Marine engines are complex systems designed to operate efficiently in demanding environments. Each element within these engines plays a crucial role in ensuring the overall performance, safety, and longevity of the system. Whether for maintenance, repair, or upgrade, knowing the specifics of these mechanisms is essential for smooth operation and long-lasting reliability.

In this guide, we’ll explore various elements that make up the core of marine propulsion units. These components work in harmony to deliver the power and control needed on the water. Understanding how each part functions can greatly enhance your ability to troubleshoot issues and perform essential maintenance.

By examining detailed illustrations, we aim to provide clarity on how different sections of the propulsion system interconnect. This knowledge can serve as a valuable resource for anyone looking to optimize engine performance and prolong its lifespan.

Johnson 115 Outboard: Key Components Overview

Understanding the primary elements of a marine engine is essential for ensuring reliable performance and maintenance. This section covers the most crucial elements that contribute to the functionality and longevity of a marine motor, highlighting their roles and interactions within the system.

Engine Block

The heart of the motor, this component houses the internal mechanisms responsible for converting fuel into motion. Its durability and structure are vital for maintaining efficiency and withstanding the harsh marine environment.

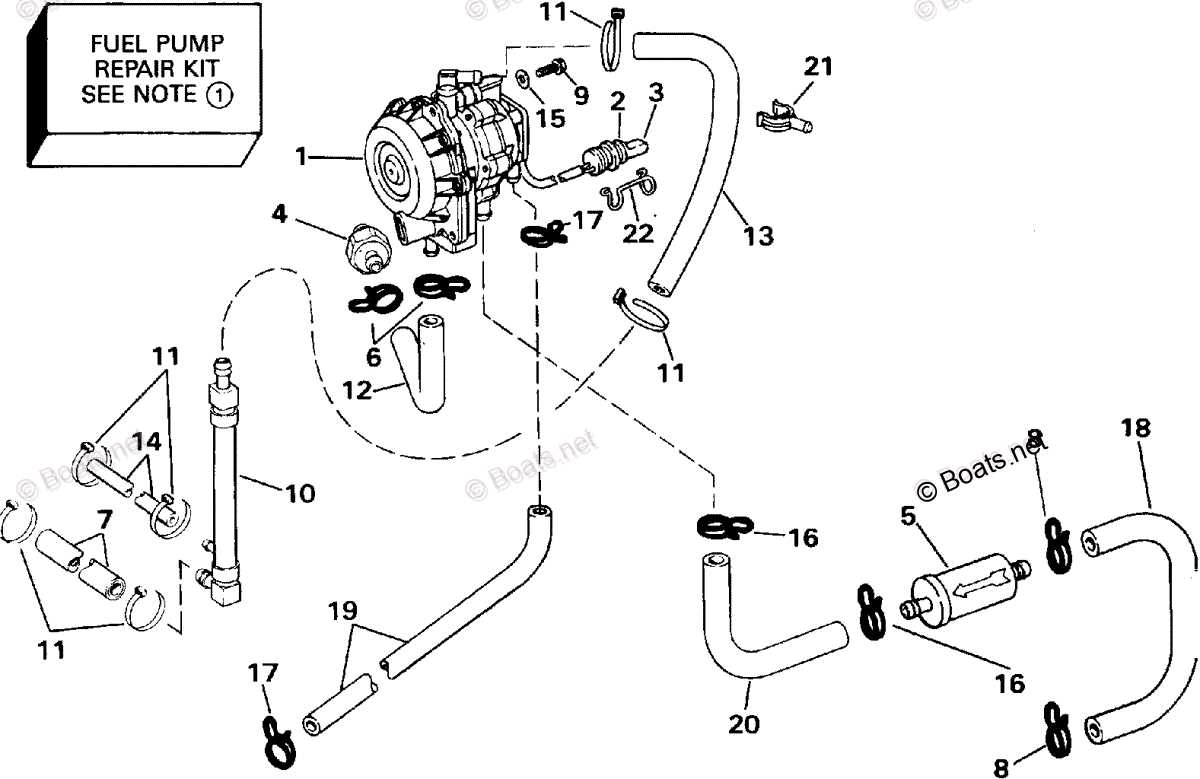

Fuel System

The fuel system ensures proper delivery of gasoline to the engine, including pumps, lines, and filters. Maintaining clean fuel flow is critical for optimal combustion and performance.

- Fuel Pump:

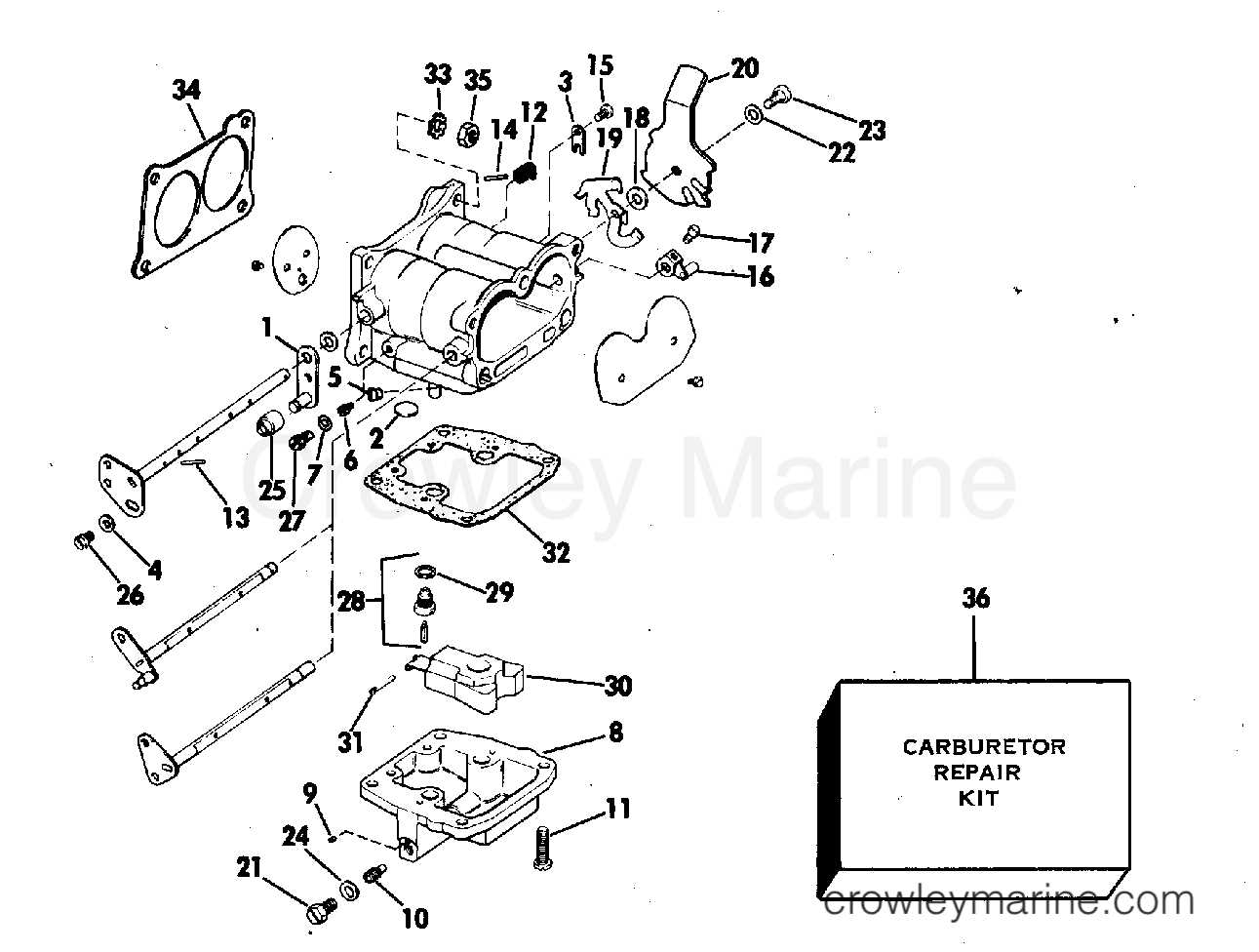

Fuel System Parts and Diagram Insights

The fuel delivery setup in marine engines is crucial for maintaining efficient and reliable performance on the water. This section offers a closer look at the components involved in the system responsible for providing the engine with a steady flow of fuel, highlighting how each part contributes to overall function.

Key Components of the Fuel Delivery Setup

Among the most critical elements are the fuel pump, carburetors or injectors, and filters. These ensure that the gasoline is properly delivered, filtered, and mixed with air for combustion. The pump is tasked with maintaining appropriate pressure, while the filtering system removes impurities, protecting the engine from damage. Efficient mixing is crucial for smooth operation, preventing stalling or power loss.

Understanding the

Cooling System Breakdown for Johnson 115

The cooling mechanism in marine engines plays a critical role in maintaining optimal performance and preventing overheating. Proper circulation of water ensures that the engine operates at the correct temperature, protecting key components from heat damage. In this section, we will explore how this system functions, covering its essential elements and their interactions within the engine structure.

Main Components of the Cooling System

The cooling process relies on several key components working together to maintain temperature balance. Understanding each part’s role is crucial for troubleshooting and maintaining peak engine efficiency.

- Water Pump: This part is responsible for drawing in water from the surrounding environment and circulating it throughout the engine.

- Battery: Provides the necessary power for starting the engine and operating electrical accessories.

- Alternator: Charges the battery while the engine is running, ensuring a continuous power supply.

- Wiring Harness: Connects various electrical components, facilitating the flow of electricity throughout the system.

- Ignition System: Responsible for igniting the fuel-air mixture in the engine cylinders.

- Switches: Control the flow of electricity to various components, allowing the operator to manage systems effectively.

- Fuse Box: Protects electrical components from overloads and short circuits by breaking the circuit when necessary.

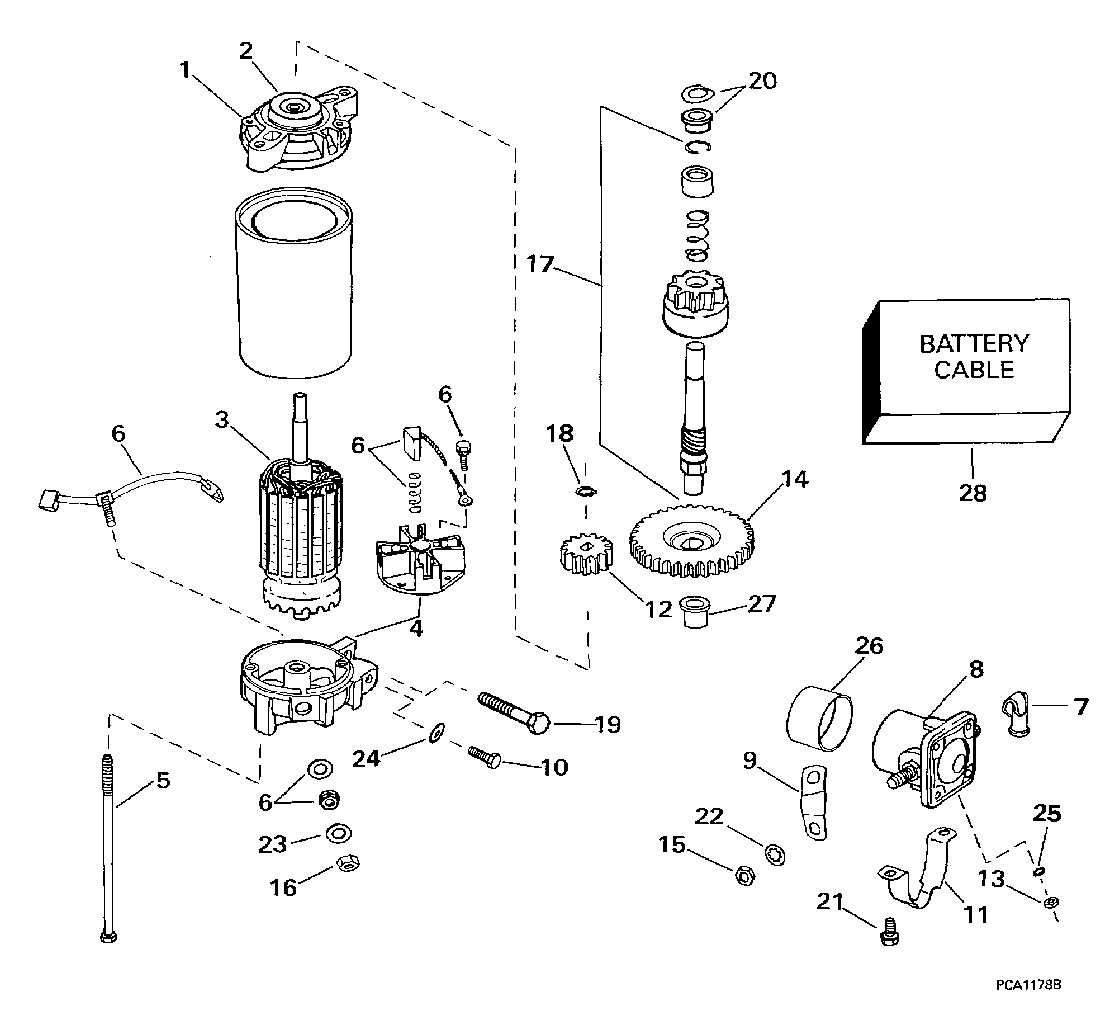

Understanding the Ignition System Components

The ignition system is a crucial part of any internal combustion engine, responsible for initiating the spark that ignites the fuel-air mixture within the engine’s cylinders. A proper understanding of its components ensures effective troubleshooting and maintenance, allowing the engine to run smoothly and efficiently. This section outlines the key elements involved in the process and their role in engine performance.

Spark Plug and Ignition Coil

At the heart of the ignition process, the spark plug and ignition coil work together to generate the high-voltage spark necessary for combustion. The coil amplifies the electrical energy from

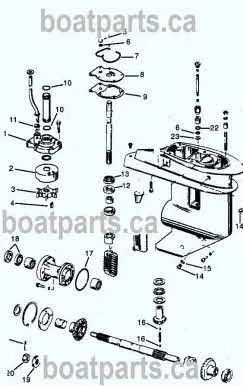

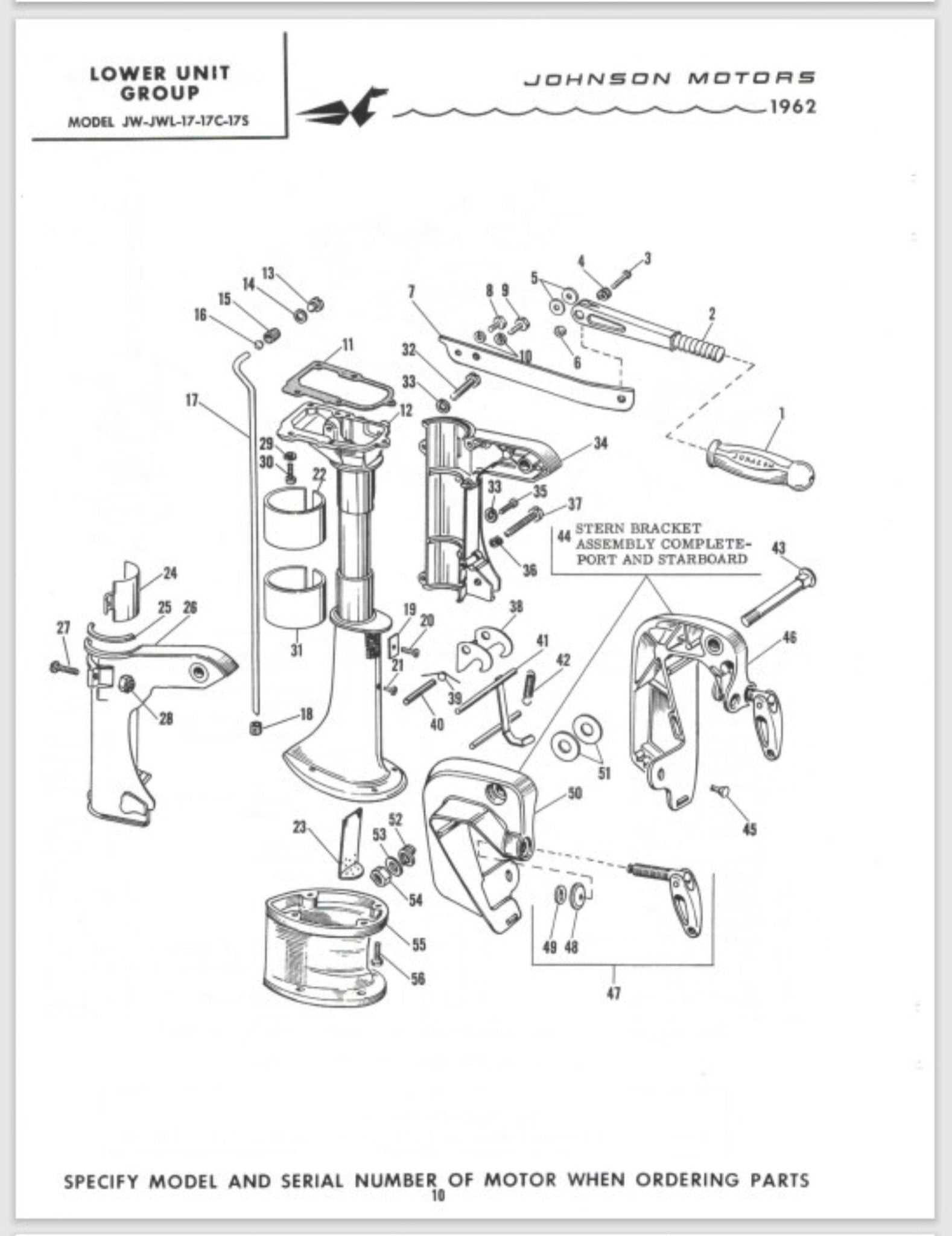

Lower Unit Assembly: Key Parts Explained

The lower section of a marine engine is essential for the overall functionality and performance of the vessel. This area houses critical components responsible for transmitting power, ensuring smooth navigation, and protecting the internal mechanisms from water exposure. Understanding the elements of this section helps in proper maintenance and troubleshooting.

One of the key components is the propeller shaft, which transmits the engine’s force to the water, allowing movement. The driveshaft connects the motor to the lower section, converting rotational energy into thrust. The gear case is another crucial part, protecting the internal gears and allowing seamless shifting between forward, neutral, and reverse modes.

The water pump ensures continuous cooling by circulating water through the engine, preventing overheating. Lastly, the anti-cavitation

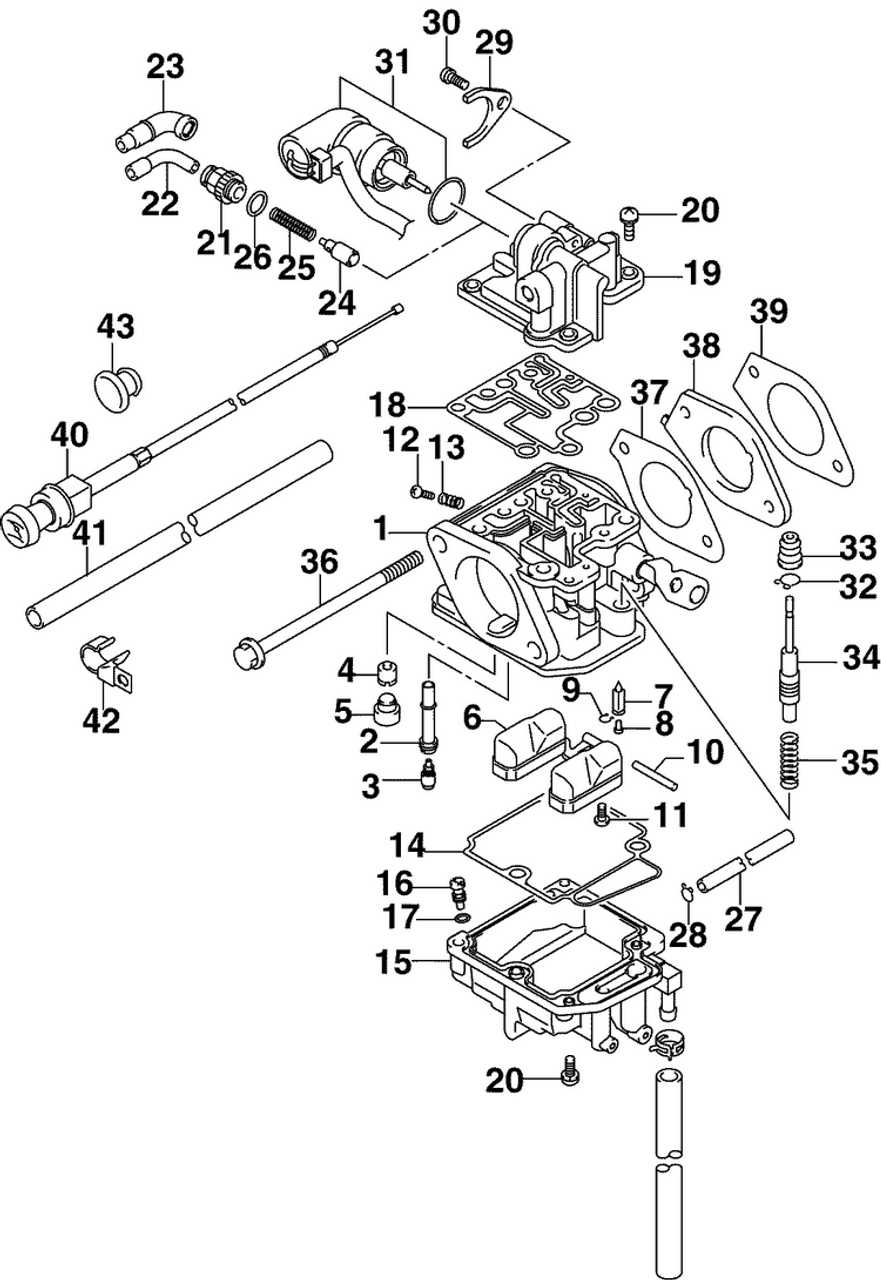

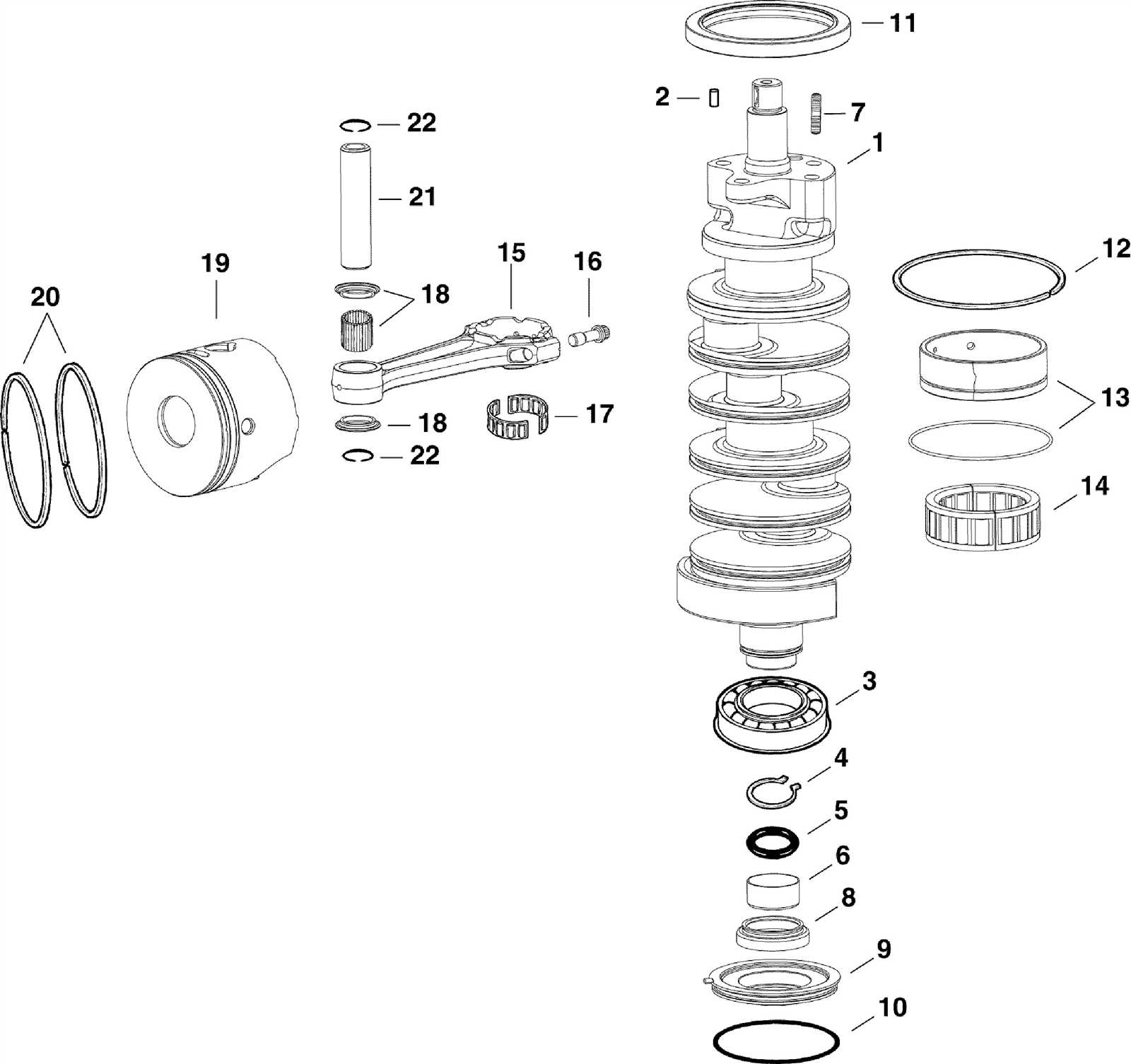

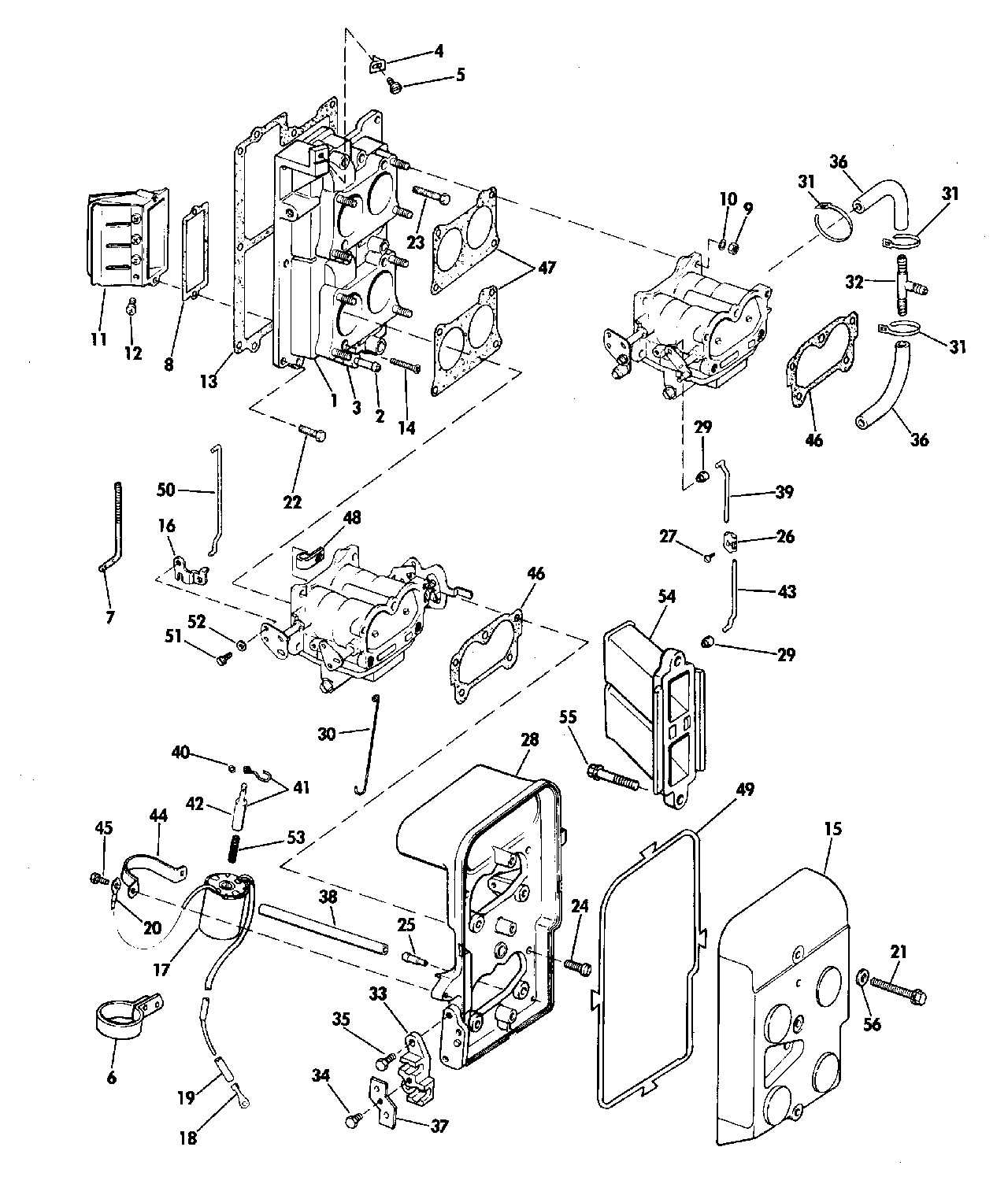

Powerhead Structure and Parts Overview

The powerhead serves as the heart of a marine propulsion system, playing a crucial role in engine operation and performance. This section delves into its fundamental components and their respective functions, providing insights into the overall architecture of the assembly.

At the core of the powerhead, the cylinder block houses the cylinders where fuel combustion occurs. Attached to this block are various essential elements, including pistons, which convert the combustion energy into mechanical motion. The cylinder head caps the cylinder block, featuring intake and exhaust ports that facilitate air and fuel flow, as well as the expulsion of exhaust gases.

Additionally, the ignition system, comprising spark plugs and coils, ensures optimal combustion timing, while the cooling system, often utilizing water passages, maintains the engine at a safe operating temperature. Together, these components contribute to the efficiency and reliability of the marine engine, underscoring the importance of each part in the overall assembly.

Electrical System Components and Layout

The electrical system in marine engines plays a crucial role in ensuring optimal performance and reliability. Understanding the various elements that comprise this system is essential for proper maintenance and troubleshooting. This section outlines the main components involved in the electrical setup and their arrangement within the unit.

The key components of the electrical system typically include:

The layout of these components is designed for efficiency and accessibility, ensuring that maintenance can be performed easily. Proper arrangement also minimizes the risk of electrical interference and enhances the overall performance of the engine. Each component must be correctly installed and connected to ensure reliable operation in various marine conditions.

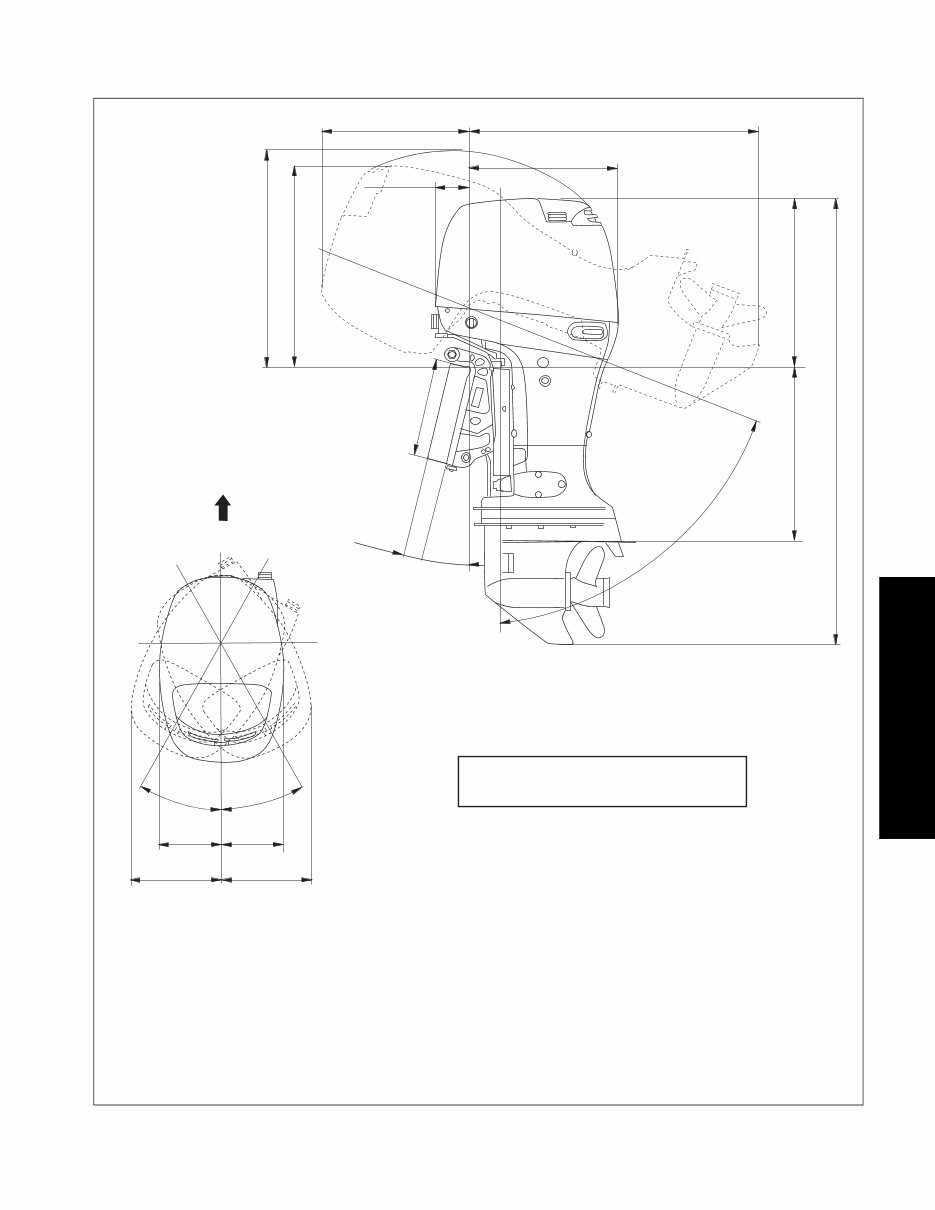

Steering Mechanism Breakdown for Johnson Outboards

The steering mechanism plays a crucial role in the overall functionality and maneuverability of marine engines. Understanding its components and operation can greatly enhance performance and safety on the water. This section delves into the intricacies of the steering system, highlighting key elements and their respective functions.

Key Components

At the heart of the steering assembly are several essential components that work in harmony to provide precise control. The steering wheel transfers the operator’s inputs, while the steering cables transmit these movements to the engine. Additionally, pivot points allow for smooth rotation, enabling effortless navigation.

Operation and Maintenance

Proper maintenance of the steering mechanism ensures longevity and reliable performance. Regular inspection of the cables for signs of wear and tear, as well as greasing the pivot points, can prevent potential failures. Understanding how these elements interact will empower users to maintain optimal steering responsiveness.

Propeller and Shaft Assembly Details

The assembly of the propeller and shaft plays a crucial role in the performance of marine propulsion systems. Understanding the components and their functions can enhance efficiency and durability, contributing to smoother navigation and better fuel economy. This section explores the essential elements involved in the assembly, highlighting their importance in overall functionality.

Key Components

The propeller and shaft assembly consists of several vital components that work together to transmit power from the engine to the water. Each part is designed to withstand the harsh conditions of marine environments, ensuring reliable operation. The main components include:

Component Description Propeller Transforms engine power into thrust, propelling the vessel forward. Shaft Connects the engine to the propeller, transferring rotational motion. Hub Secures the propeller to the shaft, allowing for efficient energy transfer. Bearings Support the shaft, reducing friction and wear during operation. Assembly Considerations

When assembling the propeller and shaft, attention to detail is essential to ensure proper alignment and functionality. Proper torque specifications and the use of quality materials are crucial to prevent premature wear and failure. Regular inspections and maintenance can help identify any issues before they escalate, contributing to the longevity of the entire propulsion system.

Throttle and Shift Linkage Diagram

This section provides an overview of the connection mechanisms responsible for controlling the acceleration and gear shifting in marine propulsion systems. Understanding these components is crucial for maintaining optimal performance and ensuring smooth operation while navigating various water conditions.

Connection Mechanism Overview

The linkage system serves as the interface between the control lever and the engine, allowing the operator to manage speed and direction efficiently. Proper adjustment and maintenance of this assembly can enhance responsiveness and prolong the lifespan of the mechanical parts involved.

Key Components

Component Description Throttle Lever Controls the engine’s speed by regulating fuel flow. Shift Cable Transfers the shift lever movement to the gearbox for gear changes. Linkage Arm Connects the throttle lever to the engine, enabling smooth operation. Adjustment Screws Allow for fine-tuning of the cable tension and position. Maintenance Tips for Key Johnson 115 Parts

Regular upkeep of essential components is crucial for ensuring the longevity and performance of your marine engine. By focusing on specific areas, you can enhance efficiency, prevent breakdowns, and maintain optimal functioning throughout the boating season.

Regular Inspection

Conduct frequent examinations of critical elements such as the fuel system, ignition components, and cooling mechanisms. Look for any signs of wear, corrosion, or leaks that may hinder performance. Addressing minor issues early can prevent more significant problems down the line.

Lubrication and Cleaning

Proper lubrication is vital for moving parts to function smoothly. Regularly apply suitable lubricants to mechanisms and inspect filters to ensure they remain clean and free of debris. A clean engine contributes to better performance and fuel efficiency.