The functionality of any outdoor machinery greatly depends on the intricate arrangement of its individual elements. A clear representation of these components enhances both the understanding and maintenance of the equipment. By visualizing how each piece interacts within the system, users can ensure optimal performance and longevity of their devices.

In this section, we delve into the specific arrangements and configurations of various parts essential for the efficient operation of cutting-edge outdoor tools. With a focus on accessibility and clarity, we will explore how each element contributes to the overall functionality, enabling users to make informed decisions during repairs or upgrades.

By gaining insight into the various components and their respective roles, operators can better appreciate the craftsmanship involved in modern machinery. This knowledge empowers users to tackle maintenance tasks with confidence, ultimately leading to a more rewarding experience with their equipment.

Overview of Husqvarna 395XP Components

This section delves into the essential elements that constitute a powerful and reliable outdoor machine designed for high-performance tasks. Understanding these components can enhance user knowledge and improve maintenance practices, ultimately leading to optimal functionality and longevity of the equipment.

The assembly includes various vital sections, each contributing to the overall efficiency and performance. The engine serves as the core, providing the necessary power for operation, while the fuel system ensures proper fuel delivery and combustion. Additionally, the ignition mechanism plays a crucial role in initiating the combustion process, allowing for smooth starts and consistent operation.

Moreover, the cutting assembly is designed for precision and durability, making it suitable for various applications. The ergonomic handles and controls enhance user experience by promoting comfort and ease of use. Understanding the interaction of these components helps in troubleshooting and optimizing the performance of the machinery.

Understanding Chain Saw Mechanics

The operation of a cutting tool involves a complex interplay of various components, each contributing to its overall functionality. A comprehensive understanding of these elements is essential for anyone looking to maintain or operate such equipment effectively. This knowledge aids in recognizing how each part works together to ensure optimal performance.

Key components of these machines include the power source, drive mechanisms, and the cutting assembly. Each part plays a crucial role in enabling the device to perform its tasks efficiently. Below is a table that highlights some of the essential elements and their respective functions:

| Component | Function |

|---|---|

| Engine | Provides power to drive the chain |

| Chain | Engages in cutting through various materials |

| Guide Bar | Directs the chain during operation |

| Clutch | Engages and disengages the chain from the engine |

| Fuel System | Supplies energy to the engine |

By familiarizing oneself with these components, operators can better appreciate the intricacies of their cutting tools, leading to more informed decisions regarding maintenance and usage.

Identifying Essential Replacement Parts

When maintaining outdoor equipment, recognizing crucial components for replacement is vital for ensuring optimal performance and longevity. Understanding the various elements that may require periodic attention allows users to keep their machinery running smoothly and efficiently. This section delves into the most common components that often need to be replaced, providing insights into their importance and function.

Common Components for Replacement

Among the essential elements, filters play a critical role in maintaining the health of the engine. These components trap debris and contaminants, preventing them from causing damage. Regularly replacing filters enhances airflow and efficiency, which is crucial for performance.

Understanding Wearable Items

Another category to consider includes wearable items, such as chains and spark plugs. These parts are subject to wear and tear due to regular usage and should be inspected frequently. Replacing them at the right intervals ensures reliable operation and reduces the risk of breakdowns during crucial tasks.

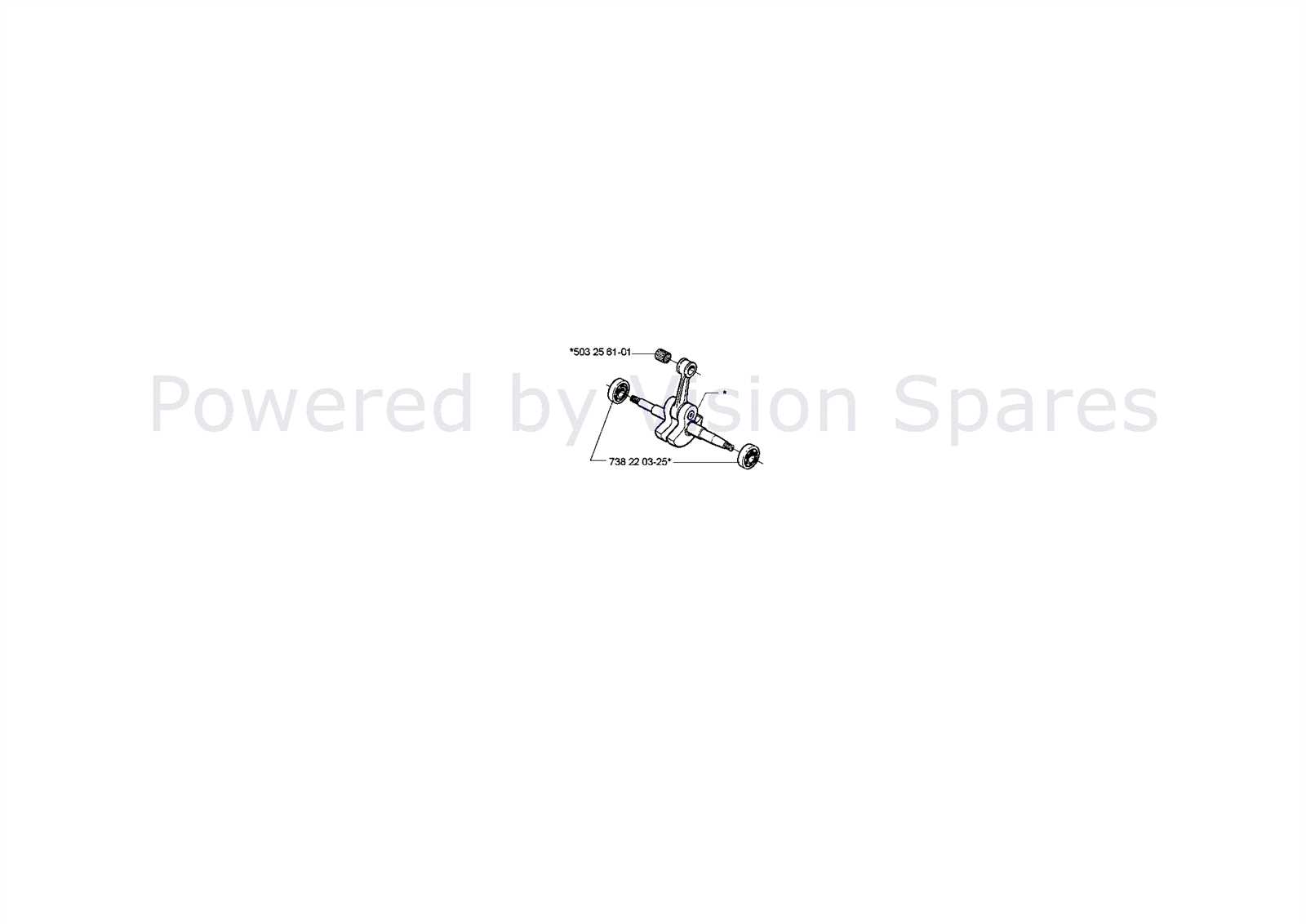

Exploring Engine Assembly Details

Understanding the intricacies of a power unit’s construction is vital for maintaining optimal performance and longevity. This section delves into the key components that contribute to the efficient operation of the engine, offering insights into their interconnections and functions.

At the heart of the assembly lies a series of essential elements, each playing a critical role:

- Cylinder: The main chamber where combustion occurs, essential for converting fuel into mechanical energy.

- Piston: This component moves up and down within the cylinder, driven by the combustion process, translating energy into motion.

- Cylinder Head: Sealing the top of the cylinder, it houses the intake and exhaust valves, controlling airflow in and out of the combustion chamber.

- Crankshaft: Converting the linear motion of the piston into rotational motion, it is pivotal in transmitting power to the drive mechanism.

- Connecting Rod: Linking the piston to the crankshaft, it plays a crucial role in translating motion between these two parts.

Each of these components must be assembled with precision to ensure the engine operates smoothly. Regular inspections and maintenance can prevent issues that may arise from wear and tear, ultimately enhancing performance and reliability.

Maintenance Tips for Longevity

Ensuring the durability and efficient performance of your equipment requires regular care and attention. By adopting a proactive approach to upkeep, you can significantly extend the lifespan of your machinery. Below are essential recommendations for maintaining your tools effectively.

| Tip | Description |

|---|---|

| Regular Cleaning | Remove debris and residue from the exterior and components to prevent damage and ensure optimal operation. |

| Routine Lubrication | Apply appropriate lubricants to moving parts to minimize friction and wear, ensuring smooth functionality. |

| Check Fasteners | Inspect and tighten bolts and screws periodically to maintain structural integrity and prevent loosening during use. |

| Replace Worn Components | Identify and replace any deteriorated or damaged parts promptly to avoid further complications and maintain efficiency. |

| Store Properly | Keep tools in a dry, protected area to safeguard against environmental factors that could lead to rust or deterioration. |

Key Features of the 395XP

This model is renowned for its robust performance and durability, making it a preferred choice among professionals in demanding environments. Its exceptional engineering ensures reliability, while various design elements contribute to enhanced efficiency and user comfort.

Power and Performance

The engine delivers impressive power output, allowing for rapid cutting through tough materials. The optimized design promotes fuel efficiency, making it suitable for extended use without frequent refueling. This combination of strength and efficiency enhances overall productivity.

User-Friendly Design

Ergonomic features ensure comfort during operation, reducing fatigue over long periods. The accessible controls and lightweight construction facilitate easy handling, allowing users to maneuver with precision. Maintenance is simplified through thoughtfully designed access points, contributing to a seamless user experience.

Parts Compatibility with Other Models

Understanding the interchangeability of components among different models can significantly enhance the maintenance and repair process. Many individuals seek to optimize their equipment by utilizing available resources, ensuring that they achieve the best performance possible without incurring excessive costs. This aspect of compatibility is particularly valuable for those who own multiple machines or are looking for economical solutions when replacing essential elements.

Below is a comparison table highlighting some common components and their compatibility across various models:

| Component | Compatible Models |

|---|---|

| Engine Assembly | Model A, Model B, Model C |

| Fuel Tank | Model D, Model E, Model F |

| Air Filter | Model G, Model H, Model I |

| Handle Grip | Model J, Model K, Model L |

By referencing this information, users can make informed decisions about utilizing compatible components from various models, ultimately saving time and resources in their maintenance efforts.

Assembly Process Simplified

The assembly procedure for complex machinery can often appear daunting. However, breaking down the process into manageable steps can facilitate understanding and efficiency. This section aims to clarify the essential components involved in the construction of a particular model, enabling users to navigate the assembly with ease.

By following a systematic approach, individuals can ensure that each part is correctly positioned and secured. Below is a simplified representation of the assembly stages, highlighting the necessary components and their respective functions.

| Step | Component | Description |

|---|---|---|

| 1 | Base Frame | The foundational structure that supports all other elements. |

| 2 | Engine | The power source responsible for driving the machinery. |

| 3 | Fuel System | Manages the delivery of fuel to the engine. |

| 4 | Cooling System | Regulates the temperature to prevent overheating. |

| 5 | Controls | Interface used for operating the device effectively. |

| 6 | Safety Features | Mechanisms that enhance user protection during operation. |

By adhering to these outlined steps and understanding the role of each component, users can achieve a more streamlined assembly experience.

Common Issues and Solutions

When operating high-performance machinery, encountering challenges is not uncommon. Understanding these frequent problems and their respective remedies can significantly enhance efficiency and longevity. Below are some prevalent concerns that users may face along with practical solutions.

Overheating is a frequent issue that can lead to reduced performance. This typically occurs when the engine operates for extended periods without adequate cooling. To address this, ensure that air intake vents are clear of debris and that the cooling fins are clean. Regular maintenance, including checking and replacing coolant as necessary, is essential.

Difficulty in starting can frustrate users. This issue may stem from fuel problems or a malfunctioning ignition system. Checking fuel lines for blockages and ensuring that the spark plug is clean and functional can resolve these starting issues. If the problem persists, consider inspecting the ignition coil.

Vibrations during operation can indicate imbalances or misalignments. Ensuring that all components are securely attached and that the blade or attachment is balanced can help minimize this issue. Regularly inspecting and tightening bolts and screws is a proactive measure.

Finally, fuel inefficiency is a concern for many operators. This can often be remedied by using high-quality fuel and maintaining the correct air-fuel mixture. Regular maintenance checks can help identify and resolve issues that lead to poor fuel consumption.

Benefits of Genuine Parts

Utilizing authentic components for machinery ensures optimal performance and longevity. These original elements are specifically designed to fit and function seamlessly within the equipment, providing a level of reliability that generic alternatives often cannot match. The importance of choosing the right pieces cannot be overstated, as it directly impacts the efficiency and safety of operations.

Quality Assurance

Authentic elements are manufactured to meet stringent quality standards. This guarantees that each component performs consistently, reducing the risk of malfunctions or breakdowns. The attention to detail in the production process ensures durability, which is crucial for heavy-duty machinery.

Enhanced Performance

Using original components enhances the overall functionality of the equipment. These parts work harmoniously with the machine’s design, maximizing efficiency and minimizing wear and tear. This synergy translates to better fuel efficiency and improved productivity.

| Feature | Genuine Components | Generic Alternatives |

|---|---|---|

| Quality | High standards | Variable quality |

| Performance | Optimal functionality | Inconsistent results |

| Durability | Long-lasting | Shorter lifespan |

| Warranty | Manufacturer’s warranty | Limited or no warranty |

Resources for Parts Sourcing

Finding reliable resources for sourcing components can significantly enhance maintenance and repair efforts. Various platforms and suppliers offer an extensive selection of materials, ensuring that users can easily access the necessary items for their machinery. Understanding where to look and what to consider is crucial for effective procurement.

Online marketplaces provide a vast array of choices, often featuring competitive prices and user reviews that help in making informed decisions. Additionally, local retailers and specialty stores may offer personalized assistance and immediate availability of specific elements. Exploring both options can yield a comprehensive understanding of what is accessible in the market.

Furthermore, online forums and communities dedicated to equipment enthusiasts can be invaluable. Members frequently share insights, recommendations, and even direct links to suppliers, enhancing the overall sourcing experience. Engaging with such groups fosters knowledge exchange and helps users stay updated on the latest trends in component availability.

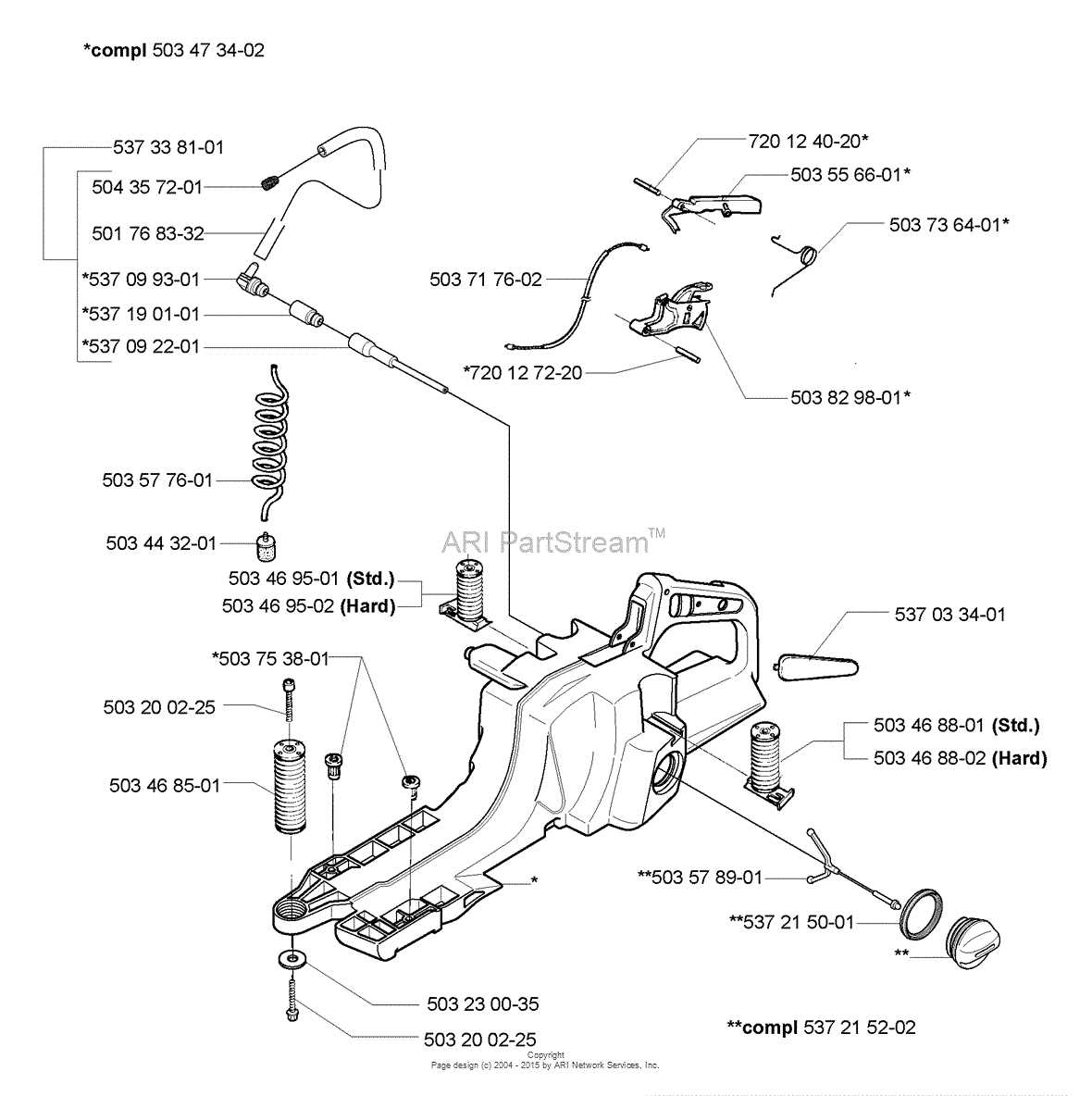

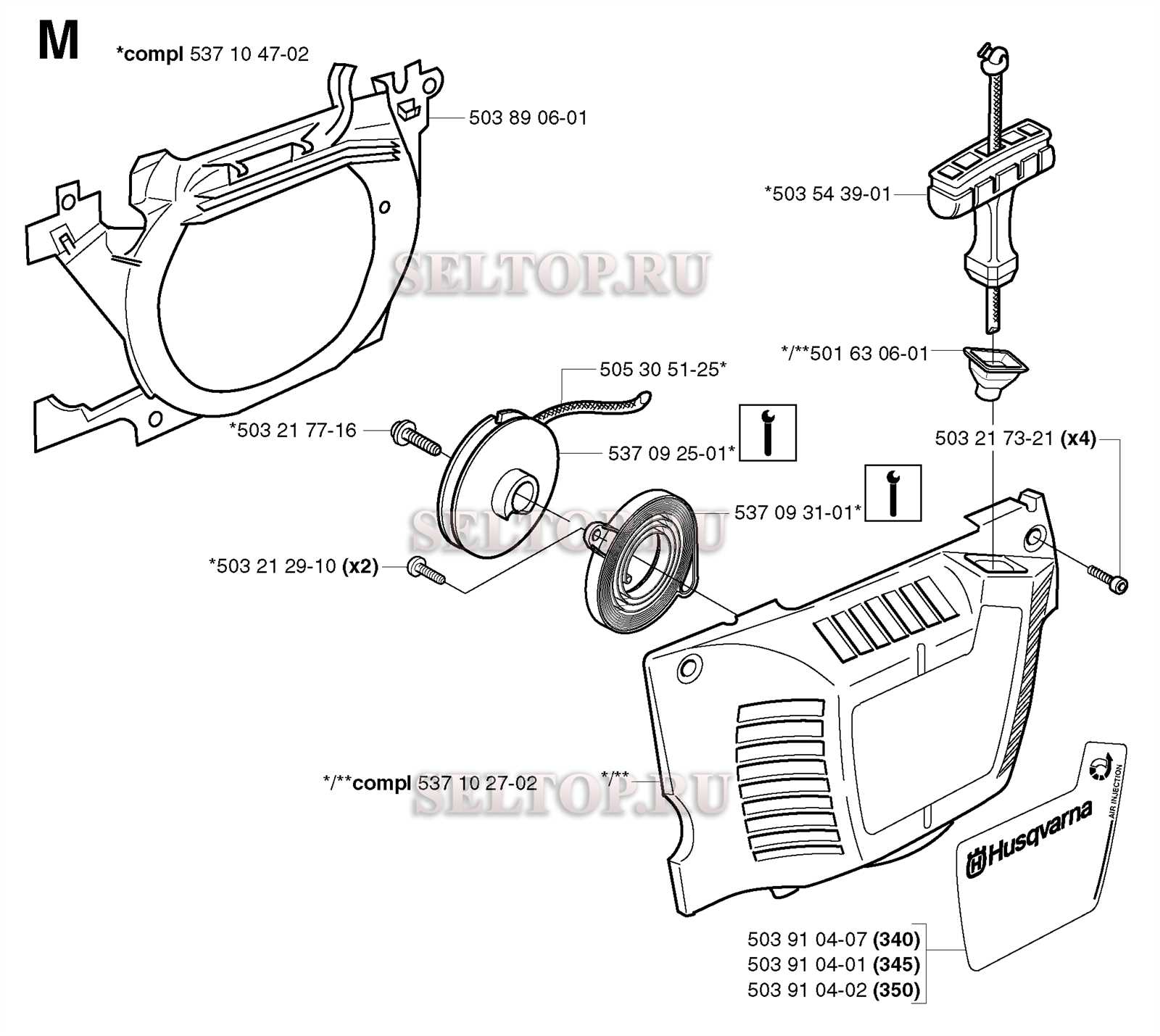

Assembly Diagram Analysis

Examining the assembly layout provides invaluable insights into the intricate arrangement of components within the equipment. This visual representation serves as a guide for understanding how various parts interact and function together, allowing for effective maintenance and repair. By analyzing this layout, one can identify the roles of individual elements and their contributions to the overall performance.

Understanding Component Relationships is crucial for anyone looking to enhance their familiarity with the machinery. Each section of the layout highlights the connection between distinct elements, revealing how they cooperate to achieve optimal functionality. Recognizing these relationships aids in troubleshooting and optimizing operations.

Identifying Potential Issues can also be facilitated by a thorough examination of the assembly layout. Observing wear and tear or misalignments within the visual guide can prompt timely interventions, preventing further damage and ensuring longevity. This proactive approach underscores the importance of regularly consulting the layout during maintenance procedures.