The intricate workings of any complex engine rely on a myriad of individual elements that contribute to its overall functionality. A comprehensive understanding of these components is crucial for effective maintenance and repair. This section aims to provide clarity on how each part interconnects, ensuring optimal performance.

When exploring the layout and configuration of these vital pieces, it becomes evident that a visual representation can greatly enhance comprehension. By examining a well-structured outline, users can easily identify and locate each segment, facilitating both troubleshooting and upgrades.

Delving into this topic not only equips enthusiasts with essential knowledge but also empowers them to make informed decisions regarding replacements and modifications. The ultimate goal is to foster a deeper appreciation for the engineering that underpins these remarkable machines.

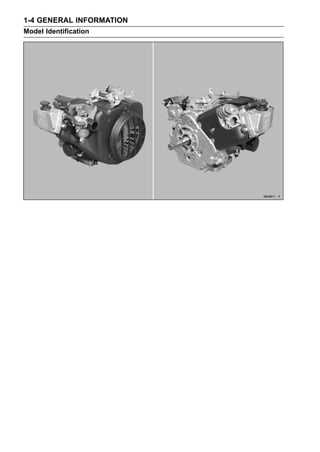

Kawasaki FJ400D Overview

This section provides a comprehensive insight into a specific model known for its reliability and performance. Designed for various applications, it offers a blend of advanced engineering and user-friendly features, making it a popular choice among enthusiasts and professionals alike.

Key Features

- Robust engine performance

- Efficient fuel consumption

- Durable construction materials

- Easy maintenance accessibility

Applications

- Industrial usage

- Landscaping tasks

- Transportation of goods

- General utility purposes

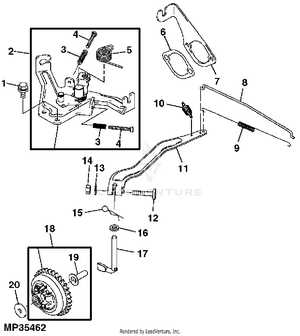

Understanding Parts Diagrams

Visual representations of components play a crucial role in comprehending the structure and functionality of machinery. These illustrations not only simplify the identification of individual elements but also aid in understanding how they interact within a system.

The Importance of Visual Aids

Using visual aids offers several advantages:

- Clarity: Simplifies complex information.

- Efficiency: Saves time in locating specific elements.

- Learning Tool: Enhances retention of information.

Key Components of Visual Representations

When examining these illustrations, it’s important to note the following elements:

- Labels: Clearly indicate each part.

- Connections: Show how components interact.

- Legend: Provides explanations for symbols used.

By familiarizing oneself with these aspects, users can effectively navigate and utilize these resources for maintenance and repair tasks. Understanding these visual guides ultimately leads to better-informed decisions and enhanced operational efficiency.

Key Components of FJ400D

This section explores the essential elements that contribute to the functionality and performance of the FJ400D model. Understanding these components allows for a deeper appreciation of its engineering and operational capabilities.

Main Elements

- Engine Assembly

- Transmission System

- Fuel System

- Cooling Mechanism

- Electrical Components

Functional Importance

- The engine assembly is the powerhouse, driving the entire unit.

- Transmission ensures smooth power delivery and handling.

- Fuel system optimizes efficiency and performance.

- Cooling mechanisms prevent overheating, maintaining operational integrity.

- Electrical components enable vital systems for control and safety.

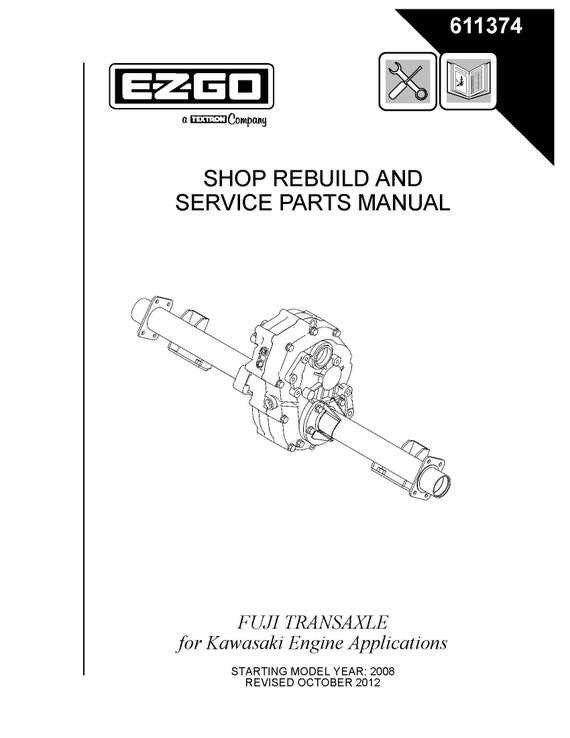

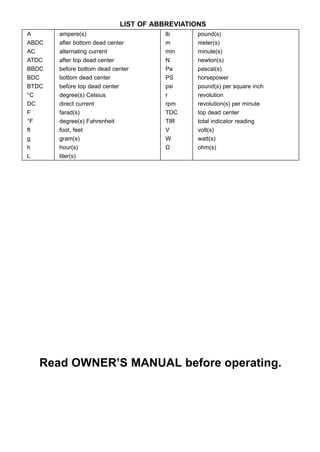

How to Read the Diagram

Understanding a schematic representation is essential for effective maintenance and repair tasks. These illustrations provide a visual breakdown of components and their interconnections, enabling users to identify parts and their functions with ease.

Begin by familiarizing yourself with the overall layout. Look for sections that categorize various elements, typically organized by function or location. Each component is often labeled with a unique identifier that correlates to a list or legend.

Next, pay attention to the lines and symbols used to depict relationships and connections between parts. Solid lines may represent direct links, while dashed lines could indicate optional or alternate pathways. Understanding these visual cues can significantly enhance your comprehension of the entire assembly.

Lastly, refer to the accompanying legend for detailed descriptions of each symbol and identifier. This crucial step ensures that you accurately interpret the information presented, leading to more efficient troubleshooting and repairs.

Common Issues with FJ400D Parts

Understanding the frequent challenges associated with specific components can greatly enhance maintenance and repair efforts. Various issues can arise due to wear, manufacturing defects, or improper handling.

1. Wear and Tear: Over time, certain elements can degrade, leading to decreased performance. Regular inspections can help identify these vulnerabilities early.

2. Compatibility Problems: Using non-genuine components may result in fitment issues. Ensuring the correct specifications is essential for optimal functionality.

3. Installation Errors: Incorrect installation can lead to malfunctions or damage. It is vital to follow proper guidelines during assembly to avoid complications.

4. Corrosion: Exposure to moisture can lead to rust and deterioration. Protecting components with suitable coatings can mitigate this risk.

5. Insufficient Lubrication: Lack of proper lubrication can cause friction and overheating, potentially leading to component failure. Regular maintenance is key to preventing this issue.

Where to Find Replacement Parts

Finding suitable components for your machinery can be a straightforward process if you know where to look. Various resources, both online and offline, offer a wide range of options for acquiring what you need. It’s essential to explore these avenues to ensure you obtain quality replacements efficiently.

| Source | Description |

|---|---|

| Online Retailers | Websites specializing in machinery supplies provide extensive inventories and competitive prices. |

| Local Dealerships | Authorized dealerships often carry genuine components and can offer expert advice. |

| Salvage Yards | These facilities can be treasure troves for used parts, often at reduced costs. |

| Forums and Communities | Online forums can connect you with other enthusiasts who may have spare parts or suggestions. |

Maintenance Tips for FJ400D

Proper upkeep is essential for ensuring longevity and optimal performance of your machinery. Regular attention to various components not only enhances efficiency but also prevents costly repairs down the line.

- Check oil levels frequently and change according to the manufacturer’s recommendations.

- Inspect air filters regularly, cleaning or replacing them to maintain airflow and engine efficiency.

- Monitor tire pressure and tread wear, replacing tires as necessary to ensure safe handling.

- Examine brakes for wear, ensuring they respond effectively to maintain safety during operation.

Additionally, keeping the machine clean can prevent dirt buildup, which may cause wear over time. Ensure all moving parts are lubricated appropriately to minimize friction and enhance performance.

- Develop a maintenance schedule to track inspections and replacements.

- Use genuine parts to ensure compatibility and reliability.

- Consult the manual for specific guidelines on maintenance procedures.

By following these tips, you’ll ensure that your equipment runs smoothly and efficiently for years to come.

Benefits of Using Original Parts

Choosing authentic components for your vehicle can significantly impact its performance and longevity. Original pieces are designed specifically for your machine, ensuring compatibility and optimal functionality. This approach not only enhances the reliability of your equipment but also contributes to safety and efficiency during operation.

Quality Assurance

One of the primary advantages of utilizing genuine components is the assurance of quality. Original manufacturers adhere to strict standards during production, which translates to superior durability and performance. In contrast, aftermarket alternatives may not meet these rigorous specifications, leading to potential issues down the line.

Long-Term Cost Savings

While the initial investment in authentic components may be higher, the long-term savings can be substantial. Genuine items are often more durable, reducing the frequency of replacements and maintenance. Additionally, they can help maintain the resale value of your vehicle, as potential buyers often prefer machines with original parts.

| Aspect | Original Components | Aftermarket Alternatives |

|---|---|---|

| Quality | High | Variable |

| Compatibility | Perfect Fit | May Vary |

| Durability | Long-Lasting | Shorter Lifespan |

| Resale Value | Higher | Lower |

Aftermarket Parts: Pros and Cons

Exploring alternative components for vehicles can be an enticing option for many enthusiasts and everyday users alike. While these options often promise affordability and unique features, they come with their own set of advantages and drawbacks that require careful consideration.

Advantages

Cost-Effectiveness: One of the most significant benefits of choosing aftermarket alternatives is their generally lower price point. Many users find that these options provide substantial savings without compromising on quality.

Disadvantages

Quality Variability: However, the quality of these components can vary greatly. Some may not meet the same standards as original equipment, potentially leading to performance issues or increased maintenance costs.

DIY Repairs with Parts Diagram

Engaging in self-repair of machinery can be a rewarding experience, allowing enthusiasts to save money and gain a deeper understanding of their equipment. With the right visual references, tackling maintenance or replacement tasks becomes significantly easier. This section delves into the benefits of utilizing a schematic for identifying components and guiding your repair process.

Understanding Component Layout

Familiarizing yourself with the layout of various elements is crucial for efficient repairs. A well-structured visual reference provides clarity on where each piece fits and how they interact. By studying these illustrations, you can pinpoint the specific parts that require attention, ensuring a streamlined approach to your project.

Steps for Effective DIY Repairs

To embark on your repair journey, follow these steps:

- Gather Tools: Ensure you have all necessary tools at hand before starting.

- Review Visual References: Examine the schematic to identify the components involved.

- Follow Instructions: Adhere to any guidelines provided to ensure proper assembly and disassembly.

- Test Functionality: After completing repairs, conduct tests to confirm everything operates smoothly.

By leveraging these resources, you can enhance your repair skills and boost the longevity of your equipment, turning challenges into opportunities for learning and growth.

Resources for Kawasaki Owners

For enthusiasts and owners of powerful machines, having access to the right materials can enhance both maintenance and performance. From manuals to community forums, these resources are invaluable for keeping your vehicle in top shape.

- Owner’s Manuals: Essential for understanding your vehicle’s specifications and care instructions.

- Online Forums: Join communities where you can share experiences, seek advice, and connect with fellow owners.

- Repair Guides: Step-by-step instructions available in print or online for tackling repairs and upgrades.

- Video Tutorials: Visual aids can greatly assist in understanding complex tasks and procedures.

Utilizing these resources can ultimately enhance your experience and ensure your machine remains reliable and efficient.