When it comes to maintaining a well-functioning outdoor vehicle, understanding its essential elements is crucial. Each machine is made up of various intricate parts that work together to ensure optimal performance. Familiarizing oneself with these components can aid in effective troubleshooting and maintenance, leading to improved longevity and efficiency.

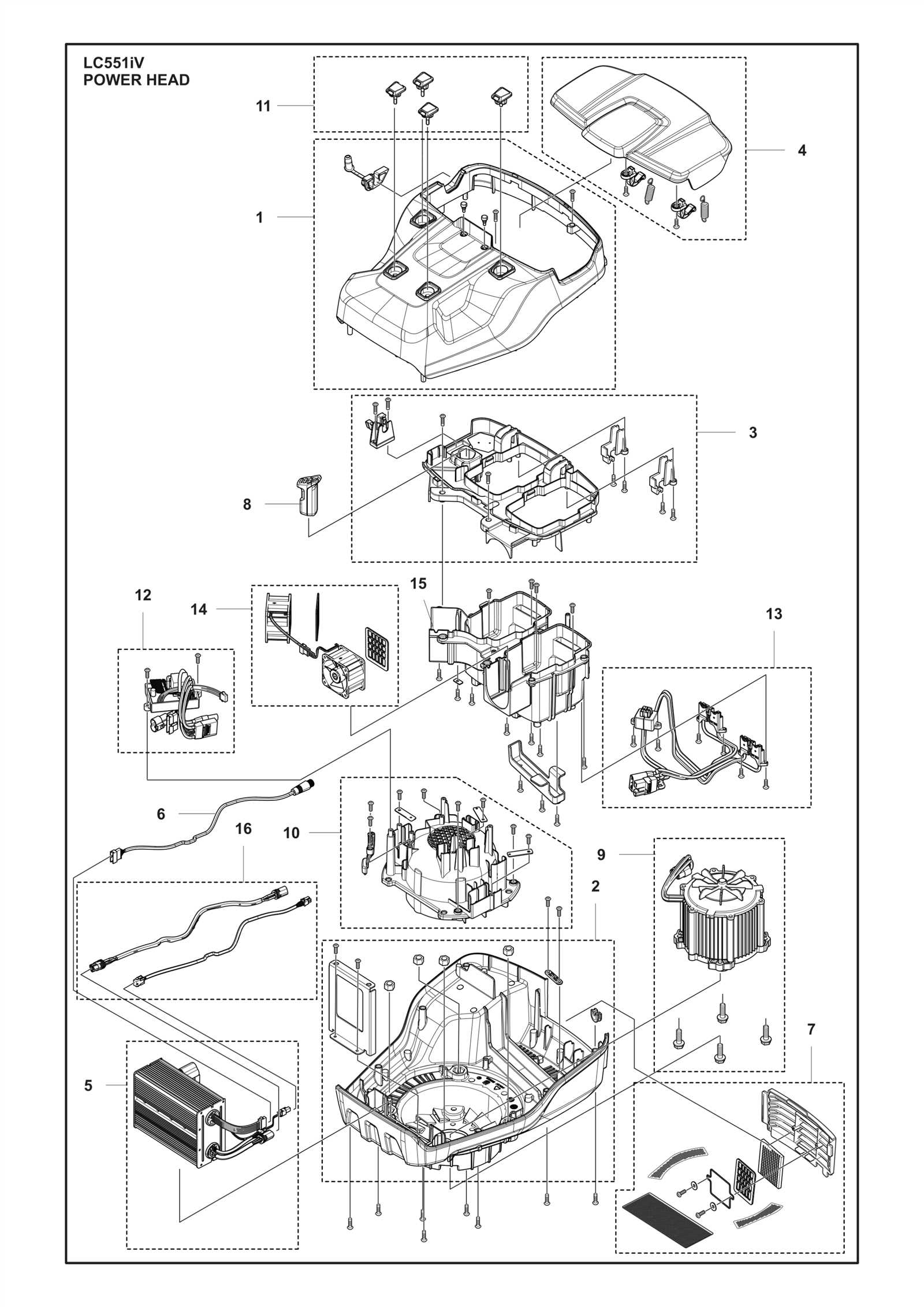

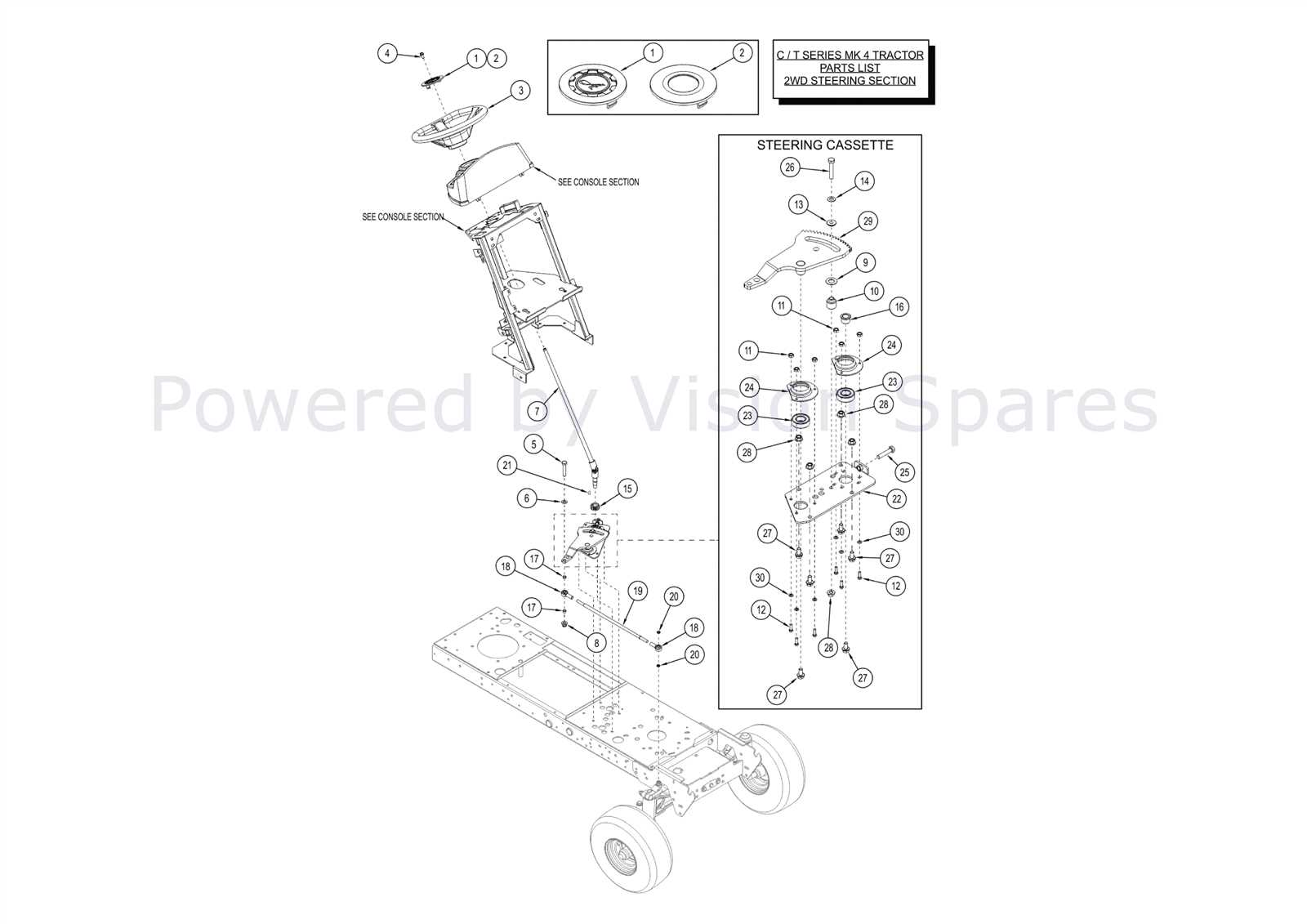

Visualization of the assembly is key for anyone looking to enhance their mechanical knowledge. By examining a visual representation of the different segments, users can quickly identify areas that may require attention. This understanding fosters confidence in performing repairs or upgrades, ultimately enhancing the user experience.

In this section, we will delve into the various elements that constitute a typical outdoor machine, providing insights into their functions and interconnections. Whether you’re a seasoned technician or a novice enthusiast, grasping these concepts will empower you to make informed decisions regarding upkeep and modifications.

Understanding the essential elements of a lawn care machine is crucial for effective maintenance and operation. Each part plays a significant role in the overall functionality, contributing to optimal performance and longevity. Recognizing these key components enables users to troubleshoot issues and ensure that their equipment runs smoothly.

Key Elements of the System

- Engine: The power source that drives the entire system, providing the necessary energy for operation.

- Deck: The housing that contains the blades, designed for efficient grass cutting.

- Transmission: The mechanism responsible for transferring power from the engine to the wheels, allowing for movement.

- Wheels: Provide mobility and stability, crucial for navigating various terrains.

- Controls: The levers and pedals that enable the operator to steer and adjust settings as needed.

Additional Considerations

- Regular inspections of the engine and fuel system can prevent operational disruptions.

- Maintaining the cutting deck ensures a clean and even cut.

- Checking the transmission fluid levels is vital for smooth gear transitions.

- Keeping the wheels and tires in good condition enhances traction and maneuverability.

- Familiarizing oneself with the control layout improves efficiency during use.

Common Replacement Parts Explained

In the realm of maintenance and repair, understanding the essential components that often require substitution is crucial for optimal functionality. Various elements play a pivotal role in ensuring efficient operation, and knowing which ones are likely to wear out or malfunction can save time and effort in the long run. This section delves into some of the most frequently replaced items, shedding light on their importance and characteristics.

Blades

Cutting elements are vital for achieving a clean and even cut. Over time, these components can become dull or damaged due to extensive use or exposure to tough conditions. Regularly checking and replacing blades not only enhances performance but also prevents unnecessary strain on the machinery.

Batteries

The power source is another critical item that may need replacement. Batteries can lose their ability to hold a charge, leading to difficulties in starting and operating machinery. Selecting the correct type and ensuring proper installation can greatly improve longevity and efficiency.

By staying informed about these common components, users can effectively manage maintenance tasks and ensure their equipment remains in peak condition.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your outdoor machinery involves regular upkeep and attention to detail. By adhering to simple maintenance practices, you can enhance the performance and durability of your equipment, ultimately saving time and resources in the long run.

Regular Inspections

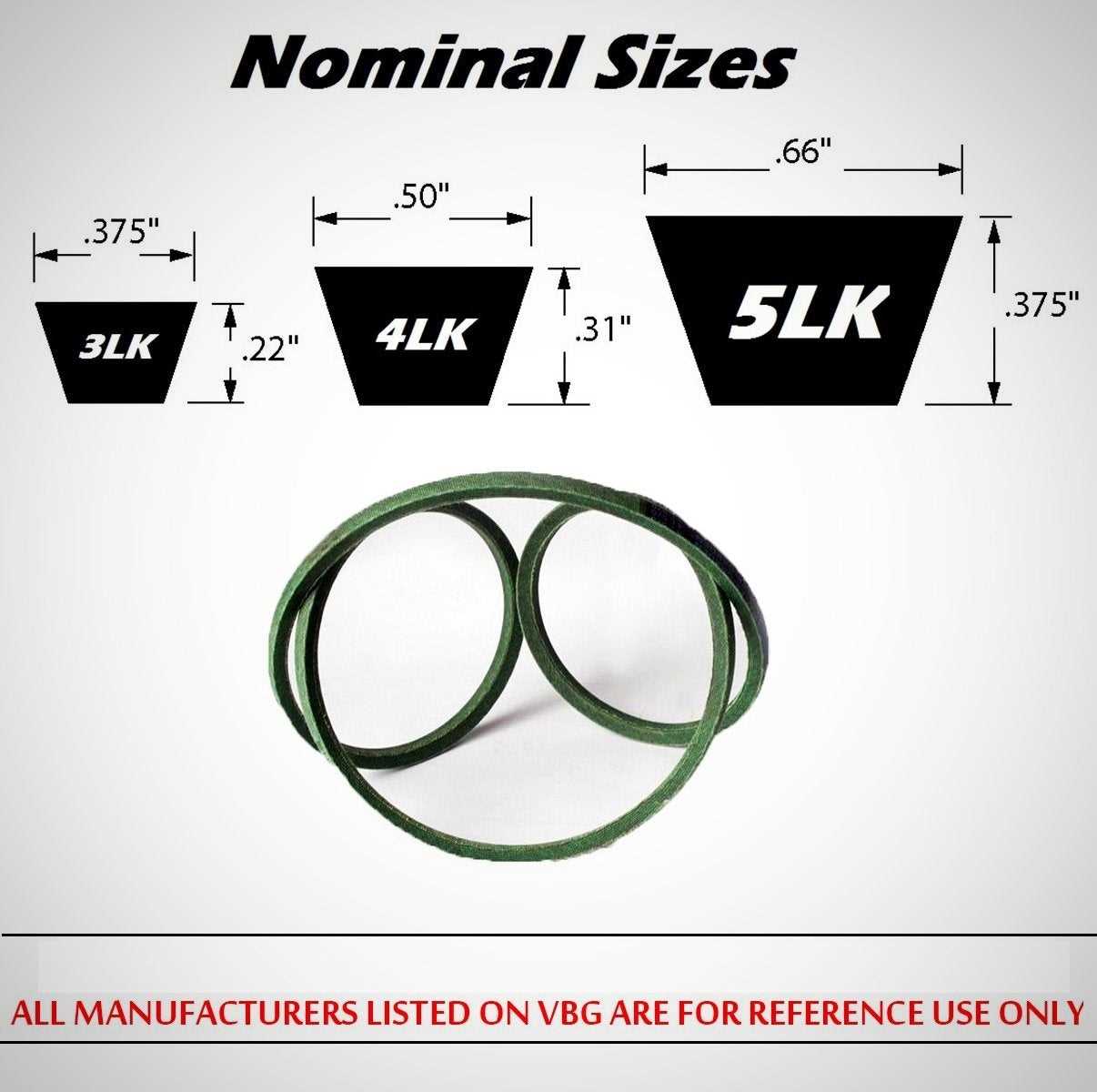

Frequent checks are essential for identifying potential issues before they escalate. Inspect belts, blades, and other vital components for wear and tear. Addressing minor problems promptly can prevent more significant repairs and ensure smooth operation.

Proper Cleaning and Storage

After each use, it is crucial to clean your machine thoroughly. Remove grass clippings, dirt, and debris from all surfaces. Storing the equipment in a dry, sheltered area helps protect it from the elements, reducing rust and other damage.

Remember to follow the manufacturer’s guidelines for maintenance schedules and use appropriate lubricants to keep moving parts functioning correctly. Taking these steps will significantly contribute to the longevity of your equipment.

Ordering Parts: Best Practices

When it comes to acquiring components for maintenance or repair, following a systematic approach can make the process smoother and more efficient. Understanding how to navigate through suppliers and identifying the right items can save both time and money.

Research and Identify Components

Before placing an order, it is crucial to research the specific components you need. Ensure you have the correct specifications, such as model numbers or serial numbers, which will help in locating the right items. Utilizing online resources, manuals, and community forums can provide valuable insights and enhance your understanding.

Choose Reputable Suppliers

Selecting trustworthy vendors is essential for ensuring quality and reliability. Look for suppliers with positive reviews and a good reputation in the market. Additionally, consider the warranty and return policies they offer, as these can be indicative of their commitment to customer satisfaction. Always compare prices and shipping options to find the best deal without compromising on quality.

Utilizing the Parts Diagram Effectively

Understanding the layout of components is crucial for anyone looking to maintain or repair machinery. A well-structured visual representation can simplify the identification of each element, ensuring that users can efficiently locate what they need. This guide will explore strategies to maximize the benefits of such a reference tool.

Identifying Components with Precision

Begin by familiarizing yourself with the overall structure. Focus on the major assemblies and their connections to grasp how each section functions together. Use the visual guide to pinpoint specific pieces, making it easier to determine what needs replacement or adjustment.

Streamlining Repair and Maintenance Tasks

When planning a repair, consult the visual layout to compile a list of necessary items. This approach minimizes time spent searching for individual elements and helps avoid purchasing unnecessary replacements. Additionally, having a clear reference can aid in reassembly, ensuring that everything fits together seamlessly.

In summary, leveraging a comprehensive visual reference can significantly enhance your ability to maintain and repair machinery. By systematically analyzing and utilizing these resources, you can ensure your equipment remains in optimal condition.

Frequently Asked Questions

This section aims to address common inquiries regarding the maintenance and components of your outdoor equipment. Understanding the essentials can enhance your experience and ensure the longevity of your machinery.

- What should I do if my equipment won’t start?

- Check the fuel level and ensure it is fresh.

- Inspect the battery connections for corrosion or loose wires.

- Examine the spark plug for signs of wear.

- How often should I perform maintenance?

- Regularly inspect and clean components according to the user manual.

- Schedule servicing every 25-50 hours of use.

- Where can I find replacement components?

- Authorized dealers often stock genuine parts.

- Online retailers provide a variety of options for your machinery.

- What are the signs of wear on the blades?

- Dull edges that no longer cut effectively.

- Visible chips or cracks on the blade surface.

- Can I perform repairs myself?

- Many minor repairs can be undertaken with basic tools.

- Refer to the user guide for specific procedures.