Understanding the intricate structure of outdoor machinery is essential for effective maintenance and repair. This section provides valuable insights into how different components interact within various models. By examining these references, users can enhance their familiarity with the equipment they own.

With a detailed examination of each element, individuals can gain clarity on the specific roles that various parts play in the overall functionality. This knowledge empowers users to tackle repairs confidently and ensures that their machinery operates at peak performance.

Whether you are a seasoned professional or a casual user, having access to comprehensive assembly references can significantly streamline your workflow. Such resources serve not only as guides for troubleshooting but also as educational tools for understanding the mechanics of your equipment.

Understanding Husqvarna Parts Diagrams

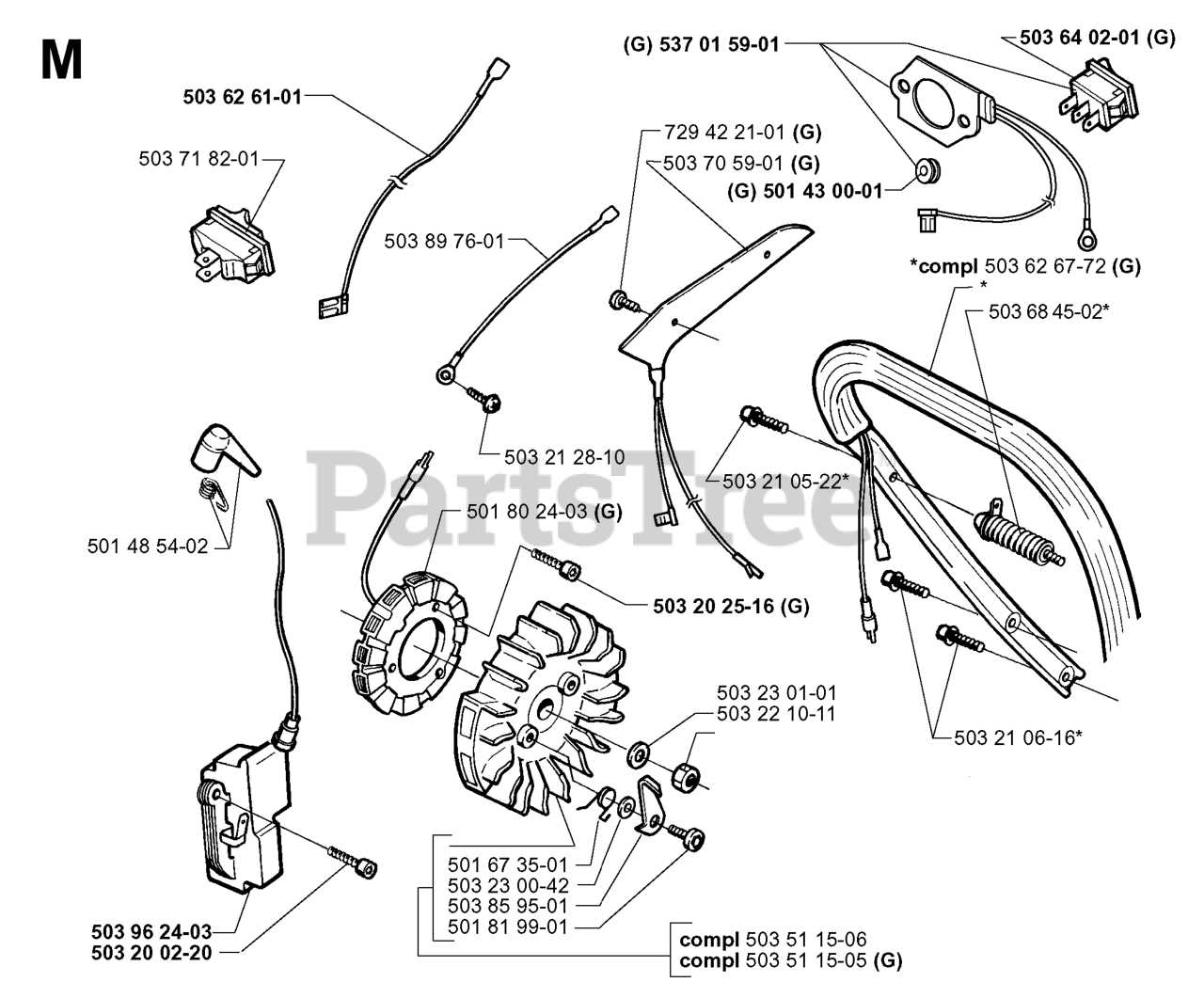

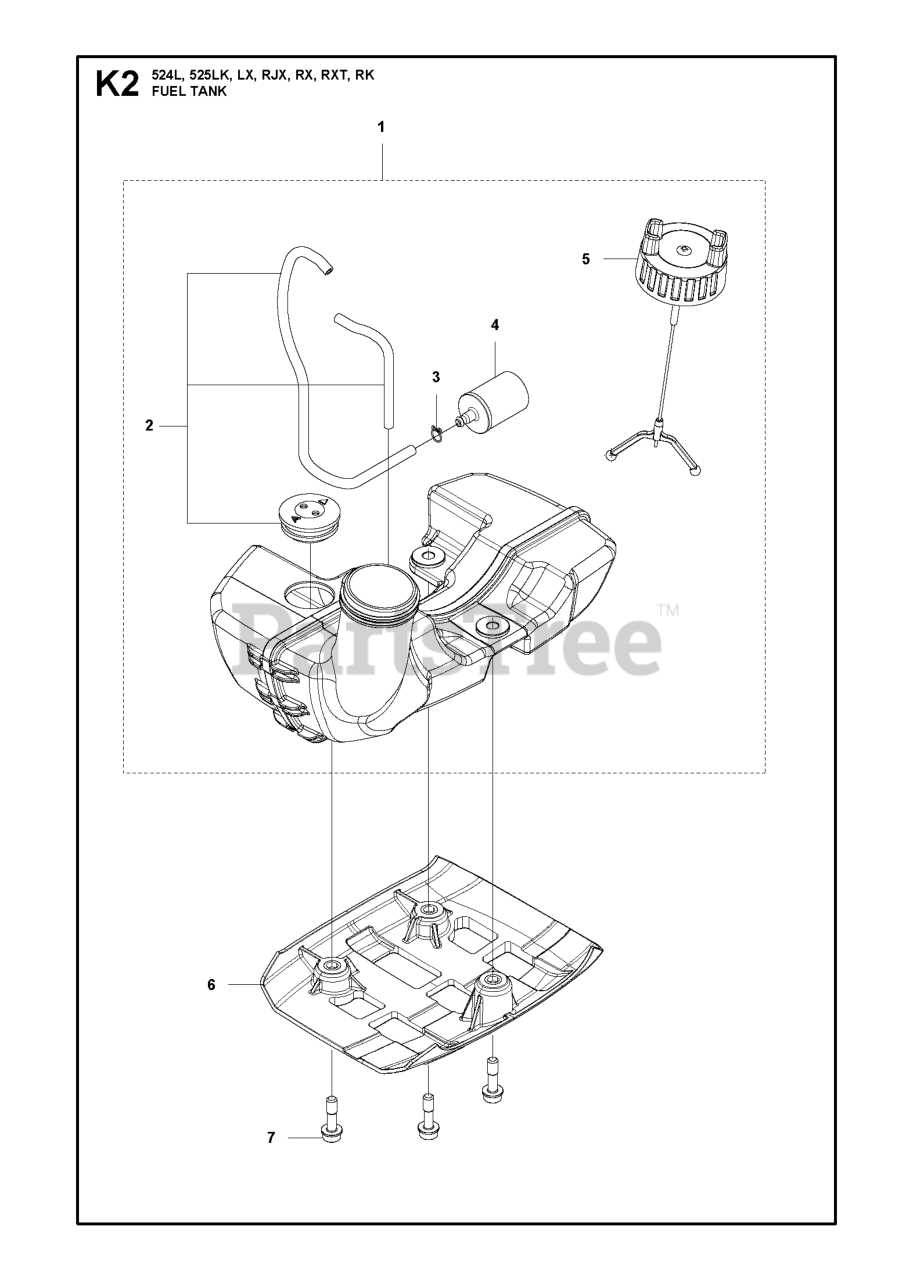

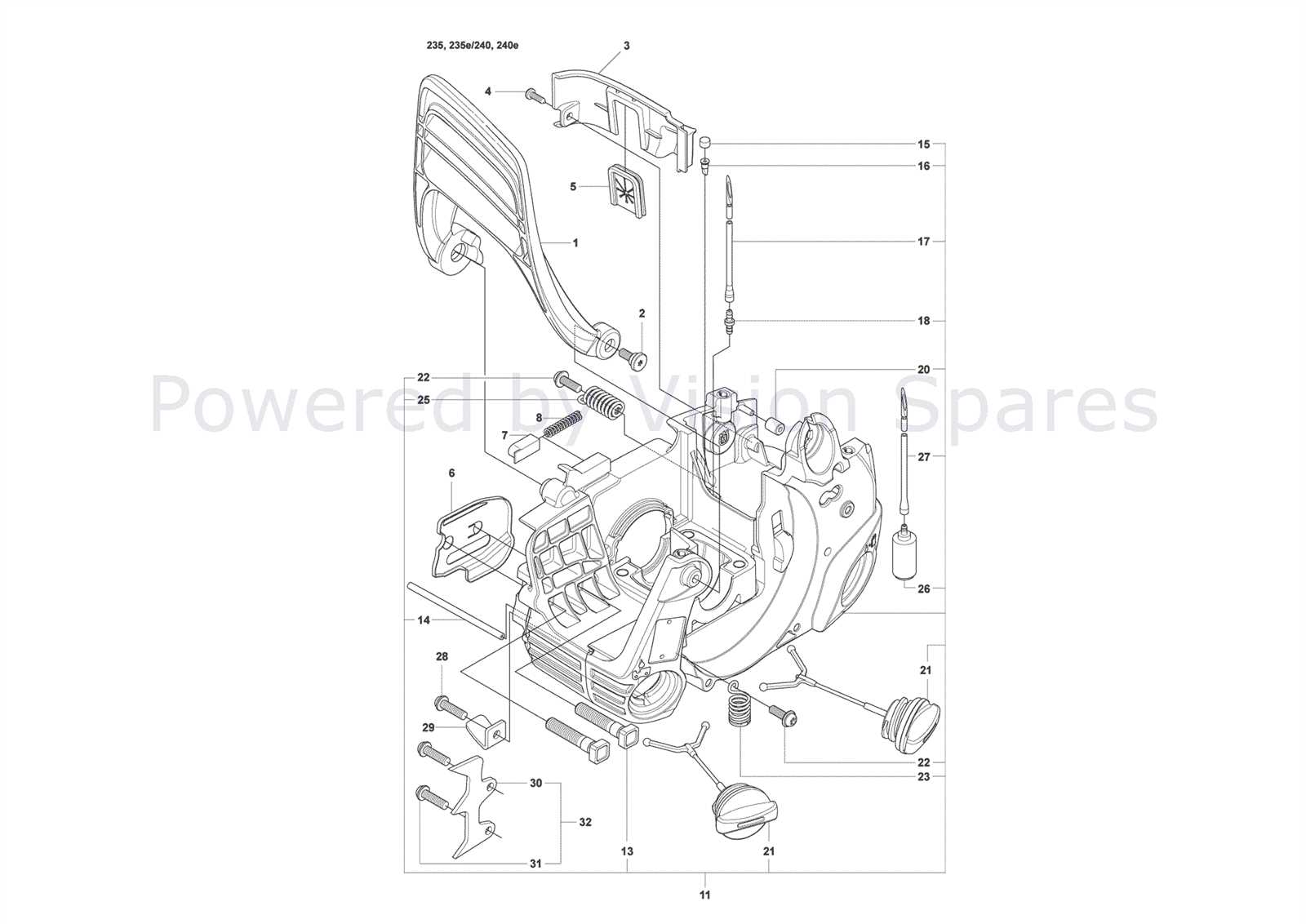

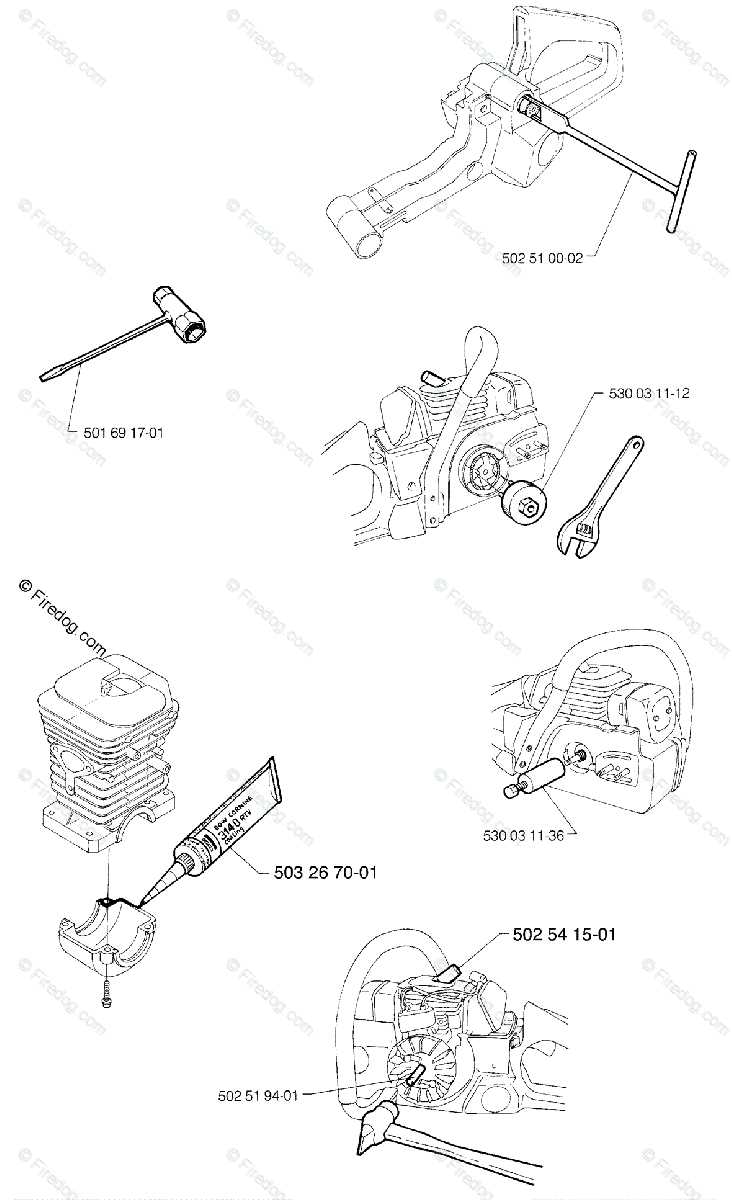

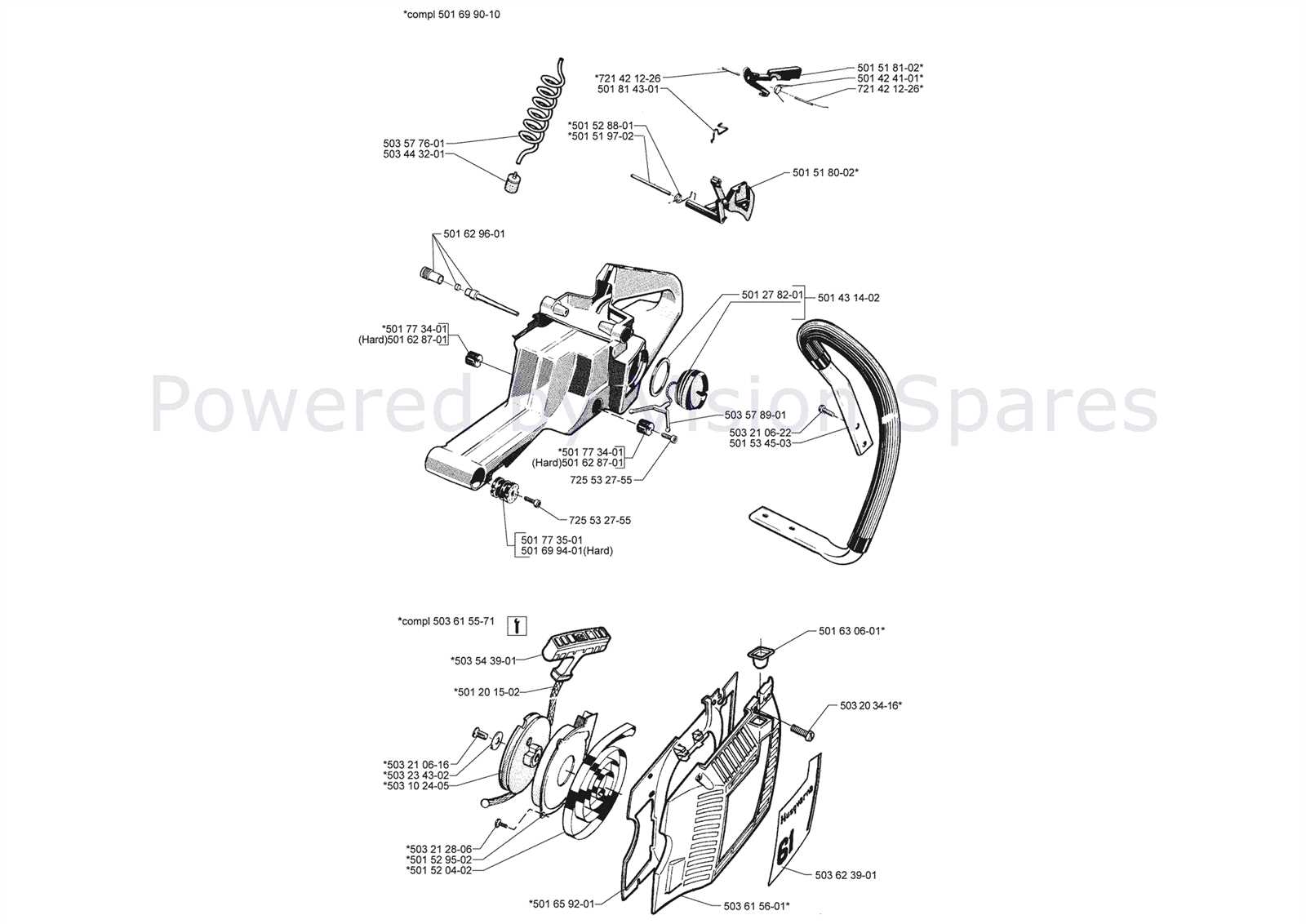

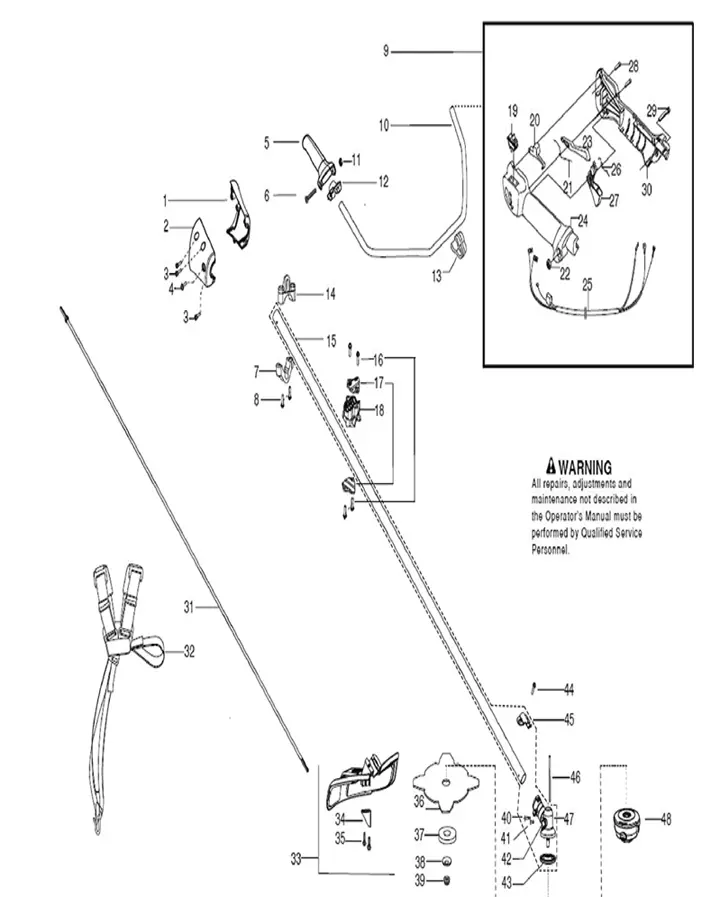

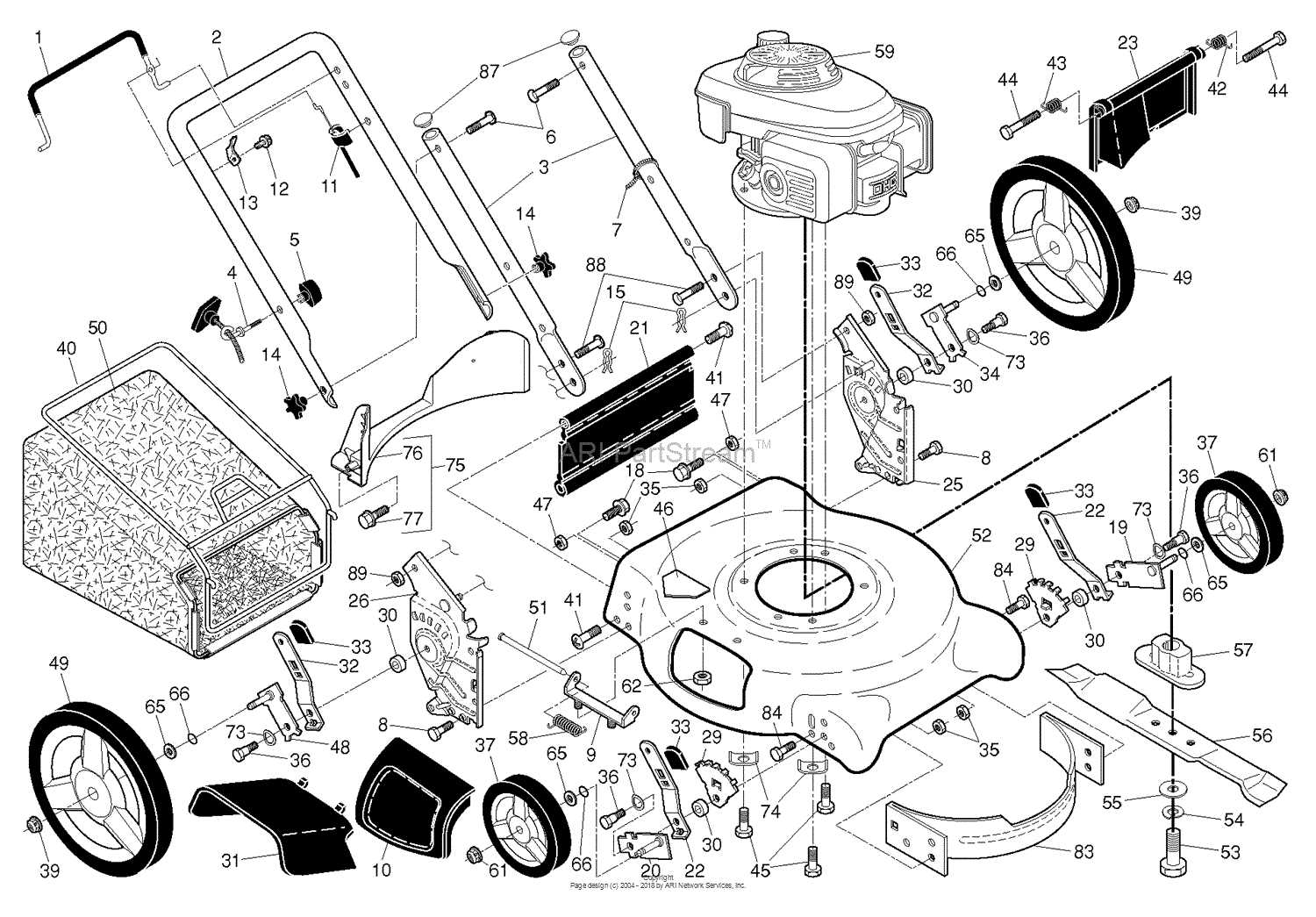

The visual representations of components play a crucial role in identifying and organizing various elements of machinery. These illustrations serve as essential tools for both enthusiasts and professionals, enabling them to navigate through the intricate assembly of equipment with ease.

By studying these visuals, one can gain insights into the relationships between different parts, making it simpler to troubleshoot issues and carry out maintenance tasks. Each section often highlights specific components, showcasing their locations and functions, which ultimately aids in efficient repairs or upgrades.

Additionally, these resources can significantly enhance the user’s understanding of the overall structure, providing clarity on how each element contributes to the machinery’s performance. Familiarity with these visuals empowers individuals to approach repairs with confidence and precision.

Importance of Accurate Diagrams

Precise visual representations are crucial for understanding the structure and functionality of complex machinery. They provide users with essential information for identifying components and their interconnections, ensuring proper assembly and maintenance. Clarity in these visuals enhances efficiency and reduces the likelihood of errors during repairs.

Enhanced Understanding

Accurate illustrations serve as a guide, simplifying the learning process for both novice and experienced individuals. By breaking down intricate systems into manageable sections, these visuals facilitate better comprehension of how each element interacts within the overall design.

Efficiency in Repairs

When dealing with machinery, having reliable visual references can significantly speed up repair processes. Technicians can quickly locate parts and follow procedures, minimizing downtime and improving overall productivity.

| Benefits | Description |

|---|---|

| Clarity | Facilitates easier understanding of component relationships. |

| Time-saving | Accelerates the repair process by providing clear guidance. |

| Reduced Errors | Minimizes mistakes by ensuring accurate identification of elements. |

How to Read Diagrams Effectively

Understanding visual representations of components is essential for successful maintenance and repair tasks. These illustrations can provide valuable insights into the arrangement and functionality of various elements, enabling you to troubleshoot issues with confidence.

1. Familiarize Yourself with Symbols: Each graphic utilizes specific symbols to denote different parts and their functions. Taking the time to learn what these icons mean will significantly enhance your comprehension.

2. Follow the Flow: Visuals often guide you through a logical sequence. Pay attention to arrows and lines, which indicate connections and the order of operations. This can help you grasp how each element interacts within the system.

3. Use a Reference Key: Many illustrations include a legend or key that explains the symbols and colors used. Referencing this section can clarify any uncertainties you may encounter while interpreting the visuals.

4. Take Notes: As you study the representation, jot down important points or create a list of parts you may need. This practice will aid in organizing your thoughts and preparing for any tasks ahead.

5. Practice Makes Perfect: The more you engage with these visuals, the more proficient you will become at reading them. Regularly reviewing different representations will build your skills and confidence over time.

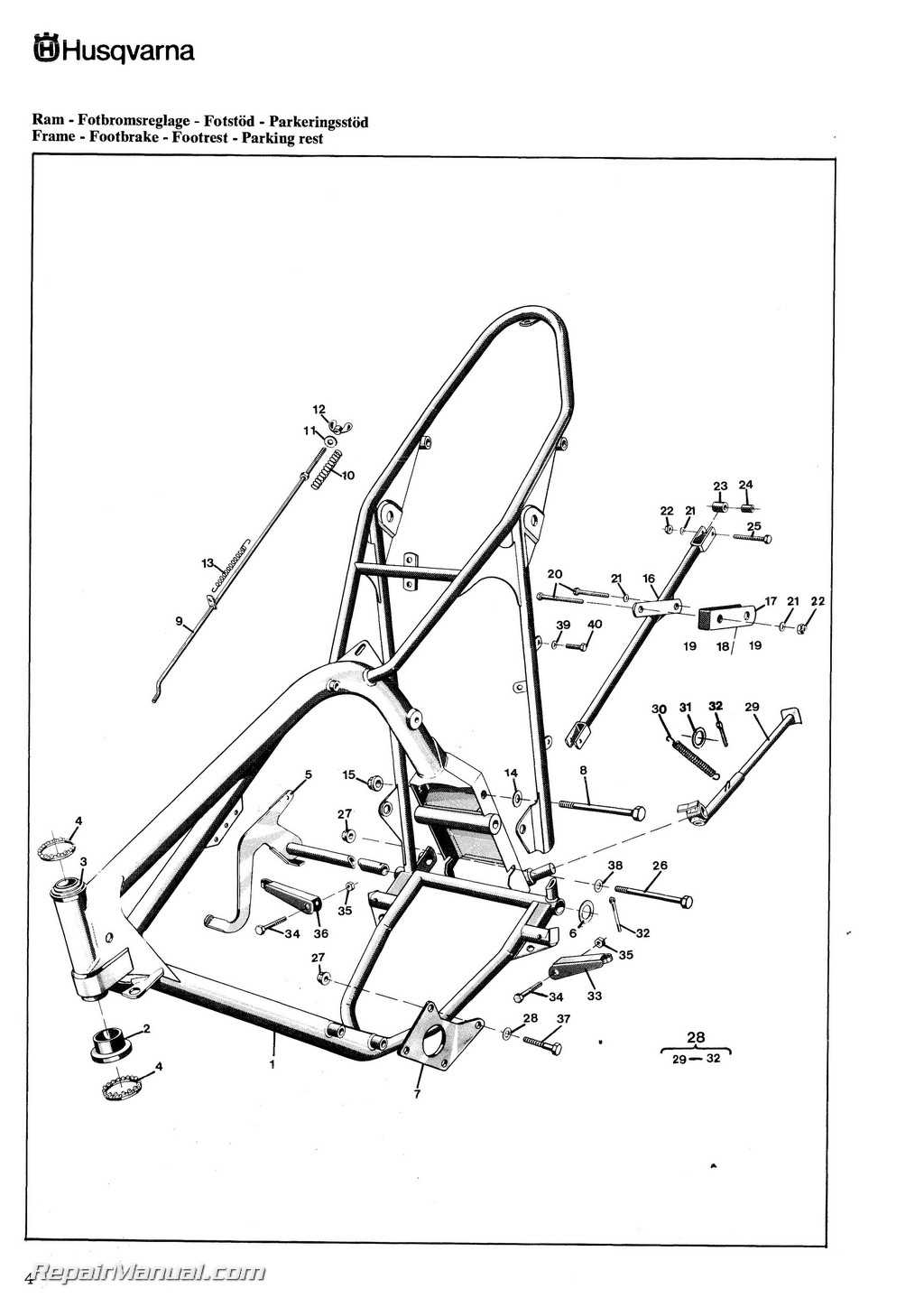

Common Components in Husqvarna Models

When exploring various models from a renowned outdoor equipment manufacturer, several essential elements consistently emerge across different types of machinery. Understanding these components enhances the user’s ability to maintain and repair their tools effectively.

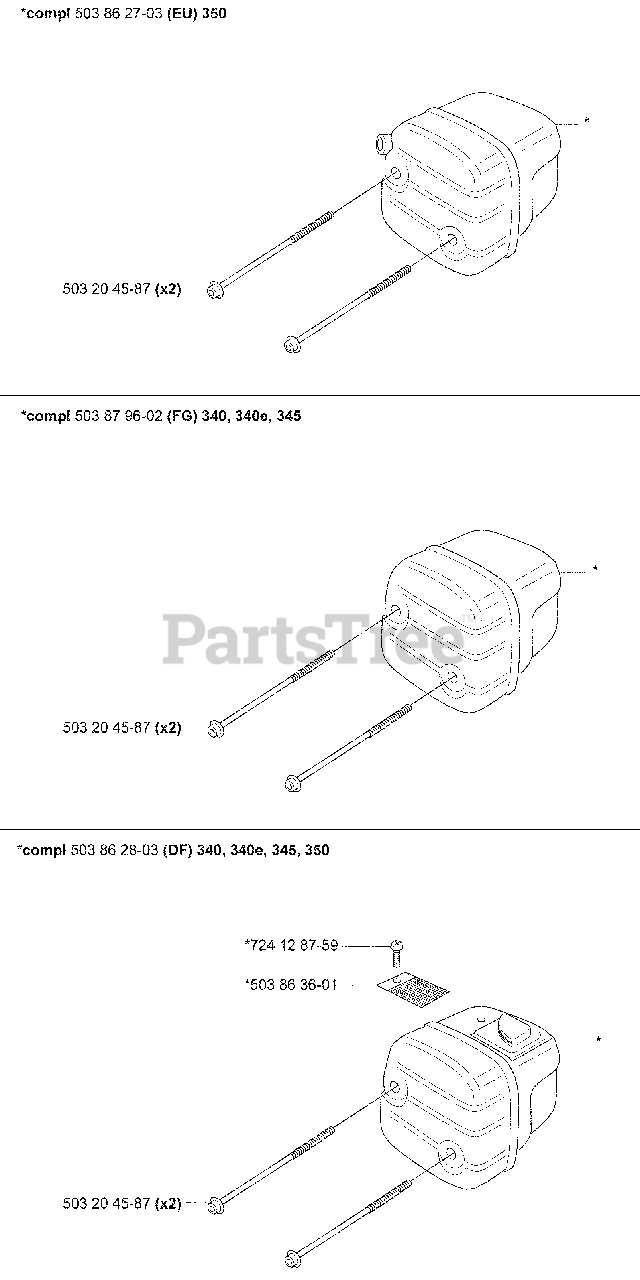

Engine and Drive Systems

The heart of any machine is its power unit, often characterized by its efficiency and reliability. Coupled with the drive mechanism, these systems work together to ensure optimal performance during operation. Regular checks on these elements can prevent mechanical failures and extend the lifespan of the equipment.

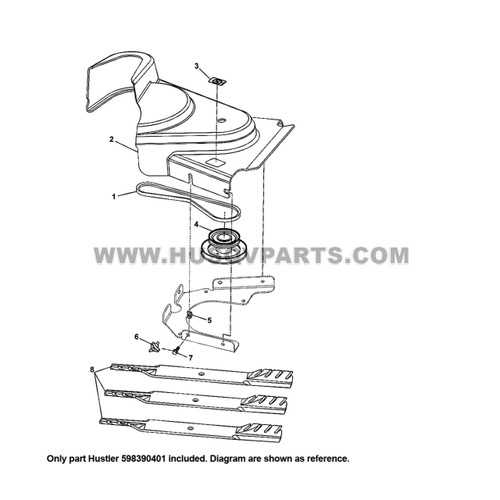

Cutting and Trimming Assemblies

Another critical aspect involves the tools used for cutting and trimming. These assemblies are designed for precision and durability, enabling users to achieve clean results. Proper maintenance, including sharpening and replacement, is vital to ensure continued effectiveness and safety during use.

Finding the Right Replacement Parts

When it comes to maintaining your equipment, identifying the correct components for replacement is essential. Understanding the specifications and compatibility of various elements can save time and ensure optimal performance. This section will guide you through the process of locating the right substitutes for your machinery.

Understanding Component Compatibility

Compatibility is crucial when selecting new elements for your equipment. Each item must meet specific requirements to function correctly. Familiarizing yourself with the relevant features can aid in making informed decisions, ensuring that the selected replacements fit seamlessly into your setup.

Resources for Locating Components

There are several resources available to help you find the right components. Online platforms, manuals, and specialized retailers can provide valuable information. Utilizing these tools effectively will enable you to narrow down your options and make precise selections.

| Resource Type | Description | Benefits |

|---|---|---|

| Online Retailers | Websites that offer a wide range of components | Convenient browsing and comparison |

| User Manuals | Official documentation for your equipment | Detailed specifications and diagrams |

| Forums and Communities | Online groups where users share experiences | Insight from fellow users and experts |

Maintenance Tips Using Diagrams

Utilizing visual representations can significantly enhance the maintenance process of outdoor equipment. These illustrations provide a clear view of various components, helping users understand assembly, disassembly, and servicing steps more effectively. This approach minimizes errors and streamlines the upkeep of machinery.

Here are some essential tips to consider when leveraging these visual aids:

| Tip | Description |

|---|---|

| Study Before Starting | Examine the illustration thoroughly to familiarize yourself with the components and their arrangement. |

| Follow Step-by-Step | Adhere to the sequence indicated in the visuals to avoid confusion during the maintenance process. |

| Check Compatibility | Ensure that the equipment and parts shown correspond to your specific model to prevent discrepancies. |

| Take Notes | Document any observations or adjustments needed, which can be useful for future reference. |

| Seek Professional Help | If uncertain about a procedure, consulting a professional can save time and prevent damage. |

Identifying Parts by Model Number

To effectively determine the necessary components for various equipment, understanding the model number is crucial. This unique identifier enables users to locate specific items tailored to their machinery, ensuring optimal performance and compatibility.

First, familiarize yourself with the model number format, as it often contains key information about the equipment’s type and specifications. Pay close attention to any letters and digits, as they can indicate variations in design or functionality.

Next, utilize online resources or manuals that correlate model numbers with their respective components. These tools can significantly streamline the process of sourcing the correct replacements or enhancements.

Finally, if uncertainties arise, consulting with professionals or customer support can provide valuable insights. Their expertise can clarify discrepancies and ensure you acquire the appropriate items for your specific needs.

Online Resources for Diagrams

Accessing comprehensive visual guides is essential for efficient maintenance and repair tasks. Numerous platforms provide valuable resources that assist users in understanding the intricacies of their equipment through detailed illustrations and schematics. These online tools enable users to find the necessary components and ensure optimal performance.

Popular Websites

| Website | Description |

|---|---|

| ExampleSite1.com | A vast repository of technical visuals with user-friendly navigation. |

| ExampleSite2.com | Offers interactive elements to enhance understanding of assembly processes. |

| ExampleSite3.com | Includes community forums for sharing insights and experiences. |

Benefits of Online Access

Utilizing digital platforms offers the advantage of instant access to resources, allowing users to troubleshoot and resolve issues promptly. Furthermore, these sites often feature updates and new visuals, ensuring that the information remains current and relevant to evolving technology.

DIY Repairs with Parts Information

When tackling repairs on your equipment, having access to detailed information about its components can greatly simplify the process. Understanding how each element fits together and functions allows for more effective troubleshooting and maintenance. This knowledge empowers you to address issues independently, saving time and costs associated with professional services.

Utilizing comprehensive resource materials can guide you through the repair process. Here’s a basic overview of essential components and their functions that may aid in your DIY efforts:

| Component | Description | Common Issues |

|---|---|---|

| Engine | Powers the machine and drives performance. | Starting problems, excessive noise. |

| Fuel System | Delivers fuel to the engine for combustion. | Clogs, leaks, improper fuel flow. |

| Blade | Cutting element that interacts with the material. | Dullness, damage, misalignment. |

| Electrical System | Controls ignition and various electronic features. | Battery issues, wiring faults. |

Having this information at hand not only enhances your confidence but also enables you to carry out repairs efficiently and effectively. Whether it’s routine maintenance or addressing specific failures, a solid understanding of your equipment’s structure is invaluable.

Frequently Asked Questions about Diagrams

This section addresses common inquiries regarding visual representations used for understanding component assemblies and maintenance. By providing clear answers, we aim to enhance user comprehension and facilitate the identification of essential elements in various models.

What types of illustrations are available for reference? Typically, users can access detailed visuals that outline different assemblies and their respective parts, assisting in both repairs and upgrades.

How can these visuals aid in troubleshooting? Clear illustrations help users pinpoint specific components, making it easier to diagnose issues and implement solutions effectively.

Are these visuals consistent across different models? While many components may remain similar, it is important to check each representation for the correct model to ensure accuracy.

Where can I find these helpful visuals? Users can often locate them on official websites or through authorized dealers, ensuring access to reliable and updated information.

Staying Safe During Repairs

When undertaking maintenance tasks, ensuring personal safety should be a top priority. Proper precautions can prevent accidents and injuries, allowing for a smoother and more effective repair experience.

First and foremost, always wear appropriate protective gear, such as gloves and safety goggles, to shield yourself from debris and potential hazards. Additionally, make sure to work in a well-lit environment to improve visibility and reduce the risk of errors.

Organizing your workspace is crucial. Keep tools and components neatly arranged to avoid tripping or misplacing items during the process. Having everything at hand can significantly streamline your work and minimize distractions.

Lastly, be mindful of your surroundings. Ensure that pets and children are kept at a safe distance while repairs are underway. By taking these simple yet effective measures, you can enhance your safety and focus on the task at hand.