When navigating the complexities of utility vehicles, a comprehensive grasp of their assembly is essential for effective maintenance and repair. Each model is comprised of various elements that work in harmony to deliver optimal performance. Familiarity with these components allows enthusiasts and professionals alike to address issues promptly and efficiently.

In this exploration, we delve into the intricate layouts that represent the numerous sections of these rugged machines. By breaking down each part and its function, users can enhance their understanding and gain insights into troubleshooting and upgrades. This knowledge not only fosters confidence in handling repairs but also promotes a deeper appreciation for the engineering behind these robust vehicles.

Whether you are an owner seeking to extend the lifespan of your machine or a technician aiming to refine your skills, having a clear visual representation of the components is invaluable. It serves as a roadmap, guiding you through the essential areas that require attention and care. Thus, a detailed study of these configurations becomes a critical resource in the realm of utility vehicles.

This section explores the popular variants of a certain utility vehicle known for its versatility and reliability. Each model caters to different needs, ensuring that users find the right fit for their specific requirements.

Popular Variants

These models are widely recognized for their performance and features. Below is a summary of some notable examples:

| Model Name | Engine Type | Load Capacity |

|---|---|---|

| Model 1 | Gasoline | 1000 lbs |

| Model 2 | Diesel | 1200 lbs |

| Model 3 | Electric | 800 lbs |

Special Features

Each variant comes with distinct attributes tailored for different tasks. Users can select based on terrain adaptability, passenger capacity, and additional functionalities, making these vehicles ideal for various applications.

Key Components and Their Functions

Understanding the essential elements of utility vehicles enhances their functionality and maintenance. Each component plays a vital role in ensuring optimal performance, safety, and reliability.

Engine and Transmission

The heart of any vehicle lies in its engine, responsible for generating power. Coupled with the transmission, it transfers that power to the wheels, enabling movement and control across various terrains.

Suspension System

The suspension system absorbs shocks and provides stability, ensuring a smooth ride. It plays a crucial role in handling and comfort, allowing the vehicle to navigate rough landscapes efficiently.

Understanding the Wiring Layout

Comprehending the electrical framework of your utility vehicle is crucial for effective maintenance and troubleshooting. A well-organized wiring system not only ensures optimal performance but also facilitates repairs and upgrades when necessary. This section delves into the intricacies of the wiring layout, highlighting key components and their functions.

Key Components of the Wiring System

- Battery: The heart of the electrical system, providing power to all components.

- Fuses: Safety devices that protect circuits from overloads.

- Switches: Control mechanisms that manage the flow of electricity to various parts.

- Connectors: Junctions that link different wiring segments, allowing for flexibility in the setup.

Understanding Wiring Schematics

- Symbols: Familiarize yourself with common symbols used to represent different components.

- Color Codes: Learn the significance of color coding in identifying wire functions.

- Connection Points: Recognize how to locate and trace connection points throughout the layout.

By grasping these fundamentals, you will be better equipped to navigate the electrical system and address any issues that may arise.

Maintenance Tips for Longevity

Ensuring the durability of your utility vehicle requires a consistent approach to upkeep. Regular maintenance not only enhances performance but also prolongs the lifespan of essential components. By following a few key practices, you can keep your machine in optimal condition and minimize the need for repairs.

Regular Inspections

Conducting routine checks on critical systems is vital. Look for signs of wear or damage, particularly in the engine, transmission, and braking systems. Regularly inspect fluid levels, including oil, coolant, and brake fluid, to ensure they are within recommended ranges. Address any issues immediately to prevent further complications.

Proper Cleaning and Storage

Cleaning your vehicle after use helps remove dirt, mud, and debris that can cause corrosion and damage over time. Additionally, when not in use, store your vehicle in a dry, sheltered area to protect it from harsh weather conditions. Consider using a cover to shield it from dust and moisture.

Identifying Genuine vs. Aftermarket Parts

Understanding the differences between authentic components and their alternatives is crucial for maintaining optimal performance and longevity. Genuine items are typically produced by the original manufacturer, ensuring compatibility and reliability. In contrast, aftermarket options may vary in quality and specifications.

Quality Assurance: Authentic components often undergo rigorous testing and meet strict standards, while alternatives may not always guarantee the same level of reliability.

Cost Considerations: While aftermarket options may appear more economical, they can lead to increased long-term expenses due to potential failures or subpar performance.

Warranty Implications: Using genuine components usually ensures that warranties remain valid, whereas installing alternatives might void certain guarantees.

Researching and comparing options is essential to make informed choices that align with your specific needs.

Tools Required for Repairs

Effective maintenance of utility vehicles requires specific instruments to ensure repairs are performed efficiently and accurately. Having the right equipment on hand can make a significant difference in the quality of work and the speed of the process.

Basic tools such as wrenches, screwdrivers, and pliers are essential for tackling common issues. Additionally, specialized equipment like torque wrenches and diagnostic scanners can provide deeper insights into mechanical problems. A well-stocked toolbox not only simplifies repairs but also enhances safety during the process.

For more extensive tasks, having items like jacks, creepers, and tool organizers can improve accessibility and comfort. Ensuring that all tools are properly maintained will ultimately extend their lifespan and reliability, making them indispensable for future projects.

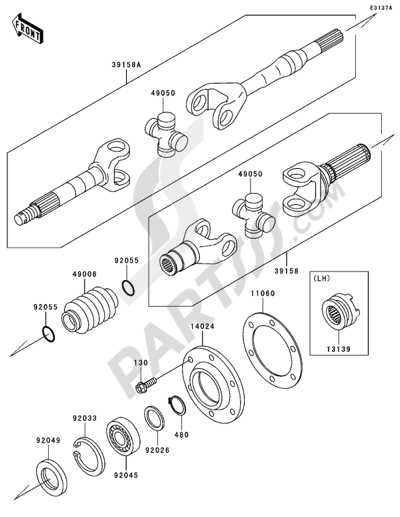

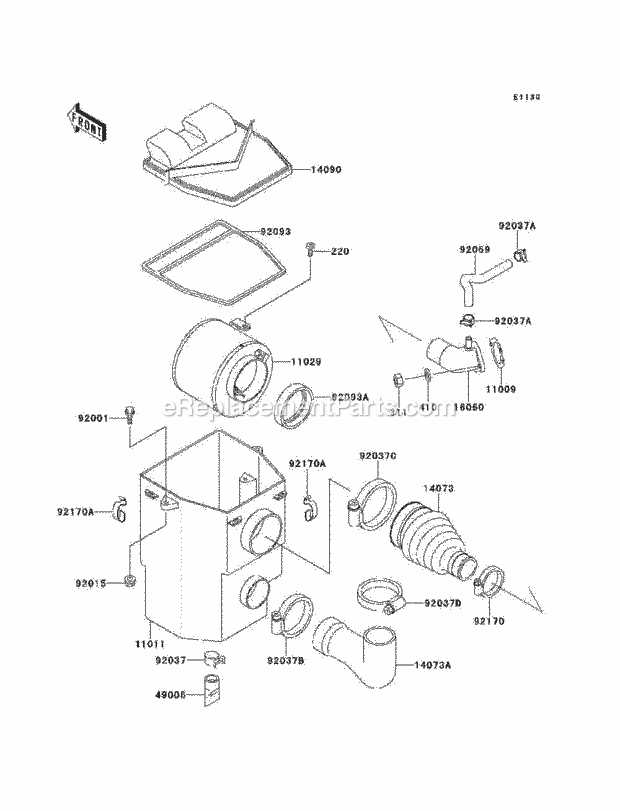

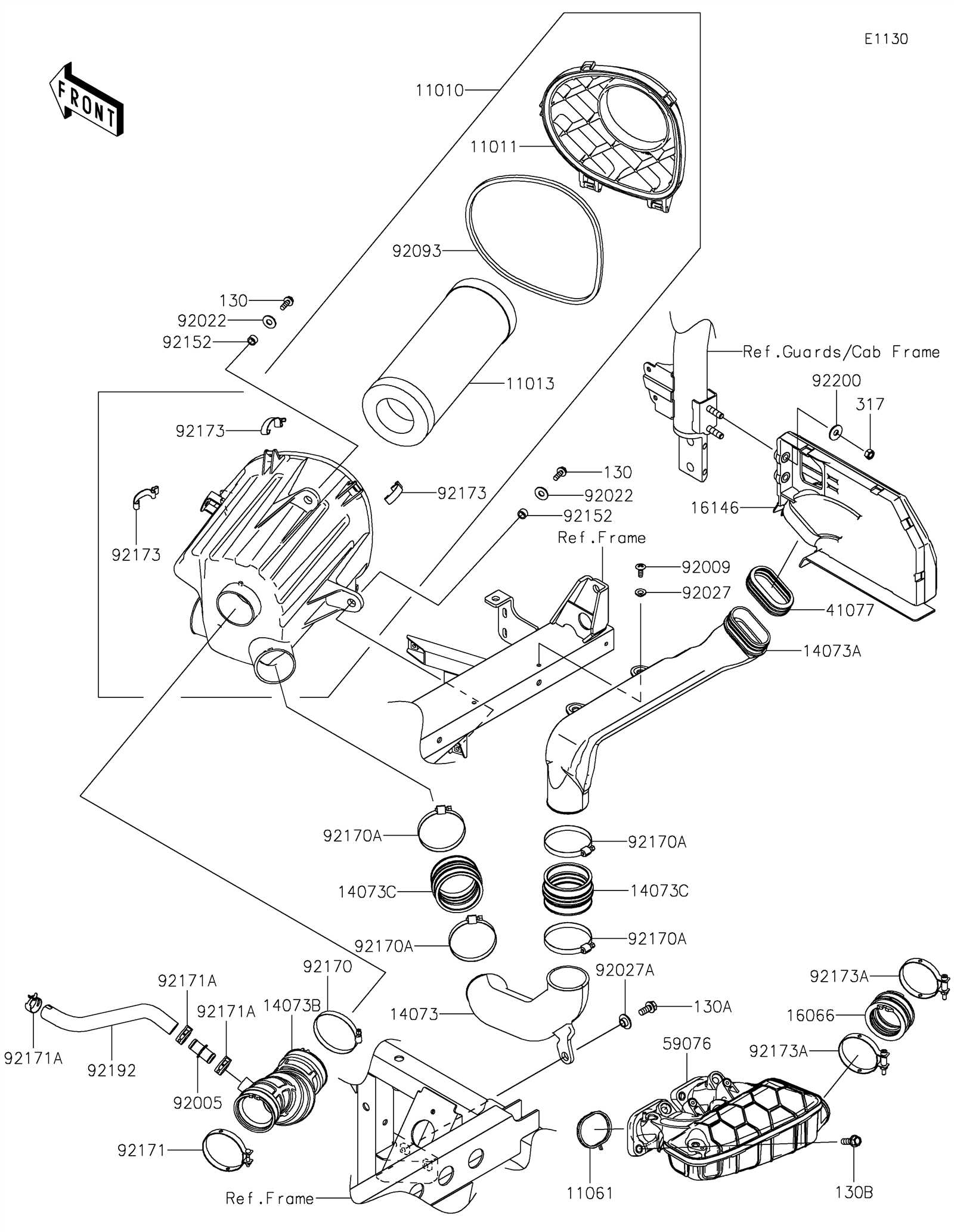

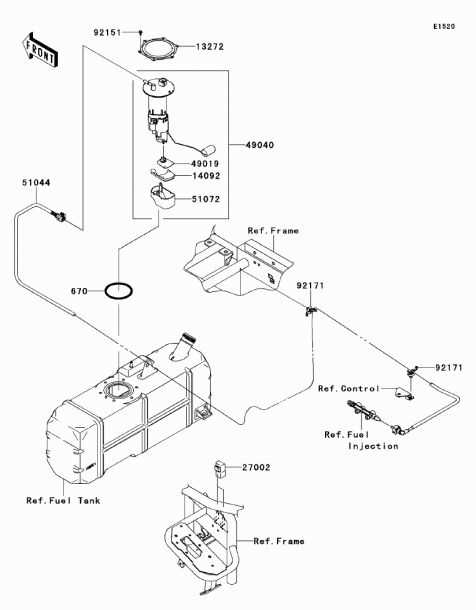

How to Read a Parts Diagram

Understanding an assembly illustration can greatly enhance your ability to maintain and repair machinery. These visual guides provide crucial information on components and their arrangement, making it easier to identify what you need for any task.

Here are some key elements to focus on when interpreting such illustrations:

- Legend: Often included, this section explains the symbols and lines used throughout the illustration.

- Labels: Look for clear labels that indicate the names or numbers of each element. These are essential for cross-referencing with inventory or catalogs.

- Views: Diagrams may present multiple perspectives–top, side, or front views. Understanding these angles is vital for accurate identification.

- Connection Points: Pay attention to how components connect. This can help you visualize the assembly and disassembly process.

To effectively utilize an assembly illustration, follow these steps:

- Start with the legend to familiarize yourself with symbols.

- Identify the main components by their labels.

- Examine the connection points for a better grasp of assembly order.

- Cross-reference with a parts list to ensure you have everything needed for your project.

By mastering these techniques, you can streamline your repair processes and enhance your overall understanding of the machinery involved.

Common Issues and Troubleshooting

When operating utility vehicles, users may encounter a variety of common problems that can affect performance and reliability. Understanding these issues and knowing how to troubleshoot them is essential for maintaining optimal functionality and ensuring a smooth riding experience.

Engine Performance Problems

One of the most frequent concerns involves engine performance. Symptoms may include stalling, reduced power, or difficulty starting. Possible causes can range from fuel system issues, such as clogged filters or bad fuel, to electrical problems, like a weak battery or faulty ignition components. Regularly inspecting these systems and replacing worn parts can mitigate many of these challenges.

Transmission and Drive Issues

Another area where users might face difficulties is with the transmission and drive system. Signs of trouble may include slipping gears, unusual noises, or an inability to shift properly. These issues can often stem from low fluid levels, leaks, or worn components. Checking fluid levels and ensuring that all connections are secure can often resolve these problems before they escalate.

Ordering Replacement Parts Online

In today’s digital age, acquiring components for your utility vehicle has never been easier. The convenience of online shopping allows you to browse an extensive selection of items from the comfort of your home, making it simple to find what you need quickly. This guide will walk you through the essential steps to ensure a smooth and successful purchasing experience.

Finding a Reputable Supplier

Before placing an order, it’s crucial to identify a trustworthy vendor. Look for online retailers that specialize in vehicle components and have a solid reputation within the community. Reading customer reviews and checking ratings can provide valuable insights into the reliability and quality of the service offered. Additionally, ensure the site has secure payment options to protect your financial information.

Verifying Compatibility

Once you’ve selected a supplier, the next step is to ensure that the item you intend to purchase is suitable for your vehicle. This often involves cross-referencing model numbers and specifications. Many websites provide search filters to help you narrow down choices based on your specific needs. Taking the time to verify compatibility can save you from future headaches and ensure your vehicle performs at its best.

Customizing Your Kawasaki Mule

Enhancing your utility vehicle can significantly improve both its functionality and aesthetic appeal. Tailoring your ride to suit your specific needs and preferences allows for a more personalized experience, whether for work or recreation. From performance upgrades to aesthetic modifications, the possibilities are vast and exciting.

When considering modifications, it’s essential to focus on key areas that will provide the most benefit. Below is a table outlining popular customization options, their purposes, and potential benefits:

| Modification Type | Purpose | Benefits |

|---|---|---|

| Lift Kits | Increase ground clearance | Improved off-road capability |

| Custom Wheels | Enhance traction and stability | Better handling and style |

| Winches | Assist in recovery situations | Increased safety and versatility |

| LED Lighting | Improve visibility | Enhanced safety during night use |

| Storage Solutions | Maximize cargo space | Better organization and convenience |

By selecting the right enhancements, you can transform your vehicle into a more efficient and enjoyable machine. Always consider compatibility and quality when sourcing modifications to ensure optimal performance and durability.

Resources for Kawasaki Mule Owners

For enthusiasts and operators of utility vehicles, having access to reliable information and resources is essential for maintenance and upgrades. This section aims to provide a comprehensive overview of valuable tools and references that can enhance your experience and ensure your vehicle runs smoothly.

Online Forums and Communities

- Join dedicated online platforms where users share tips, experiences, and advice.

- Participate in discussions about troubleshooting common issues.

- Access a wealth of knowledge from seasoned operators.

Maintenance Manuals and Guides

- Obtain official manuals that cover maintenance schedules and procedures.

- Look for downloadable resources that provide step-by-step instructions.

- Utilize video tutorials available on popular streaming sites for visual guidance.