When working with outdoor power equipment, having a clear understanding of the various elements that make up a machine is essential. A visual representation of the assembly can greatly assist users in identifying each individual piece, facilitating easier repairs and maintenance. This overview provides insight into the intricate network of components that contribute to the overall functionality of these devices.

By exploring the layout of these crucial elements, operators can enhance their troubleshooting skills and ensure their tools operate efficiently. A well-organized depiction serves not only as a reference for replacing damaged items but also as a guide for regular upkeep, helping to prolong the lifespan of the machinery.

Whether you are a seasoned technician or a casual user, familiarizing yourself with the schematic representation of these vital parts can empower you to take control of your equipment’s maintenance. This knowledge can lead to improved performance and reduced downtime, ultimately making your outdoor tasks more manageable and enjoyable.

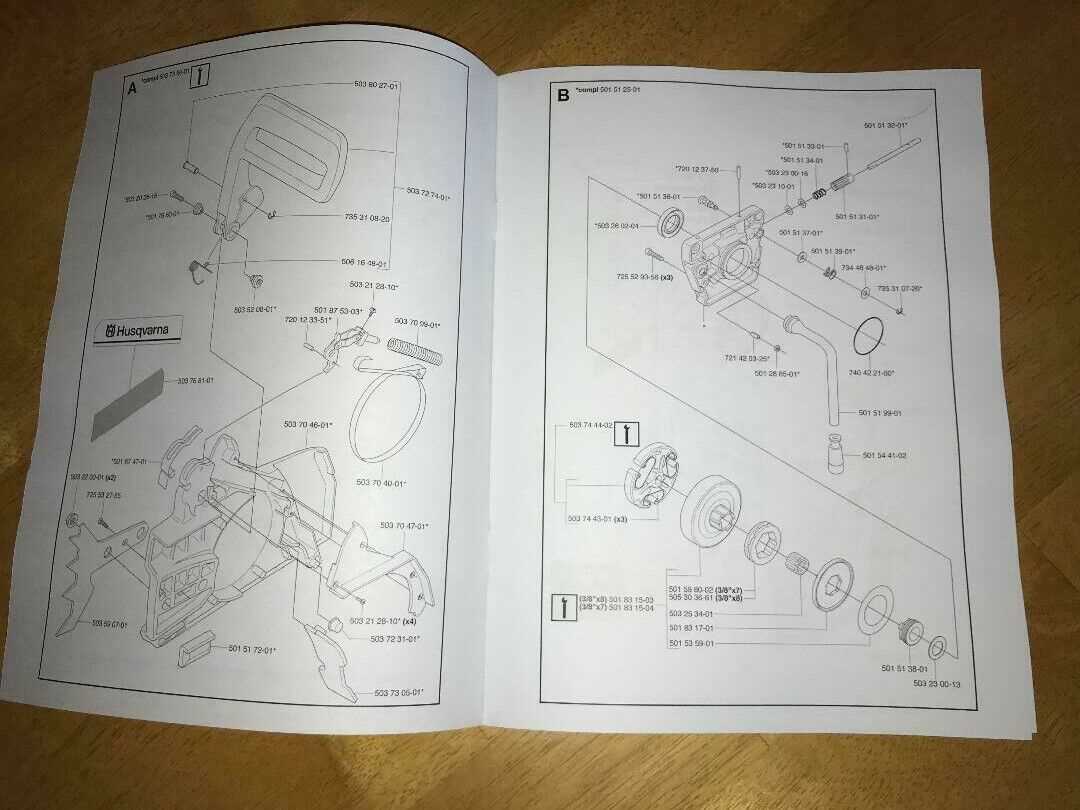

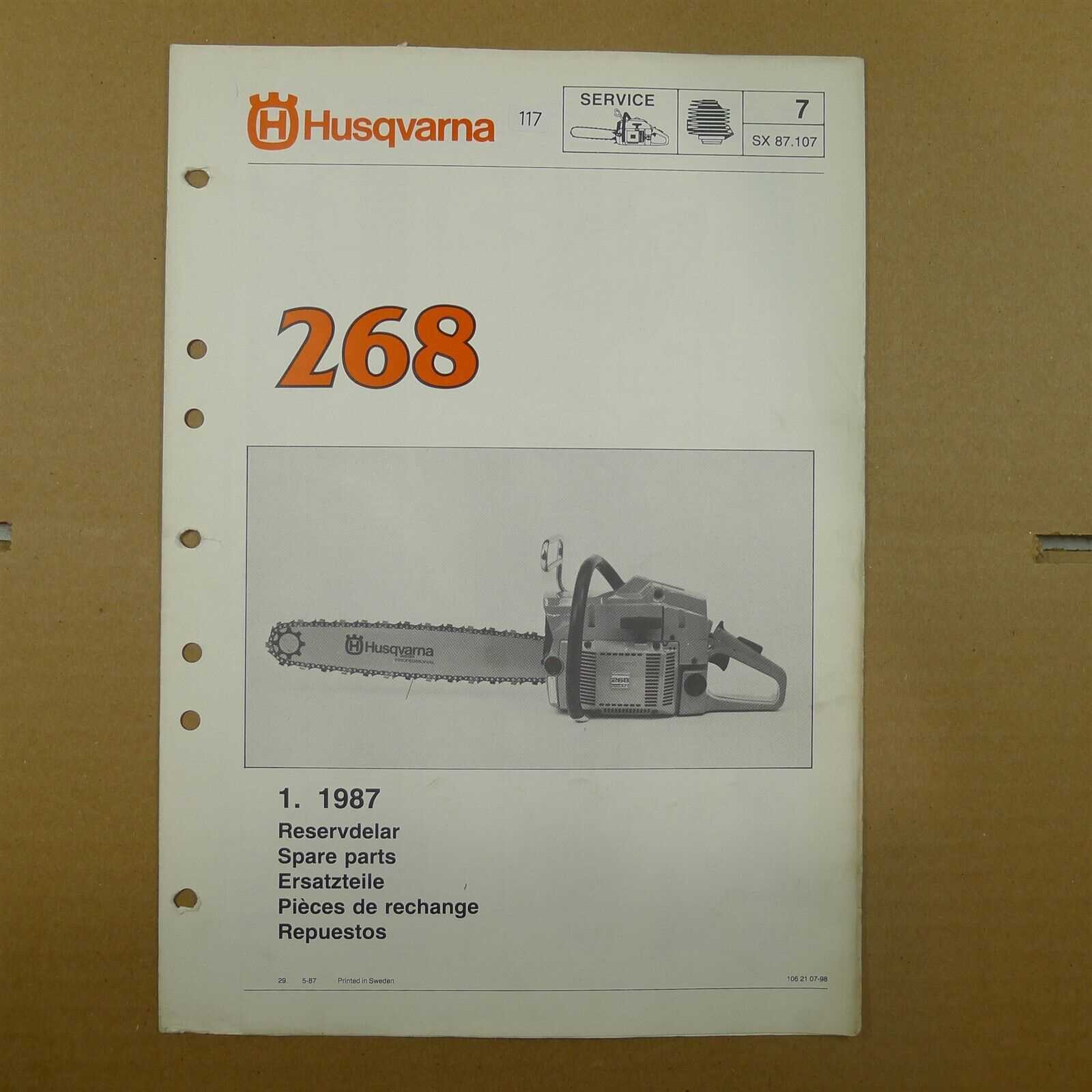

Understanding the Husqvarna 268 Diagram

This section aims to explore the intricate layout of components essential for optimal functionality. Grasping the arrangement of these elements is crucial for maintenance and troubleshooting, ensuring longevity and efficiency in performance.

| Component | Description |

|---|---|

| Engine | Core unit responsible for power generation. |

| Carburetor | Mixes air and fuel for combustion. |

| Chain Brake | Safety feature to stop the chain during emergencies. |

| Starter Assembly | Mechanism used to initiate engine operation. |

| Guide Bar | Supports and directs the cutting chain. |

Key Components of the Husqvarna 268

This section focuses on essential elements that contribute to the performance and reliability of this particular model. Understanding these components is crucial for maintenance and repair, ensuring optimal functionality and longevity of the equipment.

Engine: The heart of the machinery, the engine provides the necessary power for operation. Its efficiency and design play a vital role in overall performance.

Fuel System: This system is responsible for delivering the right mixture of fuel and air to the engine. Proper functioning of this component is essential for smooth operation and power output.

Ignition System: The ignition system initiates combustion within the engine. Reliable spark generation is crucial for starting and maintaining consistent performance.

Cutting Mechanism: This component directly influences the effectiveness of the equipment. A sharp and well-maintained cutting mechanism ensures clean and efficient work.

Housing: The outer casing not only protects internal components but also contributes to the overall ergonomics and usability of the machine. A robust housing can withstand harsh conditions while providing ease of handling.

Cooling System: Maintaining optimal temperature is vital for preventing overheating. An efficient cooling system ensures that the engine operates within safe limits, prolonging its lifespan.

Chain Brake: This safety feature stops the cutting chain in case of kickback. Its reliability is essential for user safety and operational efficiency.

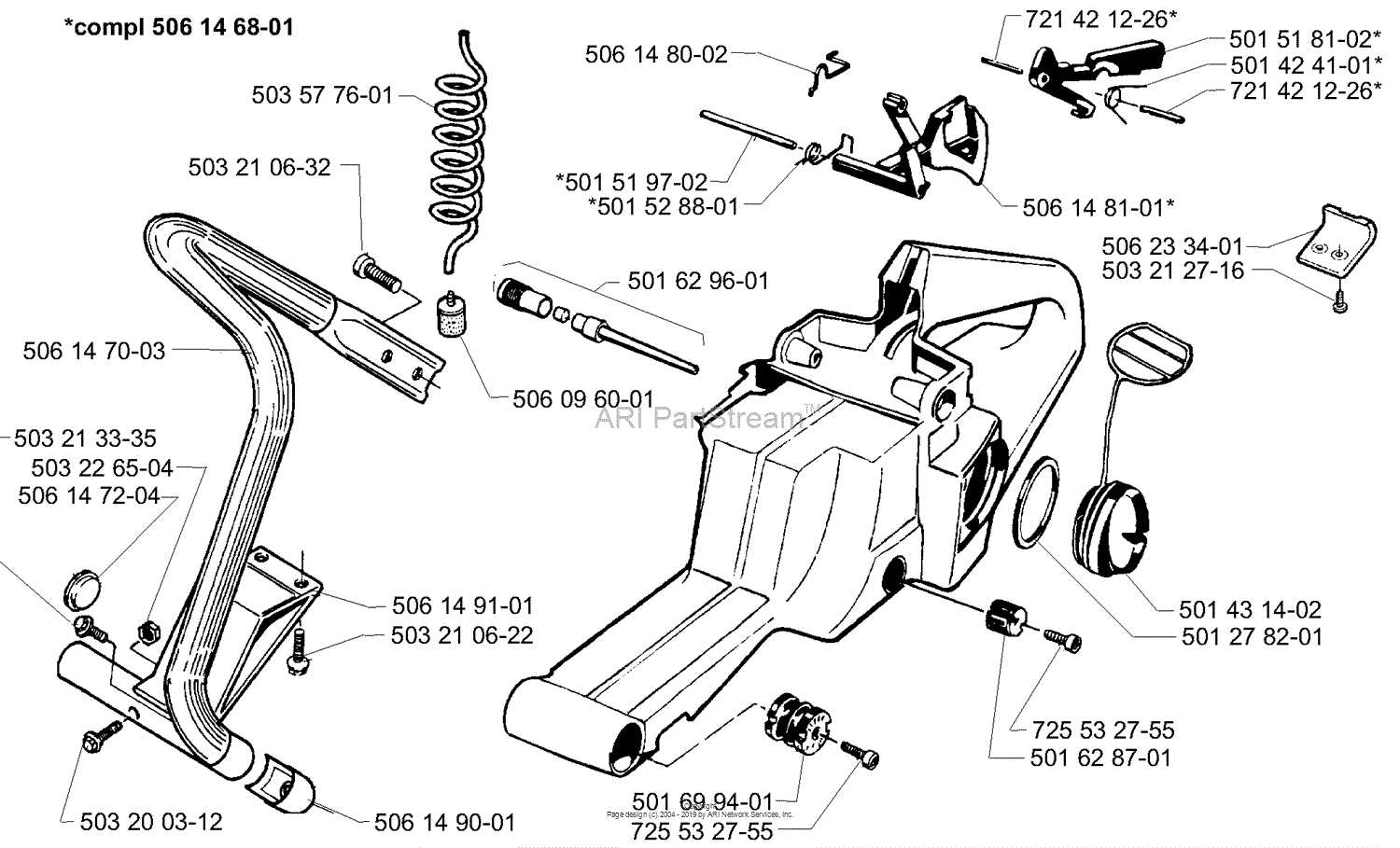

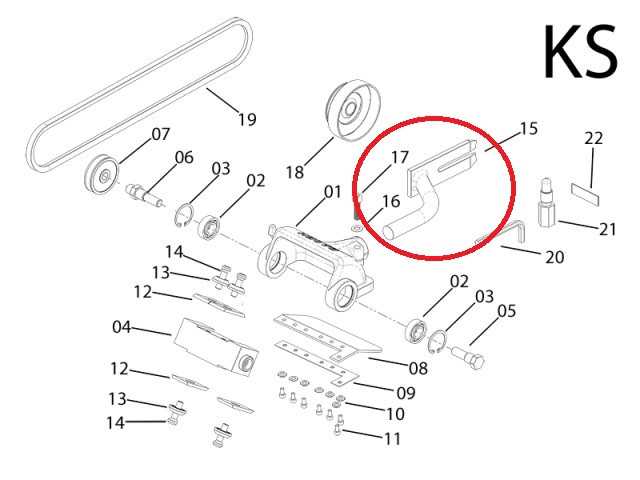

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair tasks. These visual representations provide a detailed overview of components and their relationships within a machine. By familiarizing yourself with these illustrations, you can streamline the identification and sourcing of necessary elements.

First, take note of the overall layout. Typically, these visuals are organized in a way that groups similar items together, making it easier to locate specific pieces. Next, pay attention to the labels and numbers assigned to each component. These identifiers are crucial for cross-referencing with part catalogs or ordering systems.

Additionally, observe any accompanying notes or legends that may clarify the function or specifications of certain elements. Understanding the context and purpose of each component enhances your ability to interpret the illustration accurately. Ultimately, becoming proficient in reading these visuals can greatly improve your repair efficiency and accuracy.

Importance of Accurate Diagrams

Precise visual representations play a crucial role in maintenance and repair tasks. They offer a clear reference, ensuring that components are correctly identified and assembled, which ultimately enhances efficiency and accuracy.

- Facilitates understanding of complex systems.

- Reduces the risk of errors during assembly.

- Enhances communication among technicians.

Moreover, well-structured visuals can:

- Streamline the troubleshooting process.

- Provide a reliable guide for replacements.

- Support training for new personnel.

In summary, having reliable illustrations is essential for successful repairs and maintenance, ensuring optimal performance and longevity of equipment.

Common Issues with Husqvarna 268 Parts

Various components in outdoor power equipment can encounter frequent challenges that affect performance and longevity. Understanding these issues can help users maintain their tools effectively.

Wear and Tear: Over time, certain elements are susceptible to degradation, leading to diminished efficiency. Regular inspections can identify wear before it escalates.

Fuel System Problems: Clogging in the fuel pathways often results from debris or improper fuel mixture, impacting engine performance. Cleaning or replacing filters is essential for optimal operation.

Electrical Failures: Wiring and ignition components can fail due to corrosion or physical damage. Ensuring all connections are secure and replacing faulty parts promptly can prevent further complications.

Mechanical Malfunctions: Issues such as misalignment or damage to the drive system can hinder functionality. Regular maintenance and prompt repairs can extend the lifespan of these components.

Addressing these common challenges proactively will enhance the reliability and efficiency of your outdoor machinery.

Where to Find Replacement Parts

Locating suitable components for your equipment can significantly enhance its longevity and performance. Whether you need to replace a worn-out element or upgrade for improved efficiency, understanding where to source these items is crucial. There are various avenues to explore, each with its advantages and specific offerings.

Online Retailers

The internet provides a plethora of options for purchasing new components. Many dedicated online shops specialize in machinery supplies, offering detailed catalogs that allow you to compare prices and specifications. Make sure to check customer reviews for quality assurance.

Local Dealers and Service Centers

Visiting a local distributor or service center can be beneficial. These establishments often have knowledgeable staff who can help identify the correct items you need. Additionally, purchasing locally can sometimes lead to faster access to the necessary components.

Maintenance Tips for Husqvarna 268

Proper upkeep is essential for ensuring the longevity and optimal performance of your outdoor equipment. Regular maintenance not only enhances efficiency but also minimizes the risk of unexpected breakdowns. Here are some key strategies to keep your machinery in top shape.

Regular Inspections

Conduct routine checks on vital components to identify wear and tear early. Inspect filters, spark plugs, and fuel systems to ensure everything operates smoothly. This proactive approach helps maintain peak performance.

Cleaning and Lubrication

Regular cleaning prevents debris buildup, which can hinder functionality. Use appropriate lubricants for moving parts to reduce friction and extend the lifespan of your equipment. A clean, well-lubricated machine is a reliable one.

Benefits of Using Original Parts

Choosing authentic components for your equipment ensures optimal performance and longevity. These pieces are specifically designed to meet the original manufacturer’s standards, providing reliability that generic alternatives often lack.

Enhanced Performance

Using genuine components guarantees that your machine operates at its best. Original parts are crafted to fit seamlessly, enhancing efficiency and reducing the risk of malfunction.

Increased Longevity

Investing in quality components can extend the life of your equipment. Authentic pieces are made from durable materials, minimizing wear and tear over time.

Step-by-Step Repair Process

This section outlines a comprehensive method for addressing common issues with your equipment. By following a structured approach, you can effectively identify problems and implement solutions, ensuring optimal performance and longevity.

1. Gather Necessary Tools: Before starting, collect all essential tools and components you may need. This includes wrenches, screwdrivers, and replacement items.

2. Safety First: Always prioritize safety. Wear protective gear and ensure the device is turned off and unplugged.

3. Disassemble Carefully: Begin by removing outer covers and components, taking care to note the arrangement and connections. This will aid reassembly.

4. Inspect Parts: Examine each component for wear or damage. Look for cracks, corrosion, or signs of failure that may need replacement.

5. Clean Components: Use appropriate cleaning agents to remove dirt and debris from parts, ensuring optimal functionality.

6. Replace Damaged Items: If any components are found to be faulty, replace them with suitable alternatives, ensuring compatibility.

7. Reassemble with Care: Put all parts back together in the reverse order of disassembly, making sure connections are secure.

8. Test Functionality: Once reassembled, test the device to ensure everything operates correctly and make adjustments if necessary.

9. Final Safety Check: Conduct a final safety inspection to confirm everything is secure and in good working order.

10. Maintenance Tips: After repairs, consider implementing a regular maintenance schedule to prevent future issues and enhance performance.

Tools Needed for Repairs

When tackling maintenance tasks, having the right equipment is essential for efficiency and effectiveness. The appropriate tools not only facilitate the repair process but also ensure safety and accuracy, allowing for a smoother workflow. Whether you are performing routine checks or more complex fixes, being well-prepared can make all the difference.

Essential Hand Tools

Basic hand tools such as screwdrivers, wrenches, and pliers are fundamental for any repair job. A comprehensive set that includes various sizes and types will help in handling different components. Quality tools reduce the risk of damage and make tasks easier to complete.

Power Tools and Accessories

In addition to hand tools, power tools can significantly speed up repairs. Drills, saws, and grinders, when used appropriately, can enhance precision and reduce physical strain. Ensure that you have the necessary bits and blades to complement your power tools for maximum efficiency.

Understanding Warranty and Guarantees

Warranties and guarantees serve as essential components in consumer protection, providing assurance regarding the quality and longevity of a product. They establish a promise from the manufacturer about the expected performance and reliability, allowing buyers to feel more secure in their investment.

Warranties typically cover repairs or replacements for a specified period, reflecting the manufacturer’s confidence in their craftsmanship. Guarantees, on the other hand, may offer a more definitive commitment, often allowing for a refund or exchange if the product does not meet certain standards. Understanding the nuances between these two concepts can significantly enhance your purchasing experience.

When evaluating a product, it’s crucial to read the terms associated with both warranties and guarantees. This knowledge can empower consumers to make informed decisions, ultimately leading to greater satisfaction and peace of mind.

Expert Recommendations for Owners

Maintaining your outdoor equipment is crucial for optimal performance and longevity. Here are some essential tips to ensure your machinery remains in peak condition.

Regular Maintenance Practices

- Check and replace filters regularly to ensure proper airflow.

- Keep the engine clean to prevent overheating.

- Inspect and tighten bolts and screws to avoid mechanical issues.

Parts Replacement Tips

- Always use high-quality components to maintain performance standards.

- Consult the user manual for specific recommendations on replacements.

- Keep a stock of essential spares to minimize downtime.

Upgrading Components for Better Performance

Enhancing the efficiency and capability of your equipment can significantly impact its overall functionality. By focusing on specific upgrades, you can boost performance, increase reliability, and extend the lifespan of your machine. This section explores key areas where improvements can lead to notable advancements in operation.

Engine Enhancements

One of the most effective ways to elevate performance is through engine modifications. Upgrading to a high-performance carburetor can improve fuel delivery, leading to better combustion and increased power output. Additionally, enhancing the air intake system can provide a more efficient airflow, optimizing engine performance under various conditions.

Durable Components

Investing in robust components, such as upgraded bearings and seals, can minimize wear and tear, ensuring smoother operation. Consider replacing standard parts with high-grade alternatives made from advanced materials. This not only enhances durability but also reduces maintenance frequency, allowing for uninterrupted usage and improved reliability.