Maintaining and repairing outdoor machinery can often feel overwhelming, especially when it comes to understanding its intricate components. This guide aims to simplify that process by breaking down essential elements and providing clarity on how each part functions together.

Identifying the key elements of your machine is crucial for effective troubleshooting and upkeep. By exploring the relationships between various components, users can gain valuable insights that enhance their operational experience and extend the lifespan of their equipment.

In this resource, we will delve into detailed illustrations and descriptions that highlight the ultimate functionality of each piece. This knowledge empowers users to tackle repairs with confidence and ensures optimal performance in their outdoor tasks.

Understanding Husqvarna 353 Overview

This section aims to provide a comprehensive understanding of a popular outdoor power equipment model, highlighting its key features and functionality.

The following aspects are essential for grasping the overall performance:

- Engine specifications and capabilities

- Design elements that enhance usability

- Maintenance requirements for optimal operation

- Safety features to ensure user protection

By examining these components, users can gain valuable insights into the equipment’s ultimate effectiveness and reliability.

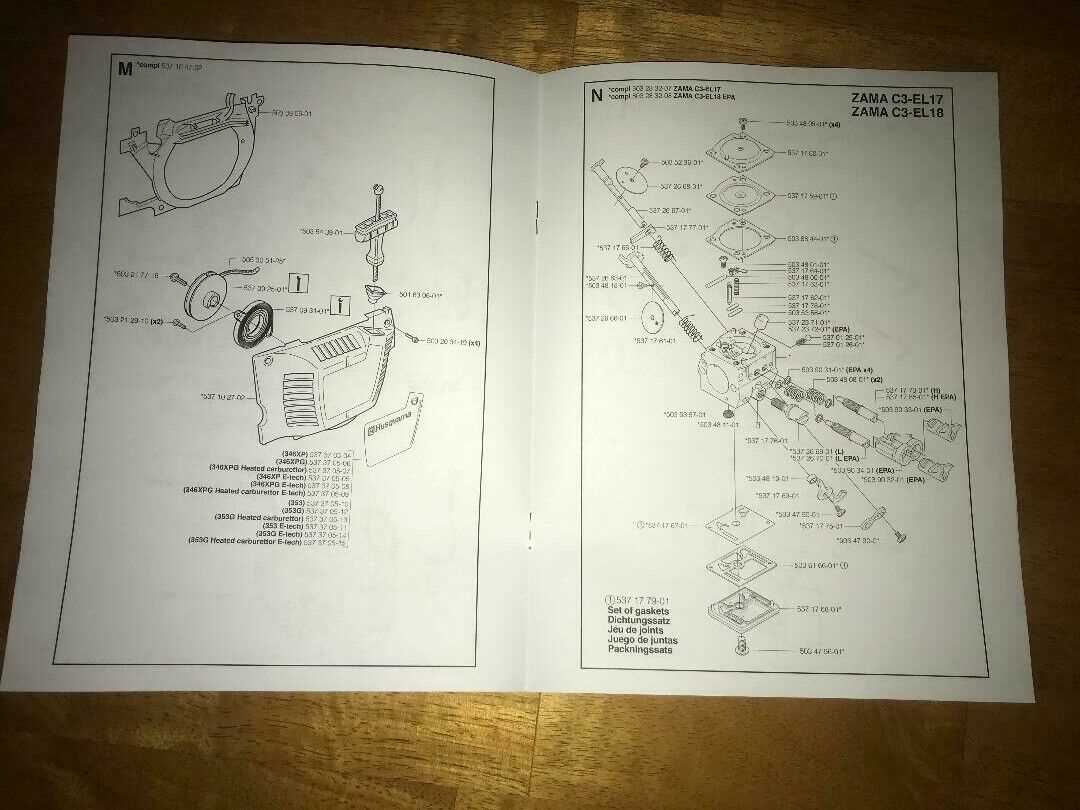

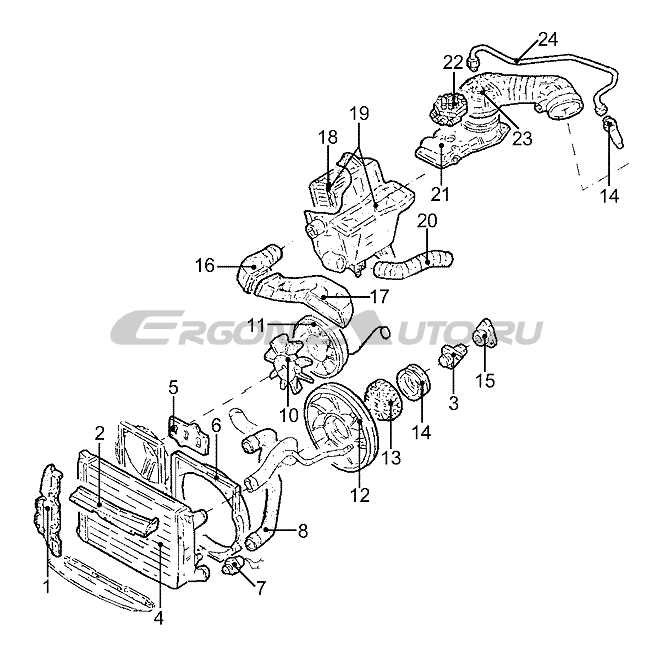

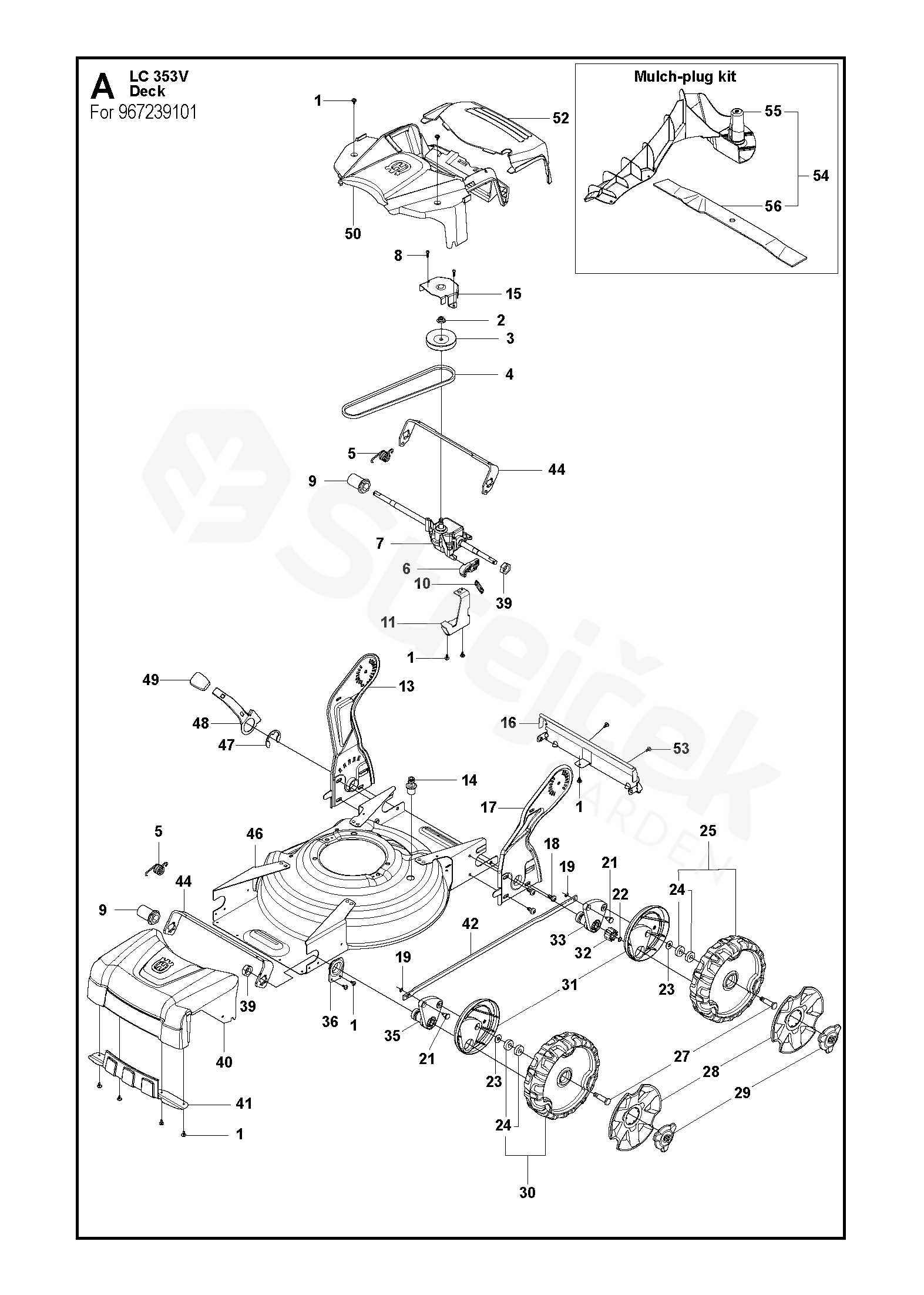

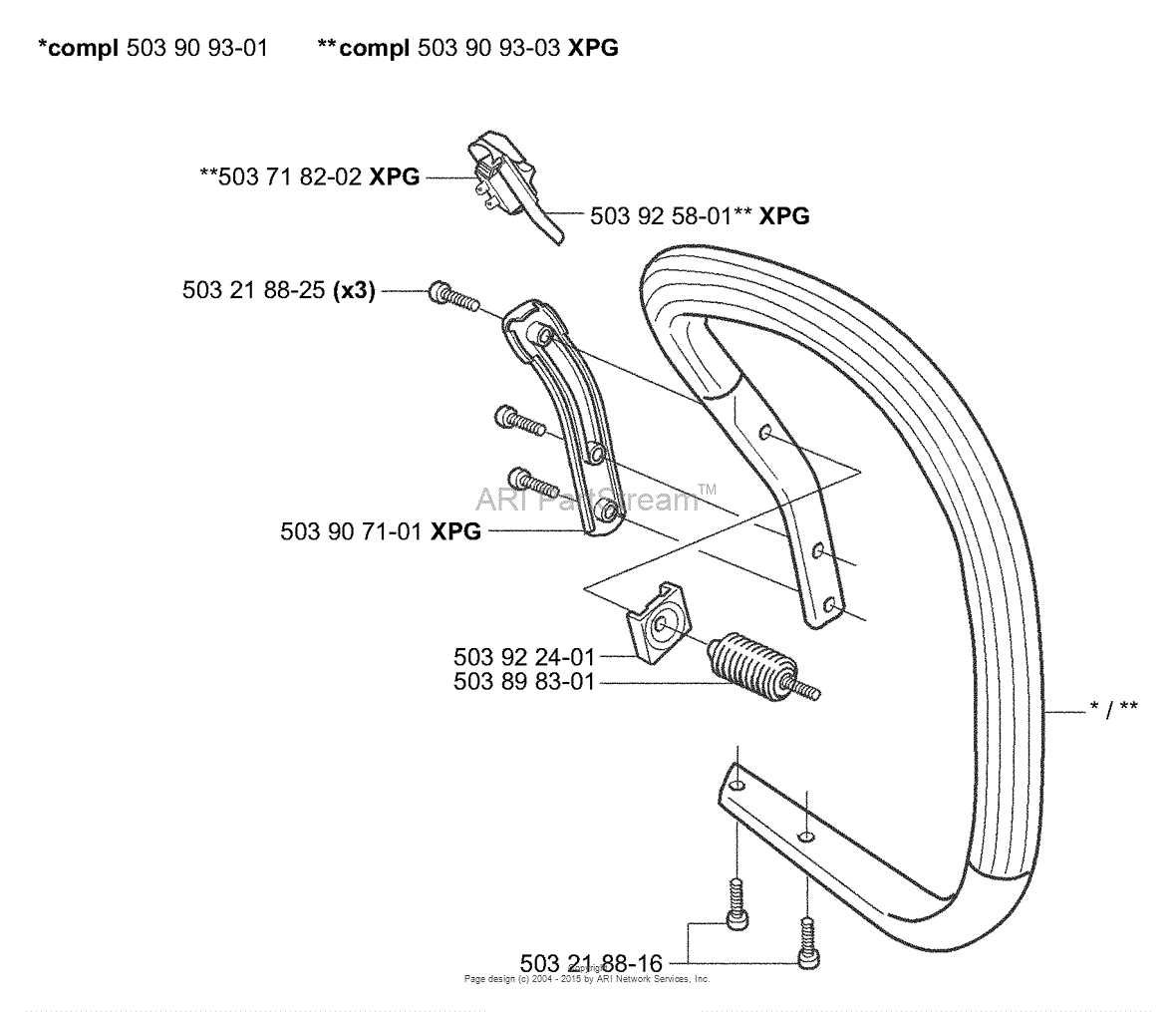

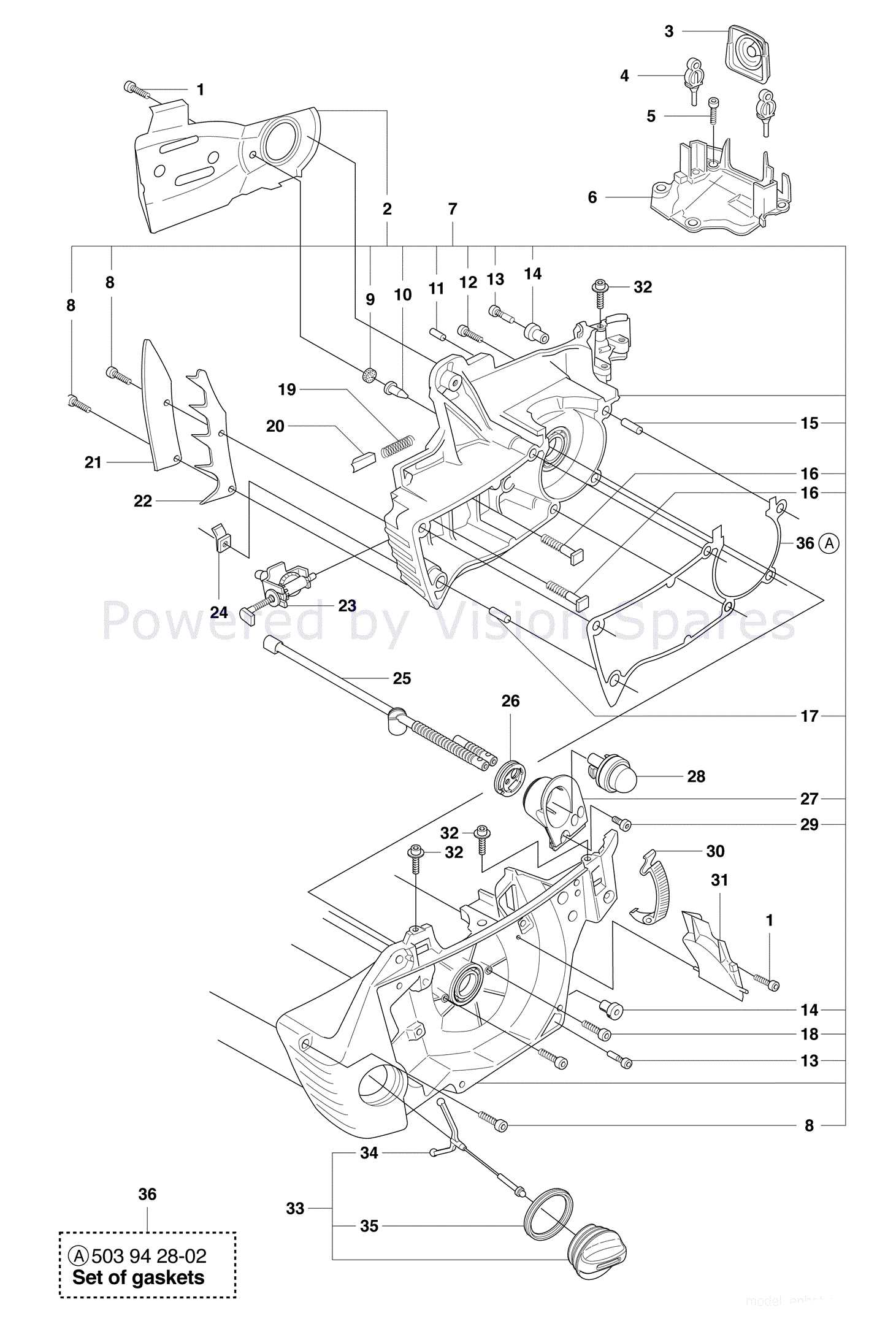

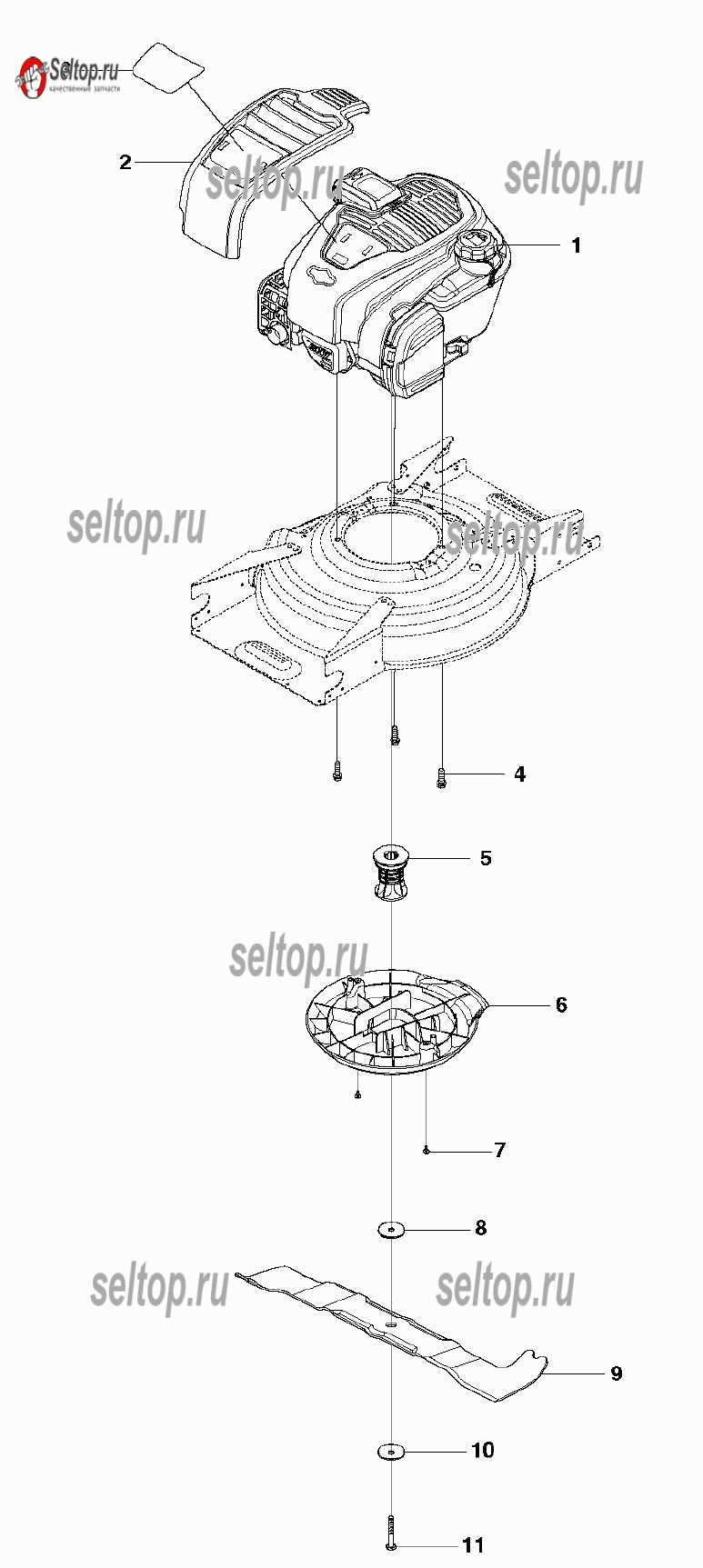

Importance of Parts Diagrams

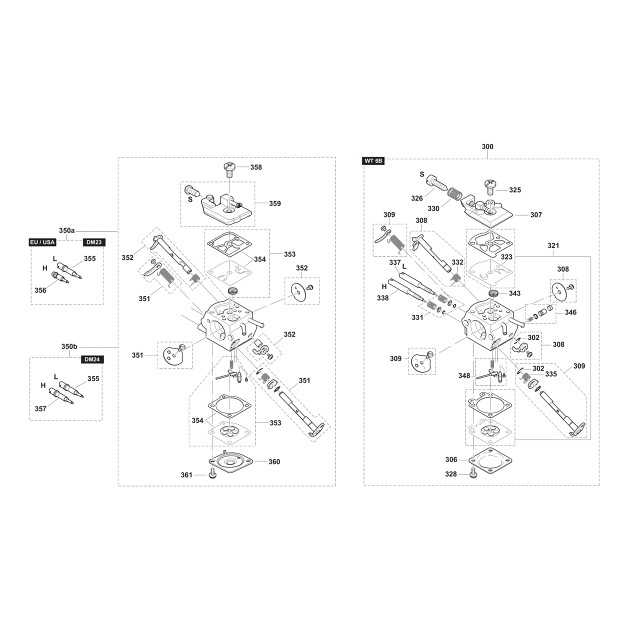

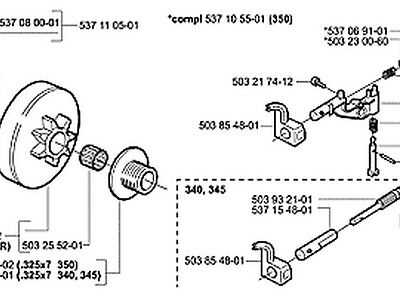

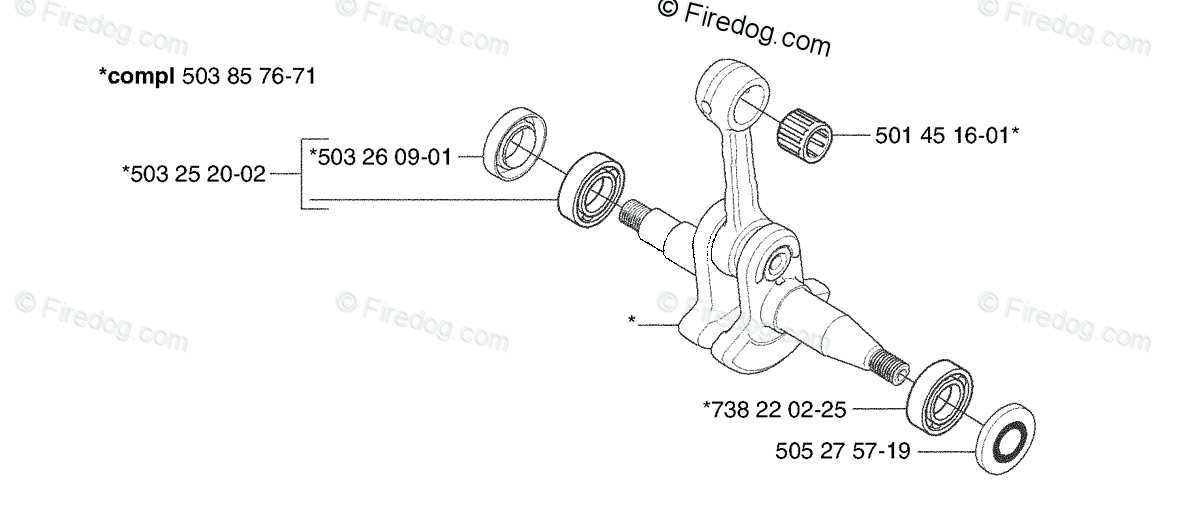

Visual representations of components play a crucial role in the maintenance and repair of machinery. They provide users with a clear overview of how different elements interact, making it easier to identify issues and understand assembly processes. These illustrations serve as essential references, guiding both novice and experienced technicians through intricate procedures.

Having access to such visuals enhances the efficiency of repairs, as they eliminate guesswork and reduce the likelihood of errors. Users can quickly locate specific elements, ensuring that the right replacements are selected and correctly installed. Moreover, these resources promote a deeper understanding of the equipment, empowering individuals to carry out repairs with confidence.

In addition to aiding in repairs, these graphical aids also facilitate communication among technicians. When discussing complex tasks, referring to a visual can streamline conversations, ensuring that everyone is on the same page. This shared understanding ultimately leads to quicker resolution times and improved overall performance of the machinery.

Key Components of Husqvarna 353

This section delves into the essential elements that contribute to the functionality and performance of the power tool. Understanding these components is crucial for maintenance and optimal operation.

Core Elements

- Engine: Provides the necessary power for operation.

- Fuel System: Ensures efficient delivery of fuel to the engine.

- Air Filter: Maintains clean air intake, protecting the engine from debris.

- Ignition System: Responsible for starting the engine and maintaining combustion.

Supporting Features

- Clutch: Engages and disengages the drive mechanism.

- Guide Bar: Directs the cutting action, aiding in precision.

- Chain: Cuts through materials, requiring regular inspection and maintenance.

- Throttle Control: Regulates engine speed and power output.

Familiarity with these components will enhance the user experience and prolong the lifespan of the tool, ensuring it remains effective in various tasks.

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for efficient maintenance and repairs. This visual guide helps identify each element, facilitating easier assembly and disassembly.

To effectively interpret such a visual aid, follow these steps:

- Familiarize with Symbols: Learn common symbols used in the illustration.

- Identify Sections: Break down the image into manageable parts, focusing on each segment.

- Use the Legend: Refer to any accompanying legend for definitions of terms and symbols.

- Trace Connections: Follow lines or arrows to understand how components interact.

By mastering these techniques, you can enhance your ability to navigate through any technical illustration with confidence.

Common Issues with Husqvarna 353

When operating outdoor power equipment, users often encounter a variety of challenges that can affect performance and reliability. Understanding these common problems can help in diagnosing issues quickly and effectively, ensuring that the machinery remains in optimal working condition.

Fuel System Troubles

One prevalent issue relates to the fuel system. Users may notice difficulty starting the engine or erratic performance while in use. This can stem from clogged filters or contaminated fuel, which can lead to reduced efficiency. Regular maintenance, including cleaning or replacing fuel filters and using fresh fuel, can mitigate these problems.

Starting Difficulties

Another frequent complaint involves starting difficulties. This can manifest as the engine not turning over or a lack of power upon ignition. Possible causes include faulty spark plugs or issues with the ignition system. Ensuring that the spark plug is clean and functioning properly is essential for reliable starts. Additionally, inspecting the ignition components for wear can prevent future headaches.

Where to Find Replacement Parts

When seeking components for outdoor equipment, various sources can provide what you need for effective repairs and maintenance. Identifying reliable avenues ensures you have access to quality materials that restore functionality.

- Authorized Dealers: Visiting certified retailers guarantees authenticity and proper fit.

- Online Marketplaces: Websites dedicated to tools and machinery often offer a wide selection.

- Manufacturer’s Website: Direct purchase from the official site can yield the latest inventory.

- Local Repair Shops: These establishments may stock necessary items or order them for you.

It’s essential to compare options for price and availability to ensure you get the ultimate value for your investment.

Maintaining Your Husqvarna 353

Proper upkeep of your outdoor equipment is crucial for its longevity and performance. Regular maintenance ensures that the machine operates smoothly, reducing the risk of breakdowns and enhancing efficiency. By following a structured approach, you can extend the life of your tool and ensure optimal functioning.

Regular Cleaning: Keep the exterior and components free from debris and dirt. A clean machine not only looks better but also performs more effectively.

Inspecting Components: Frequently check essential parts such as the air filter, spark plug, and fuel system. Replacing worn or damaged items promptly can prevent larger issues.

Lubrication: Proper lubrication of moving parts is essential. It reduces friction and wear, ensuring that everything operates seamlessly.

Storage Tips: When not in use, store your equipment in a dry, cool place. Consider draining fuel to prevent degradation and damage over time.

By committing to these maintenance practices, you can achieve the ultimate reliability and performance from your equipment.

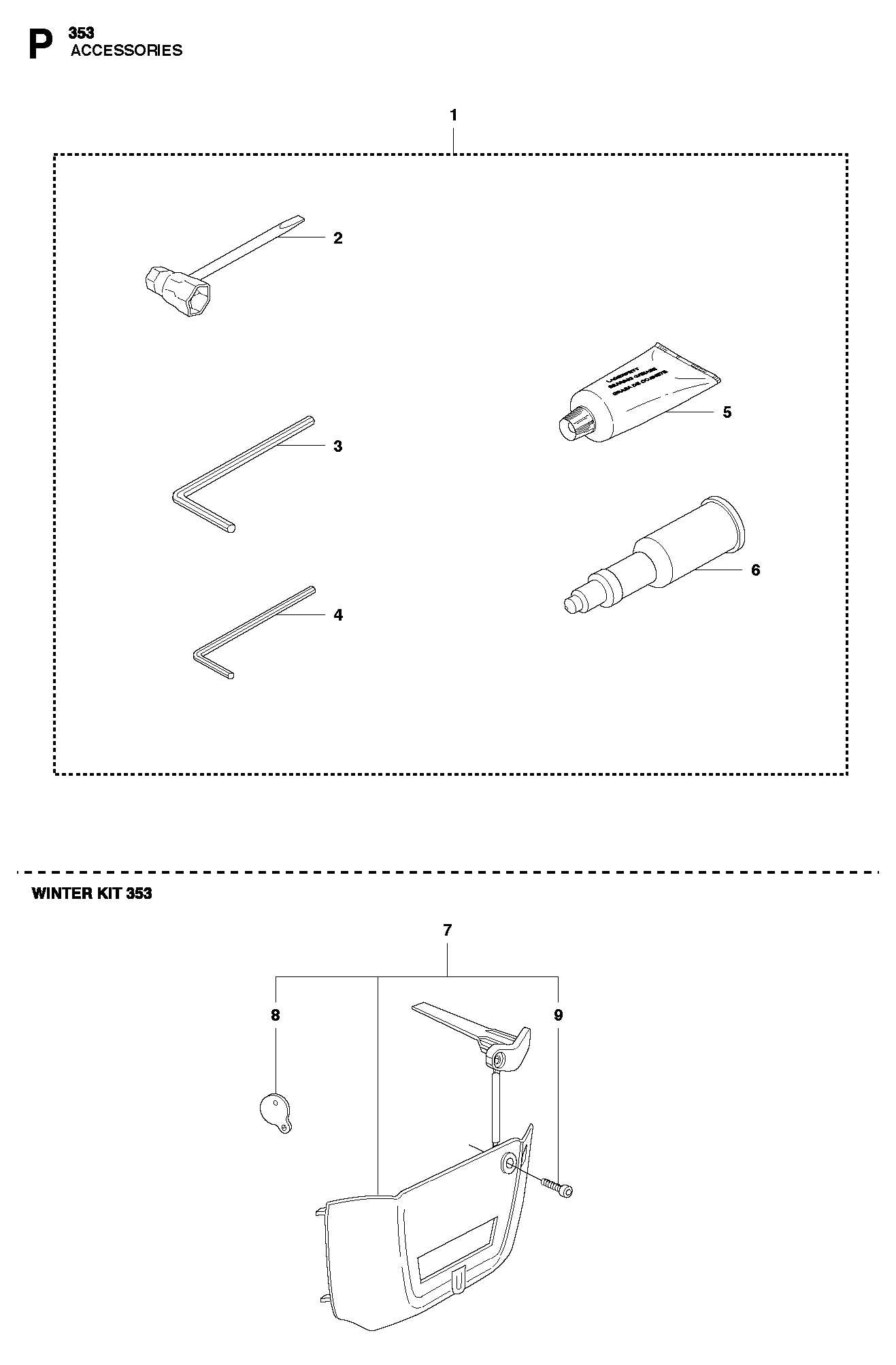

Tools Needed for Repairs

When embarking on maintenance tasks, having the right instruments is essential for efficient and effective work. The appropriate equipment not only simplifies the process but also ensures that repairs are executed safely and accurately. Understanding which tools to utilize can ultimately enhance your repair experience and outcome.

Key items to consider include wrenches, screwdrivers, and pliers, which are fundamental for disassembly and reassembly. Additionally, specialized tools may be necessary for specific components, ensuring that you can delve into more complex repairs with confidence. A reliable toolkit lays the groundwork for successful maintenance endeavors.

Finally, don’t overlook safety gear, such as gloves and goggles, which are crucial for protecting yourself during repairs. By equipping yourself with the right tools and safety measures, you set the stage for a smooth and rewarding repair process.

Tips for Efficient Repairs

When tackling repairs on outdoor equipment, having a systematic approach can significantly enhance efficiency and accuracy. By following some straightforward guidelines, you can ensure that the process is smooth, and the outcome is satisfactory. Here are several strategies to consider for effective maintenance and repair tasks.

| Tip | Description |

|---|---|

| Organize Tools | Keep all necessary tools in a designated area. This minimizes the time spent searching for items and helps maintain focus during repairs. |

| Consult Manuals | Always refer to the user manual or service guide. This resource often contains vital information about assembly, disassembly, and troubleshooting. |

| Prepare a Clean Workspace | A tidy environment reduces the risk of losing small components and makes the repair process more efficient. |

| Take Notes | Document each step of the repair process. This will help you remember the order of assembly and identify any issues that arise during the work. |

| Use Quality Replacement Parts | Opt for high-quality components that meet or exceed original specifications to ensure longevity and performance. |

| Ask for Help | If uncertain about a procedure, seek advice from knowledgeable friends or professionals. Collaboration can lead to better results and save time. |

Benefits of OEM Parts

Utilizing original components ensures optimal performance and reliability for your machinery. These items are specifically designed to fit seamlessly, reducing the risk of malfunctions and extending the lifespan of the equipment.

Quality Assurance: Original pieces are manufactured to stringent standards, guaranteeing superior quality compared to generic alternatives.

Enhanced Compatibility: When you choose OEM options, you can be confident in their compatibility with your equipment, minimizing the chances of issues that arise from mismatched components.

Warranty Protection: Using genuine components often keeps your warranty intact, providing peace of mind and protection against unexpected repair costs.

Improved Performance: Original items are engineered to work optimally with your machine, ensuring it operates at its best, which can ultimately lead to better efficiency and productivity.

Investing in genuine components is a wise decision that pays off in the long run, enhancing the overall experience and reliability of your machinery.

Frequently Asked Questions

This section addresses common inquiries related to maintenance and components for outdoor equipment. Here, we aim to provide clarity and assistance to users seeking information about their machinery and its upkeep.

What are the signs that I need to replace a component?

Look for decreased performance, unusual noises, or visible wear. If your machine struggles to operate smoothly, it may be time to consider replacements.

How can I find the right specifications for my model?

Consult the user manual or check the manufacturer’s website for detailed specifications. Accurate information ensures you select the appropriate parts for your equipment.

Is it necessary to use original components?

While aftermarket options exist, using original parts often ensures better compatibility and longevity, ultimately enhancing the machine’s performance.

Where can I purchase replacement parts?

Authorized dealers, online retailers, and specialty shops typically carry a wide range of components for various models.

How do I perform routine maintenance?

Regularly check filters, oil levels, and belts. Following a maintenance schedule helps prolong the life of your equipment and ensures optimal functioning.

Resources for Husqvarna Owners

For enthusiasts and operators of outdoor power equipment, having access to reliable resources is essential for maintenance and repair. These tools and guides can significantly enhance the experience of ownership and ensure optimal performance.

| Resource Type | Description | Link |

|---|---|---|

| User Manuals | Comprehensive guides detailing operation and care. | Visit |

| Community Forums | Online platforms for sharing tips and troubleshooting. | Visit |

| Repair Videos | Step-by-step visual guides for common repairs. | Visit |

| Parts Suppliers | Reliable sources for high-quality replacement components. | Visit |