In the realm of outdoor machinery, comprehending the intricate assembly of various elements is essential for effective maintenance and operation. Knowing how each piece fits together not only enhances functionality but also prolongs the lifespan of the equipment.

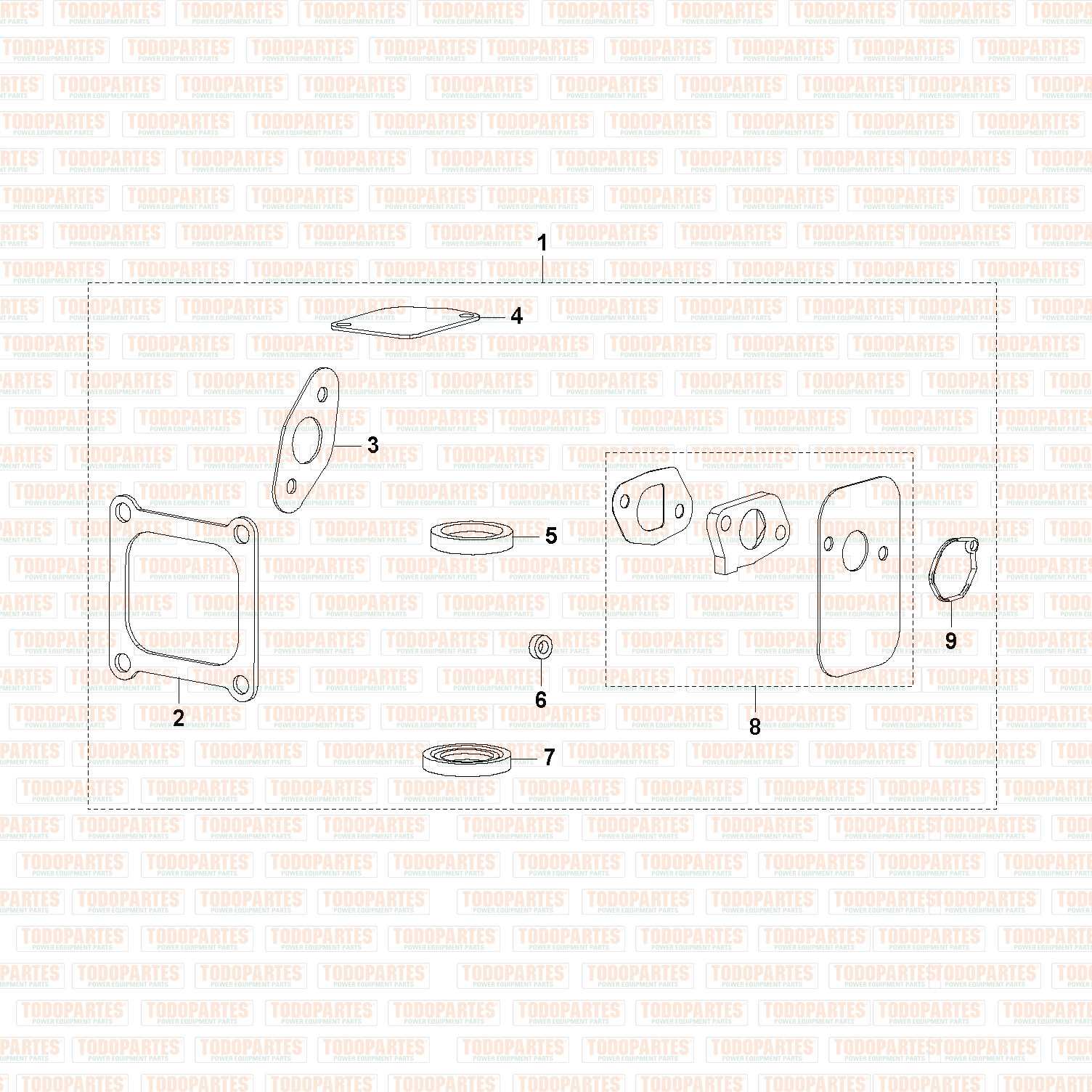

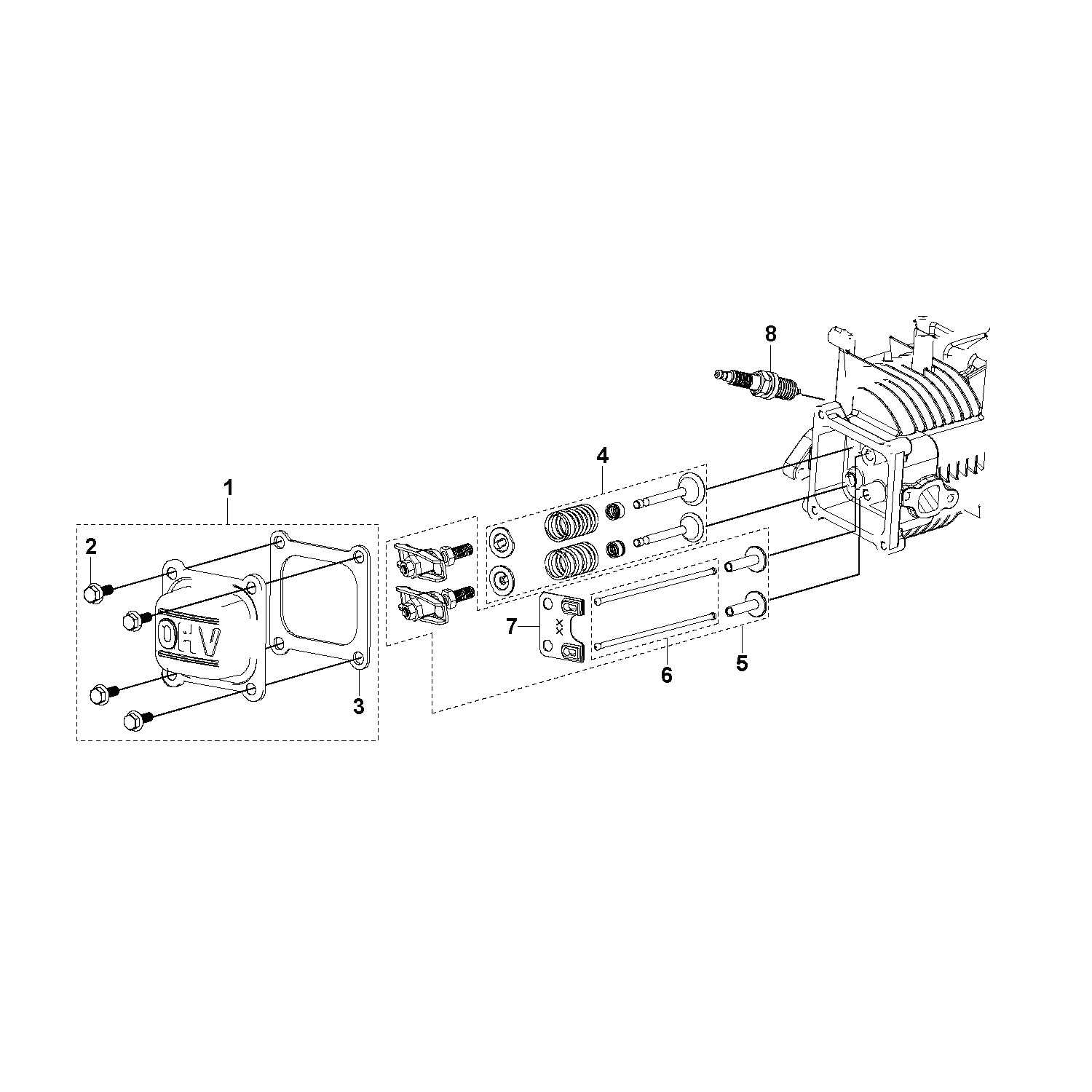

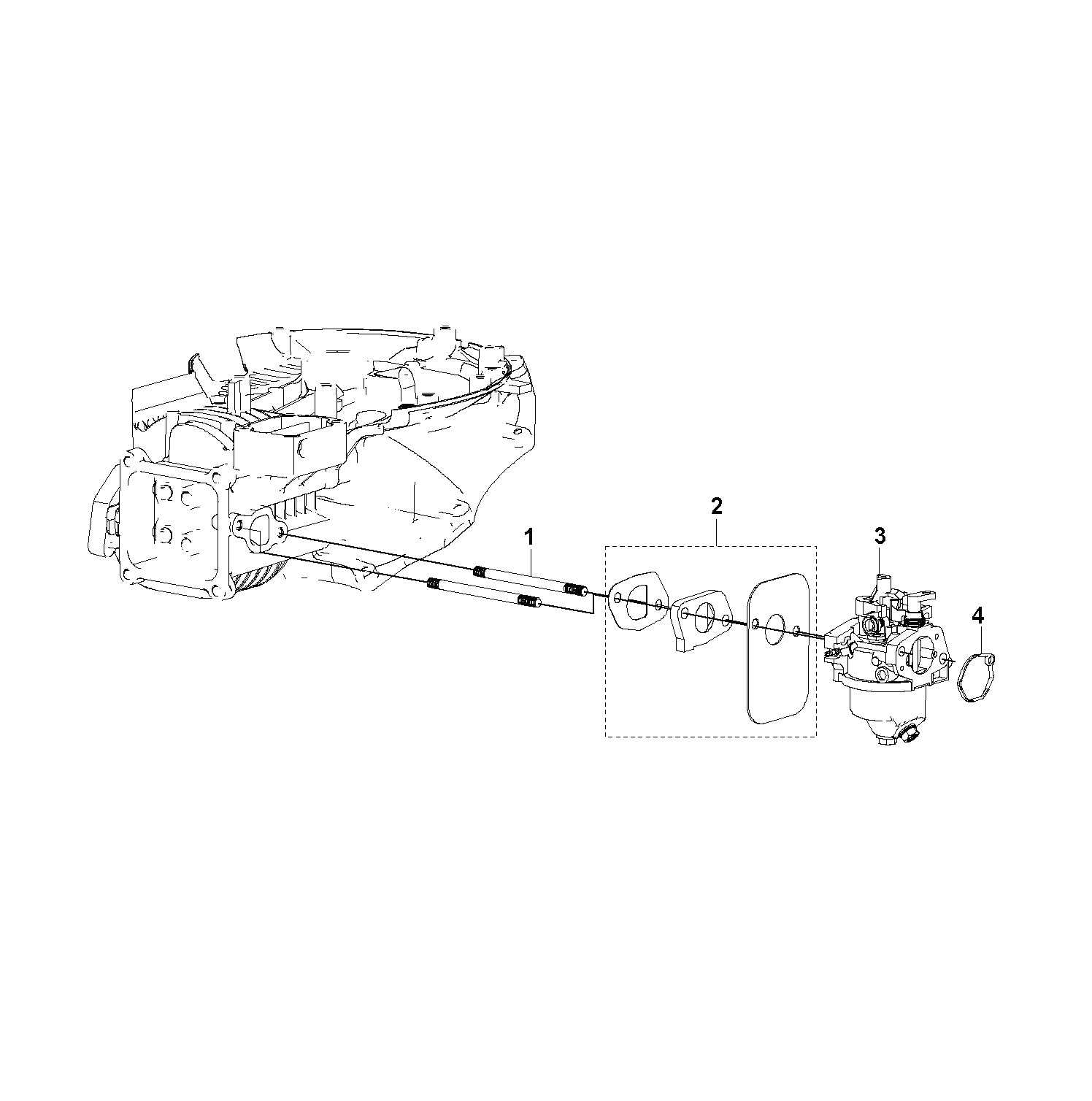

Visual representations play a crucial role in this understanding, offering clear insights into the arrangement and relationship between different components. By analyzing these illustrations, users can easily identify individual parts, facilitating repairs and replacements when necessary.

Familiarizing oneself with these visual guides empowers owners to tackle issues confidently, ensuring their machinery performs at its best. This knowledge not only aids in troubleshooting but also enhances the overall experience of operating such equipment.

This section aims to provide a comprehensive overview of the essential components of a specific lawn care machine, highlighting their functions and interrelationships. By understanding these elements, users can enhance their maintenance skills and ensure optimal performance.

| Component | Function |

|---|---|

| Engine | Drives the machine, providing necessary power. |

| Cutting Blade | Enables grass trimming with precision. |

| Handlebar | Facilitates control and maneuverability. |

| Deck | Houses the cutting blade and supports the structure. |

| Wheels | Ensure mobility across various terrains. |

| Fuel Tank | Stores the fuel required for operation. |

Essential Components Overview

This section provides a comprehensive look at key elements essential for the efficient functioning of lawn maintenance equipment. Understanding these components is crucial for optimal performance and longevity.

Core Elements

- Engine: Powers the machinery, ensuring effective operation.

- Blade: Responsible for cutting grass and maintaining a neat appearance.

- Deck: The main body housing the cutting mechanism, designed for durability.

- Wheels: Facilitate movement, providing stability and maneuverability.

- Handle: Offers control and ease of use during operation.

Supportive Features

- Throttle Control: Regulates engine speed for varying cutting conditions.

- Chassis: Provides structural integrity and houses vital components.

- Fuel System: Ensures the engine receives the necessary energy to operate.

- Exhaust System: Manages emissions and enhances engine efficiency.

Identifying Key Assembly Areas

Understanding the main sections of a device is crucial for effective maintenance and repair. By recognizing the primary components, users can navigate the assembly more efficiently, ensuring proper functionality and longevity. This section highlights the essential areas that play a significant role in the overall operation of the equipment.

Critical Component Locations

Key areas of the assembly often include the engine, transmission, and control mechanisms. Each of these sections contributes to the overall performance, and familiarity with their arrangement can simplify troubleshooting. For instance, knowing where the engine is located can expedite checks and repairs related to power issues.

Access Points for Maintenance

Accessibility to various components is vital for routine upkeep. Identifying access points allows users to perform necessary inspections and replacements without extensive disassembly. Key areas often feature removable panels or access doors, making it easier to reach critical systems.

Maintenance and Repair Insights

Effective upkeep and troubleshooting are essential for ensuring optimal performance and longevity of garden equipment. Understanding the components and their functions can greatly enhance the maintenance process, enabling users to address issues proactively.

Regular inspections and timely interventions can prevent minor problems from escalating. Below are some key considerations for maintaining your equipment:

| Task | Frequency | Notes |

|---|---|---|

| Clean Air Filter | Every 10 hours | Ensure proper airflow for engine efficiency. |

| Check Spark Plug | Every 25 hours | Replace if worn for reliable ignition. |

| Inspect Blades | After each use | Sharpen or replace for optimal cutting. |

| Change Oil | Every 50 hours | Maintains engine lubrication and performance. |

Implementing these practices will not only improve functionality but also extend the lifespan of your equipment, ensuring it remains reliable for years to come.

Common Issues and Solutions

In the realm of outdoor machinery, various challenges can arise during operation. Understanding these frequent complications and their remedies is essential for maintaining optimal performance and extending the lifespan of your equipment.

Engine Difficulty: One of the most common issues is the engine failing to start. This can often be traced back to fuel problems, such as stale fuel or a clogged filter. Solution: Regularly check and replace fuel, and ensure the filter is clean.

Overheating: Machines may also overheat, leading to decreased efficiency. This can result from inadequate lubrication or airflow blockage. Solution: Regular maintenance, including oil changes and cleaning air vents, can help prevent this.

Unusual Noises: Strange sounds during operation can indicate mechanical wear or damage. This issue often arises from loose components or lack of lubrication. Solution: Conduct regular inspections to tighten parts and ensure proper lubrication.

Diagram Interpretation Tips

Understanding technical drawings requires attention to detail and the ability to follow the layout of symbols, lines, and connections. By familiarizing yourself with the structure and organization of these illustrations, you can quickly identify how different elements are related and what their specific functions are within the larger system.

Focus on the Layout: When approaching a new technical sketch, start by analyzing the overall arrangement. Look for key sections that divide different components or systems. This will help you understand the flow and interactions between different parts.

Identify Symbols and Notations: Each symbol in a drawing has a specific meaning. Take time to review and learn common symbols, as they provide essential information about the type of components or connections involved. The more familiar you are with these, the quicker you’ll be able to interpret the illustration.

Follow the Flow of Connections: Pay close attention to how different elements are connected. Lines, arrows, and labels are crucial for showing how energy, signals, or fluids move between different sections. Understanding these paths is key to interpreting the entire layout correctly.

Ordering Replacement Parts Effectively

To ensure smooth equipment maintenance, acquiring replacement components should be approached with careful attention. A structured process helps avoid mismatches, delays, and additional expenses. Clear communication and detailed knowledge of your machine are essential when selecting and ordering the correct elements.

Identify and Confirm the Right Components

The first step in efficiently sourcing parts is accurate identification. Double-check model numbers, descriptions, and measurements to ensure compatibility with your equipment. Always verify this information against a trusted resource or service provider before making any decisions.

Choose Reliable Suppliers

Once you have identified the correct components, it’s crucial to select a reputable supplier. Opt for vendors with a proven track record of timely deliveries and quality materials. Reviews and customer feedback can be valuable in choosing the right source for your equipment needs.

Tools Required for Repairs

When working on maintenance or fixing machinery, it’s essential to have the correct set of tools. The right equipment ensures that tasks are completed efficiently and safely, reducing the risk of damaging components or prolonging the repair process. This section covers some of the most commonly used tools for general mechanical tasks.

Basic Hand Tools

For most repair tasks, having a set of essential hand tools is crucial. These include wrenches, screwdrivers, pliers, and socket sets, which are useful for handling bolts, nuts, and fasteners of various sizes. A reliable hammer is also indispensable for minor adjustments or removing stuck components.

Specialized Equipment

In addition to basic hand tools, certain repairs may require more specialized equipment. Torque wrenches, for instance, ensure bolts are tightened to the correct specifications, while pullers and clamps help in the removal and installation of parts that require extra force. An adjustable wrench can be beneficial for working with components of varying sizes.

Compatibility with Other Models

When considering the interchangeability of components across different models, it is crucial to understand how various designs align with one another. Many devices within the same brand or product line share similar specifications and construction features, enabling parts to be used interchangeably. This compatibility not only facilitates maintenance but also enhances the overall user experience by providing flexibility in repairs and upgrades.

Moreover, certain models may incorporate advancements or modifications that improve performance while still retaining a base similarity. Users should carefully consult compatibility guides and manufacturer resources to ensure that the selected components meet the required standards and specifications. This attention to detail can prevent potential issues and optimize the functionality of the device.

In summary, while exploring the compatibility of different models, it is essential to assess both shared characteristics and specific enhancements. Proper evaluation will lead to informed decisions, resulting in efficient repairs and the longevity of the equipment.

Safety Precautions During Maintenance

Ensuring safety while performing maintenance tasks is essential to prevent accidents and injuries. Following specific guidelines helps create a secure environment and promotes effective workflow. Understanding the potential hazards associated with various tools and equipment is crucial for maintaining a safe workspace.

General Safety Guidelines

Before starting any maintenance work, familiarize yourself with the equipment and its operation. Always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and sturdy footwear. Keeping the workspace clean and organized minimizes risks of slips, trips, and falls.

Handling Tools and Equipment

Using the correct tools for each task is vital for safety. Ensure that all tools are in good condition and stored properly when not in use. Pay attention to any specific safety instructions provided by manufacturers to avoid potential hazards.

| Precaution | Description |

|---|---|

| Wear PPE | Always use gloves, goggles, and appropriate clothing. |

| Check Tools | Inspect tools for damage or wear before use. |

| Work in Ventilated Area | Ensure proper airflow to avoid inhaling harmful fumes. |

| Disconnect Power | Always unplug equipment before performing maintenance. |

Frequently Asked Questions

This section aims to address common inquiries regarding the assembly and maintenance of lawn care machinery. Understanding these aspects can help users enhance their experience and ensure the longevity of their equipment.

- What should I do if I can’t find a specific component?

It’s advisable to check with authorized retailers or online resources dedicated to machinery. Many websites provide detailed listings and guides.

- How often should I inspect my equipment?

Regular inspections are recommended at least once per season. This ensures any wear and tear is addressed promptly, prolonging the lifespan of your machinery.

- Where can I find maintenance tips?

Consulting the user manual is a great start. Additionally, many forums and online communities offer insights and tips from fellow users.

- Is it necessary to use original components?

While aftermarket parts may fit, original components are designed specifically for optimal performance and reliability.

- What are the signs that a component needs replacing?

Common indicators include unusual noises, decreased performance, and visible damage. It’s crucial to address these signs to avoid further issues.

cssCopy code