The intricate world of heavy machinery is marked by a complex interplay of various elements that work in harmony to achieve optimal performance. Recognizing how each component interacts is crucial for effective maintenance and operation. This knowledge not only enhances efficiency but also extends the lifespan of the equipment.

Comprehending the layout of these vital components is essential for operators and technicians alike. A clear visualization of the structure allows for quicker identification of issues, thereby streamlining the troubleshooting process. The importance of this understanding cannot be overstated, as it serves as the foundation for effective repairs and upgrades.

Moreover, having access to detailed representations of these elements facilitates a deeper understanding of the machine’s functionality. As users delve into the specifics, they can uncover the ultimate nuances that drive performance, making them more adept at handling both routine and unexpected challenges.

Understanding Hyundai Excavators

This section explores the key aspects of heavy machinery designed for earthmoving tasks. Understanding the components and functionality of these machines is essential for efficient operation and maintenance.

Key features include:

- Durability and strength for various terrains

- Advanced hydraulic systems for enhanced performance

- Operator comfort with ergonomic controls

When considering a model, it is vital to evaluate:

- Engine power and efficiency

- Operating weight and stability

- Attachment versatility for different jobs

Ultimately, knowledge of these machines leads to better decision-making and optimal performance in various applications.

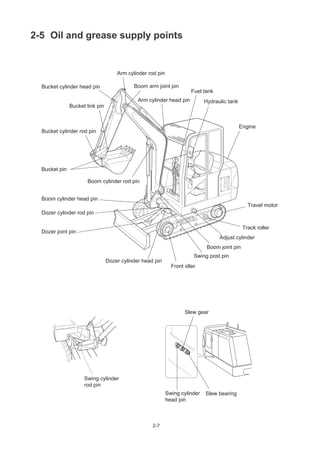

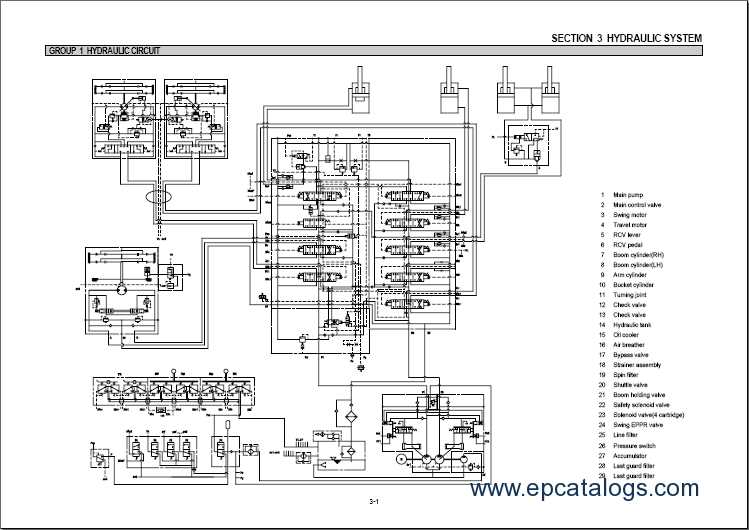

Key Components of Excavators

The efficiency and functionality of heavy machinery rely on several essential elements that work in unison. Understanding these core components is crucial for optimal operation and maintenance, ensuring that the machine performs at its best during demanding tasks.

The primary structure, often referred to as the chassis, serves as the foundation, providing stability and support for all other components. Attached to it, the arm, or boom, extends outward and upward, allowing for a wide range of motion. The attachment at the end, typically known as the bucket or tool, is designed for specific functions such as digging, lifting, or moving materials.

Another vital part is the hydraulic system, which powers the movement of the arm and attachment. This system converts fluid pressure into mechanical force, enabling precise control and heavy lifting capabilities. The operator’s cabin, equipped with controls and instruments, allows for intuitive maneuvering, making it easier to navigate complex environments.

Finally, the undercarriage, comprising tracks or wheels, ensures mobility and traction on various terrains. Together, these components create a powerful machine that can tackle a multitude of tasks in construction and excavation projects.

Importance of Parts Diagrams

Understanding the intricacies of machinery is crucial for efficient maintenance and repair. Visual representations provide clarity, enabling technicians to identify components and their interrelations easily. This knowledge enhances troubleshooting and ensures that operations run smoothly.

Visual aids serve as essential tools for both novice and experienced professionals. They simplify complex systems, allowing for quicker diagnosis and resolution of issues. When mechanics can delve into detailed illustrations, they are better equipped to make informed decisions.

Ultimately, having access to accurate schematics fosters a deeper comprehension of machinery, leading to improved performance and longevity. This foundation is vital for anyone aiming to achieve optimal results in their work.

Common Issues with Excavator Parts

Understanding the frequent challenges faced by heavy machinery can significantly enhance maintenance and performance. These complications often arise due to wear and tear, environmental factors, or improper usage. Identifying and addressing these issues early can lead to improved efficiency and longevity.

Wear and Tear

Wear and tear is a prevalent problem, particularly in high-stress components. Parts such as hydraulic systems and tracks can degrade over time, leading to decreased functionality and potential breakdowns. Regular inspections are crucial to mitigate these risks.

Environmental Impact

Exposure to harsh conditions can accelerate deterioration. Dust, moisture, and extreme temperatures can adversely affect sensitive components. Implementing protective measures and performing routine maintenance can help minimize these effects and ensure optimal operation.

How to Read a Parts Diagram

Understanding a technical illustration is crucial for efficient maintenance and repairs. These visuals provide a detailed representation of components, allowing users to identify each piece’s role and location. By familiarizing yourself with the symbols and notations used, you can streamline your repair process and ensure accurate assembly.

Start by examining the legend or key, which explains the symbols used throughout the illustration. This will help you grasp the meaning behind various icons. Next, follow the connections between components, noting how they interact and are positioned relative to one another. This comprehensive approach will enhance your ability to troubleshoot issues effectively.

Pay attention to any callouts or annotations that offer additional information about specific items, such as part numbers or special instructions. Understanding these details is essential for ordering replacements or upgrades accurately. Finally, practice makes perfect; the more you work with these visuals, the more proficient you’ll become at interpreting them.

Essential Maintenance Tips

Regular upkeep is crucial for ensuring the longevity and efficiency of heavy machinery. By adhering to a consistent maintenance schedule, operators can prevent unexpected breakdowns and enhance overall performance. Here are some key strategies to keep in mind.

Routine Inspections

Conducting frequent evaluations helps identify wear and tear before they escalate. Look for signs of damage, leaks, and unusual noises during these checks.

Proper Lubrication

Keeping components adequately lubricated minimizes friction and prolongs the lifespan of machinery. Always use the recommended lubricants for optimal results.

| Maintenance Task | Frequency |

|---|---|

| Fluid Checks | Daily |

| Filter Replacements | Monthly |

| Full Inspection | Quarterly |

| Lubrication | Weekly |

Aftermarket vs. OEM Parts

When it comes to maintaining heavy machinery, choices abound between components manufactured by original producers and those created by third parties. Each option carries its own set of advantages and drawbacks, influencing both performance and cost-effectiveness. Understanding these differences can guide owners in making informed decisions that align with their operational needs.

Original manufacturer components are typically designed to meet specific quality and durability standards, ensuring compatibility and reliability. However, they often come with a higher price tag, which may not always be feasible for all users.

In contrast, third-party alternatives may offer more competitive pricing and a variety of choices. While these components can deliver satisfactory performance, the risk of quality variance exists, which could impact machinery functionality over time. Evaluating both options helps in determining the best fit for specific requirements and budget constraints.

Identifying Wear and Tear

Recognizing signs of deterioration in machinery is crucial for maintaining efficiency and prolonging service life. Understanding the various indicators of wear allows operators to take proactive measures, ensuring optimal performance and reducing the likelihood of costly repairs.

Common symptoms of wear include:

- Unusual noises during operation

- Decreased performance or sluggish movement

- Visible cracks or breaks in components

- Fluid leaks around joints or seals

To effectively monitor these signs, operators should implement regular inspection routines. Consider the following steps:

- Conduct visual inspections for cracks or corrosion.

- Listen for abnormal sounds that may indicate underlying issues.

- Check fluid levels and look for signs of leaks.

- Test operational efficiency and response times.

Timely identification and assessment of wear and tear can prevent unexpected breakdowns and enhance overall functionality.

Ordering Replacement Components

When it comes to maintaining heavy machinery, sourcing the right replacement components is crucial for ensuring optimal performance and longevity. This process requires careful consideration of various factors, including compatibility, quality, and supplier reliability. By following a structured approach, operators can effectively navigate the complexities of acquiring the necessary items to keep their equipment running smoothly.

Firstly, it’s important to identify the specific components needed for replacement. This involves consulting technical manuals or service guides that outline the specifications and compatibility requirements. Once the exact items are determined, the next step is to research suppliers who offer these components, focusing on those known for their credibility and quality assurance.

In order to streamline the ordering process, the following table outlines key aspects to consider when selecting components:

| Factor | Description |

|---|---|

| Compatibility | Ensure that the component matches the specifications of the machinery. |

| Quality | Opt for components that meet industry standards to avoid premature failures. |

| Supplier Reputation | Research supplier reviews and ratings to gauge their reliability. |

| Warranty | Check for warranty options that provide assurance against defects. |

| Delivery Time | Consider the lead time for receiving the components to minimize downtime. |

By following these guidelines and leveraging reliable sources, operators can effectively procure the necessary components to maintain their machinery’s performance and reliability over time.

Repairing vs. Replacing Parts

When it comes to machinery maintenance, the decision to fix or substitute components is crucial. Each option carries its own set of benefits and drawbacks, and understanding these can lead to more informed choices that affect performance, longevity, and costs.

Repairing components often offers a cost-effective solution. Here are some advantages:

- Lower immediate costs compared to buying new items.

- Can extend the life of the existing component, maximizing investment.

- Environmentally friendly by reducing waste.

However, there are also challenges associated with repairs:

- Repairs may not restore full functionality.

- Potential for recurring issues if underlying problems are not addressed.

- Time-consuming process that can lead to extended downtime.

On the other hand, opting for replacement can be beneficial in several ways:

- New components typically come with warranties, ensuring reliability.

- Improved performance and efficiency with the latest technology.

- Eliminates the risk of recurring issues associated with older items.

Despite these advantages, replacing items may also present some downsides:

- Higher upfront costs, impacting budget constraints.

- Potentially longer lead times for delivery.

- Increased waste if old components are discarded.

Ultimately, the choice between fixing or substituting depends on factors such as budget, the severity of the issue, and long-term operational goals. Evaluating these aspects can help in making a well-rounded decision that aligns with specific needs.

Best Practices for Excavator Use

Operating heavy machinery requires a blend of skill, knowledge, and safety awareness. Understanding the optimal methods for using this equipment not only enhances efficiency but also minimizes risks for operators and surrounding personnel.

Regular Maintenance: Frequent inspections and servicing are crucial. Keeping machinery in top condition prevents malfunctions and extends its lifespan.

Proper Training: Ensure that all operators are well-trained. Knowledge of controls and functions leads to safer and more effective operation.

Awareness of Surroundings: Always be conscious of the work area. Identify potential hazards, including nearby personnel, structures, and uneven ground.

Load Management: Adhere to weight limits and distribute loads evenly. This practice prevents tipping and enhances stability.

Use of Safety Gear: Equip operators with necessary protective equipment. Hard hats, gloves, and eye protection are essential for safeguarding against accidents.

Clear Communication: Establish clear signals and communication methods among team members. This ensures everyone is aware of movements and actions being taken.

Follow Manufacturer Guidelines: Always consult the operator’s manual for specific recommendations and instructions related to the machinery in use.

Implementing these practices fosters a safer and more productive work environment, ultimately leading to better project outcomes.

Resources for Parts Information

Accessing accurate details regarding components is essential for efficient maintenance and repair processes. A variety of tools and resources are available to help users find the information they need, ensuring that machinery operates at peak performance.

Manufacturer Websites: Many original equipment producers offer comprehensive online databases where one can search for specific items based on model numbers or equipment type. These resources often include specifications, installation guides, and compatibility charts.

Online Retailers: E-commerce platforms specializing in machinery supplies frequently provide extensive catalogs. Customers can browse by category or use search features to locate the exact components they require, often accompanied by reviews and ratings to guide purchasing decisions.

Forums and Community Groups: Engaging with online communities can yield valuable insights. Users often share personal experiences, troubleshooting tips, and recommendations for reputable suppliers, creating a collaborative environment for knowledge exchange.

Service Manuals: Comprehensive service manuals are invaluable, offering detailed information about assembly and disassembly, as well as troubleshooting procedures. These documents often include visual aids to facilitate understanding.

Local Distributors: Establishing a relationship with local distributors can provide direct access to inventory and personalized service. These professionals can offer guidance based on experience and familiarity with specific equipment needs.

Future Trends in Excavator Technology

The evolution of heavy machinery is entering a new phase marked by innovation and efficiency. As industries seek to optimize operations and reduce environmental impact, several key trends are shaping the future landscape of these powerful machines.

- Automation and Robotics: Increasing use of automated systems and robotic technology is revolutionizing how operators interact with machinery. Autonomous operation minimizes human error and enhances productivity.

- Telematics and Connectivity: Advanced telematics systems enable real-time monitoring and data collection. This connectivity allows for better maintenance scheduling, enhancing uptime and reducing operational costs.

- Electric and Hybrid Solutions: The shift towards electric and hybrid power sources is gaining momentum. These alternatives not only lower emissions but also promise reduced fuel costs and quieter operation.

- Advanced Materials: The use of lightweight and durable materials is on the rise, leading to improved performance and efficiency. Innovations in material science contribute to enhanced durability and reduced wear.

- Smart Technologies: Integration of smart technologies, such as AI and machine learning, enables predictive analytics and improved decision-making. This capability assists operators in optimizing performance and safety.

These emerging trends signify a transformative period for machinery, focusing on sustainability, efficiency, and enhanced functionality. As the industry continues to innovate, the future looks promising for the next generation of heavy-duty equipment.