The efficient operation of any marine engine relies on a well-organized assembly of crucial elements. A thorough examination of these components not only enhances performance but also extends the lifespan of the unit. By gaining insight into the arrangement and functionality of each part, users can better appreciate the engineering behind their vessels.

In this section, we will explore the intricate layout that defines the various elements of a 50 HP marine engine. Highlighting each critical section will enable boat owners and enthusiasts to understand how these components interact and contribute to the overall efficiency of their vessels. Knowledge of this layout can be invaluable for maintenance and troubleshooting, ensuring that every outing on the water is smooth and trouble-free.

Moreover, understanding the relationship between these components empowers users to make informed decisions regarding upgrades and replacements. Whether embarking on a new project or seeking to improve an existing setup, familiarity with the organization of the engine’s elements is essential for success. This exploration will serve as a comprehensive guide to mastering the essentials of a 50 HP engine, paving the way for better performance and reliability.

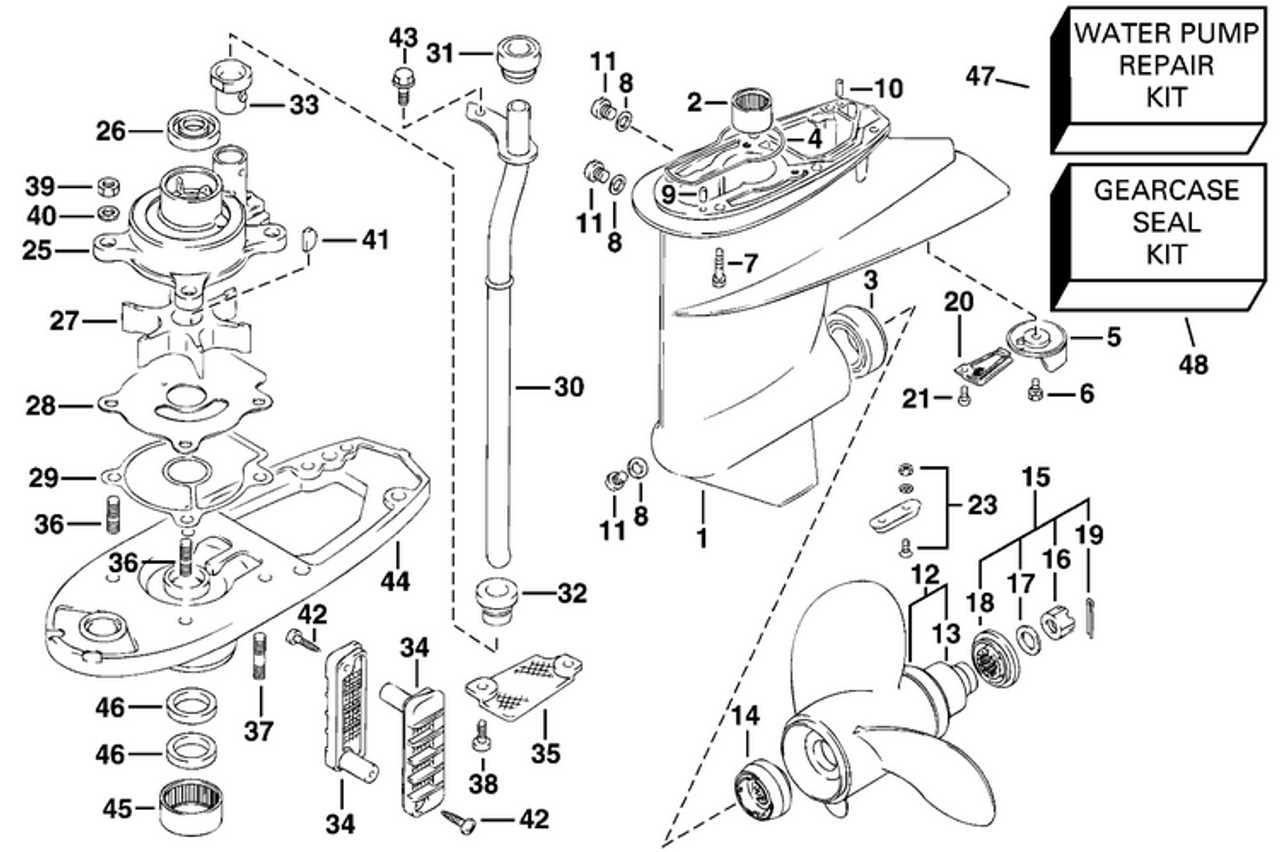

The functioning of marine propulsion systems relies on a variety of critical elements that work in harmony to deliver power and efficiency. Understanding these components is essential for maintenance, troubleshooting, and enhancing performance.

- Powerhead: This is the engine’s core, housing the combustion chamber and essential mechanisms that generate power.

- Gearcase: Responsible for transferring power from the engine to the propeller, it includes gears and lubrication systems to ensure smooth operation.

- Propeller: The blade assembly that converts rotational energy into thrust, enabling the vessel to move through water.

- Fuel System: Comprising the tank, lines, and pump, this system ensures the engine receives the correct fuel mixture for efficient combustion.

- Cooling System: A critical component that prevents overheating by circulating water around the engine to dissipate heat.

- Ignition System: This system generates the spark necessary for combustion, typically involving coils, plugs, and timing controls.

- Steering Mechanism: Allows for the navigation and control of the vessel, integrating with the engine’s throttle and gear controls.

Each of these components plays a vital role in the overall performance and reliability of marine propulsion systems. Regular maintenance and understanding their functions can lead to a more enjoyable and safe boating experience.

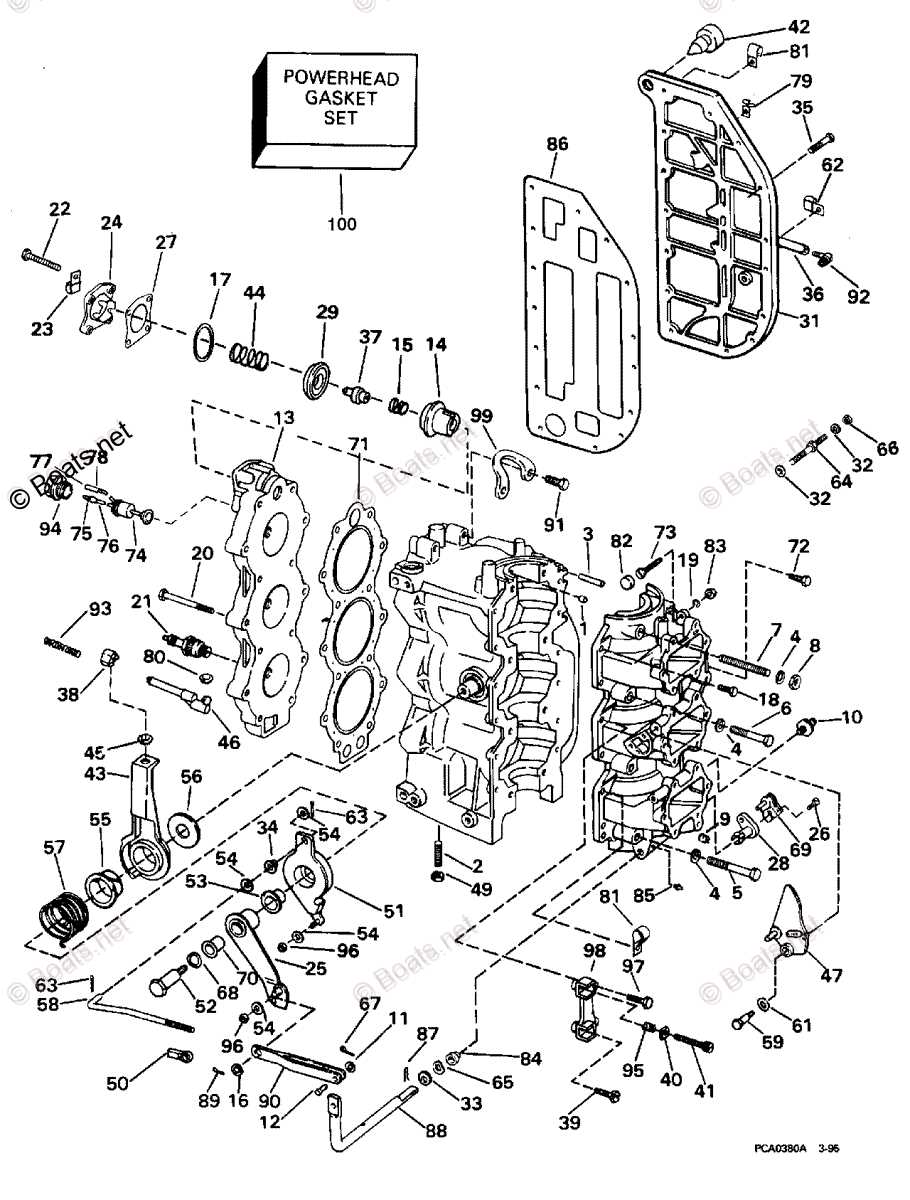

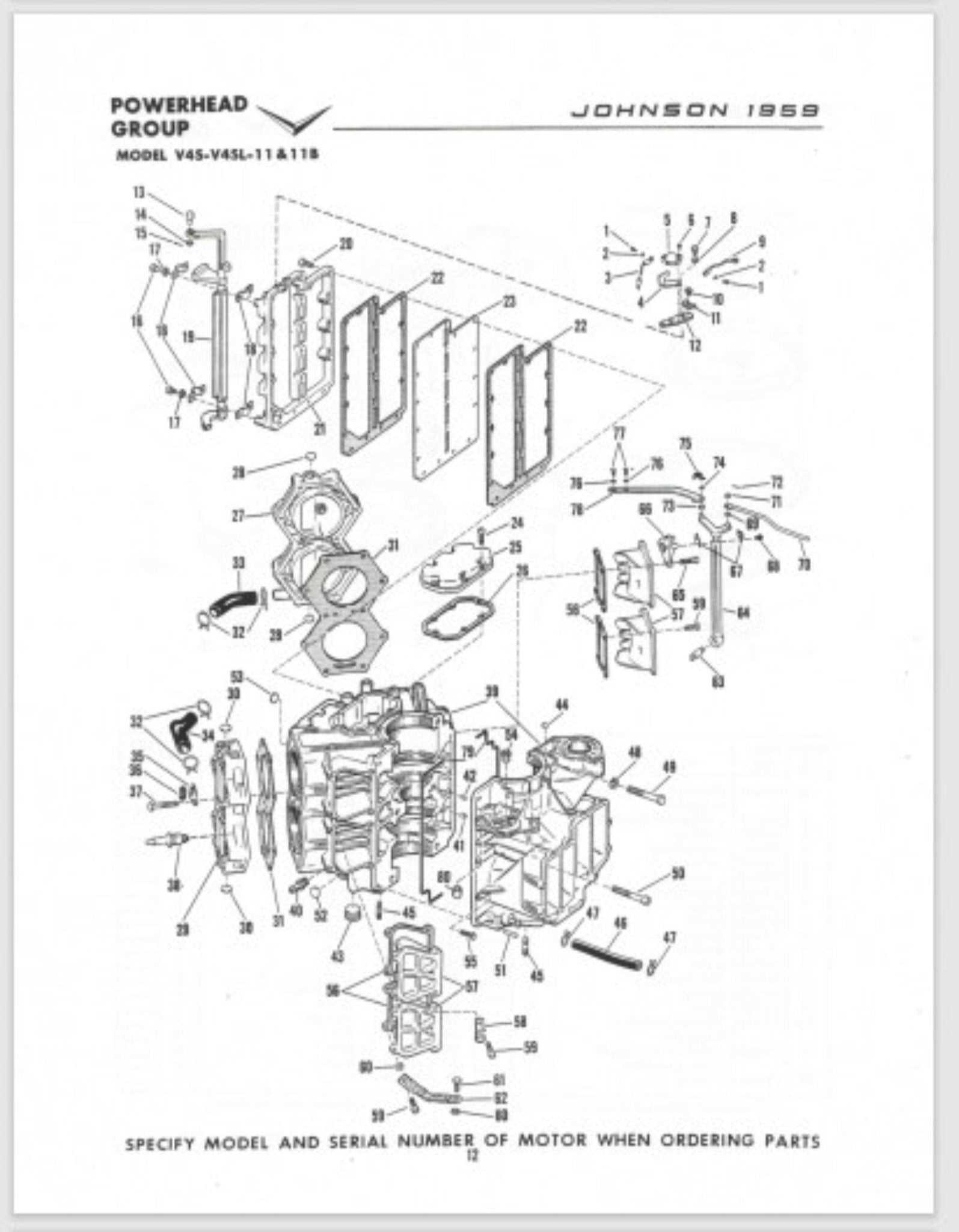

Understanding the Powerhead Assembly

The powerhead assembly serves as the heart of a marine propulsion system, playing a crucial role in converting fuel into mechanical energy. This intricate unit houses various components that work in harmony to ensure optimal performance and efficiency. Gaining insight into its structure and function can significantly enhance one’s understanding of the entire system.

Key Components of the Powerhead

This assembly consists of several vital elements, each contributing to the overall operation. Familiarity with these components can aid in troubleshooting and maintenance.

| Component | Description |

|---|---|

| Cylinder Block | Houses the cylinders and facilitates the combustion process. |

| Pistons | Move within the cylinders to convert pressure from combustion into mechanical energy. |

| Cylinder Head | Seals the combustion chamber and contains the intake and exhaust valves. |

| Crankshaft | Transforms the linear motion of the pistons into rotational motion. |

| Fuel Delivery System | Ensures the correct mixture of fuel and air enters the combustion chamber. |

Importance of Maintenance

Regular maintenance of the powerhead assembly is essential for reliable operation and longevity. Neglecting any of its components can lead to performance issues, making it vital for users to understand how to care for and address potential problems effectively.

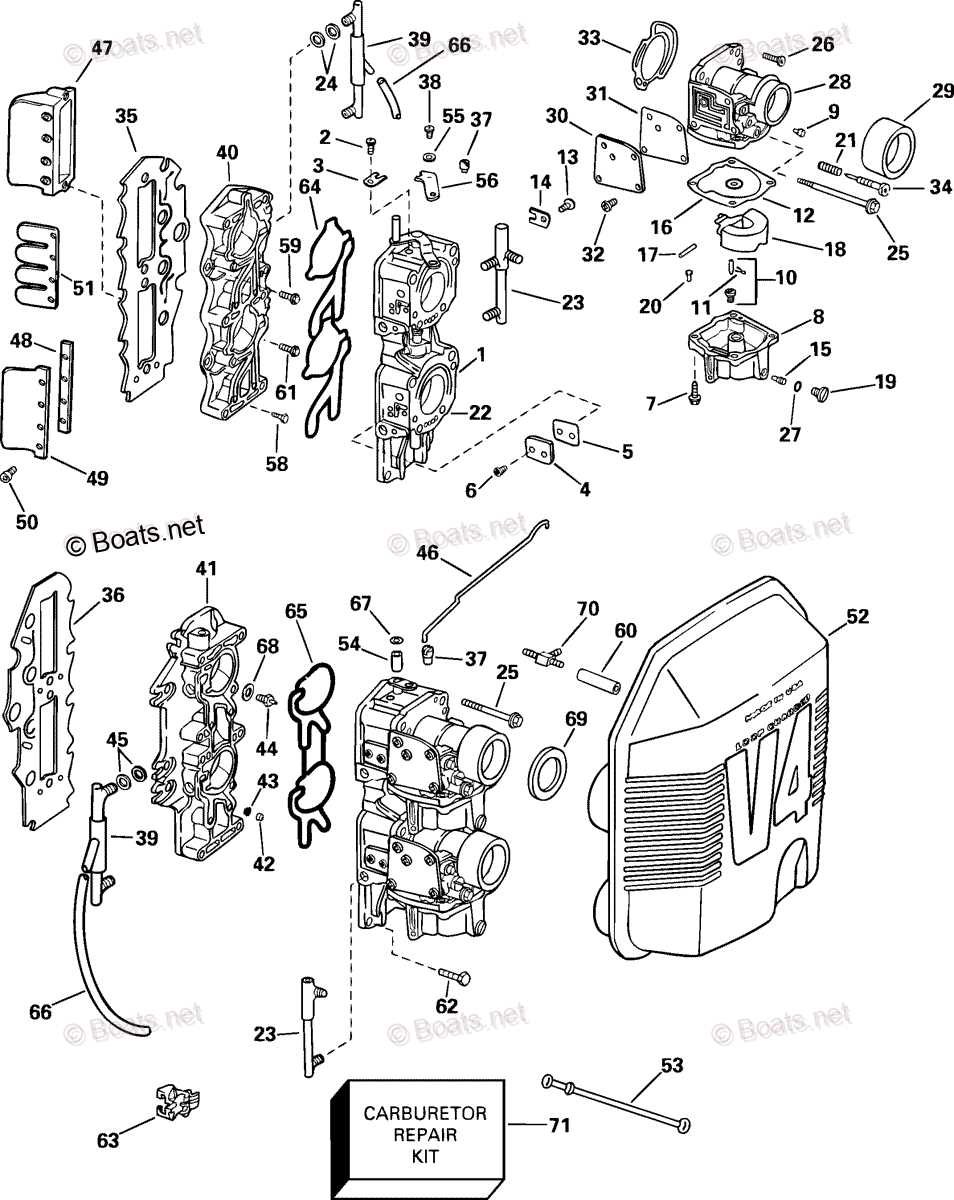

Fuel System and Components

The fuel delivery mechanism plays a crucial role in the performance and efficiency of marine propulsion systems. Understanding the various elements involved in this system can help ensure optimal operation and longevity. This section delves into the key components that comprise the fuel system, detailing their functions and significance.

Key Components

Essential elements of the fuel delivery system include the fuel tank, pump, filters, and carburetor or fuel injection system. Each part works harmoniously to ensure that the engine receives the correct amount of fuel for efficient combustion.

| Component | Description |

|---|---|

| Fuel Tank | Holds the fuel necessary for operation and can vary in size based on the application. |

| Fuel Pump | Moves fuel from the tank to the engine, ensuring adequate pressure and flow. |

| Fuel Filter | Removes impurities from the fuel to protect the engine and other components. |

| Carburetor / Fuel Injector | Mixes fuel with air for combustion; can be of different types based on design. |

Maintenance Tips

Regular maintenance of the fuel system is vital for preventing issues such as clogging and inefficiencies. It is recommended to inspect and replace filters periodically, check for leaks, and ensure the fuel is clean and free from contaminants.

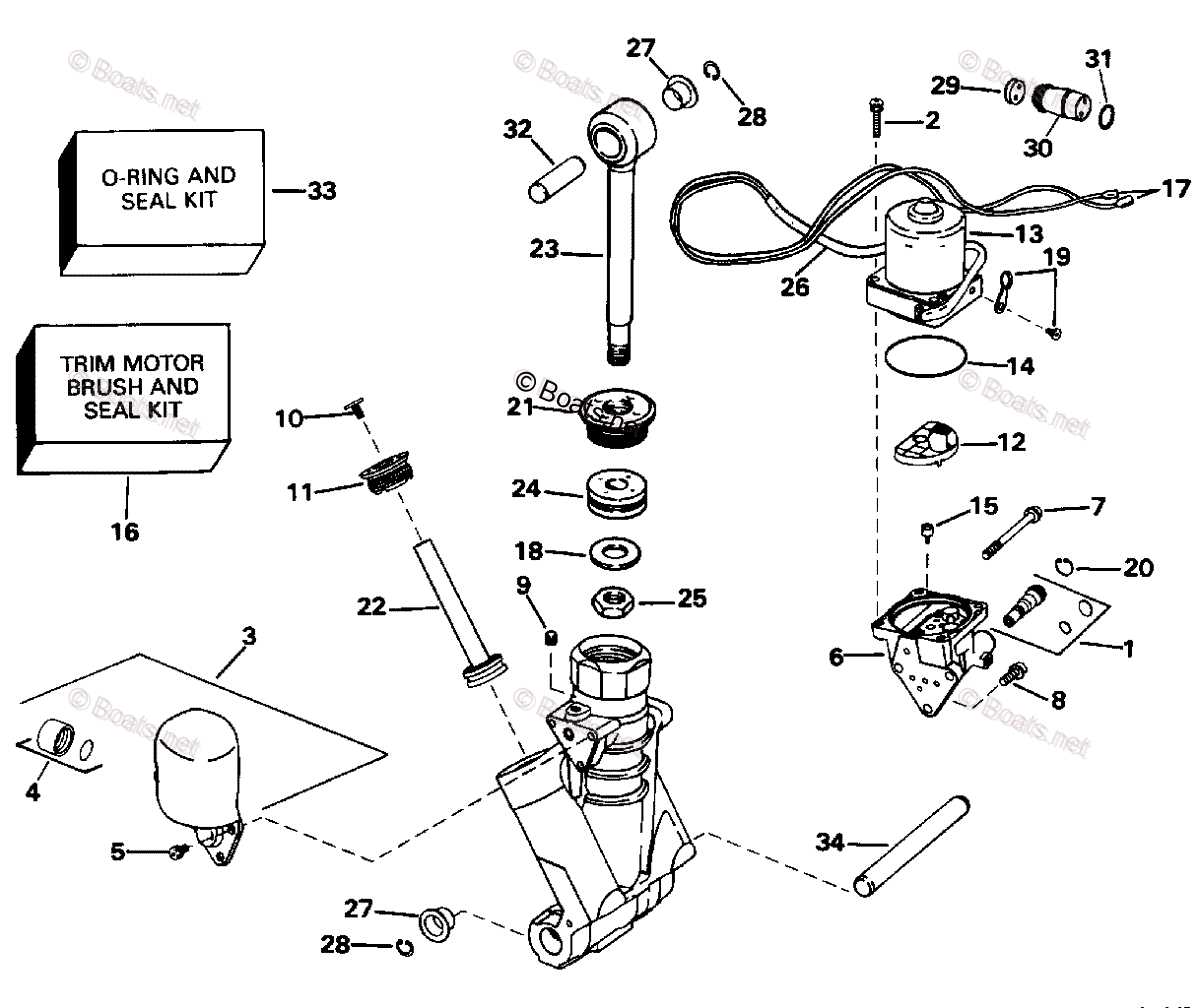

Electrical Wiring and Connections

Understanding the intricacies of electrical systems is essential for maintaining optimal performance in marine engines. Proper wiring and connections ensure that all components function harmoniously, providing reliable operation and safety. This section delves into the various aspects of electrical circuitry, emphasizing the significance of clear and secure connections.

Each element within the system has a specific role, from power distribution to signal transmission. Using high-quality materials and adhering to recommended practices is vital for minimizing the risk of failures. Regular inspections and maintenance can help identify potential issues before they escalate, ensuring longevity and efficiency.

Familiarity with the layout and functionality of the wiring harnesses, connectors, and terminals will aid in troubleshooting and repairs. Additionally, understanding the color-coding and marking conventions used in marine wiring can facilitate easier identification and organization of connections. A well-structured electrical system contributes significantly to the overall reliability and performance of the vessel.

Cooling System Elements Explained

The efficient operation of marine engines relies heavily on a well-designed cooling mechanism. This system plays a crucial role in maintaining optimal temperature levels, preventing overheating, and ensuring longevity. Various components work in harmony to regulate the engine’s heat, each serving a specific function that contributes to the overall effectiveness of the cooling process.

Water Pump: This essential part draws in water from the surrounding environment. It is responsible for circulating the coolant through the engine and expelling it back out, ensuring a continuous flow that helps dissipate heat.

Thermostat: Acting as a regulator, the thermostat controls the flow of coolant based on the engine’s temperature. It ensures that the engine reaches the ideal operating temperature efficiently, allowing it to function at peak performance.

Cooling Jacket: This component envelops the engine block and serves as a conduit for the coolant. As the fluid flows through the jacket, it absorbs heat from the engine, thereby preventing excessive temperatures and maintaining a stable environment for operation.

Heat Exchanger: This element plays a vital role in transferring heat from the engine to the coolant. It ensures that the coolant absorbs the necessary heat while keeping the engine’s temperature within safe limits.

Hoses: These flexible conduits connect various components of the cooling system. They transport coolant throughout the engine, facilitating the movement of heat away from critical areas.

Understanding these key components provides insight into how marine engines maintain their performance and reliability. Proper maintenance of each part is essential to ensure the overall efficiency of the cooling system, thereby extending the lifespan of the engine.

Maintenance and Common Issues

Proper upkeep of marine engines is crucial for ensuring optimal performance and longevity. Regular maintenance not only enhances functionality but also minimizes the risk of frequent breakdowns. Understanding common challenges can help owners proactively address issues before they escalate.

-

Routine Maintenance:

- Regularly check and change the oil to ensure smooth operation.

- Inspect and replace fuel filters to prevent clogs and engine strain.

- Examine the cooling system for blockages or leaks to avoid overheating.

- Clean or replace spark plugs as necessary for reliable ignition.

-

Common Issues:

- Starting difficulties, often caused by battery issues or fuel supply problems.

- Overheating, which can result from inadequate coolant circulation or a faulty thermostat.

- Excessive vibrations, typically indicating imbalances or misalignments in the propeller.

- Unusual noises, which may signal mechanical wear or the need for lubrication.

By adhering to a consistent maintenance schedule and being aware of potential problems, users can significantly enhance the reliability and efficiency of their marine engines.

Identifying Replacement Parts Easily

When it comes to maintaining your marine equipment, recognizing the necessary components for repair or replacement is crucial for optimal performance. Knowing how to identify these essential elements can save time and ensure that your vessel operates smoothly. This section provides insights on how to effectively pinpoint the required items without confusion.

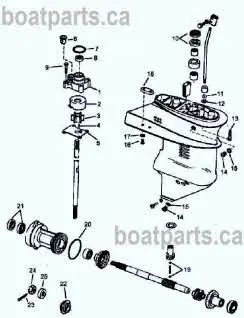

Utilizing Visual References

One of the most effective methods for recognizing essential components is through the use of visual aids. Diagrams or images can serve as valuable tools, allowing you to match the physical items to their respective illustrations. This approach helps eliminate guesswork, making the identification process more straightforward.

Common Components Overview

Familiarizing yourself with the most commonly used elements can significantly ease the identification process. Below is a table showcasing various components typically found in marine equipment:

| Component Name | Description | Function |

|---|---|---|

| Propeller | A rotating blade that propels the vessel | Movement and steering |

| Fuel Filter | A device that removes impurities from fuel | Protects the engine |

| Ignition Coil | A transformer that generates high voltage | Starts the engine |

| Water Pump | A component that circulates water | Cooling the engine |

Tools Required for Repairs

Proper maintenance and troubleshooting of marine propulsion systems necessitate a selection of essential instruments. Familiarity with these tools will facilitate efficient repairs and enhance the longevity of your vessel’s engine.

Essential Hand Tools

Having a variety of hand tools on hand is crucial for any repair task. Commonly used items include wrenches, screwdrivers, and pliers. These tools will help in loosening or tightening various components, ensuring that everything is secured properly. Additionally, a socket set is invaluable for accessing hard-to-reach fasteners.

Specialized Equipment

In some instances, specialized equipment may be required to address specific issues. A compression gauge is useful for assessing the engine’s health, while a multimeter aids in diagnosing electrical problems. Furthermore, a propeller puller can simplify the removal of stubborn components, allowing for easier inspection and maintenance.

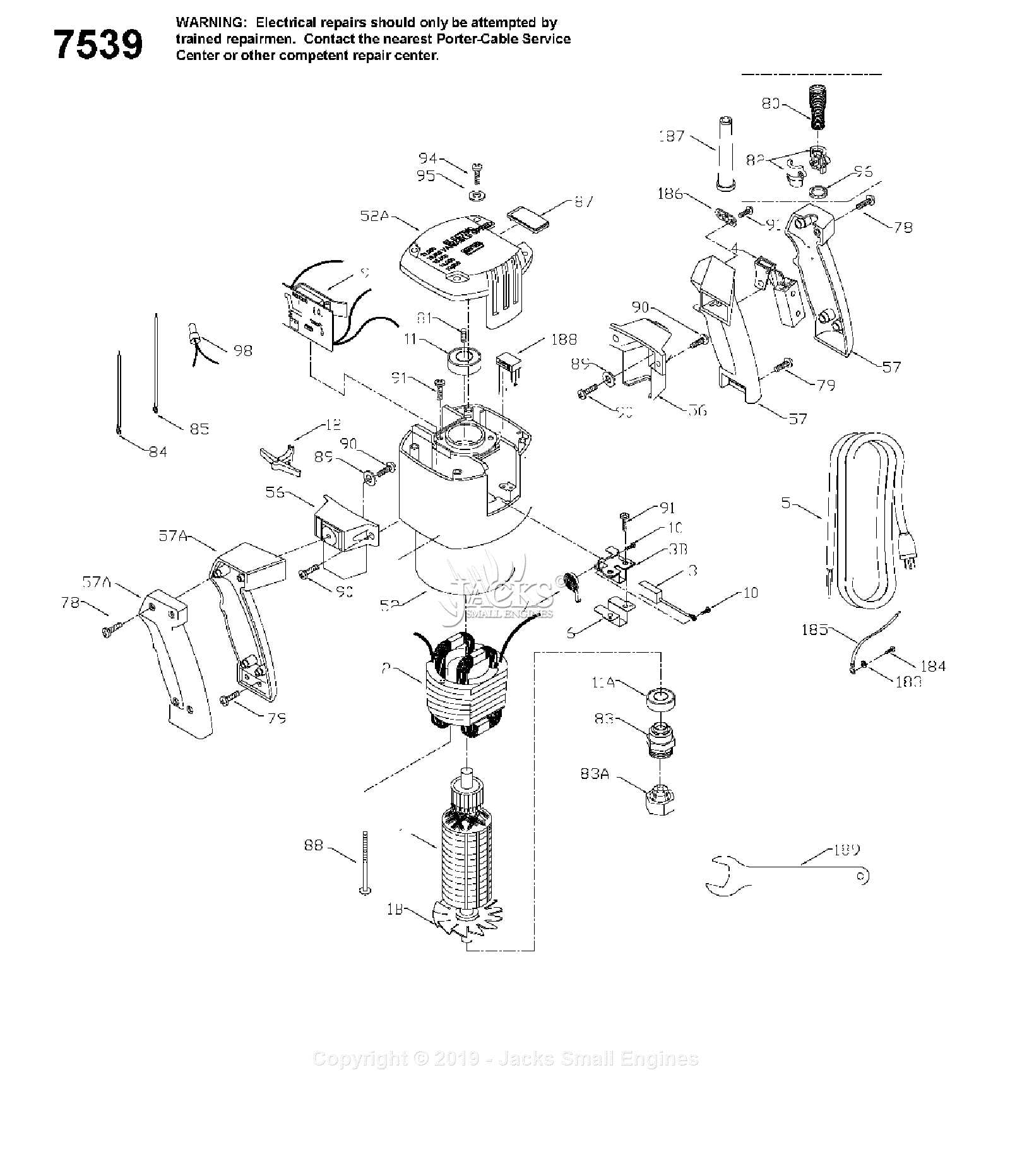

Diagram Interpretation and Analysis

Understanding the visual representation of mechanical components is crucial for effective maintenance and repair. An accurate illustration can serve as a valuable tool, providing insights into the relationship between various elements and their functions. Analyzing such visuals allows users to identify potential issues and plan their approach to servicing the equipment.

Effective interpretation requires a keen eye for detail. Each segment of the illustration is carefully labeled, guiding the observer in recognizing the specific role each element plays within the assembly. This not only aids in pinpointing individual components but also enhances the understanding of how they interact within the system.

Moreover, familiarity with the layout can lead to more efficient troubleshooting. By tracing connections and dependencies, users can anticipate problems and devise strategies to address them proactively. This proactive stance is essential for anyone looking to extend the lifespan of their equipment and ensure optimal performance.

Resources for Sourcing Parts

Finding the right components for your marine engine can be crucial for its performance and longevity. Several avenues exist to help enthusiasts and professionals acquire the necessary items to ensure their vessels operate smoothly. Whether you’re looking for OEM options or aftermarket alternatives, understanding where to look can make all the difference.

Online retailers often offer a wide selection of components, making them a convenient choice for many. Websites dedicated to marine supplies typically provide detailed catalogs, allowing users to search by specifications or model numbers. Additionally, forums and communities centered around marine interests can be invaluable resources, as members frequently share insights about their preferred suppliers and experiences.

Local marine shops are another excellent option for sourcing necessary equipment. These establishments often have knowledgeable staff who can assist in identifying the right items and may even provide insights into installation and maintenance. Networking with other boat owners can also lead to discovering reliable sources and potentially finding used components in good condition.