When maintaining a compact utility vehicle, having a clear understanding of its individual components is essential for effective repairs and upgrades. Familiarity with the various elements can significantly enhance your experience, whether you are a professional or a dedicated enthusiast. This knowledge not only aids in troubleshooting but also helps ensure that the machine operates at its optimal performance.

Visual aids play a crucial role in this learning process. They can simplify the intricate relationships between different parts, making it easier to identify specific areas that require attention. By having a detailed representation of these components, users can effectively navigate through their maintenance tasks.

In addition to understanding the layout, recognizing the function of each element is vital. This insight allows for informed decision-making when it comes to repairs and replacements. With the right information at hand, you can ensure that your equipment continues to perform reliably and efficiently.

Key Components of BX1860

The essential elements of this compact tractor play a crucial role in its overall performance and functionality. Understanding these components can enhance maintenance practices and operational efficiency. Each part contributes to the machine’s ability to perform various tasks effectively, making it a versatile tool for agricultural and landscaping needs.

One of the primary features is the robust engine, which provides the necessary power for various applications. Coupled with a durable transmission system, it ensures smooth operation across different terrains. The hydraulic system is another vital aspect, enabling efficient lifting and maneuvering of implements.

Additionally, the chassis design contributes to stability and control, allowing for easy navigation. The operator’s station is ergonomically designed, offering comfort and accessibility to controls, which enhances user experience during prolonged use. Together, these components create a reliable and effective machine for diverse tasks.

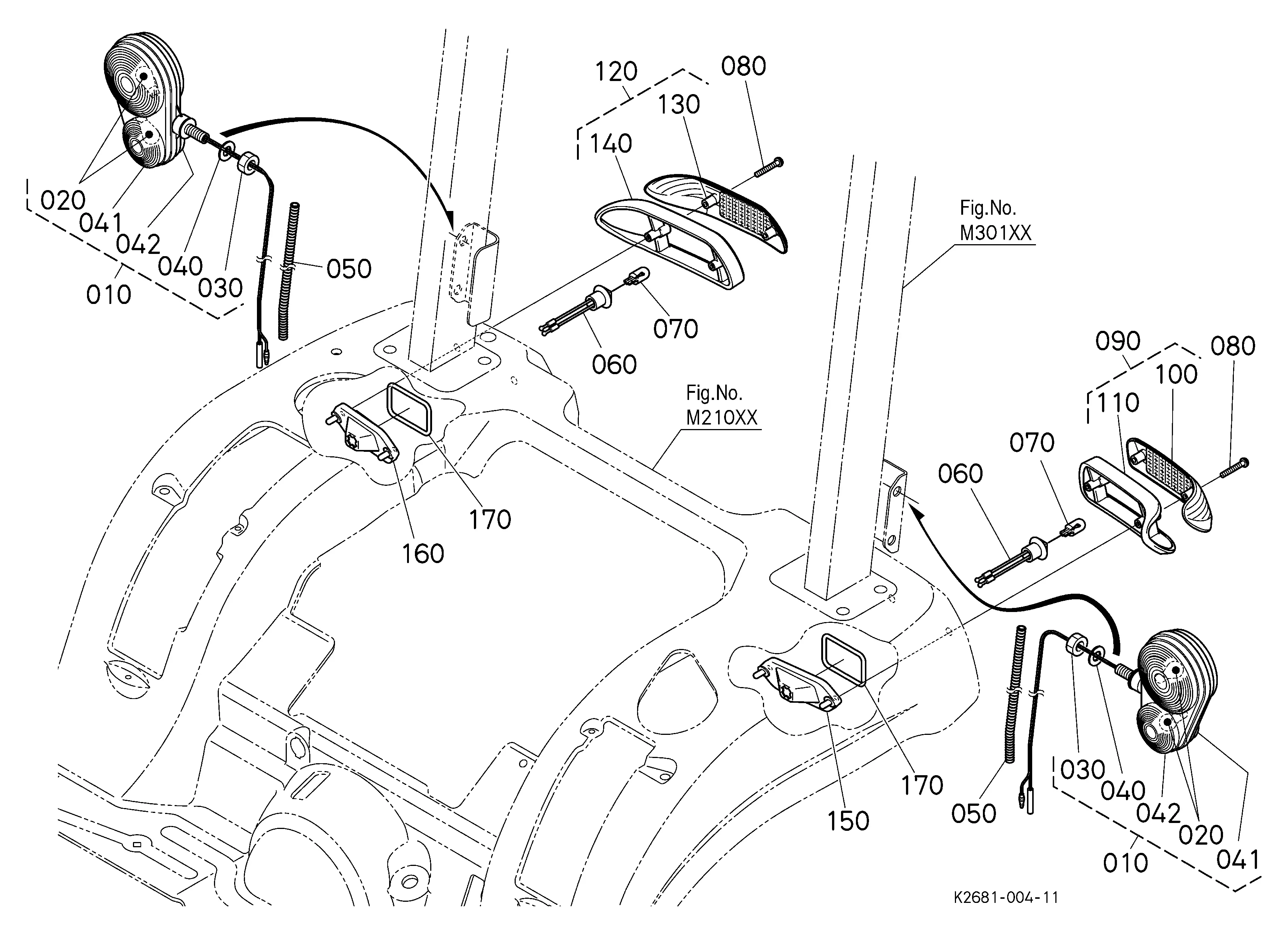

Understanding the Parts Diagram

The schematic representation of components serves as a vital resource for anyone involved in machinery maintenance and repair. By providing a visual layout, it simplifies the identification and organization of individual elements, ensuring that users can efficiently navigate through complex assemblies.

Comprehending this visual guide is essential for several reasons:

- Enhanced Clarity: Visual aids help in easily recognizing various components and their functions.

- Efficient Maintenance: Understanding the layout allows for quicker repairs and replacements.

- Improved Safety: Knowing the placement of elements can prevent accidents during service work.

Additionally, users should familiarize themselves with common symbols and notations used in these illustrations. This knowledge can significantly enhance the effectiveness of repairs and maintenance tasks.

By utilizing this type of schematic representation, operators can ensure their equipment remains in optimal working condition, ultimately extending its lifespan and improving performance.

Maintenance Tips for Kubota BX1860

Proper upkeep is essential for ensuring the longevity and efficiency of your compact utility tractor. By following a regular maintenance schedule, you can prevent potential issues and keep your machine operating smoothly. This section provides valuable insights into effective care practices that can enhance performance and reliability.

Regular Inspection

Routine checks are vital to identify any signs of wear or damage early on. Examine key components such as the engine, hydraulic system, and belts. Look for leaks, loose connections, or unusual noises during operation. Addressing these issues promptly can save you time and money in the long run.

Fluid Changes and Filter Replacement

Maintaining optimal fluid levels is crucial for the tractor’s performance. Regularly change the engine oil and replace filters to ensure clean, efficient operation. Pay attention to other fluids, including hydraulic oil and coolant, as these are essential for smooth functionality.

Common Replacement Parts Explained

Understanding essential components for maintenance is crucial for optimal performance of machinery. Familiarity with these elements can help users identify when replacements are necessary and ensure that equipment runs efficiently.

- Filters: These are vital for maintaining fluid cleanliness. Regularly changing oil, air, and fuel filters can enhance engine performance and prolong its lifespan.

- Batteries: A reliable power source is essential for starting and operating machinery. Choosing the correct battery type and capacity can prevent unexpected breakdowns.

- Belts and Hoses: These components transfer power and fluids. Inspecting them for wear and tear can prevent failures that may disrupt operations.

- Blades and Cutting Tools: For equipment that requires cutting or trimming, keeping these tools sharp is critical for effective performance. Regular sharpening and timely replacement can improve results.

- Tires: Proper tire maintenance ensures traction and stability. Regularly checking tire pressure and tread can enhance safety and efficiency on various terrains.

Awareness of these common components allows operators to proactively address issues, minimizing downtime and ensuring that their equipment remains in peak condition.

How to Use the Parts Diagram

Understanding the visual representation of components can significantly enhance maintenance and repair processes. By interpreting these illustrations, users can efficiently identify necessary elements and streamline their workflow.

Identifying Components

Begin by familiarizing yourself with the layout of the illustration. This will help you locate specific items quickly. Here are some tips for effective identification:

- Look for labeled sections that correspond to various assemblies.

- Note the numbering or coding that indicates each individual component.

- Cross-reference these labels with your maintenance manual for clarity.

Planning Repairs

Once you have identified the required items, you can plan your repair or maintenance tasks accordingly. Consider the following steps:

- Make a list of all components you need to replace or service.

- Gather the necessary tools and equipment for your tasks.

- Prioritize tasks based on accessibility and urgency.

Identifying Faulty Components

Recognizing defective elements in machinery is crucial for maintaining optimal performance. Addressing issues promptly can prevent further damage and ensure the equipment operates smoothly. This section provides insights into how to identify potential failures effectively.

Common Signs of Malfunction

- Unusual noises during operation, such as grinding or clicking sounds.

- Decreased performance or power output.

- Visible wear or damage on components.

- Fluid leaks around connections and seals.

- Inconsistent or erratic functioning of the machine.

Inspection Techniques

- Conduct a visual examination for any signs of damage or wear.

- Listen for abnormal sounds while the machinery is in operation.

- Check fluid levels and look for leaks.

- Use diagnostic tools to analyze performance metrics.

- Consult technical manuals for specific testing procedures related to the equipment.

Finding Genuine Kubota Parts

When seeking authentic components for your agricultural machinery, it’s essential to ensure that you are acquiring items that meet the original quality and performance standards. Genuine replacements not only enhance the efficiency of your equipment but also prolong its lifespan, ensuring it operates smoothly for years to come.

Identifying Authentic Components

To locate reliable items, start by researching reputable dealers who specialize in machinery supplies. Look for authorized distributors who can guarantee the authenticity of their inventory. Always verify the part numbers and descriptions to match them with your equipment’s specifications.

Benefits of Using Original Components

Choosing authentic replacements can significantly impact the functionality and durability of your machinery. These items are designed specifically for your equipment, ensuring perfect fit and optimal performance. Furthermore, using genuine products often results in better warranty coverage, providing peace of mind and financial security.

Assembly and Disassembly Instructions

This section provides essential guidelines for assembling and disassembling the equipment effectively. Following these steps ensures proper handling and maintenance, contributing to the longevity and optimal performance of the machinery.

Preparation for Disassembly

Before beginning the disassembly process, it is crucial to prepare adequately:

- Gather all necessary tools and equipment.

- Ensure a clean and organized workspace to prevent misplacing components.

- Review the user manual for any specific instructions related to your model.

- Disconnect the power source and allow the machine to cool down if it has been in use.

Disassembly Steps

- Remove any covers or shields protecting the components.

- Loosen and detach any bolts or screws securing parts in place.

- Carefully lift out the components, ensuring not to damage surrounding areas.

- Place all removed items in labeled containers for easy identification during reassembly.

Assembly Process

Once disassembly is complete, the following steps will guide you through the reassembly:

- Begin with the largest components and work your way to smaller parts.

- Ensure all bolts and screws are tightened to the specified torque settings.

- Reconnect any electrical or hydraulic systems as needed.

- Replace covers and shields to protect internal mechanisms.

After assembly, perform a thorough inspection to verify that everything is in place and functioning correctly. Always consult the user manual for any specific reassembly guidelines.

Aftermarket Parts: Pros and Cons

When considering alternatives for vehicle components, it’s essential to weigh the benefits and drawbacks. Aftermarket options can provide a cost-effective solution, yet they may come with certain risks and uncertainties.

One significant advantage of opting for these alternatives is often the lower price point. Many manufacturers offer similar or even superior quality components at a fraction of the original equipment cost. This affordability can be particularly beneficial for those on a budget or looking to maintain older models.

However, it’s crucial to acknowledge potential downsides. The quality of aftermarket components can vary widely, and in some cases, they may not meet the rigorous standards set by original manufacturers. This discrepancy can lead to premature wear or even failure, ultimately costing more in the long run.

Furthermore, the warranty implications can be a concern. Using non-original components might void the warranty of the vehicle, leaving owners vulnerable to future repair costs. Therefore, it’s advisable to conduct thorough research and consider the reputation of the manufacturer before making a purchase.

In conclusion, while aftermarket options can present appealing benefits such as affordability and availability, it’s vital to weigh these against the potential for compromised quality and warranty issues. Making an informed choice will help ensure a satisfactory outcome.

Diagram Interpretation for Beginners

Understanding visual representations is crucial for those venturing into the world of machinery. These illustrations serve as guides, offering insights into various components and their interrelations. By grasping the basics, even novices can navigate through these visuals with confidence.

Starting with the Basics: A well-structured visual aid typically includes labeled parts and lines connecting them. These labels often highlight specific features, making it easier to identify each element’s function. The connections signify how these components interact, providing a clearer understanding of the overall system.

Color Coding and Symbols: Many visuals utilize color coding or symbols to distinguish between different types of components. Recognizing these patterns can simplify the learning process. For example, red might indicate electrical elements, while blue could represent hydraulic parts. Familiarity with these color schemes enhances comprehension.

Practice Makes Perfect: The best way to become proficient in interpreting these visuals is through practice. Regular exposure to various illustrations will build confidence and familiarity. As you become more adept, you’ll find it easier to troubleshoot issues and perform maintenance tasks effectively.

Resources for BX1860 Owners

Owning a compact utility vehicle can be an exciting yet challenging experience. Accessing the right materials and information is crucial for maintaining and optimizing performance. This section aims to guide owners in finding valuable resources that will enhance their understanding and upkeep of their machinery.

Official Manuals: Comprehensive guides are essential for troubleshooting and servicing. These manuals provide step-by-step instructions for various tasks, ensuring that you can perform maintenance correctly and safely.

Online Forums: Engaging with communities online can be a great way to connect with fellow enthusiasts. These platforms allow owners to share experiences, seek advice, and discuss modifications, providing a wealth of knowledge from practical use.

Local Dealerships: Authorized dealers offer not only parts but also expert advice tailored to your specific model. They can assist with service schedules and recommend the best practices for keeping your vehicle in top condition.

Video Tutorials: Visual guides can simplify complex tasks. Numerous channels provide detailed demonstrations on maintenance procedures, making it easier to follow along and understand what needs to be done.

Replacement Parts Retailers: Numerous suppliers specialize in high-quality components compatible with your machine. Comparing options from various retailers can help you find the best deals and ensure the longevity of your vehicle.