When maintaining or repairing a vehicle, having a clear understanding of how different components are positioned and interact is essential. Each system within a vehicle relies on a network of interconnected elements that work together to ensure optimal performance. Understanding these relationships can greatly simplify any mechanical tasks or upgrades.

The visual representation of a vehicle’s structure offers a detailed overview of how various mechanical and electrical elements fit into the overall design. Such insights allow both professionals and enthusiasts to navigate through the complex framework of automotive systems efficiently. This guide will provide a deeper look into these elements, assisting in the identification and location of crucial components.

By gaining a clear perspective on the internal layout, vehicle owners and mechanics alike can better anticipate which elements may require attention during servicing or repairs. This knowledge is invaluable for ensuring that all components are functioning as intended and that any issues can be addressed promptly.

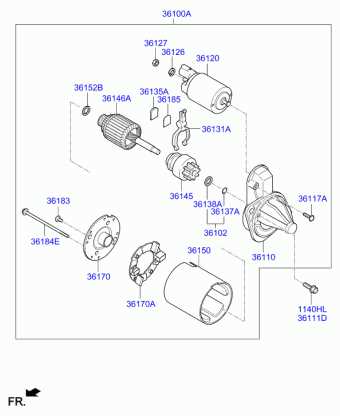

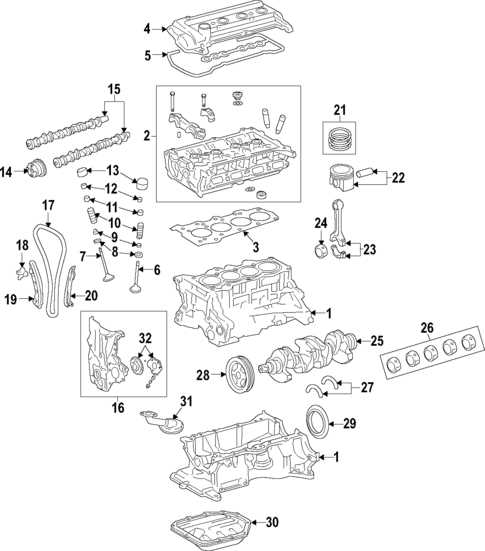

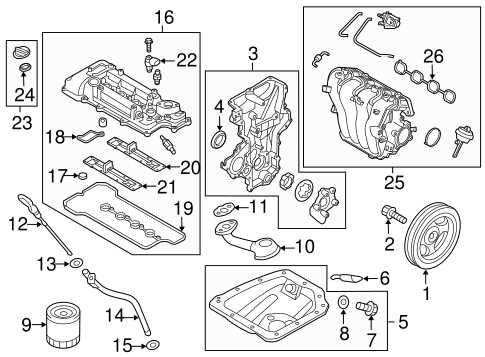

2016 Hyundai Accent: Engine Component Breakdown

The heart of any vehicle lies in its powertrain, where various mechanical and electronic systems work together to ensure optimal performance. Understanding the critical components of this area can help drivers and technicians maintain and repair the vehicle more effectively.

Main Structural Elements

- Engine Block – The foundation that houses the cylinders and provides the framework for other essential parts.

- Cylinder Head – Positioned atop the block, it contains the intake and exhaust valves, as well as the combustion chambers.

- Crankshaft – Converts the up-and-down motion of the pistons into rotational force to power the vehicle.

Additional Vital Systems

- Fuel Injection System – Ensures the correct mixture of fuel and air enters the combustion chamber for efficient power generation.

- Cooling Mechanism – Includes the radiator and water pump, which help maintain optimal operating temperatures and prevent overheating.

- Lubrication Circuit – Distributes oil throughout the engine to reduce friction and protect moving parts from wear.

By knowing the role of each component, one can easily identify potential issues and ensure the longevity of the engine’s performance.

Identifying Key Parts of the Engine

Understanding the main elements within a vehicle’s engine is crucial for maintaining its performance and efficiency. Each component plays a vital role in ensuring that the motor operates smoothly and efficiently, from power generation to fuel management. Recognizing these components can assist in regular upkeep and troubleshooting.

Main Components

The engine consists of several core elements responsible for converting fuel into motion. The cylinder block forms the foundation of the motor, housing essential parts like pistons, which move to generate energy. The crankshaft, connected to the pistons, transforms this motion into rotational energy, driving the vehicle forward.

Supporting Systems

Beyond the core, the engine features systems designed to regulate temperature and airflow. The cooling system ensures that the motor maintains optimal operating temperatures, preventing overheating. Meanwhile, the intake system allows the proper amount of air into the engine, balancing the fuel mixture for efficient combustion.

Transmission System Overview for Hyundai Accent

The transmission system plays a crucial role in the overall performance and efficiency of any vehicle. It is responsible for transferring power from the engine to the wheels, ensuring smooth and efficient operation. This system allows the driver to control speed and torque, adjusting the vehicle’s behavior to various driving conditions. Understanding its components and functionality is essential for proper maintenance and troubleshooting.

Key Components of the system include a series of gears, shafts, and clutches that work together to deliver the appropriate amount of power to the wheels. The interaction between these elements ensures that the engine operates at an optimal range, preventing unnecessary strain and fuel consumption.

There are two main types of transmissions commonly used: manual and automatic. Each has its unique advantages. Manual systems give the driver more control, allowing for gear shifting at precise intervals, while automatic ones offer a more seamless driving experience by handling the shifts without manual intervention. Regardless of the type, regular maintenance is crucial to ensure longevity and performance.

How the Transmission Components Function Together

The transmission system is a complex assembly that works seamlessly to ensure smooth power transfer from the engine to the wheels. By coordinating the efforts of several components, the system adjusts speed and torque, adapting to different driving conditions and ensuring the vehicle moves efficiently and effectively.

Key Transmission Elements

- Torque Converter: This component connects the engine to the transmission, allowing for a fluid transfer of power and enabling the vehicle to come to a stop without stalling.

- Planetary Gear Set: A critical element that adjusts the gear ratios, providing the necessary torque for both acceleration and cruising.

- Clutch Packs and Bands: These parts engage and disengage various gears, controlling the flow of power through the system.

How They Work Together

- First, the engine generates power, which is passed to the torque converter.

- The torque converter adjusts the power flow, sending it to the planetary gear set.

- The planetary gear set, aided by clutch packs and bands, selects the appropriate gear ratio based on driving speed and conditions.

- Finally, the adjusted power is transferred to the driveshaft, which moves the wheels.

All these componen

Exhaust System Configuration and Components

The exhaust system plays a crucial role in ensuring optimal vehicle performance, emissions control, and noise reduction. By guiding exhaust gases away from the engine and reducing harmful emissions, it contributes to both engine efficiency and environmental standards. Understanding its design and key elements is essential for maintaining vehicle functionality.

Main Sections of the Exhaust Assembly

The exhaust system is composed of several interconnected segments, each serving a specific purpose. Starting from the manifold, it directs the gases into pipes leading to the catalytic converter, which helps in reducing pollutants. Further along, the muffler dampens the noise, and finally, the gases exit through the tailpipe.

Essential Components and Their Functions

The primary components include the manifold, catalytic converter, muffler, and tailpipe. The manifold collects gases from the engine’s cylinders, while the catalytic converter minimizes harmful emissions. The muffler reduces the sound level of exhaust gases, and the tailpipe ensures safe expulsion of the remaining gases. Proper maintenance of these components ensures a well-functioning and eco-friendly vehicle.

Detailed Look at the Exhaust Layout

The exhaust system plays a crucial role in the overall performance of a vehicle, managing the expulsion of gases produced during combustion. Understanding its configuration helps in maintaining efficiency and optimizing engine output. This section delves into the intricate components and their arrangement within the exhaust framework.

Components of the Exhaust System

- Exhaust Manifold: Collects gases from the engine cylinders and directs them towards the exhaust pipe.

- Catalytic Converter: Reduces harmful emissions by converting toxic gases into less harmful substances.

- Resonator: Modifies sound and minimizes noise from the exhaust.

- Muffler: Further reduces noise before the gases exit the system.

- Exhaust Pipe: Channels the gases away from the vehicle.

Layout Overview

The arrangement of these components is designed to facilitate efficient gas flow while minimizing back pressure. Key considerations include:

- Flow Dynamics: Ensuring gases move smoothly through the system.

- Material Selection: Using heat-resistant and corrosion-resistant materials to enhance longevity.

- Mounting Position: Proper placement to avoid contact with other vehicle parts.

In summary, a well-structured exhaust configuration is essential for optimal vehicle performance, contributing to both efficiency and compliance with emissions standards.

Fuel System Parts and Their Functions

The fuel system is a vital component of any vehicle, responsible for delivering the necessary fuel to the engine for optimal performance. Understanding the various elements involved in this system helps in diagnosing issues and maintaining efficiency. Each component plays a specific role in ensuring that the engine receives fuel at the right pressure and in the right quantity.

Key Components of the Fuel System

- Fuel Pump: This device draws fuel from the tank and delivers it to the engine. It ensures a steady flow and pressure necessary for combustion.

- Fuel Filter: Positioned between the fuel tank and engine, this filter removes impurities and debris from the fuel, protecting the engine from damage.

- Fuel Injector: This component sprays fuel directly into the engine’s combustion chamber, ensuring an optimal air-fuel mixture for efficient combustion.

- Fuel Rail: The fuel rail distributes the fuel from the injector to each cylinder, maintaining consistent pressure throughout the system.

- Fuel Pressure Regulator: This unit maintains the correct fuel pressure within the system, allowing the engine to function efficiently.

Functions of the Fuel System Components

- Fuel Pump: Transports fuel and maintains required pressure levels.

- Fuel Filter: Ensures clean fuel reaches the engine, enhancing performance and longevity.

- Fuel Injector: Atomizes fuel for better mixing with air, improving combustion efficiency.

- Fuel Rail: Delivers fuel uniformly to all cylinders, promoting balanced engine operation.

- Fuel Pressure Regulator: Adjusts pressure based on engine demand, optimizing fuel delivery.

Understanding the Fuel Delivery Mechanism

The fuel delivery system is a crucial component of any internal combustion engine, responsible for transporting fuel from the tank to the engine in a controlled manner. This system ensures that the correct amount of fuel reaches the engine, allowing for efficient combustion and optimal performance.

At the core of this mechanism is the fuel pump, which draws fuel from the tank and pushes it through a series of lines. These lines are designed to withstand pressure and prevent leaks. Once the fuel reaches the engine, it passes through a fuel filter, which removes impurities that could affect performance. The filtered fuel then enters the fuel injectors, which atomize the fuel and mix it with air before it enters the combustion chamber.

Understanding this mechanism is essential for diagnosing issues related to fuel delivery, such as poor engine performance or reduced fuel efficiency. Regular maintenance of the fuel system components can help ensure that the engine operates smoothly and efficiently.

In summary, the fuel delivery mechanism is a sophisticated system that plays a vital role in the performance of an engine. Proper functioning of this system is essential for maintaining the overall health of the vehicle and ensuring a reliable driving experience.

Brake System Components in Hyundai Accent

The braking mechanism of a vehicle plays a crucial role in ensuring safety and control during operation. A well-functioning system is essential for effective stopping power and overall driving performance. This section will explore the various elements that comprise the braking assembly, highlighting their importance and functionality.

1. Brake Pads: These components are designed to create friction against the brake rotors, which is essential for slowing down or stopping the vehicle. High-quality pads ensure optimal performance and longevity, contributing to safety on the road.

2. Brake Rotors: These circular discs are attached to the wheels and work in conjunction with the brake pads. When pressure is applied to the brake pedal, the pads clamp down on the rotors, generating the necessary friction to halt motion.

3. Brake Calipers: The calipers house the brake pads and contain the pistons that apply pressure when the brakes are engaged. This component is vital for maintaining the efficiency of the braking system, as it ensures even distribution of force on the rotors.

4. Brake Lines: These tubes transport brake fluid from the master cylinder to the calipers. Maintaining the integrity of these lines is critical for the proper function of the braking system, as any leaks can lead to decreased performance.

5. Brake Master Cylinder: This component generates hydraulic pressure when the brake pedal is pressed. It is a key player in the braking process, as it ensures that fluid is distributed to the appropriate areas within the braking system.

Understanding these fundamental components and their roles can significantly enhance one’s ability to maintain and troubleshoot the braking assembly. Regular inspections and timely replacements of worn parts are essential for ensuring a safe driving experience.

Key Parts of the Braking Mechanism

The braking system is a crucial component in ensuring vehicle safety and performance. It operates through a combination of various elements that work together to create the necessary force to slow down or stop the vehicle. Understanding these key components can help in recognizing their significance and potential issues that may arise during operation.

Brake Pads are essential friction materials that press against the brake rotors to generate stopping power. Their condition significantly affects the overall braking efficiency, making regular inspections important for maintaining optimal performance.

Brake Rotors, also known as discs, are the circular metal components that the brake pads clamp down on when the brakes are applied. Over time, they can become warped or worn, leading to reduced braking effectiveness and uneven wear on the pads.

Calipers play a vital role in the braking mechanism by housing the brake pads and utilizing hydraulic pressure to clamp them onto the rotors. Proper functioning of the calipers is essential for responsive braking and overall safety.

Brake Lines are responsible for transporting brake fluid from the master cylinder to the calipers. Any leaks or blockages in these lines can lead to a decrease in braking performance, highlighting the need for regular maintenance and inspections.

Master Cylinder is a key component that converts the force exerted on the brake pedal into hydraulic pressure. This pressure is transmitted through the brake lines to activate the calipers, making its proper functioning essential for effective braking.

Suspension System Breakdown for a Smooth Ride

The suspension system plays a crucial role in ensuring a comfortable and stable driving experience. It absorbs shocks from the road, maintains tire contact with the surface, and enhances vehicle handling. Understanding its components and functionality can significantly improve the performance and longevity of your vehicle.

Key Components of the Suspension

This system consists of various elements working together harmoniously. The main components include shocks, struts, springs, and control arms. Each part serves a unique purpose, contributing to the overall effectiveness of the system. For instance, springs support the vehicle’s weight and absorb bumps, while shocks dampen the oscillations caused by road imperfections.

Importance of Regular Maintenance

Regular inspection and maintenance of the suspension components are vital for optimal performance. Worn-out parts can lead to a decline in handling and comfort, potentially affecting safety. Ensuring that the system is in top condition not only enhances ride quality but also prolongs the lifespan of tires and other related components. Investing in timely maintenance pays off with a smoother and safer driving experience.

Main Elements of the Suspension Structure

The suspension system plays a critical role in vehicle dynamics, providing a balance between ride comfort and handling stability. It consists of various components that work together to absorb shocks from the road, maintain tire contact, and enhance overall safety. Understanding these elements is essential for diagnosing issues and ensuring optimal performance.

Key Components

- Shock Absorbers: These devices dampen the impact of road irregularities, preventing excessive bounce and maintaining control.

- Springs: Coiled or leaf springs support the vehicle’s weight and help maintain a stable ride height while allowing for movement.

- Control Arms: These link the wheel hubs to the chassis, allowing for controlled movement during suspension travel.

- Ball Joints: Acting as pivot points, ball joints enable the connection between control arms and the steering knuckles, allowing for smooth steering and suspension movement.

Additional Elements

- Stabilizer Bars: These components reduce body roll during cornering, enhancing stability and handling.

- Mounts: Rubber or hydraulic mounts isolate vibrations and provide a secure attachment between suspension components and the vehicle body.

- Trailing Arms: These assist in maintaining proper wheel alignment and help with vehicle handling during acceleration and braking.

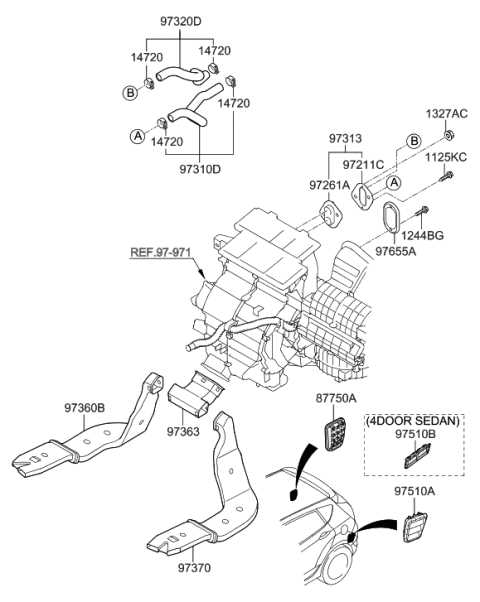

Cooling System Overview and Components

The cooling system plays a crucial role in maintaining optimal engine temperature, preventing overheating, and ensuring efficient performance. It comprises various elements that work in harmony to regulate heat produced during the combustion process. Understanding these components is essential for effective maintenance and troubleshooting.

Key Components of the Cooling System

The primary components include the radiator, water pump, thermostat, and cooling fans. The radiator dissipates heat from the engine coolant, while the water pump circulates this coolant throughout the engine block and back to the radiator. The thermostat regulates coolant flow based on temperature, ensuring that the engine operates within a safe range. Additionally, cooling fans assist in airflow, enhancing heat dissipation, particularly during idle or low-speed conditions.

Maintenance and Importance

Regular maintenance of the cooling system is vital to prevent engine damage. This includes checking coolant levels, inspecting hoses for leaks, and ensuring the radiator and fans are functioning correctly. Neglecting the cooling system can lead to severe overheating, resulting in costly repairs and decreased vehicle performance.