The efficient functioning of a lifting device relies on a variety of essential elements working together seamlessly. Each component plays a crucial role in ensuring that the system operates smoothly and effectively. A thorough understanding of these individual elements is vital for anyone looking to optimize performance or conduct maintenance.

Identifying the different sections and their respective functions allows operators to diagnose issues and implement solutions effectively. By examining the configuration of these components, users can gain valuable insights into the mechanics behind their operation. This knowledge is fundamental for achieving reliability and safety in any lifting application.

In the following sections, we will delve into the intricate details of these mechanisms, exploring their structure and interconnections. Understanding how each piece contributes to the overall functionality will empower users to enhance their systems and ensure longevity.

This section will delve into the essential elements that constitute a specific type of lifting equipment. Understanding these components is crucial for both effective operation and maintenance, ensuring optimal functionality in various applications.

Key Elements of the Equipment

- Drum: The cylindrical part that houses the cable.

- Gearbox: A mechanism that transmits power from the motor to the drum.

- Motor: The source of power that drives the operation.

- Controller: The device that regulates the speed and direction of the equipment.

- Clutch: A component that allows the operator to engage or disengage the drum from the motor.

Importance of Each Component

Each element plays a vital role in ensuring the reliability and efficiency of the system. Regular inspection and understanding of how these parts interact can lead to improved performance and longevity.

- Durability: High-quality components contribute to overall strength.

- Efficiency: Well-designed parts ensure smooth operation.

- Safety: Proper functionality minimizes risks during use.

Overview of Winch Functionality

Understanding the mechanics of a pulling device is essential for its effective application across various industries. These machines are designed to facilitate the movement of heavy objects by utilizing a combination of gears, cables, and powerful motors. Their ability to generate significant force makes them invaluable in construction, towing, and rescue operations.

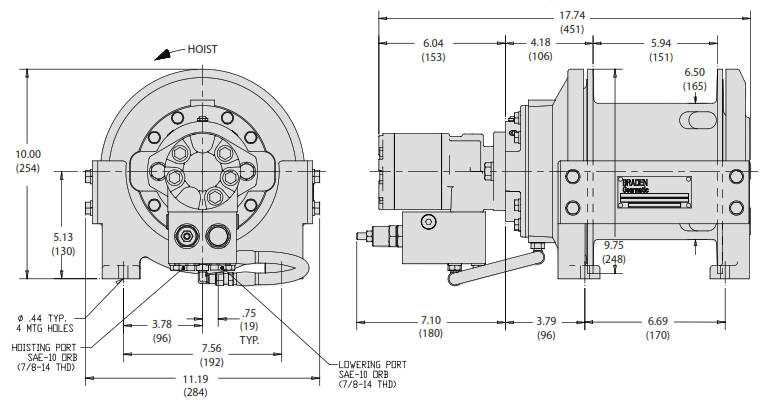

The operation of such devices revolves around the conversion of rotational energy into linear motion. When activated, the motor spins a drum, which winds the cable. As the cable tightens, it generates tension that allows for lifting or dragging substantial weights. This process is often enhanced by various control systems that ensure precision and safety during use.

Moreover, the design often incorporates safety features and adjustable settings, providing operators with versatility in handling different loads. Understanding these fundamental principles is crucial for anyone working with such equipment, ensuring both efficiency and safety in their operations.

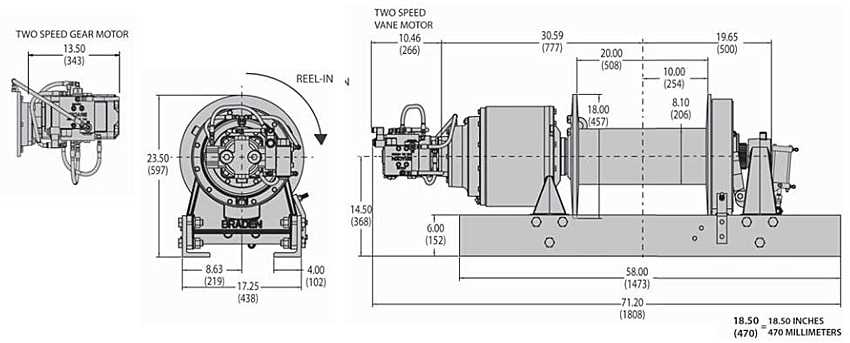

Key Elements of Braden Winches

The essential components of a pulling mechanism play a crucial role in ensuring its efficiency and reliability. Understanding these key elements helps users appreciate the functionality and performance of this equipment. Each part contributes to the overall operation, facilitating seamless operation in various applications.

Main Components

- Drum: The cylindrical element around which the cable winds, essential for the storage of the rope.

- Motor: The driving force that powers the system, providing the necessary torque for lifting and pulling tasks.

- Gearbox: Transmits power from the motor to the drum, allowing for speed reduction and increased torque.

- Frame: The structure that houses and supports all the components, providing stability during operation.

- Control System: The interface through which the operator manages the device, ensuring precise movements.

Functional Importance

- Safety: Each component is designed with safety features to prevent accidents during operation.

- Durability: High-quality materials are used to withstand the demanding conditions of various environments.

- Maintenance: Understanding these elements aids in effective upkeep, enhancing the longevity of the equipment.

Types of Braden Winch Models

In the realm of mechanical devices designed for heavy lifting and pulling, there exists a variety of models tailored to meet specific operational needs. Each variant boasts unique characteristics that enhance performance in different environments and applications.

Understanding the distinctions among these models is essential for selecting the right equipment for your tasks. Here are some prominent types:

- Electric Models: These units are powered by electric motors, offering a cleaner and quieter operation. They are suitable for indoor applications and areas where emissions are a concern.

- Pneumatic Models: Utilizing compressed air, these versions are ideal for environments where electric power is not available. They are commonly used in construction and industrial settings.

- Hydraulic Models: Known for their powerful lifting capabilities, these variants use hydraulic fluid to generate force, making them perfect for heavy-duty tasks.

- Portable Models: Designed for easy transport, these units are lightweight and can be easily moved to various job sites, offering flexibility in operation.

Choosing the right type involves considering factors such as the load capacity, power source, and intended use. Each model’s features cater to specific requirements, ensuring efficient operation in diverse scenarios.

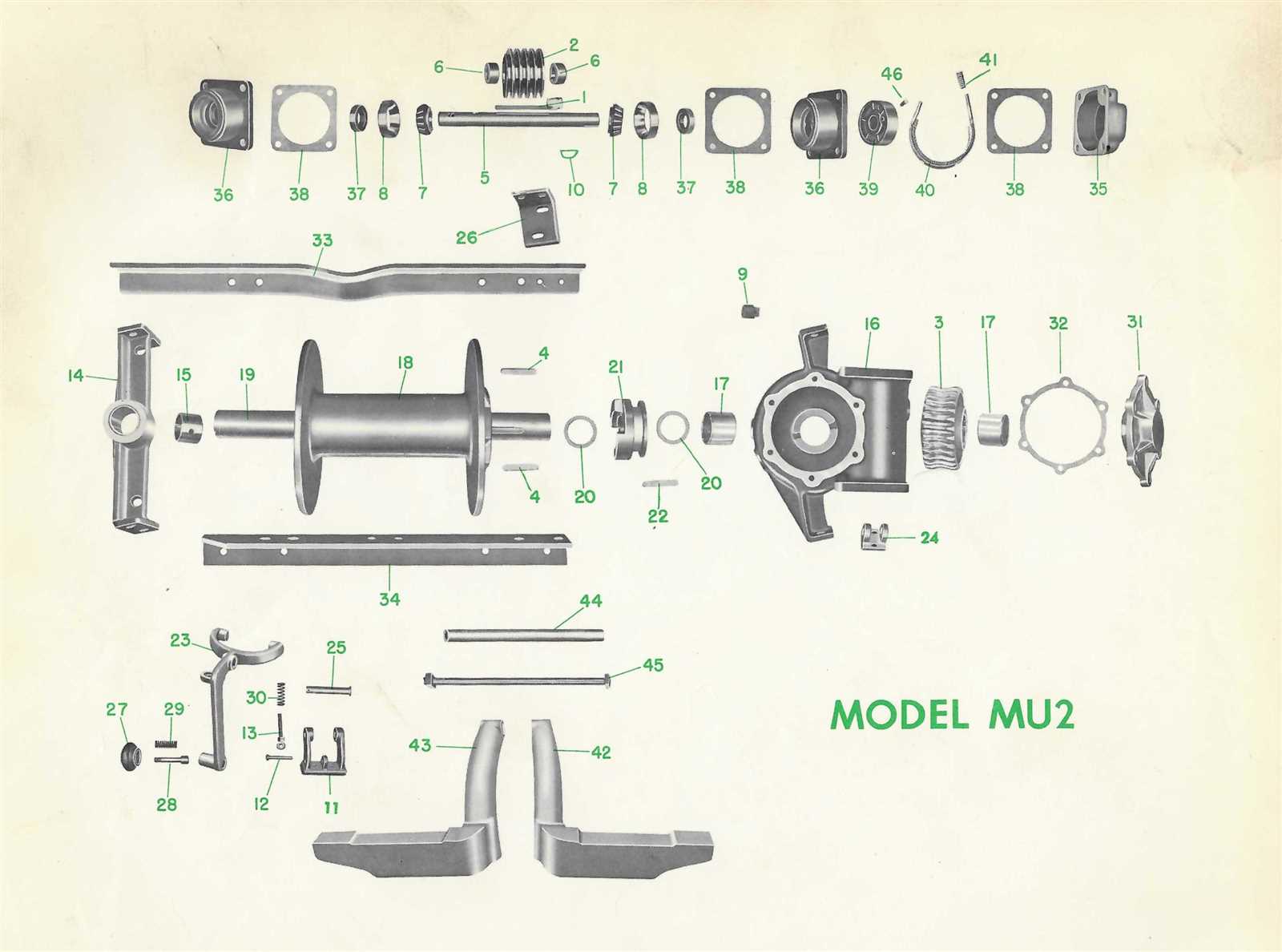

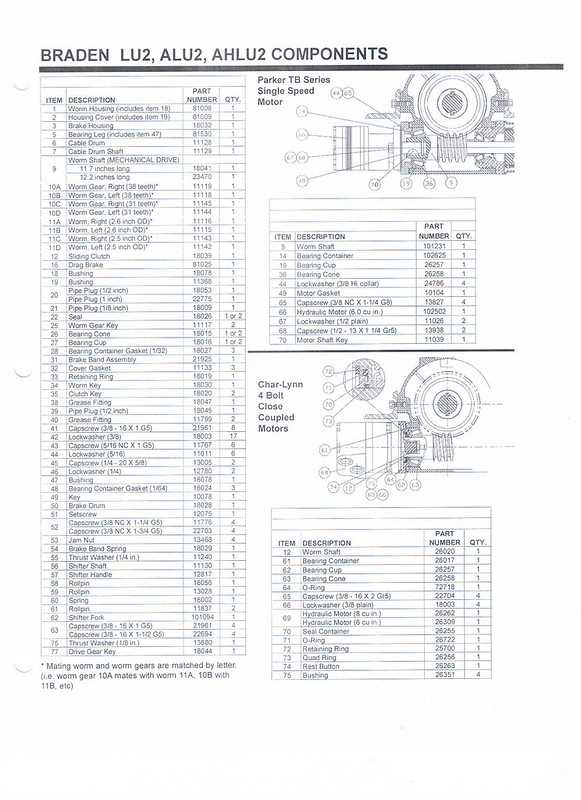

Common Parts in Winch Diagrams

Understanding the essential components of a pulling mechanism is crucial for effective operation and maintenance. Each element plays a vital role in ensuring the overall functionality and efficiency of the system. Familiarity with these individual elements can enhance both troubleshooting efforts and the effectiveness of modifications.

Motor: The driving force behind the operation, this component converts electrical energy into mechanical energy, enabling movement.

Drum: This cylindrical part serves as the central hub for the cable, allowing it to wind and unwind smoothly during operation.

Gearbox: Essential for torque multiplication, this assembly facilitates the conversion of high-speed rotation into the lower-speed, high-torque output required for lifting or pulling tasks.

Control Switch: This interface allows the operator to manage the mechanism’s functions easily, providing control over both the direction and speed of the cable movement.

Mounting Bracket: This structural element secures the entire assembly to a stable surface, ensuring safety and stability during operation.

Cable: The lifeline of the system, this strong and flexible element transmits the pulling force, connecting the load to the mechanism.

Awareness of these common elements enhances one’s ability to operate, maintain, and troubleshoot the equipment effectively, ensuring optimal performance in various applications.

Maintenance Tips for Winch Parts

Regular upkeep is essential for ensuring the longevity and optimal performance of your equipment. By following a few simple guidelines, you can prevent wear and tear, minimize downtime, and enhance reliability. Understanding the basic care requirements will help you maintain functionality and safety during operation.

Routine Inspections

Conducting frequent checks of the essential components is vital. Look for any signs of damage, corrosion, or loose connections. Pay close attention to moving elements, as they are more susceptible to wear. Ensuring that everything is securely fastened will help avoid unexpected failures.

Lubrication and Cleaning

Keeping the mechanical elements well-lubricated reduces friction and prevents premature deterioration. Use appropriate lubricants for different surfaces and follow the manufacturer’s recommendations. Additionally, regularly clean the equipment to remove dirt and debris that could hinder performance and contribute to wear.

Identifying Winch Wear and Tear

Recognizing the signs of deterioration in mechanical equipment is crucial for maintaining optimal performance and longevity. Over time, various components may experience degradation due to constant use and environmental factors. By being vigilant, one can prevent potential failures and ensure smooth operation.

Common Indicators of Damage

Several visible signs can indicate issues with the equipment. Look for cracks or chips on the exterior casing, which may suggest structural weakness. Additionally, unusual noises during operation, such as grinding or squeaking, can signify internal wear. Excessive rust or corrosion can also point to neglect and potential failure of metal components.

Maintenance Practices

Regular inspections and maintenance routines are essential for early detection of problems. Implementing a systematic approach to checking for wear can help identify issues before they escalate. Ensure that lubrication is applied to moving parts, and replace any damaged elements promptly. Taking proactive steps will enhance reliability and extend the service life of the machinery.

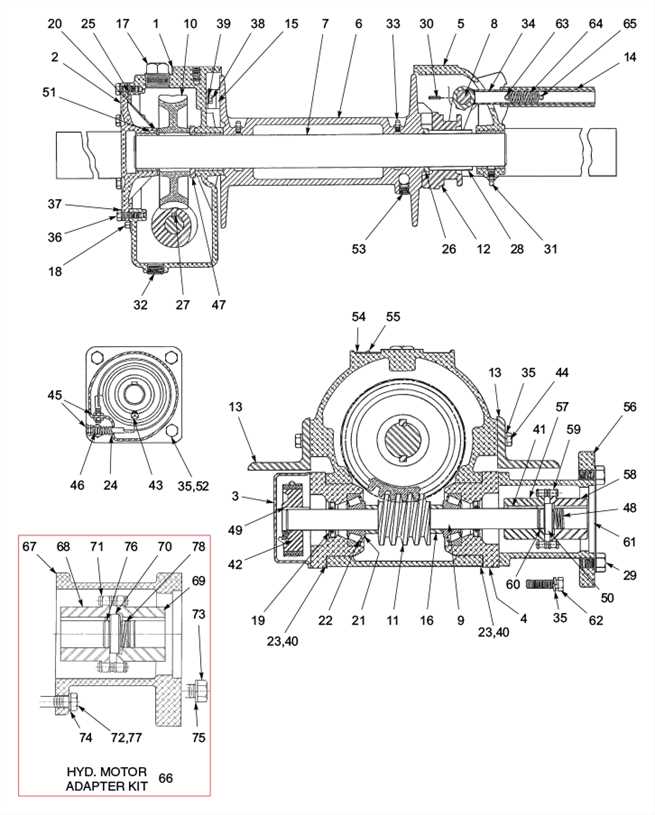

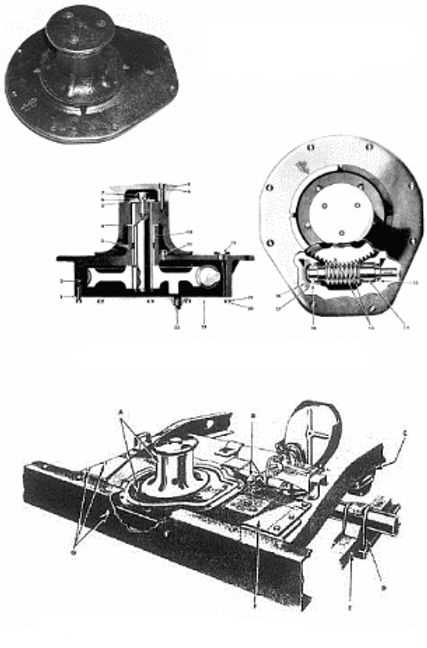

Installing Braden Winch Components

When it comes to setting up essential machinery for effective operations, understanding the installation of various components is crucial. This process involves ensuring that each element functions harmoniously to achieve optimal performance. Whether you are replacing parts or assembling a new unit, following a systematic approach will enhance both efficiency and reliability.

Preparation is key before diving into the assembly. Ensure that all necessary tools and components are at hand. It’s important to consult the specific guidelines that pertain to the model you are working with, as there can be unique requirements for different configurations. Take time to inspect all components for any signs of wear or damage that could affect their functionality.

During installation, attention to detail cannot be overstated. Each element must be positioned accurately to ensure secure connections and proper operation. Begin by fastening the base components securely, followed by attaching the operational mechanisms. Make sure to tighten all fasteners to the recommended torque specifications to prevent any loosening during use.

After completing the assembly, conducting a thorough functionality check is vital. Run the system through its paces, testing each feature to verify that everything operates smoothly. Any irregularities should be addressed immediately to avoid complications in the future. With careful installation and attention to detail, the machinery will provide reliable service for years to come.

Tools Needed for Winch Repair

Maintaining and fixing your lifting device requires specific implements to ensure effective operation. Having the right tools can simplify the process, reduce downtime, and enhance safety during repairs. Below is a comprehensive list of essential instruments that are helpful for the task.

Essential Instruments

- Wrenches: Both standard and metric sizes are vital for loosening and tightening various components.

- Screwdrivers: A set that includes different types (flathead and Phillips) for handling screws and fasteners.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications.

- Pliers: Useful for gripping, twisting, and cutting wires or small parts.

- Socket Set: Offers various sizes to fit different nuts and bolts.

- Multimeter: Essential for checking electrical connections and diagnosing issues.

Safety Equipment

- Safety Glasses: Protects eyes from debris during repairs.

- Gloves: Provides hand protection and improves grip while handling components.

- Steel-Toed Boots: Safeguards feet from heavy objects that may fall during maintenance.

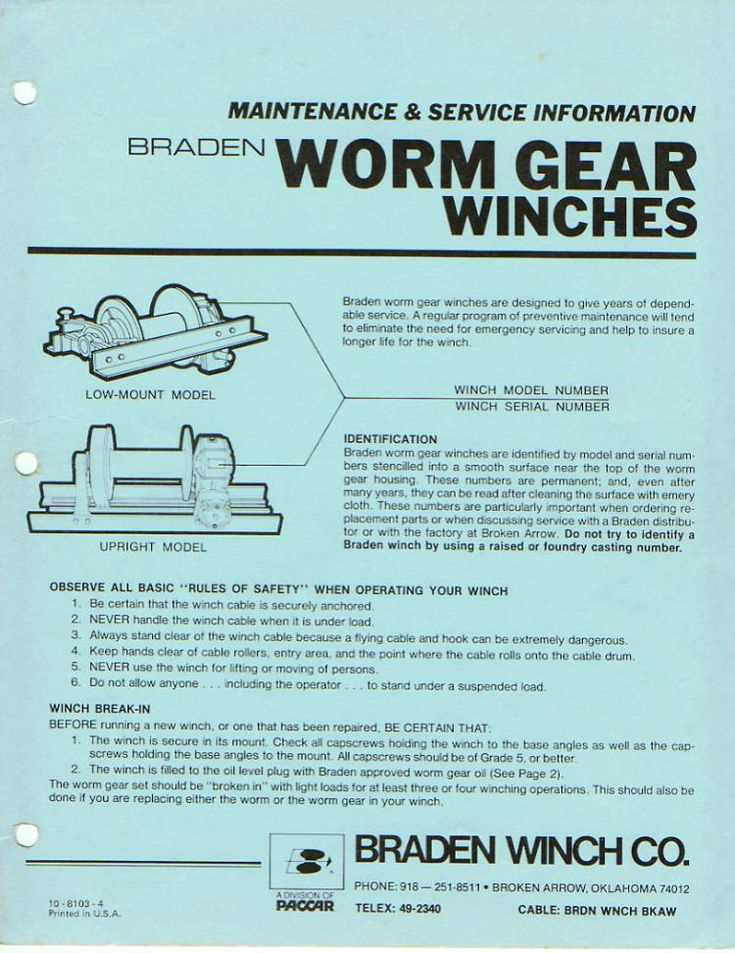

Safety Precautions When Operating Winches

Operating lifting devices requires careful attention to safety. Whether you’re handling small or large loads, ensuring the right procedures are followed can prevent accidents and protect both equipment and individuals involved. Proper preparation and awareness of potential hazards are essential to smooth and secure operation.

Inspect Before Use

Before starting, always examine the equipment thoroughly. Check for any signs of wear, damage, or other issues that could affect performance. Confirm that all controls function as intended and that the mechanism is properly secured to handle the load. Regular inspections are a critical step in avoiding malfunctions during operation.

Stay Alert During Operation

While using lifting equipment, it’s important to remain focused and vigilant. Ensure that all workers keep a safe distance, and that nobody is positioned in a hazardous area. Follow all recommended guidelines and never exceed the recommended weight limits. Staying attentive and following the correct procedures can minimize risks and promote a safe working environment.

Understanding Winch Hydraulic Systems

Hydraulic systems are designed to offer power transmission through fluid movement, providing efficient force multiplication and control. By converting energy into fluid pressure, these systems allow for the lifting and moving of heavy loads with precision and minimal effort. Their versatility and reliability make them essential in a wide range of industrial applications.

At the core of this system, pressurized fluid flows through a network of components, driving motion and transferring power. Control valves manage the fluid’s direction and flow, while cylinders or motors convert hydraulic pressure into mechanical energy. This balance between fluid control and force distribution ensures smooth and effective operation under varying conditions.

| Component | Function |

|---|---|

| Pump | Generates fluid pressure by converting mechanical energy into hydraulic power. |

| Control Valve | Regulates fluid flow and direction to ensure efficient operation. |

| Hydraulic Motor | Converts hydraulic pressure into mechanical movement, providing the necessary torque for lifting tasks. |

| Fluid Reservoir | Stores the hydraulic fluid and supplies it to the system as needed. |

Comparing Braden Winches to Competitors

When choosing the right tool for heavy-duty lifting or pulling tasks, it’s important to compare various brands to see which offers the most reliable and efficient solutions. Different models from multiple manufacturers bring unique strengths and limitations, providing a range of features that cater to specific needs. Evaluating key characteristics like durability, ease of use, and technological advancements can help in making a well-informed decision.

- Durability: Some brands focus on robust construction, ensuring long-lasting performance in harsh conditions. Others may prioritize lightweight designs, sacrificing some sturdiness.

- Ease of Operation: User-friendly mechanisms are a common selling point, but certain brands take simplicity to another level, minimizing the learning curve for new users.

- Technological Features: With advancements in automation, certain products are equipped with innovative control systems, allowing for more precise handling of loads compared to older models.

- Cost Efficiency: While some options might be more expensive, they often justify the price with advanced features or higher reliability. Others may offer budget-friendly solutions without compromising essential functionality.

Ultimately, each brand brings its own set of pros and cons, making it essential to align your selection with the specific requirements of your tasks and environment.

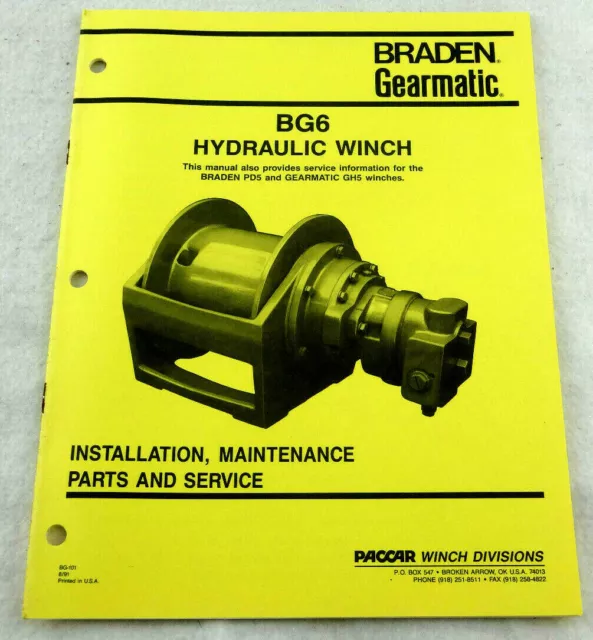

Resources for Braden Winch Support

When dealing with equipment maintenance or repairs, having access to the right resources can make a significant difference. Whether you’re looking for technical manuals, service guides, or troubleshooting tips, finding reliable support materials is essential to ensuring the smooth operation of your machinery. Knowing where to look for accurate and comprehensive information can save both time and effort.

Official Documentation

The best place to begin your search is with official resources. These are often provided by manufacturers and offer detailed insights, including technical specifications, service instructions, and maintenance guidelines. Accessing authorized materials ensures that the information is accurate and up-to-date, reducing the risk of errors during repair or upkeep tasks.

Third-Party Guides

In addition to official sources, third-party websites and forums often provide useful insights. These platforms typically feature contributions from experienced users who have encountered similar issues. While these may not be as detailed as official documents, they can offer practical tips and workarounds that simplify complex tasks.