The intricate mechanisms that enhance agricultural machinery’s efficiency are crucial for modern farming practices. Among these systems, the coupling apparatus plays a vital role in transferring power from the engine to various implements, enabling seamless operation. A thorough understanding of its components can significantly improve maintenance and functionality.

In this exploration, we will delve into the essential elements of this power transmission system, highlighting how each component interacts within the overall assembly. By dissecting the configuration and functionality of these mechanisms, operators can gain valuable insights into optimizing performance and ensuring longevity.

Whether you are a seasoned technician or a curious farmer, comprehending the layout and interconnections of these elements can empower you to make informed decisions regarding repairs and upgrades. Join us as we navigate the complexities of this pivotal agricultural tool, revealing the secrets that drive efficiency on the field.

Understanding PTO Systems in Tractors

Power take-off systems play a crucial role in agricultural machinery, enabling the transfer of mechanical energy from the tractor to various implements. These systems allow for the efficient operation of attachments such as mowers, balers, and sprayers, enhancing productivity in farming operations.

Components of Power Transfer Systems

The primary elements of these energy transfer systems include the drive shaft, clutch mechanism, and connection points. The drive shaft serves as the conduit for power, while the clutch enables operators to engage or disengage the system as needed. Proper maintenance of these components is essential for optimal performance and longevity.

Importance of Understanding Functionality

Comprehending how these energy transfer systems work is vital for farmers and operators. It not only aids in troubleshooting issues but also maximizes the efficiency of machinery. By recognizing the signs of wear and understanding the operational requirements, users can ensure their equipment remains in top condition, reducing downtime and increasing yield.

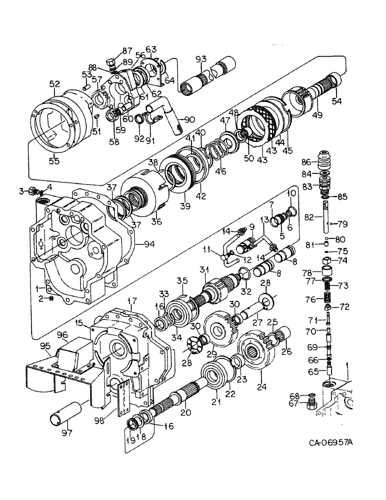

Components of International 1086 PTO

The power take-off system is a crucial element in agricultural machinery, enabling the transfer of power from the engine to various implements. Understanding its key components is essential for effective maintenance and operation. Each element plays a vital role in ensuring smooth functionality and optimal performance during use.

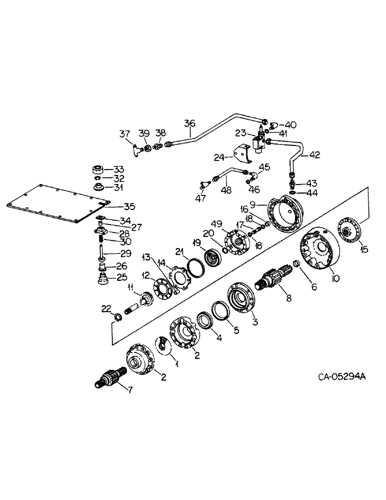

The drive shaft is the main conduit for power transmission, connecting the engine to attached implements. It must be robust enough to handle high torque levels while allowing for flexibility in operation. Couplings serve to connect the drive shaft to different tools, ensuring secure attachment and facilitating quick changes when needed.

Another important component is the gearbox, which regulates the speed and torque delivered to the implements. This mechanism allows operators to adjust performance based on the specific requirements of different tasks. Additionally, bearings are critical for supporting the rotating elements, reducing friction, and ensuring longevity of the system.

Finally, the control mechanisms, including levers and switches, allow the operator to engage and disengage the system easily. Proper understanding and maintenance of these components can significantly enhance the efficiency and lifespan of the equipment.

How PTO Drives Agricultural Equipment

The power transfer mechanism is crucial in modern farming, enabling machinery to operate efficiently and effectively. By connecting various implements to a source of energy, this system facilitates the seamless operation of tools that enhance productivity on the field.

Mechanics of Power Transfer

This system typically consists of a rotating shaft that delivers energy from the primary engine to various implements. As the engine runs, it generates rotational force, which is transmitted to equipment such as mowers, balers, and tillers, allowing them to perform essential agricultural tasks.

Benefits of Using a Power Transfer System

Utilizing this mechanism increases versatility, allowing farmers to switch between different implements quickly. Additionally, it optimizes fuel efficiency and minimizes wear on machinery, leading to enhanced longevity and reduced operational costs.

Maintenance Tips for PTO Parts

Proper upkeep of your equipment is essential for ensuring optimal performance and longevity. Regular maintenance routines can help prevent costly repairs and enhance the efficiency of your machinery. This section outlines key practices that will keep your drive mechanisms functioning smoothly and effectively.

Regular Inspections

Conduct routine checks to identify any wear or damage. Look for signs of fraying, cracks, or unusual noises during operation. Timely detection of issues can prevent further complications and ensure safe usage.

Lubrication and Cleaning

Keep moving components well-lubricated to reduce friction and prevent overheating. Regularly clean the drive system to remove dirt and debris, which can hinder performance. Use appropriate lubricants and cleaning agents to ensure the best results.

Identifying PTO Issues in Tractors

Recognizing problems in the power take-off system is crucial for maintaining efficient tractor performance. Addressing these issues promptly can prevent more significant breakdowns and ensure smooth operation in various agricultural tasks.

Common signs of malfunction include:

- Unusual noises during operation

- Inconsistent power delivery

- Vibrations felt through the machinery

- Visible wear or damage on components

To diagnose these issues effectively, consider the following steps:

- Inspect the connection points for any signs of wear.

- Check fluid levels and quality in the transmission.

- Listen for irregular sounds while engaging the system.

- Test the engagement mechanism for responsiveness.

By delving into these areas, operators can identify and rectify potential failures, ensuring longevity and reliability in their equipment.

Common PTO Parts and Their Functions

This section explores essential components of power transfer systems, highlighting their roles and significance in enhancing machinery performance.

- Drive Shaft: Transmits rotational power from the engine to other machinery.

- Gearbox: Modifies the speed and torque to suit various applications.

- Coupling: Connects the drive shaft to attachments, ensuring secure and efficient operation.

- Clutch: Allows for engagement and disengagement of power transfer, providing control over operation.

- U-joint: Facilitates angular movement between connected shafts, accommodating various positions.

Understanding these components is crucial for effective maintenance and optimal functionality in agricultural and industrial equipment.

Upgrading Your PTO for Efficiency

Enhancing the performance of your machinery can lead to significant improvements in productivity and energy consumption. Focusing on the power take-off system can yield remarkable benefits, ensuring that the equipment operates at its full potential.

Here are key areas to consider when optimizing your system:

- Regular Maintenance: Consistent upkeep can prevent wear and tear, extending the lifespan of components.

- Efficient Components: Upgrading to higher-quality parts can enhance performance and reduce energy waste.

- Proper Calibration: Ensuring that all elements are accurately calibrated can maximize output and minimize inefficiencies.

Additionally, consider the following steps:

- Assess current system performance to identify weaknesses.

- Research compatible upgrades that fit your specific machinery needs.

- Consult with experts to gain insights on the latest advancements.

By prioritizing these strategies, you can significantly boost operational efficiency, leading to better overall performance and cost savings. Embrace the opportunity to refine your setup for optimal results.

Replacement Options for PTO Components

When maintaining agricultural machinery, it is essential to consider various alternatives for key drive components. These elements play a crucial role in ensuring that equipment operates efficiently and effectively. Whether facing wear and tear or performance issues, exploring replacement choices can enhance functionality and prolong the lifespan of your machinery.

Aftermarket solutions often provide a cost-effective way to replace essential components, allowing for compatibility with a range of machines. Additionally, opting for original manufacturer parts ensures that you receive high-quality replacements tailored specifically to your equipment. Assessing both new and refurbished options can lead to informed decisions that align with your operational needs.

Another aspect to consider is the availability of custom solutions that cater to unique requirements. Collaborating with suppliers who specialize in customized components can yield parts designed to enhance performance under specific conditions. Ultimately, exploring these avenues will help you maintain peak efficiency and reliability in your machinery.

PTO Safety Precautions for Operators

Ensuring safety during operation is crucial for preventing accidents and injuries in machinery usage. Operators must be vigilant and adhere to established safety guidelines to create a secure working environment.

- Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and sturdy footwear.

- Keep the work area clear of obstacles and debris to prevent tripping hazards.

- Be aware of moving parts and maintain a safe distance when machinery is in operation.

- Ensure that all safety guards are in place and functioning before starting the equipment.

Operators should also:

- Read the equipment’s manual thoroughly to understand operational limits and safety features.

- Conduct regular maintenance checks to identify potential issues before they escalate.

- Communicate effectively with team members regarding safety procedures and any observed hazards.

By prioritizing these precautions, operators can significantly reduce risks and enhance safety on the job site.

Diagram Overview of International 1086 PTO

This section provides an essential guide to understanding the configuration and components involved in the power take-off system of a well-known agricultural machine. By examining the layout and connections, users can gain insights into how each element functions together to optimize performance and efficiency in field operations.

Component Breakdown

The system comprises various elements that work in harmony. Key components include the drive shaft, engagement mechanisms, and supporting structures. Each part plays a pivotal role in transmitting power effectively from the engine to attached implements, ensuring smooth operation during tasks.

Functionality Insights

Understanding the mechanics involved is crucial for troubleshooting and maintenance. By delving into the specifics of the assembly, operators can identify potential issues and make informed decisions about repairs and upgrades. This knowledge ultimately enhances productivity and extends the lifespan of the machine.

Expert Insights on PTO Performance

Understanding the intricate workings of power transfer systems is essential for optimizing machinery functionality. These systems play a crucial role in delivering energy from the engine to various attachments, ensuring efficiency and effectiveness in agricultural tasks.

Performance is influenced by several factors, including the design and maintenance of the components involved. Regular inspections and timely replacements can significantly enhance operational reliability. Moreover, expert evaluations often reveal the importance of aligning mechanical elements to prevent undue stress and wear.

In-depth knowledge of system specifications allows operators to maximize output and achieve their ultimate productivity goals. Technicians with experience in these systems emphasize the value of understanding load capacities and compatibility with different implements.