In the world of small engine maintenance and repair, having a clear representation of each element is crucial for ensuring optimal performance. A comprehensive visual guide helps both professionals and enthusiasts navigate the complexities of engine assemblies. By familiarizing oneself with these schematics, one can enhance troubleshooting skills and facilitate efficient repairs.

When dealing with engine maintenance, it’s essential to identify the various components and their interconnections. These illustrations serve as invaluable tools for understanding how different parts interact and function together. Whether you’re a seasoned technician or a newcomer, grasping these relationships can significantly streamline your repair process.

Utilizing detailed visual resources not only aids in identifying specific components but also empowers users to order replacements accurately. Clarity in these layouts minimizes the risk of errors, ultimately contributing to a smoother maintenance experience. Embracing this knowledge fosters a deeper appreciation for engine mechanics and promotes long-term reliability.

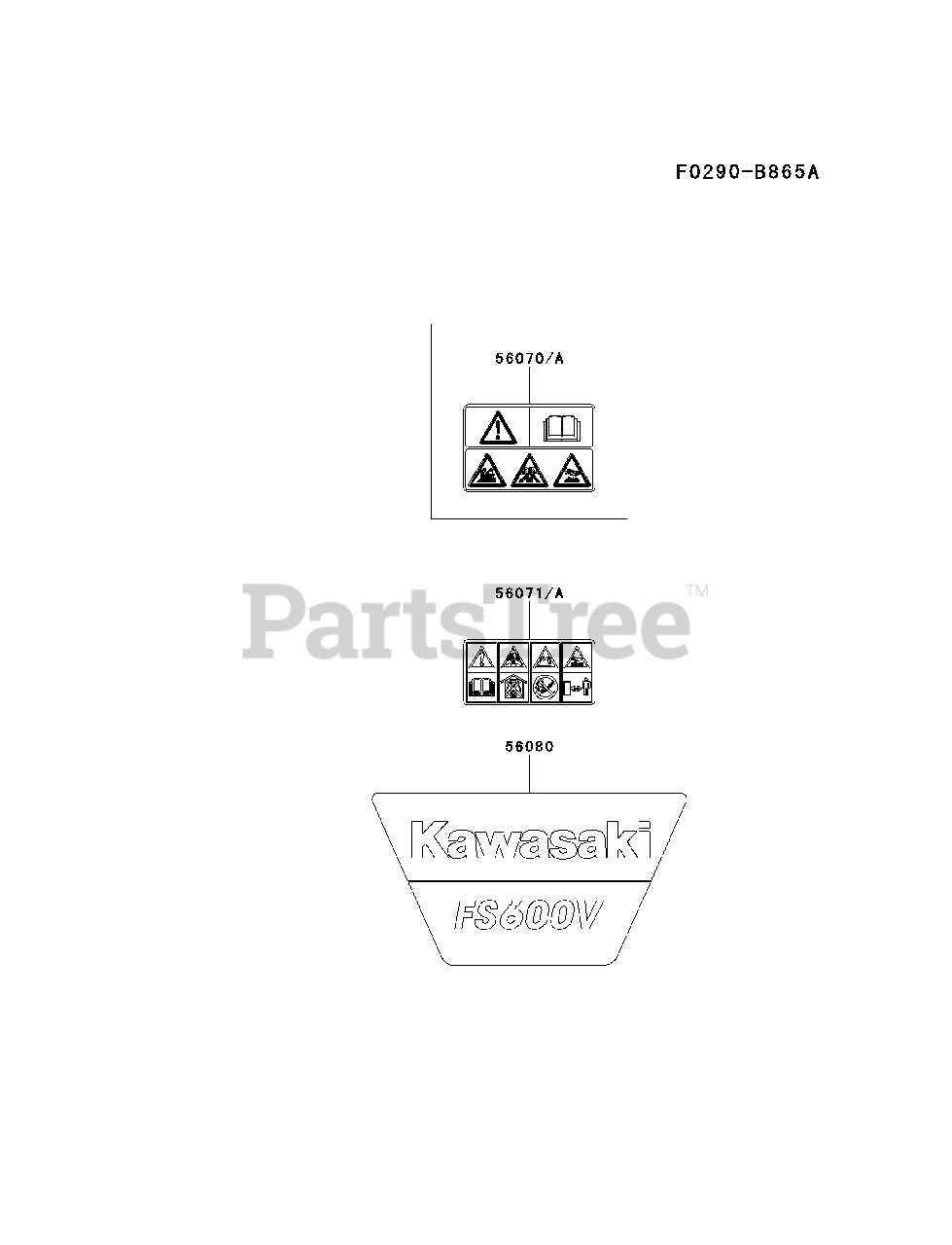

Kawasaki FS600V Overview

This section provides a comprehensive look at a well-regarded engine model known for its reliability and efficiency in various applications. Renowned for its robust construction, this power unit is often found in both commercial and residential machinery, making it a versatile choice for users.

Key Features

The engine boasts several noteworthy attributes that enhance its performance. With a powerful output, it is capable of handling demanding tasks while maintaining fuel efficiency. The design prioritizes ease of maintenance, allowing users to conduct regular servicing without hassle. Furthermore, the innovative cooling system ensures optimal operation even in challenging conditions.

Applications

This engine is suitable for a range of applications, including lawn care equipment, gardening tools, and industrial machinery. Its adaptability makes it a popular option among professionals and hobbyists alike. The combination of power and efficiency ensures that it meets the needs of diverse environments, from residential gardens to large-scale commercial operations.

Importance of Parts Diagrams

Understanding the components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools, offering clarity on how each element fits within the larger system. These illustrations enhance comprehension, allowing users to identify specific sections and troubleshoot issues efficiently.

Furthermore, having access to these visuals streamlines the ordering process for replacement elements, ensuring that the right items are acquired without unnecessary delays. By facilitating accurate communication between technicians and suppliers, they ultimately contribute to minimizing downtime and optimizing operational efficiency.

Moreover, these guides are invaluable for those looking to delve deeper into the workings of their equipment. They foster a sense of confidence among users, empowering them to perform repairs and upgrades with greater assurance. In this way, clear visual references become a cornerstone of successful equipment management.

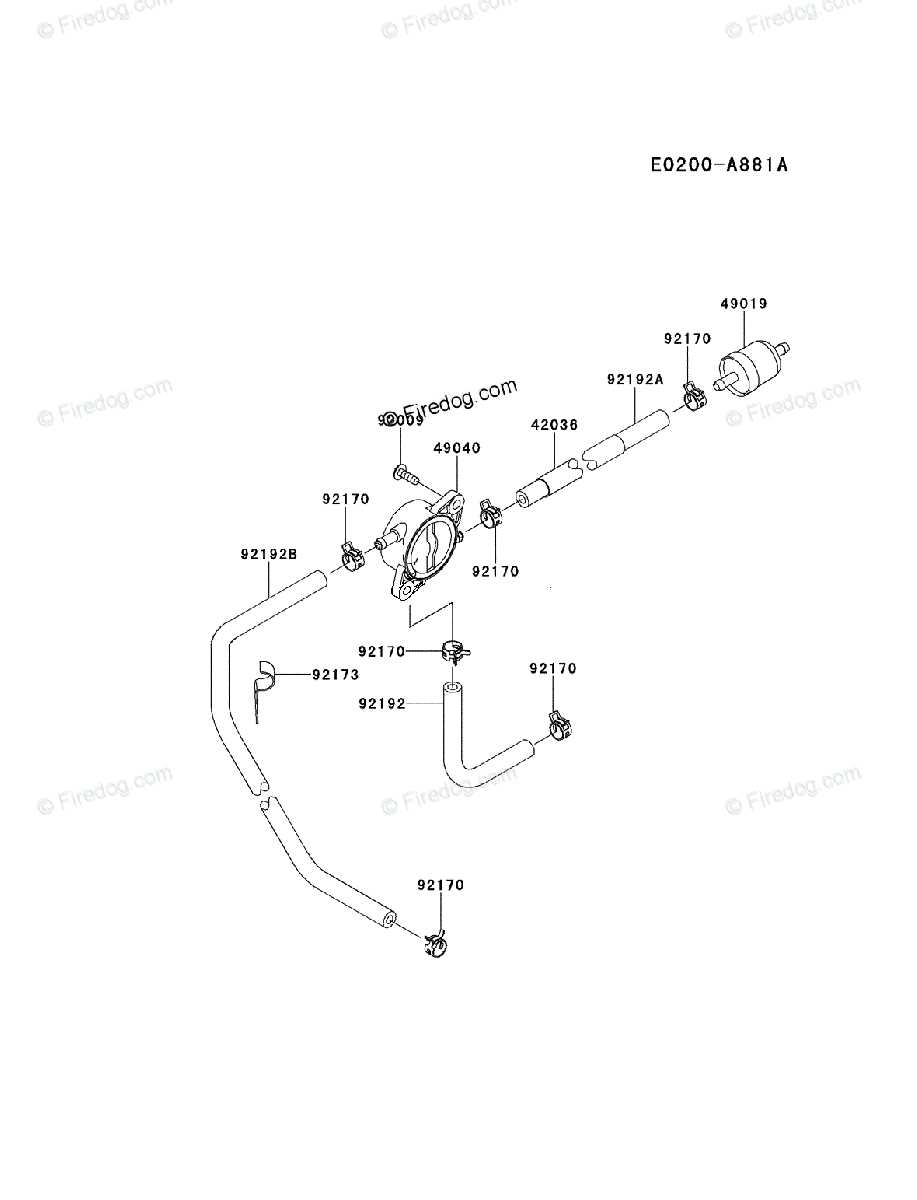

Common Issues with FS600V Engines

Engines of this type often encounter a variety of challenges that can affect performance and reliability. Understanding these common problems is essential for proper maintenance and troubleshooting.

| Issue | Description | Solution |

|---|---|---|

| Overheating | Excessive temperatures can lead to engine failure. | Check the cooling system and ensure proper airflow. |

| Fuel Leaks | Leaks can cause reduced efficiency and fire hazards. | Inspect fuel lines and replace damaged components. |

| Starting Problems | Difficulty in starting may stem from battery issues or ignition failure. | Test the battery and check the ignition system. |

| Noisy Operation | Unusual noises often indicate wear or lack of lubrication. | Examine and replace worn parts, ensuring proper oil levels. |

Key Components of Kawasaki FS600V

This section focuses on the essential elements that contribute to the overall functionality and efficiency of the engine. Understanding these components is crucial for proper maintenance and troubleshooting.

- Engine Block: The core structure housing critical internal mechanisms, ensuring durability and stability.

- Cylinder Head: Responsible for housing the valves and spark plugs, playing a vital role in the combustion process.

- Piston: Transforms the pressure from combustion into mechanical energy, driving the crankshaft.

- Crankshaft: Converts linear motion from the piston into rotational motion, essential for power delivery.

- Fuel System: Comprising the fuel tank, filter, and carburetor, it ensures the proper mixture of air and fuel for combustion.

- Cooling System: Maintains optimal operating temperatures to prevent overheating, including fans and coolant passages.

- Exhaust System: Directs harmful gases away from the engine and reduces noise, contributing to environmental compliance.

Familiarity with these critical components enables users to perform effective maintenance and repairs, ensuring longevity and performance of the engine.

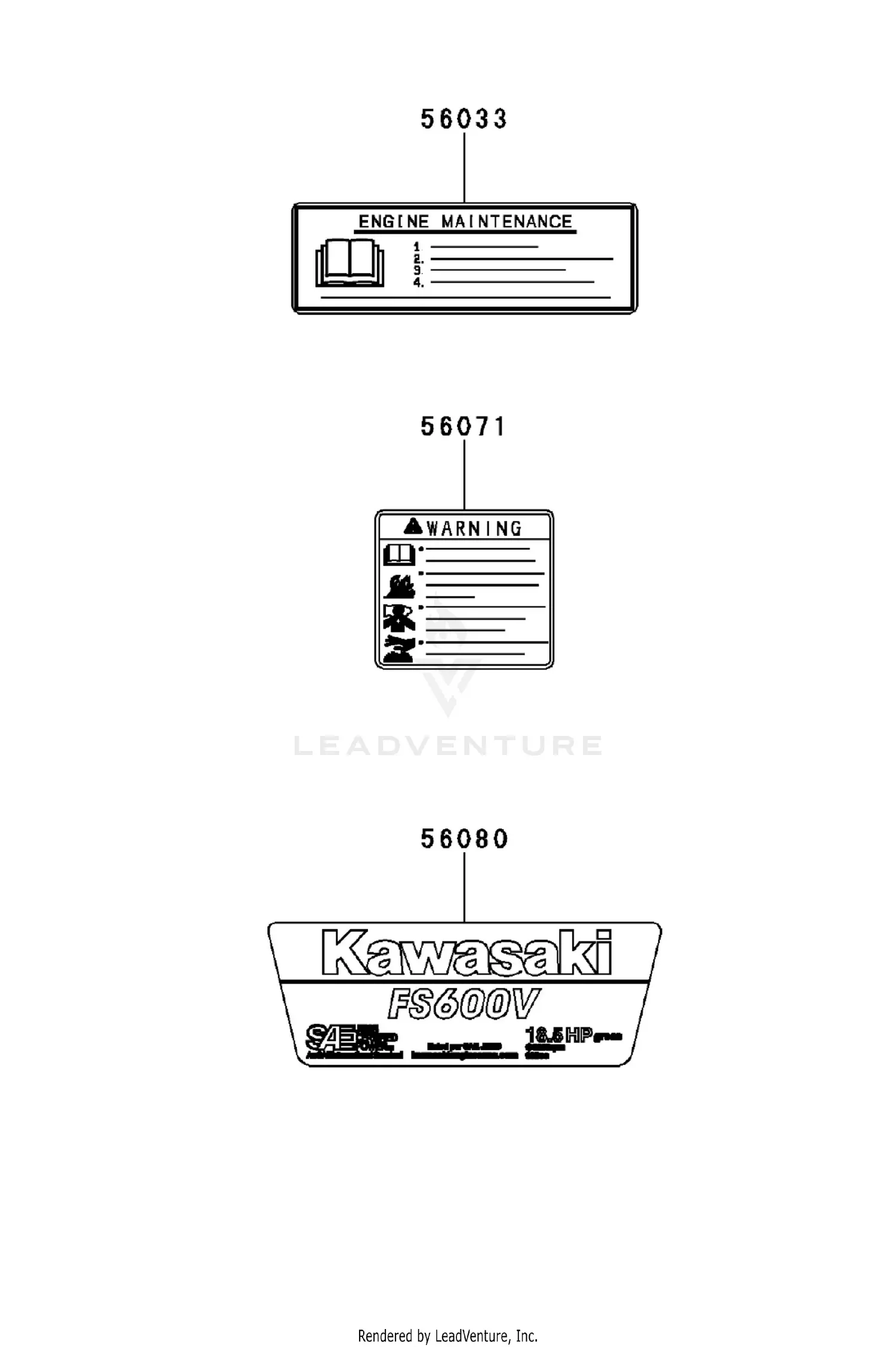

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repairs. These illustrations serve as guides, offering a clear layout of various elements and their interconnections. By familiarizing yourself with these visuals, you can efficiently identify and source necessary items for your machinery.

1. Familiarize Yourself with Symbols: Each illustration utilizes specific symbols to denote different parts. Take time to learn what each symbol represents, as this knowledge will simplify the identification process.

2. Study the Numbering System: Components are often labeled with unique numbers that correspond to a list or key. Cross-referencing these numbers helps in locating the correct items quickly.

3. Note the Groupings: Parts are usually organized into sections based on their function or location. Understanding these groupings aids in grasping the overall assembly and can streamline the repair process.

4. Pay Attention to Annotations: Additional notes or instructions may be included alongside the visuals. These annotations provide vital information regarding installation or compatibility, ensuring you make informed decisions.

5. Use the Visual as a Reference: Keep the illustration handy when working on your equipment. Referring back to the visual can clarify doubts and reinforce your understanding of how various components fit together.

By mastering the art of interpreting these visuals, you can enhance your repair skills and ensure the longevity of your equipment.

Benefits of Using OEM Parts

When it comes to maintaining and repairing machinery, opting for original equipment manufacturer components can offer a multitude of advantages. These products are specifically designed for compatibility, ensuring optimal performance and longevity.

One significant benefit of using genuine components is the assurance of quality. Manufacturers create these items using high standards, which often leads to increased reliability and reduced risk of failure. Additionally, utilizing OEM items can maintain the integrity of warranties, safeguarding your investment over time.

| Advantages | Description |

|---|---|

| Quality Assurance | Manufactured to meet strict specifications, ensuring durability and performance. |

| Warranty Protection | Using original parts helps preserve manufacturer warranties and guarantees. |

| Optimal Compatibility | Designed to work seamlessly with existing systems, minimizing installation issues. |

| Long-Term Savings | While initially more expensive, they often reduce long-term maintenance costs due to their reliability. |

Ultimately, choosing OEM options can lead to a smoother operation and peace of mind, knowing that the machinery is equipped with components specifically crafted for its needs.

Maintenance Tips for FS600V

Proper upkeep of your engine is crucial for its longevity and optimal performance. Regular attention to specific components can prevent costly repairs and ensure smooth operation.

- Check and change the oil regularly to maintain lubrication and reduce wear.

- Inspect air filters frequently; clean or replace them to ensure efficient airflow.

- Examine spark plugs for wear; replace them as necessary to guarantee proper ignition.

- Keep fuel lines clear and check for leaks to avoid potential hazards.

- Regularly inspect belts and cables for signs of wear or damage.

Adhering to these guidelines will help you delve into effective maintenance practices, leading to the ultimate performance of your machinery.

Finding Replacement Parts Easily

Locating suitable components for your equipment can often seem daunting. However, with the right approach, you can simplify the process significantly. Understanding where to search and what resources are available is key to ensuring you find the right items without unnecessary hassle.

Start by utilizing online marketplaces and specialty retailers that focus on machinery supplies. These platforms often have extensive catalogs and allow for easy navigation through various categories. Additionally, reading customer reviews can provide insights into the quality and compatibility of specific items.

Furthermore, consider consulting user manuals or official guides that outline the specifications and alternatives for the components you need. Such resources can save time and help prevent potential errors when selecting replacements.

Networking with local repair shops or joining online forums can also prove invaluable. Experienced users can share recommendations and might even direct you to reliable suppliers, ensuring that you get the right replacements swiftly and efficiently.

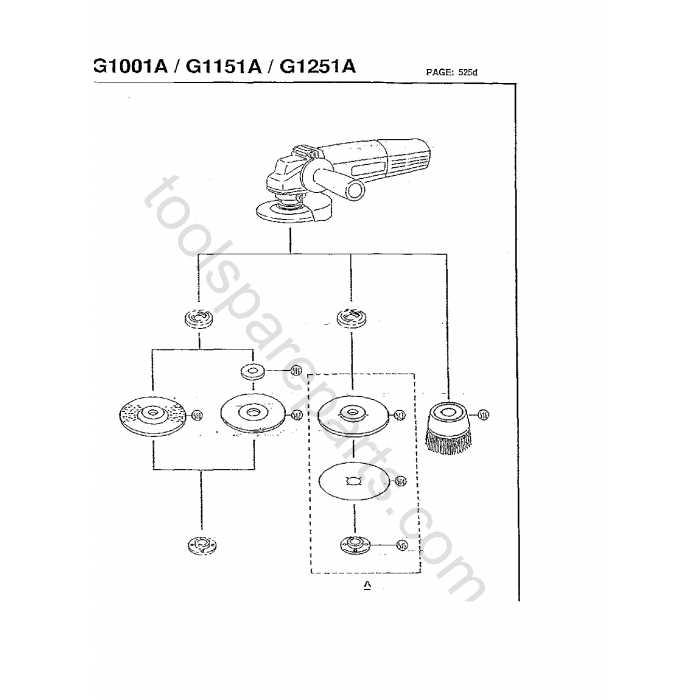

Popular Upgrades for Kawasaki Engines

Enhancing the performance and efficiency of small engines can significantly improve their functionality and lifespan. Many enthusiasts seek modifications that not only boost power but also enhance reliability and reduce maintenance needs. Here are some widely favored upgrades to consider.

1. Performance Air Filters

Switching to a high-flow air filter allows for better airflow, leading to improved combustion and increased horsepower. These filters often require less frequent cleaning compared to standard options.

- Improved airflow

- Higher horsepower potential

- Reduced maintenance frequency

2. Exhaust System Enhancements

Upgrading the exhaust system can significantly impact engine efficiency. A performance exhaust allows for quicker gas expulsion, resulting in better torque and power delivery.

- Enhanced torque

- Quieter operation options

- Stylish designs available

These upgrades not only enhance performance but also provide a personalized touch to the machinery. Whether for work or leisure, optimizing engine components can lead to a more satisfying experience.

Understanding Engine Specifications

Comprehending the intricacies of engine specifications is essential for optimal performance and maintenance. These details provide insights into the mechanics and capabilities of an engine, influencing its efficiency, power output, and overall functionality.

Key Components

Several critical elements contribute to an engine’s performance, including displacement, horsepower, torque, and fuel type. Each factor plays a vital role in determining how effectively an engine operates under various conditions.

Importance of Specifications

Accurate knowledge of these specifications enables users to make informed decisions regarding compatibility, upgrades, and repairs. Understanding these aspects ultimately leads to enhanced performance and longevity of the engine.

Resources for Parts Diagrams

Accessing detailed visuals for machinery components is crucial for maintenance and repair. These resources enable users to identify specific elements and understand their functions within the system.

Online Platforms

- Manufacturer Websites

- Specialized Repair Forums

- Online Retailers

Print Materials

- User Manuals

- Service Guides

- Catalogs from Distributors

Utilizing these resources effectively can enhance your ability to maintain and service your equipment, ensuring optimal performance.

Cost Analysis of Replacement Parts

Evaluating the expenses associated with component replacements is crucial for maintaining equipment efficiency and longevity. Understanding these costs helps in budgeting and making informed purchasing decisions.

Factors Influencing Costs

- Quality of the components

- Supplier pricing strategies

- Shipping and handling fees

- Market demand fluctuations

- Warranties and guarantees offered

Cost Comparison Strategies

- Research multiple vendors for price variations.

- Consider aftermarket options as alternatives.

- Evaluate the total cost of ownership, including installation.

- Track historical price trends to anticipate future expenses.