The functionality of a professional-grade lawn maintenance machine relies on its intricate assembly of components. Understanding these elements is essential for effective operation and maintenance. This section will delve into the various sections and functionalities, offering clarity on how each part contributes to the overall performance of the equipment.

In this detailed overview, we will explore the layout of the machinery, highlighting the critical components that ensure efficient grass cutting and maneuverability. Recognizing the significance of each element will aid in troubleshooting and enhance your ability to perform necessary repairs or upgrades.

By familiarizing yourself with the structure and arrangement of the equipment, you will gain valuable insights into optimizing its use. Whether you’re a seasoned professional or a newcomer to lawn care, this guide will serve as a comprehensive resource for understanding the intricacies of your mowing machine.

This section provides a comprehensive outline for an informative piece focusing on a specific riding machine model. Each heading will explore various components and aspects related to its design, functionality, and maintenance. The aim is to equip readers with valuable insights into the structure and elements that enhance the performance of this equipment.

-

Introduction to the Riding Equipment

-

Key Features and Specifications

-

Components Breakdown

-

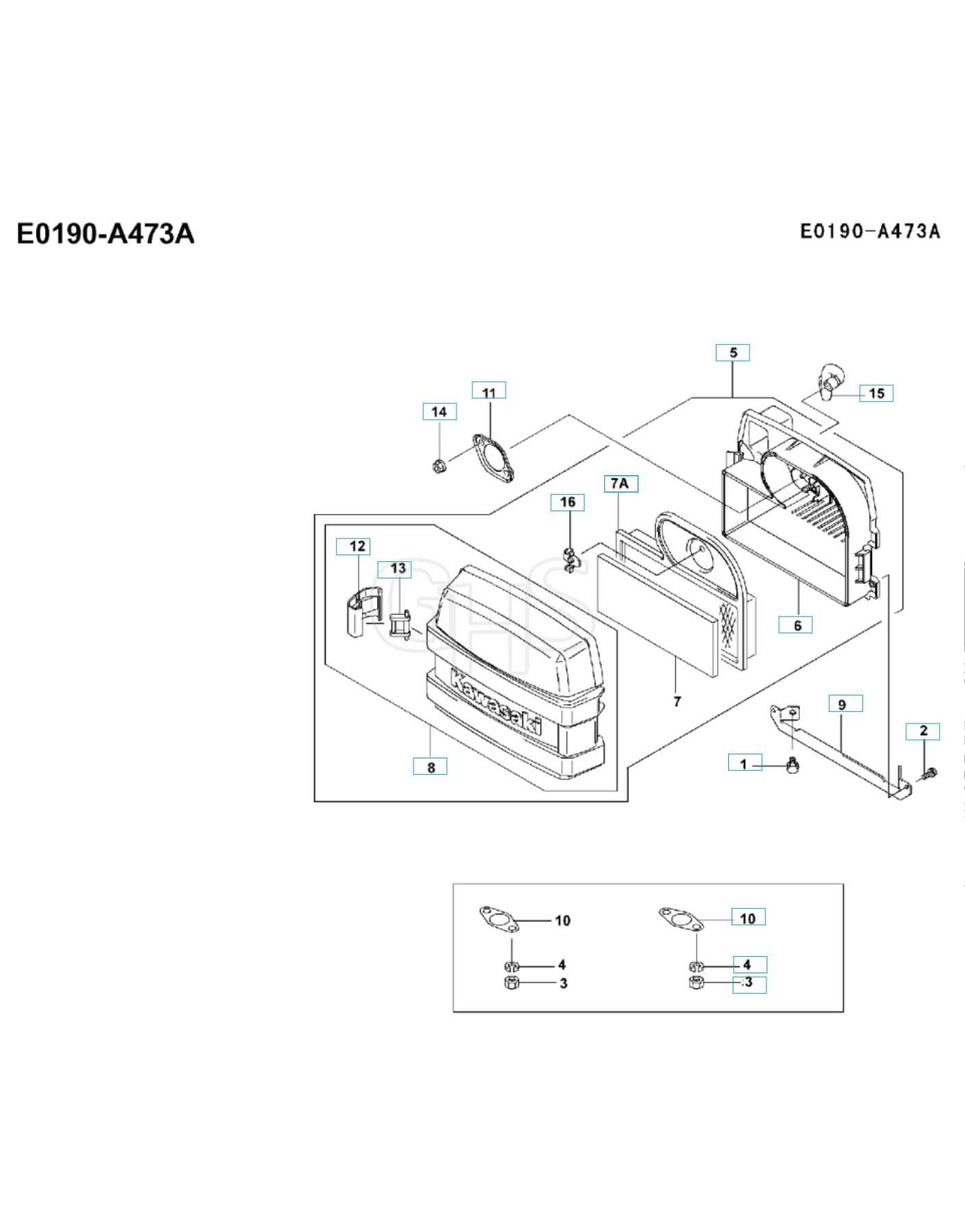

Engine and Performance Insights

-

Transmission System Overview

-

Steering Mechanism Explained

-

Chassis and Frame Analysis

-

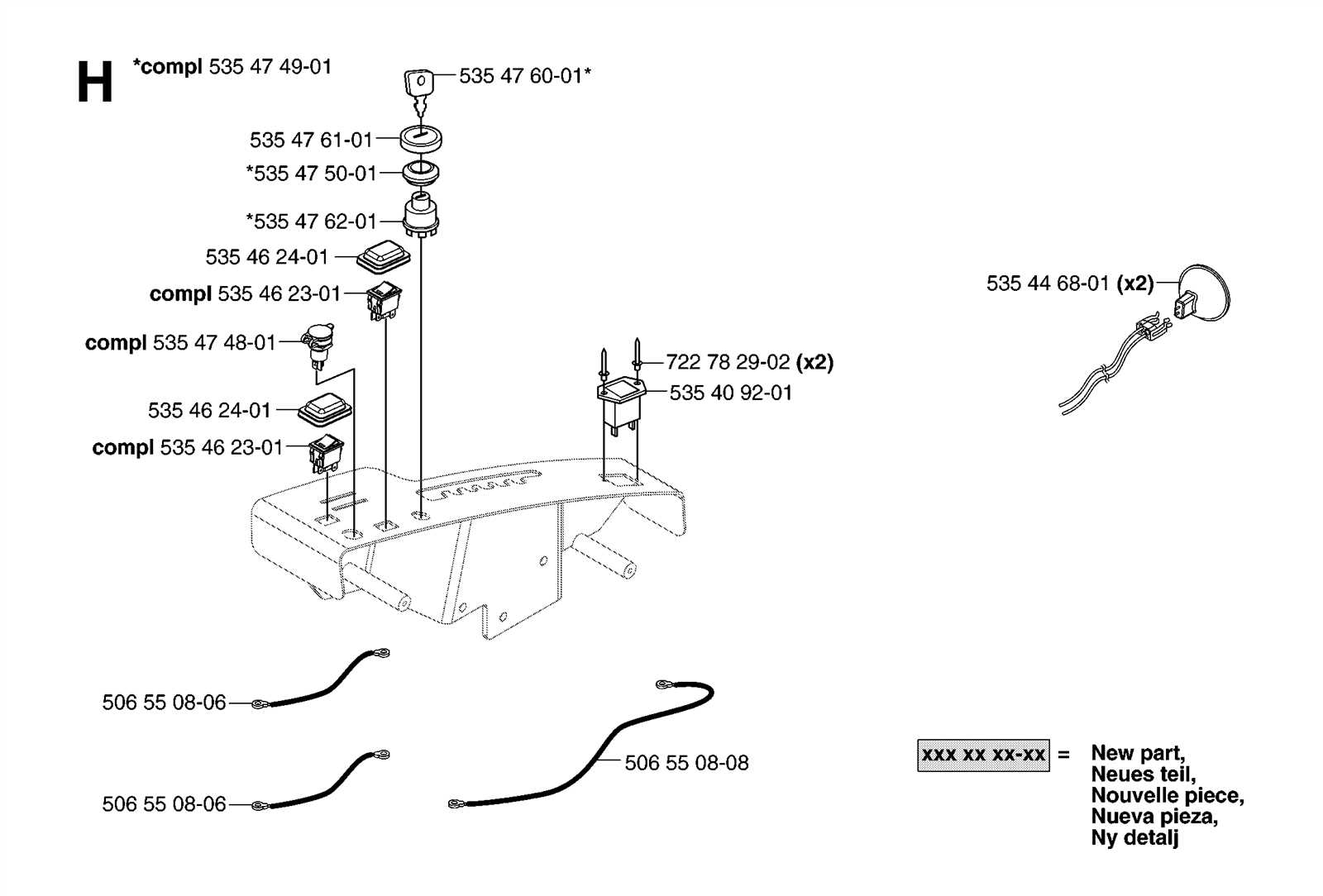

Electrical System Components

-

Maintenance Tips for Longevity

-

Common Issues and Troubleshooting

-

Aftermarket Accessories and Upgrades

-

Conclusion and Final Thoughts

This outline serves as a foundation for developing a detailed exploration of the riding machine, addressing the needs and interests of both potential buyers and current owners.

Key Features and Specifications

This section highlights the essential characteristics and technical details that define the performance and capabilities of the machine. Understanding these features is crucial for users looking to optimize their experience and ensure the proper functioning of their equipment.

Engine Type: The unit is equipped with a robust engine designed for reliability and efficiency, allowing for smooth operation under various conditions.

Cutting Width: A significant cutting width ensures that the device can cover more ground in a single pass, enhancing productivity during use.

Transmission System: Featuring an advanced transmission system, it provides seamless gear shifting and improved maneuverability, making it easier to navigate tight spaces.

Fuel Capacity: The ample fuel capacity allows for extended operation without frequent refueling, making it ideal for larger tasks.

Deck Design: The innovative deck design promotes superior cutting performance and helps maintain a clean workspace by directing clippings efficiently.

Comfort Features: Ergonomically designed controls and comfortable seating enhance user experience, reducing fatigue during prolonged use.

Safety Mechanisms: Equipped with various safety features, the device ensures secure operation and minimizes risks while in use.

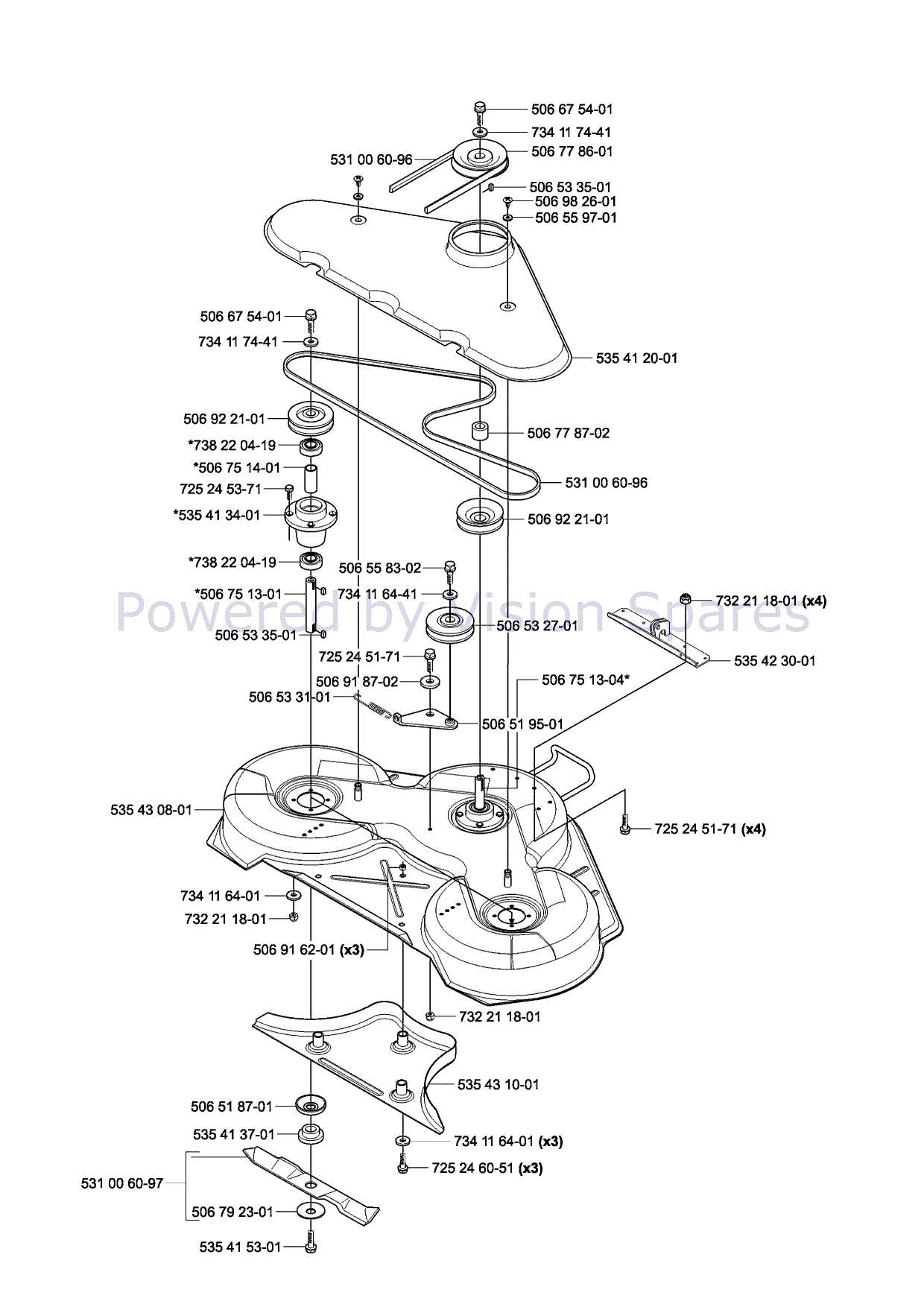

Understanding the Parts Breakdown

This section aims to provide a clear overview of the components involved in the machinery. A thorough examination of each element reveals its role and function within the overall system. This understanding is crucial for effective maintenance and troubleshooting.

Key Components Overview

- Engine Assembly

- Transmission System

- Chassis Structure

- Cutting Mechanism

- Steering System

Maintenance and Replacement Insights

Regular upkeep is essential for optimal performance. Knowing how to identify and replace worn-out components can extend the lifespan of the machinery. Consider the following:

- Inspect the engine regularly for signs of wear.

- Ensure the cutting mechanism is sharp and functioning properly.

- Check the steering system for responsiveness.

- Monitor the transmission fluid levels consistently.

Importance of Regular Maintenance

Routine upkeep is essential for ensuring optimal performance and longevity of any equipment. Neglecting this aspect can lead to decreased efficiency, potential breakdowns, and costly repairs. By prioritizing consistent care, users can enjoy a smoother operation and a more reliable experience.

Benefits of Consistent Upkeep

- Enhanced Performance: Regular servicing helps maintain the machinery at peak functionality, ensuring effective operation.

- Increased Lifespan: Proactive maintenance can significantly extend the life of the equipment, allowing for better long-term investment.

- Cost Efficiency: By addressing minor issues before they escalate, users can save on expensive repairs and downtime.

- Safety Assurance: Proper maintenance ensures that all components are functioning correctly, reducing the risk of accidents or malfunctions.

Key Maintenance Tasks

- Inspecting and cleaning filters to ensure optimal airflow.

- Checking fluid levels and replacing them as necessary.

- Sharpening blades to maintain cutting efficiency.

- Regularly examining belts and cables for wear and tear.

- Conducting seasonal tune-ups to prepare for varying operating conditions.

Implementing a regular maintenance schedule can greatly enhance the reliability and efficiency of equipment. By understanding the significance of consistent care, users can prevent future problems and enjoy a seamless operating experience.

Common Replacement Parts List

This section provides an overview of frequently needed components for maintenance and repair. Understanding which elements are typically replaced can aid in keeping equipment functioning optimally.

Below is a list of essential items that often require substitution:

- Blades: Vital for cutting efficiency and should be checked regularly for wear.

- Filters: Ensures clean air and fuel intake, promoting engine performance.

- Belts: Essential for the transmission system, these should be inspected for signs of fraying or damage.

- Batteries: Critical for starting mechanisms, they need replacement after a certain cycle life.

- Wheels: Ensure smooth mobility; check for cracks or excessive wear.

- Seat cushions: Provide comfort during operation; consider replacing if worn out.

Keeping a stock of these components can significantly reduce downtime and enhance operational efficiency.

How to Identify Component Wear

Recognizing signs of deterioration in machinery components is essential for maintaining optimal performance and prolonging the lifespan of equipment. By observing specific indicators, operators can determine when parts need attention, ensuring safety and efficiency in operations.

Key Indicators of Wear

- Visual Inspection: Regularly examine components for noticeable damage, such as cracks, rust, or deformation.

- Unusual Noises: Listen for strange sounds during operation, which may indicate internal wear or misalignment.

- Performance Changes: Note any decrease in performance, such as reduced speed or difficulty in starting, as these may signal underlying issues.

Methods for Assessment

- Conduct routine inspections at set intervals to monitor the condition of each component.

- Utilize diagnostic tools to measure wear levels, such as thickness gauges or ultrasonic testers.

- Document findings and compare them to previous assessments to identify trends in wear over time.

By employing these strategies, operators can effectively detect component wear, ensuring timely maintenance and preventing potential failures.

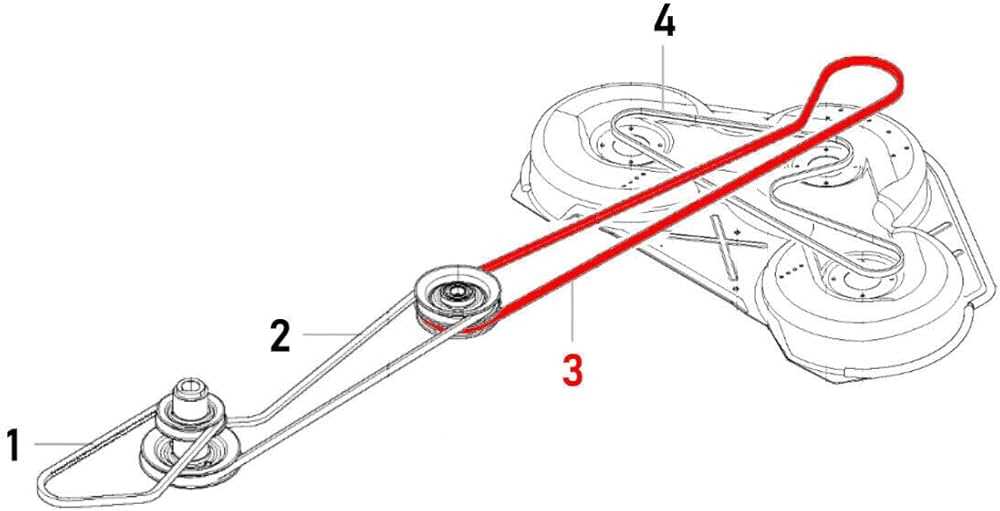

Assembly Diagram Explained

This section delves into the visual representation of the construction and arrangement of various components, providing a comprehensive overview that aids in understanding the overall design and functionality. By interpreting the layout, users can enhance their knowledge of how different elements interact and are organized within the system.

Understanding the Components

Each element depicted in the visual guide plays a crucial role in the operation of the machine. Here are some key aspects to consider:

- Functionality: Each part serves a specific purpose, contributing to the overall efficiency.

- Interaction: The relationship between components is vital for optimal performance.

- Maintenance: Recognizing components can simplify upkeep and repairs.

Interpreting the Layout

The arrangement within the visual representation allows for a clearer understanding of assembly. Pay attention to the following:

- Start by identifying major components, such as the chassis and engine.

- Follow the connections to see how each part links to another.

- Look for notes or symbols that indicate specific instructions or warnings.

By mastering the information presented, users can ensure proper assembly and troubleshooting when necessary.

Step-by-Step Disassembly Guide

This section provides a comprehensive approach to safely taking apart a specific model of garden equipment. Following this guide ensures that each component is handled properly, preventing damage and facilitating efficient reassembly.

Before beginning the disassembly process, gather the necessary tools and ensure you have a clean workspace. This will help keep track of small parts and avoid losing any components during the process.

- Preparation:

- Disconnect the power source to ensure safety.

- Remove any attachments that may interfere with disassembly.

- Removing the Outer Casing:

- Locate the screws securing the outer casing.

- Use the appropriate screwdriver to remove these screws.

- Gently lift the casing away from the main body.

- Accessing Internal Components:

- Identify the internal parts that need attention.

- Carefully disconnect any wires or connectors.

- Take note of the placement of each component for reassembly.

- Removing Individual Parts:

- Unscrew or unclip each part as necessary.

- Store screws and small components in labeled containers.

- Final Checks:

- Ensure all components have been removed and are accounted for.

- Clean the area before starting the reassembly process.

By following these detailed steps, the disassembly of the equipment can be completed effectively, allowing for maintenance or repairs as needed.

Tools Needed for Repairs

When performing maintenance and repairs on outdoor machinery, having the right tools is essential for ensuring efficiency and precision. A well-equipped toolkit can simplify the process, allowing for effective diagnosis and resolution of various issues.

Below is a list of common tools that are often required for various repair tasks:

| Tool | Description |

|---|---|

| Socket Set | Used for loosening and tightening nuts and bolts. |

| Wrench | Ideal for gripping and turning nuts and bolts of various sizes. |

| Screwdriver Set | Essential for removing and securing screws in different configurations. |

| Pliers | Useful for gripping, twisting, and cutting wires or small components. |

| Torque Wrench | Ensures fasteners are tightened to the manufacturer’s specifications. |

| Multimeter | Used for electrical diagnostics to measure voltage, current, and resistance. |

| Oil Filter Wrench | Facilitates the removal of oil filters during maintenance. |

Troubleshooting Common Issues

When operating complex machinery, various problems may arise that can hinder performance or functionality. Understanding the typical issues and their potential causes is essential for effective resolution. This section aims to provide insights into common challenges encountered during operation and maintenance, along with suggested remedies to ensure smooth functionality.

Identifying Mechanical Failures

Mechanical failures often manifest as unusual noises, vibrations, or a lack of movement. These issues may be due to worn components or improper assembly. Regular inspections and timely replacement of damaged parts can prevent further complications and ensure the machine operates at its optimal level.

Addressing Electrical Malfunctions

Electrical malfunctions can disrupt operation, leading to failures in starting or inconsistent performance. Checking connections, fuses, and wiring can help diagnose these problems. Ensuring that the electrical system is well-maintained will enhance reliability and longevity.

Where to Find Genuine Parts

When it comes to maintaining your equipment, sourcing authentic components is crucial for optimal performance and longevity. Ensuring that you acquire high-quality replacements not only guarantees compatibility but also enhances the overall functionality of your machine.

Authorized Dealers

One of the most reliable sources for acquiring original components is through authorized retailers. These vendors are sanctioned by the manufacturer and typically offer:

- Verified quality and authenticity

- A comprehensive selection of components

- Expert advice and support

Online Resources

The internet provides a wealth of options for finding genuine components. Various platforms allow users to search for specific items, compare prices, and read customer reviews. Some key advantages include:

- Convenience of shopping from home

- Access to a wider variety of products

- The ability to find competitive pricing

Benefits of OEM Components

Using original equipment manufacturer components ensures optimal performance and reliability for your machinery. These components are specifically designed and tested to meet the exact specifications required for seamless integration and functionality. Investing in these parts can significantly enhance the longevity and efficiency of your equipment.

Quality Assurance

OEM components undergo rigorous quality control processes, guaranteeing that each piece meets high manufacturing standards. This commitment to excellence results in superior durability and performance compared to generic alternatives, which may not offer the same level of reliability.

Enhanced Compatibility

Original components are engineered to fit perfectly with your equipment, reducing the likelihood of issues related to improper fitting or functionality. This compatibility not only improves overall performance but also minimizes the risk of wear and tear, ensuring that your machine operates smoothly for an extended period.