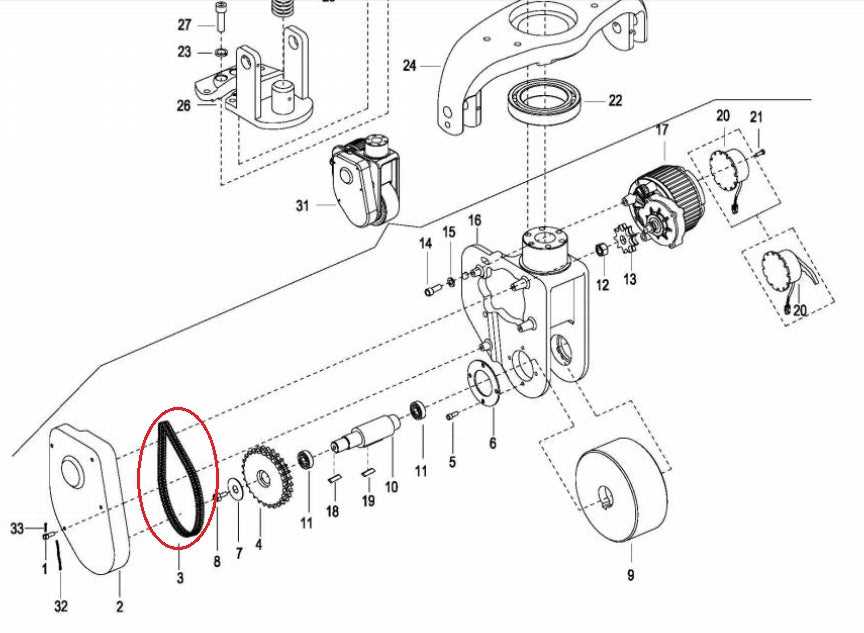

Understanding the various elements that contribute to a functional assembly is essential for effective maintenance and operation. Each element plays a significant role in ensuring that the entire system operates smoothly and efficiently. This section aims to provide a clear representation of these components, highlighting their interconnections and functionality.

By examining the structure and arrangement of these individual segments, one can gain valuable insights into how they work together to achieve optimal performance. A comprehensive grasp of this assembly will not only aid in troubleshooting issues but also enhance the overall effectiveness of the setup.

Whether you are a novice or an experienced user, familiarizing yourself with the different elements will empower you to make informed decisions regarding repairs, modifications, or upgrades. This knowledge is crucial for anyone looking to maximize the potential of their configuration.

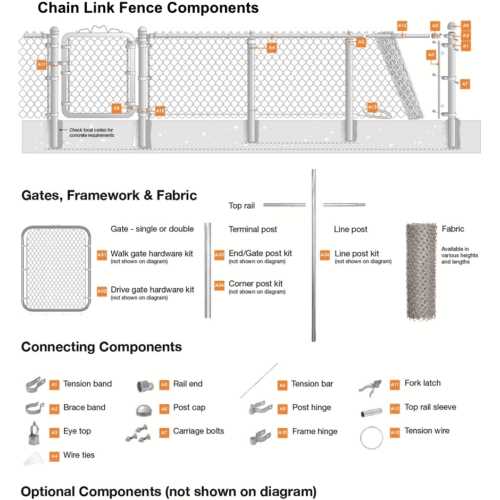

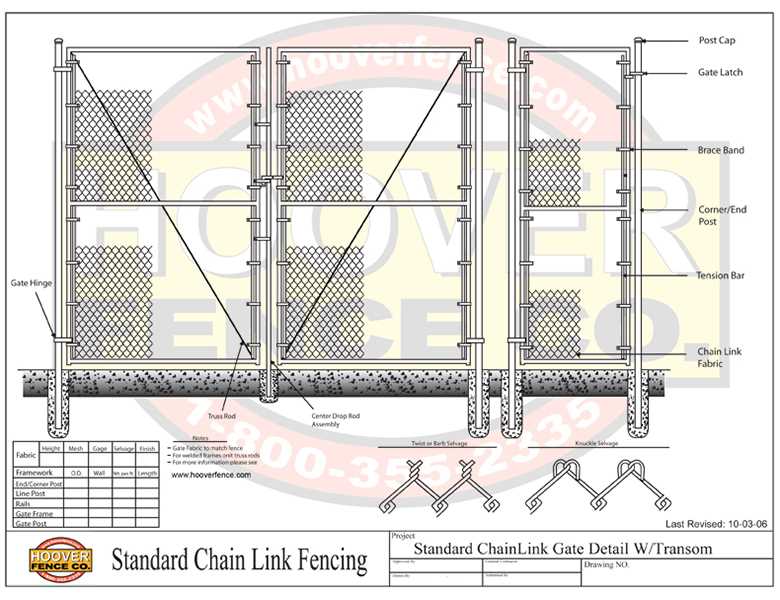

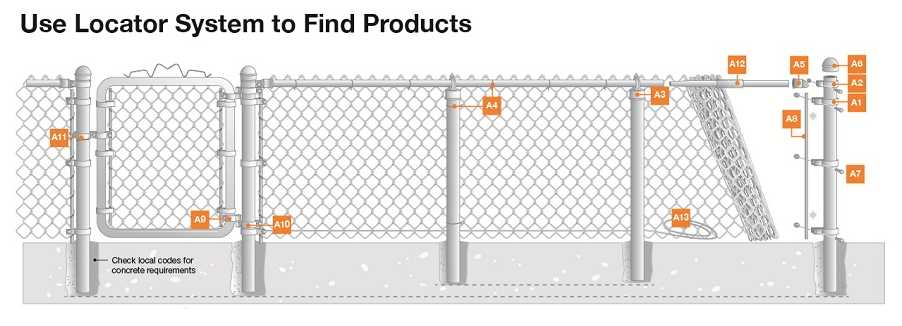

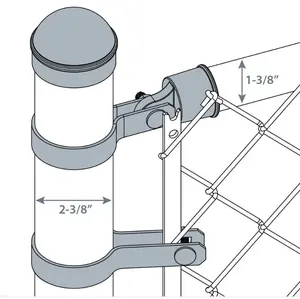

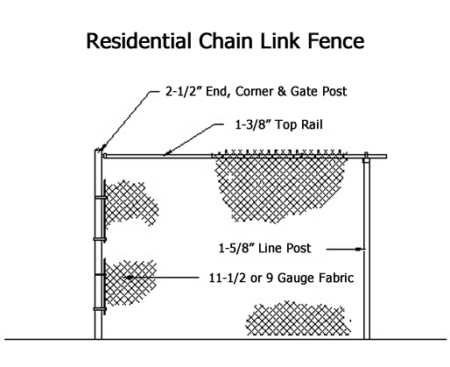

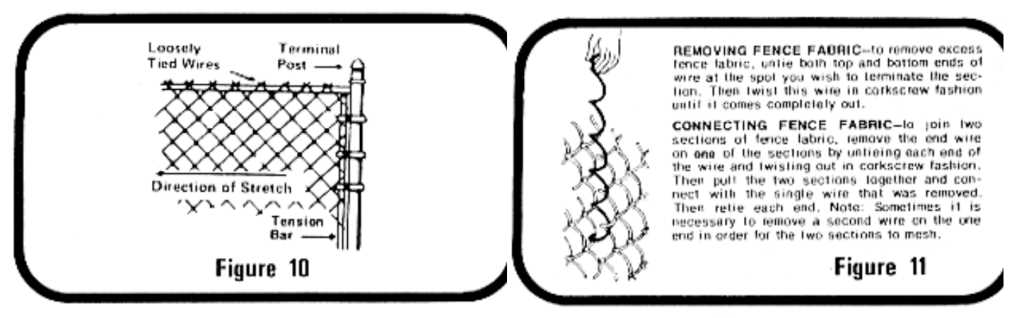

This section aims to provide an overview of the essential elements involved in a fencing system, detailing their functions and relationships. By examining these components, readers will gain a clearer understanding of how each contributes to the overall structure and stability of the enclosure.

Introduction to Fencing Elements

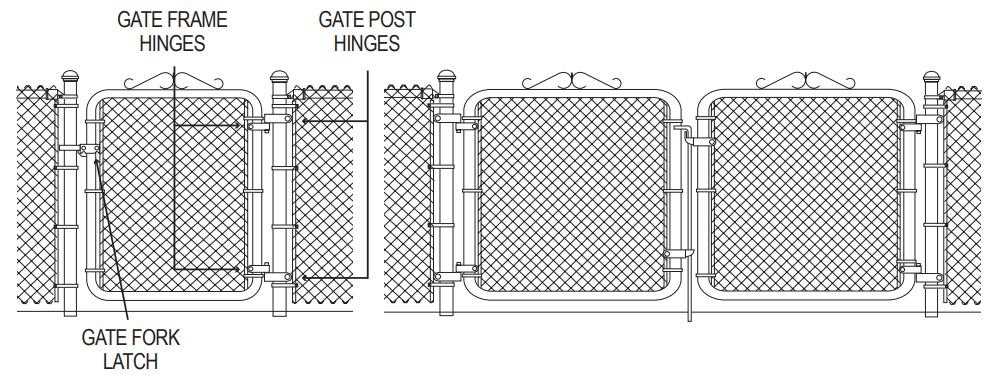

Fencing systems consist of various elements that work together to form a secure boundary. Understanding these components is crucial for effective installation and maintenance.

Key Components of Fencing Systems

- Posts: Vertical supports that hold the entire structure in place.

- Rails: Horizontal supports that connect the posts.

- Fabric: The material that creates the barrier, providing security and visibility.

- Fittings: Accessories used to connect and secure the components.

- Gates: Entry points that allow access while maintaining the enclosure.

Benefits of Understanding Components

- Improves installation accuracy.

- Enhances maintenance knowledge.

- Facilitates effective repairs.

- Increases lifespan of the structure.

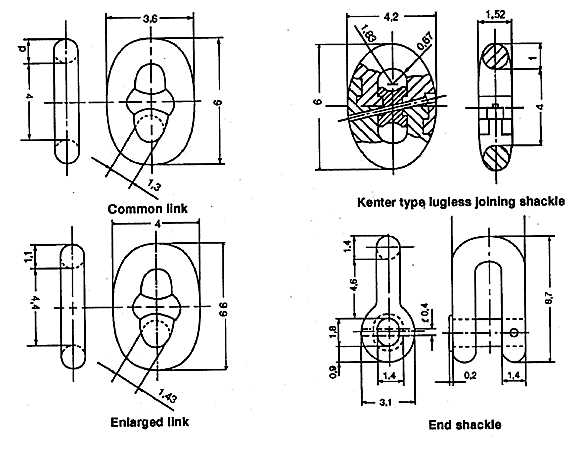

Types of Chain Links Explained

In the realm of interconnected elements, various forms exist, each serving distinct purposes and applications. Understanding the characteristics and functionalities of these components can enhance their utilization in different settings.

Overview of Common Types

The following are some prevalent varieties of interconnecting elements:

- Standard Links: Typically used for general applications, offering basic strength and flexibility.

- Heavy-Duty Variants: Designed for demanding tasks, these are constructed with robust materials to withstand greater loads.

- Decorative Models: Often employed in aesthetic applications, combining functionality with visual appeal.

Specialized Forms

Some configurations are tailored for specific purposes:

- Quick-Release Versions: Allow for easy detachment, ideal for scenarios requiring frequent adjustments.

- Locking Designs: Provide enhanced security by preventing accidental disconnection, suitable for critical applications.

- Adjustable Options: Facilitate size modifications, accommodating various requirements and enhancing versatility.

Importance of Proper Assembly

Ensuring the correct configuration of components is crucial for the overall functionality and longevity of any structure. A well-executed assembly process minimizes the risk of failures and enhances performance. This section highlights the significance of meticulous assembly in maintaining efficiency and safety.

Benefits of Accurate Assembly

- Enhanced Durability: Properly configured components reduce wear and tear, extending the lifespan of the system.

- Improved Performance: Correct assembly ensures that all elements function harmoniously, optimizing operational efficiency.

- Safety Assurance: A well-assembled structure minimizes risks, preventing accidents caused by malfunctioning parts.

- Cost Efficiency: Reducing the likelihood of repairs and replacements leads to significant savings over time.

Key Considerations for Assembly

- Ensure all components are clean and free from debris before starting.

- Follow manufacturer guidelines and specifications closely to maintain integrity.

- Utilize the appropriate tools and techniques to achieve a secure fit.

- Conduct regular inspections to identify any potential issues early.

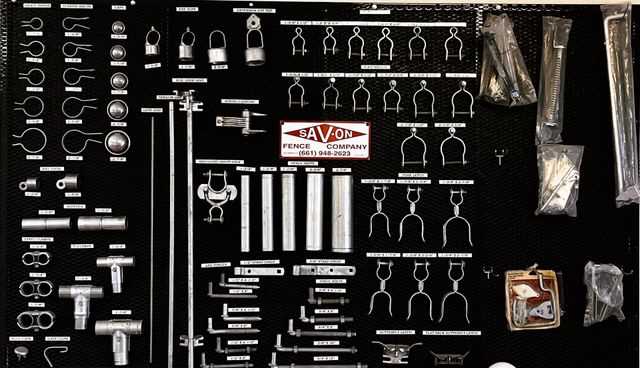

Tools Needed for Installation

When undertaking the setup of a fencing system, having the right equipment is crucial for a successful and efficient installation. The necessary tools not only facilitate the process but also ensure that the final structure is stable and secure. Below is a comprehensive list of essential tools required for this task.

Essential Hand Tools

Basic hand tools are the foundation for any installation project. These include pliers, hammers, and screwdrivers, which allow for adjustments and fixes during the assembly. Having a reliable tape measure is also vital for accurate spacing and placement of the components.

Power Tools for Efficiency

In addition to hand tools, power tools can significantly speed up the installation process. A drill is essential for creating holes in various materials, while a saw may be needed for cutting pieces to the desired length. Using a level ensures that the setup is even and correctly aligned, contributing to the overall durability of the structure.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and functionality of your equipment. Regular care not only extends its lifespan but also enhances performance. Here are some effective strategies to consider:

- Regular Inspections: Frequently check the components for signs of wear or damage. Early detection can prevent costly repairs.

- Cleaning: Keep all surfaces clean to avoid the buildup of dirt and debris. Use appropriate cleaning agents that will not harm the materials.

- Lubrication: Apply suitable lubricants to moving parts to reduce friction and prevent wear. This will also help to maintain smooth operation.

- Proper Storage: When not in use, store the equipment in a dry, protected area to shield it from environmental factors that could lead to deterioration.

- Follow Manufacturer Guidelines: Adhere to the maintenance instructions provided by the manufacturer for optimal care and to avoid voiding warranties.

Implementing these practices can significantly enhance the longevity of your equipment, ensuring it operates efficiently for years to come.

Common Issues and Solutions

In any assembly of interconnected elements, various challenges can arise that hinder optimal functionality. Understanding these common problems and their respective solutions is essential for maintaining efficiency and performance.

Frequent Problems

- Wear and tear of components leading to reduced performance.

- Misalignment during installation, causing operational difficulties.

- Corrosion or rusting due to exposure to elements.

- Improper tension or slack affecting stability.

Proposed Solutions

- Regularly inspect and replace worn components to ensure reliability.

- Follow installation guidelines to maintain proper alignment.

- Apply protective coatings to prevent corrosion and extend lifespan.

- Adjust tension as necessary to maintain optimal stability.

Safety Precautions When Working

Ensuring a safe working environment is essential for preventing accidents and injuries during any task. By adhering to specific guidelines and employing best practices, individuals can significantly reduce risks associated with their activities. Prioritizing safety not only protects workers but also promotes efficiency and enhances overall productivity.

Personal Protective Equipment

Utilizing appropriate personal protective gear is crucial when engaging in various tasks. Items such as gloves, helmets, goggles, and safety shoes can provide vital protection against potential hazards. Always ensure that the equipment fits properly and is in good condition to maximize its effectiveness.

Proper Training and Awareness

Receiving proper training and maintaining awareness of the environment are fundamental aspects of workplace safety. Familiarize yourself with the tools and materials used, as well as any potential risks they may pose. Regularly reviewing safety protocols and participating in training sessions can empower workers to respond effectively in emergency situations.

Choosing the Right Materials

Selecting suitable substances is essential for creating durable and effective constructions. The right choices can significantly enhance the performance, longevity, and overall quality of the final product. When making these decisions, several factors should be considered to ensure optimal results.

Here are some key considerations to keep in mind:

- Durability: Opt for materials that can withstand environmental factors such as moisture, temperature fluctuations, and physical stress.

- Weight: Assess the impact of weight on the structure’s stability and ease of installation.

- Cost: Balance quality and affordability. Consider long-term savings from using high-quality materials against initial costs.

- Aesthetics: Choose materials that align with the desired visual appeal and style of the project.

- Compatibility: Ensure selected materials work well with other components and systems in the construction.

By carefully evaluating these aspects, you can make informed decisions that contribute to the success and reliability of your project.

Chain Link Design Variations

The diversity in the construction of fencing systems is vast, showcasing various styles and configurations to meet different needs and aesthetic preferences. These variations can influence not only the overall appearance but also the functionality and durability of the structures.

Customizable Features: Many designs allow for a range of customization options. These can include different gauge materials, coatings for weather resistance, and unique patterns that enhance visual appeal. The adaptability of such structures makes them suitable for both residential and commercial applications.

Patterns and Textures: The choice of design can introduce unique patterns and textures that contribute to the visual character of the installation. For instance, diagonal or zigzag arrangements can provide a distinct look while maintaining structural integrity.

Functional Variations: Different configurations can cater to specific functional requirements, such as increased security or visibility. Certain designs incorporate additional elements like gates or barriers, enhancing their practical use in various environments.

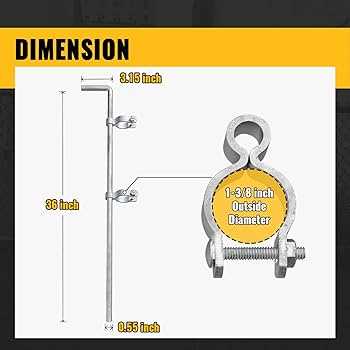

Visual Representation of Components

Understanding the various elements that compose a system is crucial for effective analysis and maintenance. A visual representation provides clarity and enhances the comprehension of how individual components interact within the larger framework. This section emphasizes the importance of visual aids in grasping complex structures.

Benefits of Visual Illustrations

- Facilitates easier identification of individual elements.

- Improves communication among team members.

- Enhances troubleshooting by providing a clear overview.

Common Elements in Visual Aids

- Nodes: Represent the main components.

- Connections: Indicate relationships and interactions.

- Labels: Provide essential information about each element.