Maintaining a lawn mower is essential for ensuring its longevity and efficiency. By familiarizing yourself with its various elements, you can effectively troubleshoot issues and perform necessary repairs. This section aims to provide valuable insights into the intricate layout of your mowing machine, allowing you to navigate its structure with ease.

The arrangement of components is crucial for understanding how your mower operates. Each element plays a vital role in its overall functionality, from the engine to the blades. Grasping the relationship between these parts empowers you to make informed decisions during maintenance or upgrades, enhancing your mowing experience.

Equipped with the right knowledge, you can identify specific pieces that may require attention or replacement. This understanding not only helps in keeping your equipment in top condition but also aids in optimizing its performance. With a comprehensive overview of the assembly, you will be better prepared to tackle any challenges that arise during usage.

Understanding the essential components of machinery is crucial for efficient operation and maintenance. Familiarity with the critical mechanical elements ensures smoother performance and easier troubleshooting when issues arise. This section will outline the primary elements that contribute to the functionality of such equipment.

The following are some key mechanical components that are vital for optimal performance:

- Engine: This is the powerhouse of the equipment, responsible for providing the necessary energy for operation.

- Transmission: This system transfers power from the engine to the wheels, allowing for movement and control.

- Deck: The housing that contains the cutting blades, essential for the effective operation of cutting tasks.

- Wheels: These components enable mobility and are designed to handle various terrains.

- Control Mechanisms: Handles and levers that allow the operator to maneuver the equipment safely and efficiently.

Recognizing these components is essential for anyone involved in operating or servicing the machinery. Knowledge of these parts can significantly enhance the understanding of how the equipment functions as a whole.

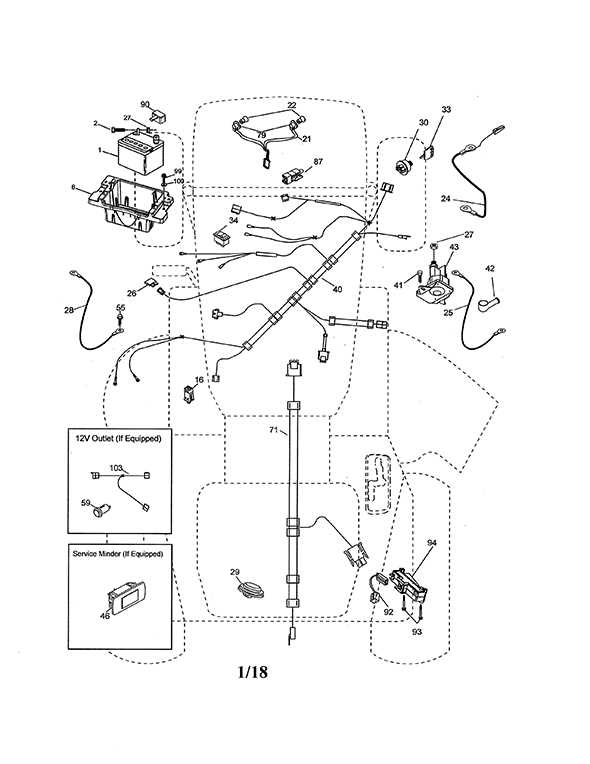

Electrical System Overview

The electrical framework of a lawn care apparatus is integral to its efficient operation. This system comprises various components that work in unison to power the machine and ensure seamless functionality. Understanding this network is essential for maintaining the equipment and diagnosing any issues that may arise.

At the heart of the electrical assembly are key elements that facilitate energy distribution and control. These components include the battery, wiring harness, switches, and connectors. Each part plays a crucial role in delivering power to the motor and accessories, contributing to the overall performance of the equipment.

| Component | Function |

|---|---|

| Battery | Supplies electrical energy to start the engine and power accessories. |

| Wiring Harness | Connects all electrical components, facilitating efficient energy transfer. |

| Switches | Controls the flow of electricity, enabling the user to operate different functions. |

| Connectors | Ensures secure connections between wires and components, maintaining reliability. |

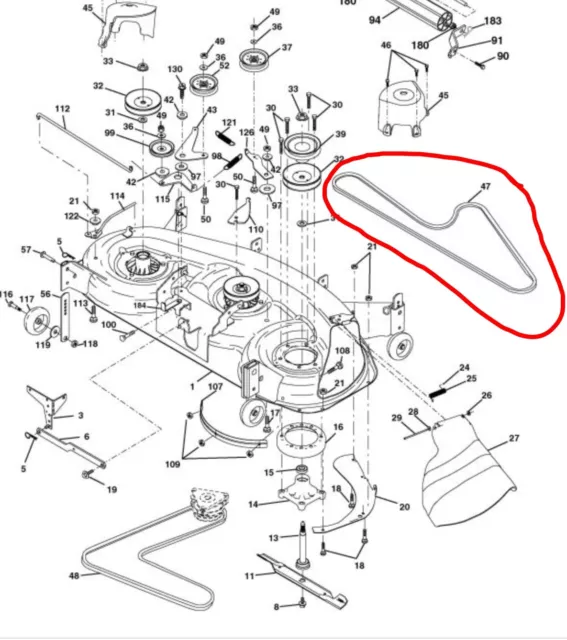

Exploring the Drive Mechanism

The drive system is a critical component of many outdoor machinery, playing a vital role in translating engine power into effective movement. Understanding how this mechanism functions can enhance maintenance efforts and improve overall performance. This section delves into the various elements that comprise the drive assembly and their interconnections.

Components of the Drive System

Several key elements work together within the drive system to ensure smooth operation:

- Transmission: Responsible for shifting power from the engine to the wheels, allowing for speed variations.

- Belts: These flexible loops transmit energy from the engine to other components, adapting to various speeds and loads.

- Wheels: The final output of the drive system, these components are crucial for traction and mobility.

- Axles: They serve as the connecting points between the wheels and the drive assembly, facilitating movement.

Functionality and Maintenance Tips

To ensure optimal performance of the drive mechanism, consider the following maintenance practices:

- Regularly inspect belts for wear and tear, replacing them as necessary.

- Keep the transmission fluid at recommended levels to prevent overheating.

- Check wheel alignment and inflation to ensure even wear and optimal handling.

- Lubricate axles periodically to reduce friction and prolong lifespan.

Understanding these components and their maintenance can significantly enhance the efficiency and reliability of the equipment.

Maintenance of Cutting Deck Elements

Regular upkeep of the cutting mechanism is essential for optimal performance and longevity of the lawn care equipment. This process involves ensuring that all components are in good working condition and free from debris, which can hinder efficiency. By adhering to a consistent maintenance schedule, operators can enhance the effectiveness of their machine and reduce the likelihood of unexpected breakdowns.

Key aspects of maintenance include inspecting blades for sharpness and wear, checking for proper alignment, and cleaning the deck to prevent grass buildup. Additionally, lubricating moving parts and replacing any damaged components will help maintain smooth operation. Performing these tasks not only improves cutting efficiency but also contributes to the overall health of the lawn.

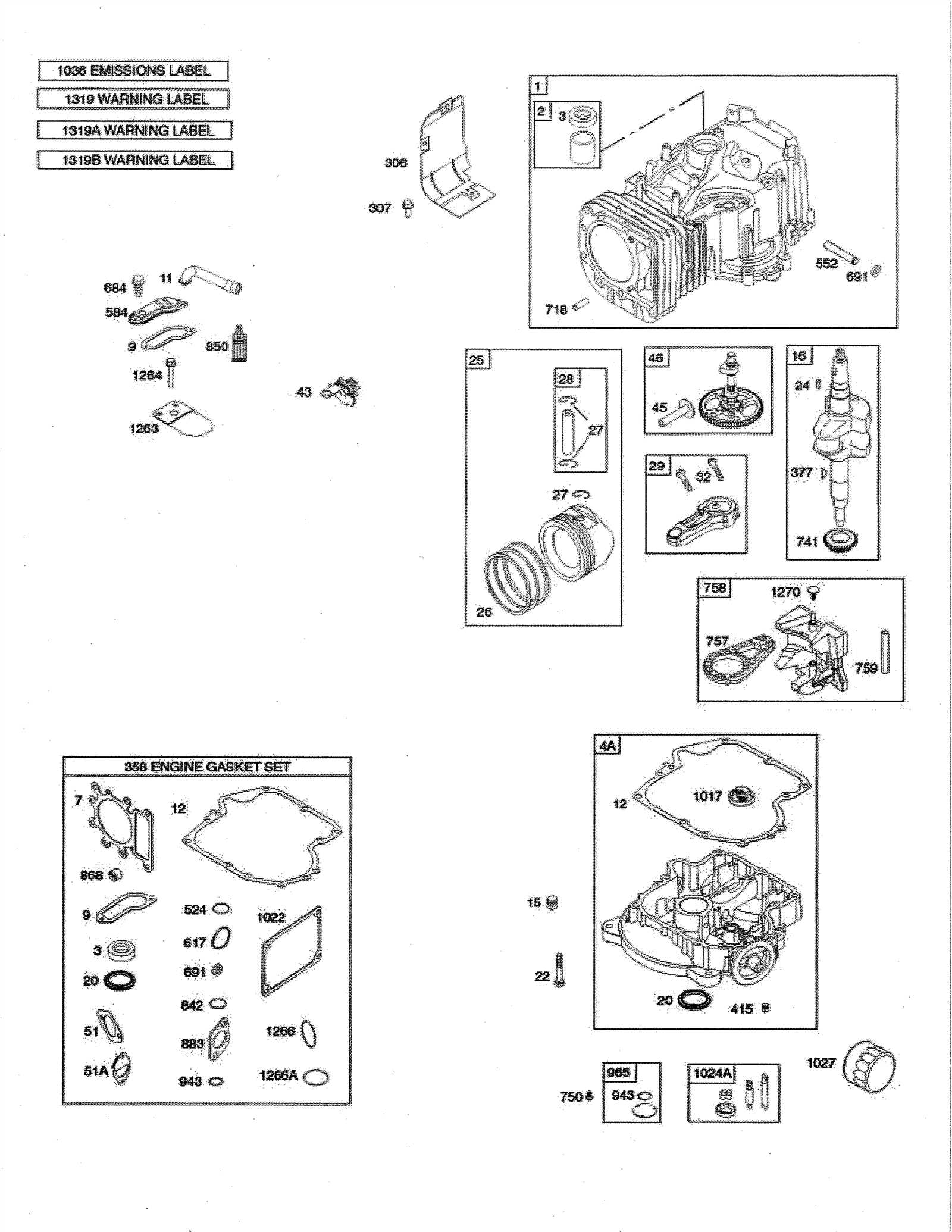

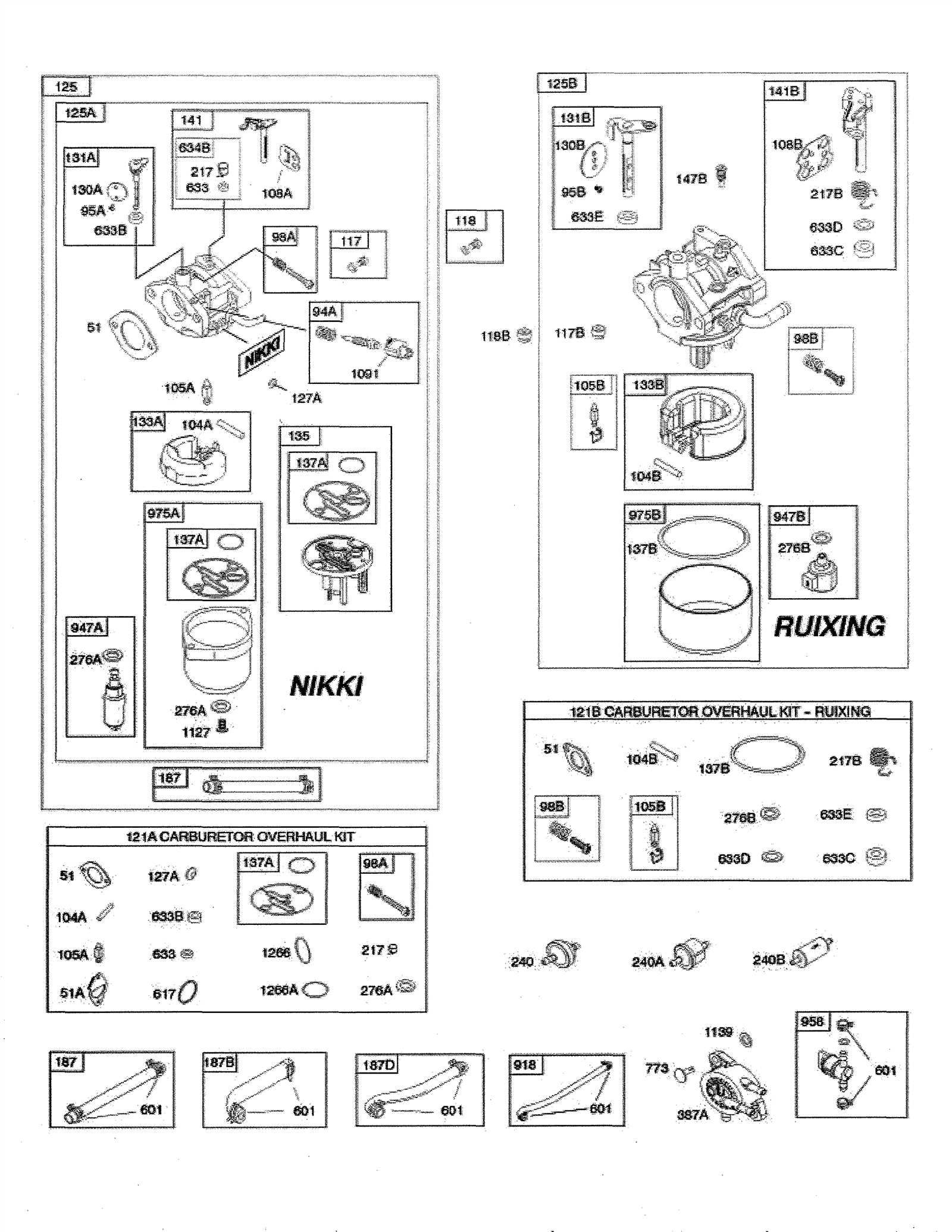

Fuel System Parts Explained

The fuel system of a lawn mower is essential for delivering the necessary energy to power the engine. Understanding the components involved in this system can enhance maintenance and ensure optimal performance. Each element plays a crucial role in the efficient operation of the machine, contributing to its longevity and reliability.

Key Components of the Fuel System

Several vital elements make up the fuel system, each with its unique function:

- Fuel Tank: The reservoir that holds the gasoline until it is needed by the engine.

- Fuel Line: A flexible tube that transports fuel from the tank to the engine, ensuring a steady flow.

- Fuel Filter: A component that removes impurities from the fuel before it reaches the engine, protecting it from damage.

- Fuel Pump: An essential part that draws fuel from the tank and pushes it towards the engine at the required pressure.

- Carburetor: A device that mixes air with fuel in the correct ratio for combustion, playing a crucial role in the engine’s efficiency.

Maintaining the Fuel System

Regular maintenance of the fuel system is necessary for optimal performance. Here are some essential tips:

- Check the fuel level regularly and refill as needed.

- Inspect the fuel lines for any signs of wear or leaks.

- Replace the fuel filter as recommended to ensure clean fuel delivery.

- Clean or service the carburetor periodically to maintain proper air-fuel mixture.

Cooling System Components Breakdown

The effective regulation of temperature is crucial for the longevity and performance of any machinery. Understanding the various elements of the cooling apparatus is essential for maintaining optimal operation. Each component plays a specific role in dissipating heat and ensuring the engine runs efficiently.

Key Components of the Cooling System

- Radiator: The primary unit that dissipates heat from the coolant, allowing it to cool before returning to the engine.

- Coolant: A mixture of water and antifreeze that circulates through the system, absorbing heat from the engine.

- Water Pump: Responsible for circulating the coolant throughout the system to maintain a consistent temperature.

- Thermostat: A valve that regulates the flow of coolant based on the engine’s temperature, ensuring it remains within an optimal range.

- Hoses: Flexible conduits that transport coolant between various components, facilitating heat exchange.

Maintaining Cooling Efficiency

Regular inspections and maintenance of these elements are vital to prevent overheating and ensure the machinery operates smoothly. Key practices include:

- Checking coolant levels and topping off as necessary.

- Inspecting hoses for leaks or signs of wear.

- Cleaning the radiator to prevent debris buildup that can hinder airflow.

- Replacing the thermostat and water pump as part of routine maintenance.

Common Replacement Parts Guide

Over time, regular maintenance and wear can require the need to refresh certain components to keep your equipment in optimal working condition. Understanding which elements are most frequently exchanged can help you plan ahead and ensure smooth operation.

Key Components That Need Replacing

- Blades: Regular mowing leads to dull edges, making sharp replacements essential for effective cutting.

- Filters: Both air and oil filters can become clogged and require periodic swaps to maintain engine efficiency.

- Belts: Overuse may result in cracks or breaks, so keeping an eye on belt integrity is vital for proper function

Tools Required for Repairs

When it comes to maintaining or fixing outdoor equipment, having the right set of tools is essential for ensuring a smooth and efficient repair process. Equipped with the proper instruments, even complex tasks become more manageable, allowing for precise adjustments and quick replacements.

Basic Tools for Routine Maintenance

- Wrench set: Essential for loosening and tightening bolts and nuts of various sizes.

- Screwdrivers: Both flathead and Phillips types are needed for different fasteners.

- Pliers: Useful for gripping, bending, or holding objects during the repair process.

- Socket set: Provides flexibility in accessing hard-to-reach areas and dealing with various bolt sizes.

Specialized Tools for Complex Fixes

- Torque wrench: Ensures that bolts and screws are tightened to the correct level of force.

- Multimeter: Useful for diagnosing electrical issues by measuring

Tips for Efficient Maintenance

Regular upkeep is crucial for ensuring that equipment performs at its best and avoids unexpected breakdowns. Following a structured approach will not only enhance longevity but also reduce the need for costly repairs. It is important to pay attention to routine tasks and perform them consistently to maintain optimal operation.

Routine Checks and Inspections

Frequent inspections help identify potential issues before they become serious problems. Begin by examining key areas that are prone to wear and tear. Tighten any loose components and replace any that show signs of damage. Ensure that all connections are secure and that there are no visible signs of wear or leaks.

Maintenance Task Frequency Inspect moving parts Accessing the Parts Diagram Online

Finding detailed visual guides for your equipment is essential for proper maintenance and repair. With digital resources available, you can easily navigate to the exact illustrations you need to identify components and understand how they fit together in your machine.

To obtain these visual references online, follow these simple steps:

- Visit the official website of the manufacturer or a trusted retailer.

- Use the search bar to enter the model number or name of your equipment.

- Locate the section dedicated to product manuals or technical guides.

- Click on the relevant link to view or download the visual representation of the equipment’s layout.

In some cases, you may need to register or provide specific details about your machine. Once accessed, these illustrations offer a convenient way to review the structure of your device for repairs or part replacements.