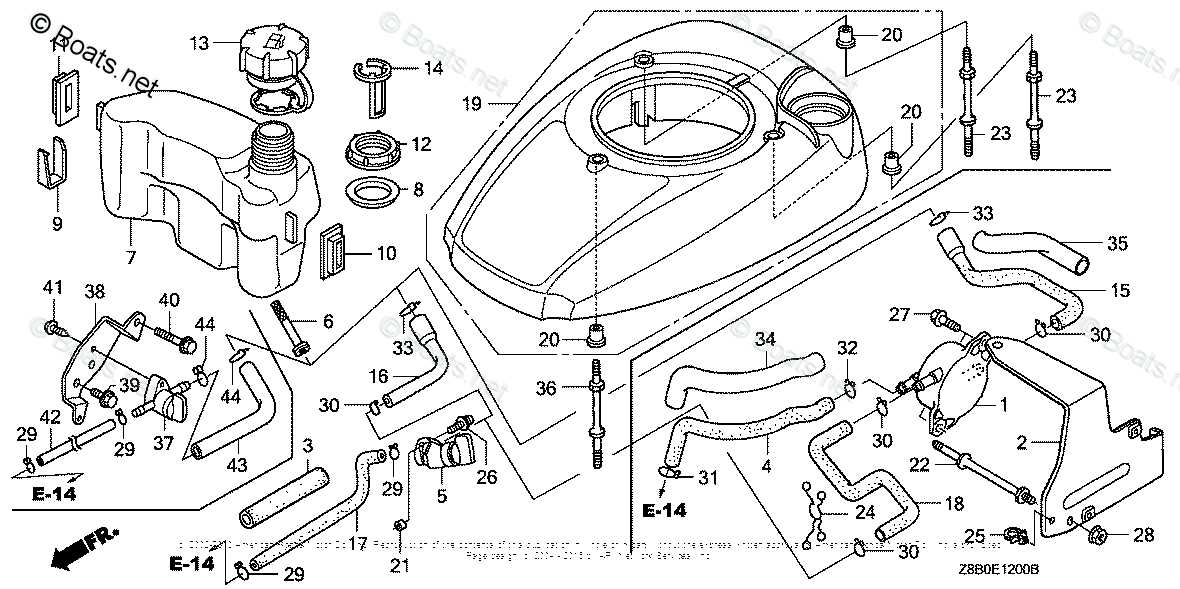

Fuel Tank Assembly and Function

The fuel tank assembly plays a crucial role in the proper functioning of the engine, ensuring consistent fuel supply to support optimal performance. It serves as the reservoir for storing fuel before it is delivered to the engine for combustion. Understanding its components and how they interact is essential for maintaining the efficiency and longevity of the equipment.

Components of the Fuel Tank Assembly

| Component | Description |

| Fuel Tank | The main container that holds the fuel securely, designed to prevent leaks and withstand various environmental conditions. |

| Fuel Cap | A crucial part that seals the tank to prevent fuel spillage and contamination, often equipped with a vent to regulate pressure. |

| Fuel Filter | Filters out impurities and debris from the fuel before it reaches the engine, ensuring clean fuel intake. |

| Fuel Lines | Transports fuel from the tank to the engine, typically made of durable materials to withstand fuel pressure and environmental factors. |

Function of the Fuel Tank Assembly

The primary function of the fuel tank assembly is to store fuel safely and deliver it efficiently to the engine as needed. It ensures a steady flow of clean fuel, which is essential for maintaining engine performance and reliability. Proper maintenance of the fuel tank assembly includes regular inspection for leaks, cleaning or replacing filters as necessary, and ensuring all connections are secure to prevent fuel system malfunctions.

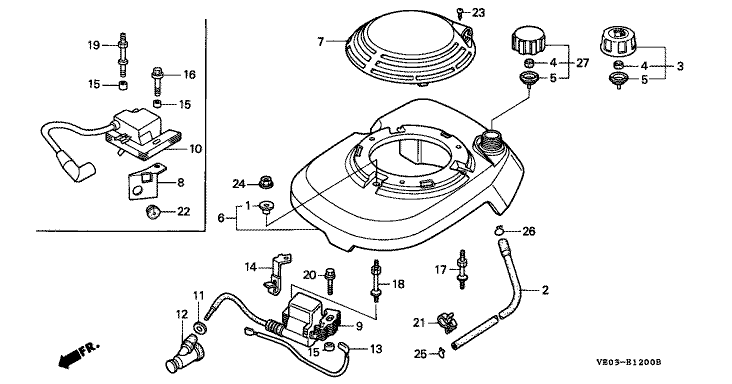

Ignition System Components and Diagram

In this section, we delve into the essential components and configuration of the ignition system. It encompasses the fundamental elements that facilitate the ignition process, allowing for efficient engine operation. Understanding these components provides insights into how the ignition system functions in starting and maintaining the engine’s performance.

Key Components: The ignition system comprises several critical parts, each playing a vital role in the ignition process. These components work together seamlessly to generate the spark needed to ignite the air-fuel mixture within the combustion chamber.

Ignition Coil: This component transforms low voltage from the battery into the high voltage needed to create a spark. It serves as the ignition system’s power source, ensuring reliable spark generation across all engine cycles.

Spark Plug: A crucial component that directly initiates combustion by producing a spark across a small gap. It is designed to withstand high temperatures and pressures within the combustion chamber.

Ignition Switch: Controls the activation of the ignition system, allowing the operator to start and stop the engine. It plays a pivotal role in the overall safety and operation of the vehicle or equipment.

Diagram Overview: Visualizing the ignition system through a diagram provides a clearer understanding of how these components interact. It illustrates the flow of electrical current, from the ignition switch to the spark plug, highlighting the sequential process of ignition.

This section outlines the fundamental aspects of the ignition system without using specific terms related to the Honda GVC160 or parts diagrams, focusing instead on the general principles and components.

Cylinder and Piston Mechanism

The cylinder and piston setup is a key component of the internal combustion process. This mechanism is responsible for converting energy produced by fuel combustion into mechanical movement, which powers the engine. The relationship between the cylinder and the piston is fundamental to ensuring efficient energy transfer and overall performance of the system.

The piston moves within the cylinder, driven by the expansion of gases during combustion. This back-and-forth motion is transferred to the crankshaft, resulting in rotational energy. The precision of the piston’s fit inside the cylinder, along with proper lubrication, minimizes friction and wear, ensuring smooth operation and longevity of the mechanism.

Maintaining the integrity of this mechanism is crucial for optimal function. Regular checks for wear or damage to the piston and cylinder can help prevent costly repairs and extend the lifespan of the engine.

Carburetor Parts and Their Roles

The carburetor is a vital component in an engine’s fuel system, responsible for ensuring the right mixture of air and fuel. Understanding the different elements involved in its operation can help maintain efficient performance and prolong the system’s lifespan.

Key Components

Among the main sections of the carburetor are the float chamber, which regulates fuel levels, and the throttle valve, controlling the airflow. These parts work together to achieve the necessary balance of air and fuel for optimal engine functioning.

Supporting Elements

Additional components include jets that precisely measure fuel flow and the choke, which aids in adjusting the air intake during cold starts. Each piece plays a critical role in maintaining the overall balance required for smooth engine operation.

Oil System Overview and Maintenance

The oil system is a crucial component of any small engine, playing a vital role in ensuring smooth operation and longevity. Proper lubrication is essential for reducing friction between moving parts, thus preventing wear and overheating. Regular maintenance of this system can significantly enhance the performance and reliability of the engine.

Key Components of the Oil System

The oil system consists of several essential elements that work together to provide effective lubrication. These components include the oil pump, oil filter, oil reservoir, and various passages that circulate the oil throughout the engine. Each part must be functioning correctly to maintain optimal oil flow and ensure that all moving parts receive adequate lubrication.

Maintenance Tips

To ensure the longevity and efficiency of the oil system, regular maintenance is necessary. Here are some important practices to follow:

| Maintenance Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 50 hours | Replace old oil with fresh oil to maintain optimal lubrication. |

| Filter Replacement | Every 100 hours | Change the oil filter to prevent contaminants from circulating. |

| Inspect Oil Level | Before each use | Check the oil level to ensure it is within the recommended range. |

By following these maintenance tips, the oil system will continue to function effectively, supporting the overall performance of the engine.

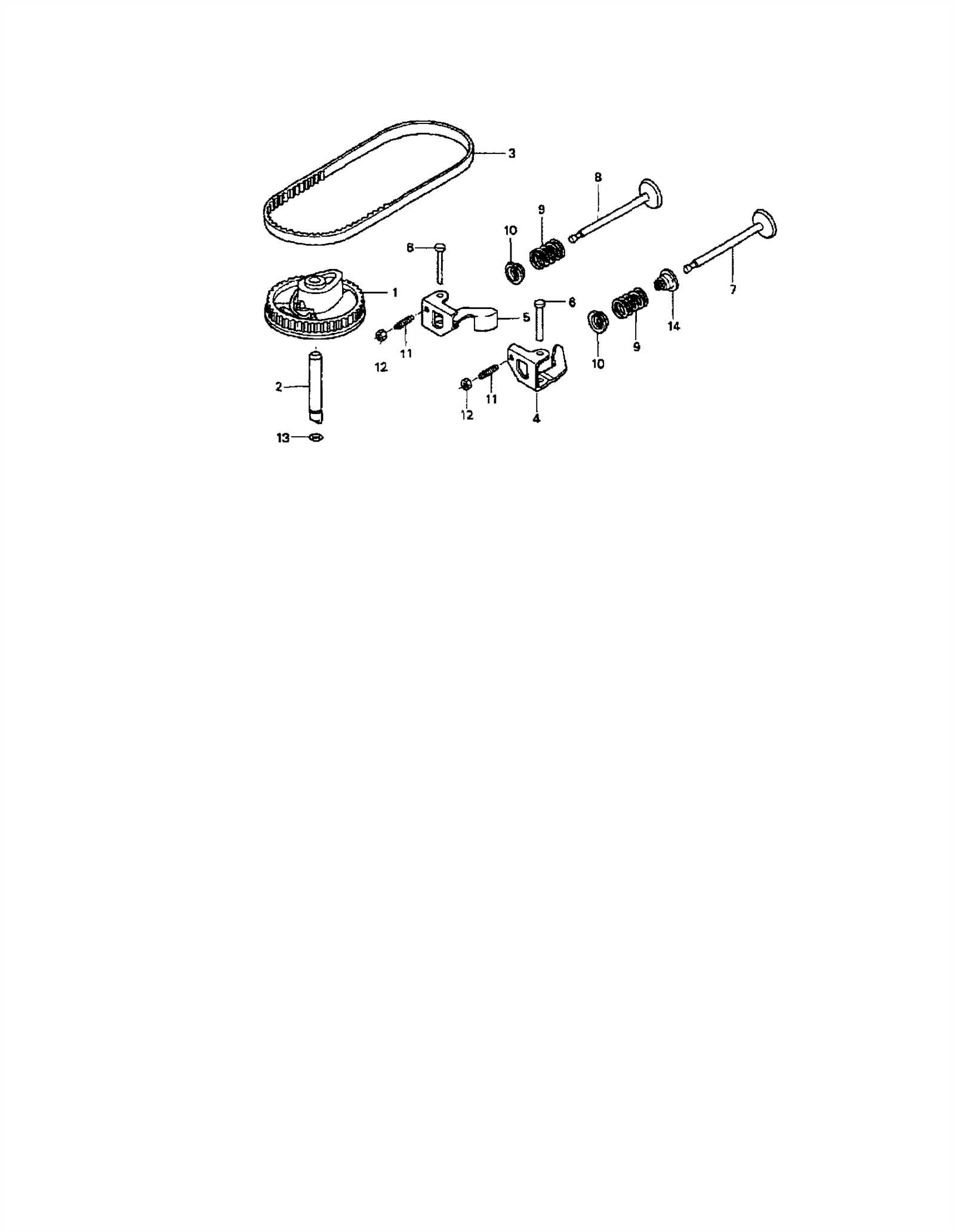

Valve and Camshaft Assembly

The valve and camshaft assembly plays a crucial role in the efficient operation of an internal combustion engine. This component regulates the flow of air and fuel into the combustion chamber, as well as the expulsion of exhaust gases. Understanding its structure and function is essential for maintaining optimal performance.

Components of the Assembly

- Camshaft: This component controls the timing and movement of the valves.

- Valves: These include intake and exhaust valves that open and close at specific intervals.

- Valve Springs: These springs ensure that the valves return to their closed position after being opened.

- Lifters: They transfer the motion from the camshaft to the valves, enabling their movement.

- Push Rods: These rods connect the lifters to the rocker arms in overhead valve designs.

Functionality and Maintenance

Proper alignment and functioning of the camshaft and valves are vital for engine efficiency. Any misalignment can lead to performance issues, including power loss and increased fuel consumption. Regular maintenance checks should include inspecting the condition of the valve springs and ensuring that the camshaft is well-lubricated to prevent wear and tear.

Crankshaft and Connecting Rods

The crankshaft and connecting rods play a crucial role in the functionality of various machinery. These components are integral to the conversion of linear motion into rotational movement, ensuring efficient power transmission throughout the system.

The crankshaft is a robust shaft that transforms the reciprocating motion of the pistons into rotational motion. Its design allows it to withstand high levels of stress and torque, making it essential for engine performance.

- Key Functions of the Crankshaft:

- Converts linear motion from the pistons into rotational energy.

- Maintains balance within the engine for smooth operation.

- Provides mounting points for various engine components.

Connecting rods link the pistons to the crankshaft, playing a vital role in the motion transfer process. Their construction is designed to handle significant loads while ensuring minimal friction during operation.

- Important Aspects of Connecting Rods:

- Facilitates the transfer of force between the piston and crankshaft.

- Ensures alignment and prevents misalignment during movement.

- Made from materials that offer durability and resistance to wear.

Understanding the mechanics of these components can greatly enhance maintenance practices and overall performance. Regular inspection and timely replacement of worn parts are essential to keep the system running efficiently.

Cooling System Components and Diagram

The effective management of temperature is essential for the smooth operation of any engine. The cooling system plays a vital role in maintaining optimal thermal conditions, ensuring that the engine operates efficiently and prevents overheating. This section delves into the various elements of the cooling mechanism and their arrangement.

Key Elements of the Cooling Mechanism

The cooling system comprises several critical components. The radiator serves as a heat exchanger, dissipating excess heat from the engine coolant. Additionally, the water pump circulates the coolant through the system, ensuring consistent flow. The thermostat regulates the temperature by controlling the coolant’s movement between the engine and the radiator. Other vital parts include hoses, which transport the coolant, and the fan, which enhances airflow to facilitate cooling.

Understanding the Layout

Visualizing the configuration of these components can greatly aid in understanding their interactions. Each part is strategically positioned to optimize thermal management. The coolant flows through the engine, absorbing heat, before reaching the radiator, where it cools down before being recirculated. This cycle is crucial for maintaining the performance and longevity of the engine.

Exhaust System and Muffler Parts

The exhaust assembly plays a crucial role in the efficient operation of a combustion engine. It is responsible for channeling gases away from the engine, reducing noise, and minimizing harmful emissions. Understanding the components involved in this system is essential for proper maintenance and functionality.

Key Components: The exhaust system typically includes several integral elements, each serving a specific function. The manifold collects exhaust gases from the engine and directs them into the exhaust pipe. The muffler helps to dampen noise produced during combustion, while the catalytic converter reduces toxic emissions by converting harmful gases into less harmful substances.

Regular inspection of these components ensures optimal performance. Any signs of wear or damage, such as rust or leaks, should be addressed promptly to maintain the overall efficiency of the engine’s exhaust system.