In the realm of farming equipment, a thorough comprehension of individual elements is crucial for optimal performance and maintenance. These machines are intricate systems that rely on various interconnected pieces, each playing a vital role in ensuring efficiency in agricultural tasks. By gaining insights into these components, operators can enhance productivity and extend the lifespan of their equipment.

Recognizing the Layout of these crucial parts facilitates easier troubleshooting and repairs. An organized representation not only aids in identifying specific components but also assists in understanding how they interact with one another. This knowledge empowers users to make informed decisions when it comes to repairs and upgrades.

Moreover, mastering the intricacies of these mechanisms can lead to significant cost savings and improved operational efficiency. With a clear visual guide, farmers and technicians can delve into the maintenance processes with confidence, ultimately leading to enhanced agricultural output.

Understanding the International 1486 Parts Diagram

Comprehending the layout of machinery components is essential for effective maintenance and troubleshooting. This knowledge empowers users to identify and locate essential elements swiftly, ensuring optimal performance and longevity of equipment. Mastery of such illustrations can significantly enhance operational efficiency.

Importance of Component Identification

Recognizing individual elements within the schematic is crucial for repairs and upgrades. Each part plays a vital role, and understanding their interconnections can lead to more informed decision-making when addressing issues.

How to Utilize the Illustration Effectively

To make the most of the visual representation, start by familiarizing yourself with the key labels and symbols used. Pay attention to the organization of components, and delve into the details to uncover how each part functions within the system. This approach will ultimately enhance your understanding and capability to manage machinery effectively.

Overview of the International 1486 Tractor

This section provides a comprehensive look at a renowned agricultural machine that has made significant contributions to farming practices. Known for its reliability and performance, this vehicle stands out in the realm of heavy-duty farming equipment.

Key features of this model include:

- Robust engine capable of handling various field tasks.

- Advanced hydraulic system designed for efficient implement operation.

- Spacious cabin offering comfort for long working hours.

- Durable construction that withstands harsh agricultural conditions.

The machine has been widely used in diverse farming environments, showcasing its adaptability and effectiveness. Farmers appreciate its balance of power and maneuverability, making it suitable for both small and large-scale operations.

In addition, the vehicle’s design incorporates:

- Ergonomic controls for ease of use.

- Versatile attachments that enhance productivity.

- Efficient fuel consumption, promoting cost savings.

Overall, this agricultural powerhouse remains a favorite among operators, cementing its legacy in the industry.

Key Components Illustrated in Diagrams

This section focuses on the crucial elements represented visually to enhance understanding of machinery and its functionalities. Through detailed illustrations, users can grasp the relationships and roles of various components, facilitating better maintenance and operation.

| Component | Description |

|---|---|

| Engine | The powerhouse that drives the entire system. |

| Transmission | Responsible for transferring power from the engine to the wheels. |

| Chassis | The structural framework that supports all components. |

| Hydraulic System | Enables various functions through fluid power. |

| Electrical System | Controls the ignition, lighting, and other electronic features. |

Importance of Accurate Parts Identification

Proper identification of components is crucial for ensuring efficient operation and maintenance of machinery. Accurate recognition prevents errors in repairs and replacements, ultimately enhancing the performance and longevity of equipment.

Benefits of Precise Component Recognition

- Reduces downtime by facilitating quicker repairs.

- Minimizes costs associated with incorrect replacements.

- Enhances safety by ensuring correct installation and usage.

- Improves efficiency in inventory management.

Consequences of Misidentification

- Increased risk of equipment failure.

- Potential safety hazards for operators.

- Financial losses due to wasted resources.

- Damage to reputation from service delays.

Common Issues and Repair Solutions

When working with heavy machinery, operators often encounter various challenges that can impact performance and efficiency. Understanding these common problems and their solutions is essential for maintaining optimal functionality and prolonging the lifespan of the equipment.

Hydraulic System Failures

A frequent concern in these machines is the malfunction of the hydraulic system. Symptoms may include slow or unresponsive movement, fluid leaks, or unusual noises. To address these issues, start by checking the hydraulic fluid levels and inspecting for any leaks in hoses and connections. If low levels are detected, refill with the recommended fluid. For persistent leaks, replacing damaged seals or hoses is advisable. Regular maintenance, including flushing the system and replacing filters, can prevent future complications.

Engine Performance Problems

Engine-related issues can manifest as difficulty starting, irregular idling, or reduced power output. Common culprits include dirty air filters, clogged fuel injectors, or worn spark plugs. To resolve these problems, first inspect and clean or replace the air filter. Then, check the fuel system for clogs and consider using a fuel injector cleaner. If the problem persists, examining the ignition system may reveal worn components that require replacement. Regular servicing and timely part replacement can greatly enhance engine reliability.

Maintenance Tips for Long-lasting Performance

Ensuring optimal functionality and extending the lifespan of machinery requires consistent care and attention. Regular maintenance practices not only enhance efficiency but also prevent unexpected breakdowns, leading to a more reliable experience.

Regular Inspections

Conducting routine assessments is essential. Check for any signs of wear, leakage, or misalignment. Addressing minor issues promptly can avert major repairs in the future.

Proper Lubrication

Utilizing appropriate lubricants at designated intervals is crucial. This reduces friction and minimizes wear on moving components, ultimately contributing to smoother operation and longevity.

Where to Find Replacement Parts

When it comes to sourcing components for machinery, understanding where to locate high-quality alternatives is crucial. Numerous resources exist to assist enthusiasts and professionals in acquiring the necessary items to keep equipment running smoothly.

Online Retailers

Many individuals turn to online marketplaces, which offer a vast array of options. Websites dedicated to machinery often feature detailed catalogs, allowing you to search based on specifications. Customer reviews can help guide your choices, ensuring you select reliable products.

Local Dealers and Salvage Yards

Exploring local dealerships and salvage yards can also yield valuable finds. Personal interactions with sellers may lead to exclusive offers or insights on the best components for your needs. Additionally, these venues often provide support in identifying the right pieces for your equipment.

Comparison with Other International Models

This section delves into the distinctions and similarities between various machinery models produced by the same manufacturer. By examining these machines, we can gain insights into their unique features and performance characteristics, which highlight the evolution of design and functionality across the lineup.

Many models share a foundational architecture, yet they differ significantly in terms of engine capacity, operational efficiency, and technology integration. For instance, while some variants may prioritize power output, others focus on fuel efficiency or ease of maintenance. Such differences can be crucial for users depending on their specific agricultural or industrial needs.

Technical specifications are often a focal point in these comparisons. Features such as transmission types, hydraulic systems, and control interfaces can vary, impacting user experience and operational capabilities. Understanding these variations helps potential buyers make informed decisions based on their requirements and preferences.

Furthermore, user feedback and historical performance data can shed light on the reliability and longevity of different models. Some machines might excel in tough conditions, while others are optimized for precision tasks. These factors contribute to a broader understanding of how each model stands in the competitive landscape.

Visual Representation of Engine Layout

Understanding the arrangement and interaction of components within an engine is crucial for effective maintenance and performance optimization. A clear illustration of this layout can enhance comprehension, enabling mechanics and enthusiasts alike to visualize the intricacies of the system.

Component Arrangement

The positioning of each element, from the cylinder block to the intake manifold, plays a significant role in the overall functionality. An organized layout not only aids in troubleshooting but also highlights the flow of air and fuel throughout the system.

Benefits of Visualization

Utilizing graphical representations fosters deeper insights into mechanical relationships. By delving into these visual aids, one can better appreciate how modifications might affect performance, leading to informed decisions in upgrades or repairs. The ultimate goal is to enhance both efficiency and reliability through a comprehensive understanding of the engine’s architecture.

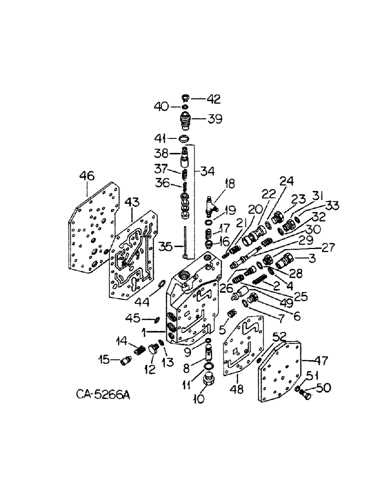

Hydraulic System Explained in Diagrams

Understanding the mechanisms that drive hydraulic systems is crucial for effective operation and maintenance. Visual representations provide clarity on how different components interact and function together. By exploring these illustrations, one can gain insights into the flow of fluid, the role of various elements, and the overall efficiency of the system.

Key Components of Hydraulic Systems

Hydraulic systems are composed of several integral parts, each contributing to the system’s performance. Key elements include pumps, cylinders, valves, and reservoirs. The pump initiates the movement of fluid, while cylinders convert hydraulic energy into mechanical force. Valves regulate the flow and pressure, ensuring the system operates smoothly. Understanding the function of each component is essential for troubleshooting and optimizing performance.

Fluid Dynamics in Action

The flow of hydraulic fluid plays a pivotal role in system functionality. Diagrams illustrate how fluid moves through various pathways, demonstrating principles such as pressure transmission and flow rates. By analyzing these visual aids, operators can identify potential bottlenecks or inefficiencies, leading to improved maintenance strategies and enhanced operational reliability.

Electrical Wiring and Components Overview

Understanding the electrical systems within machinery is crucial for maintaining optimal performance and ensuring safety. This section will delve into the various elements that make up the wiring infrastructure, highlighting their functions and interconnections. A comprehensive grasp of these components enables effective troubleshooting and enhances the efficiency of operations.

The electrical setup includes various parts such as switches, connectors, and control units, each playing a pivotal role in the overall functionality. Knowledge of these components allows for better maintenance practices and a deeper appreciation of the system’s complexity.

| Component | Function |

|---|---|

| Switch | Controls the flow of electricity by opening or closing the circuit. |

| Connector | Facilitates the joining of different wiring sections, ensuring a secure electrical connection. |

| Control Unit | Manages and regulates electrical signals to various parts of the system. |

| Relay | Acts as a switch that opens and closes circuits using an electromagnet. |

| Fuse | Protects the circuit by breaking the connection in case of excessive current flow. |

By familiarizing oneself with these essential components, operators can better understand the electrical architecture, leading to enhanced troubleshooting capabilities and improved overall system reliability.

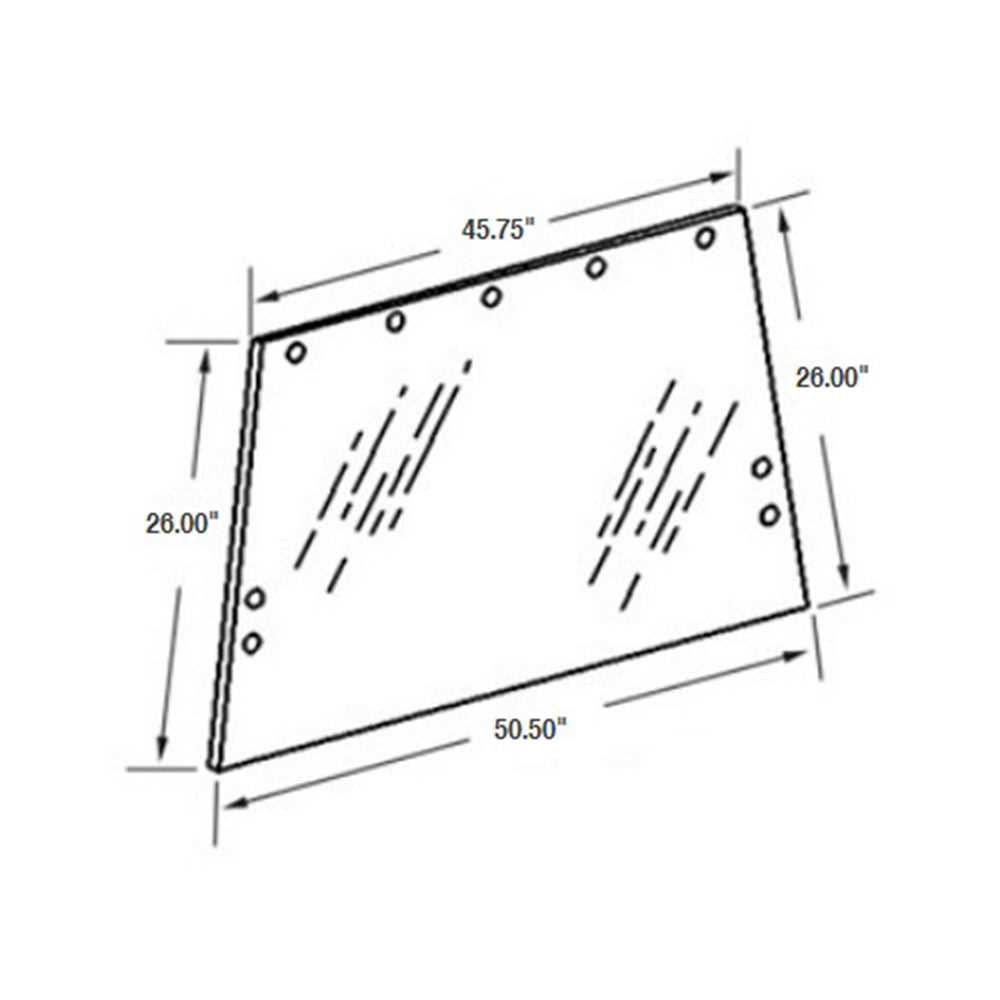

Understanding the Diagram Legend and Symbols

Comprehending the key to any technical illustration is essential for effective interpretation and application. A well-structured legend serves as a roadmap, guiding users through the various elements and their meanings. Familiarity with these symbols enhances the ability to troubleshoot, repair, or optimize machinery efficiently.

Key Components of the Legend

- Symbols: Graphical representations that indicate specific functions or parts.

- Color Codes: Distinct hues that categorize elements or denote certain conditions.

- Numbers: Unique identifiers that correlate to descriptions or lists for clarity.

Commonly Used Symbols

- Circles: Often signify connections or junction points.

- Arrows: Indicate movement or direction of fluid flow.

- Boxes: Represent components or housing that contain mechanisms.

By understanding these aspects, one can navigate the illustration with confidence, ensuring accurate assessments and actions. Mastery of the legend is the foundation of effective mechanical comprehension.