In the realm of machinery, comprehending the intricate arrangement of engine elements is crucial for effective maintenance and repair. A well-organized visual representation serves as an invaluable tool for technicians and enthusiasts alike, enabling them to identify specific components and their functions with ease.

Detailed schematics offer insights into the interplay of various parts, helping users to pinpoint issues and streamline the troubleshooting process. By studying these layouts, individuals can enhance their understanding of mechanical systems and ensure optimal performance.

Moreover, having a clear reference for the configuration of engine elements empowers users to make informed decisions when sourcing replacements or upgrades. This knowledge fosters confidence in tackling repairs, ultimately leading to a more efficient and reliable operation.

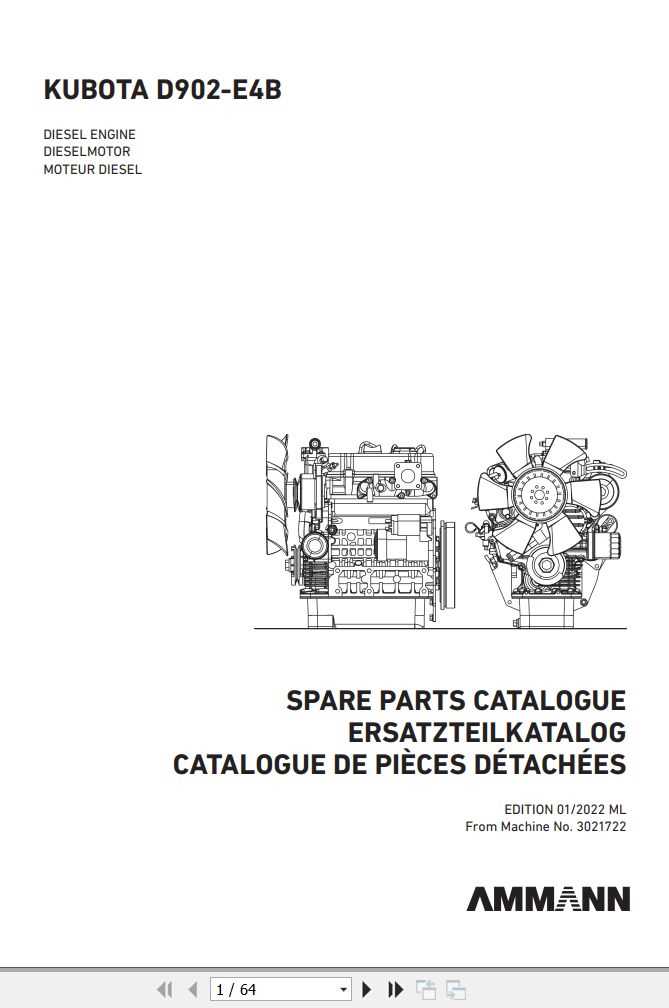

Kubota D902 Overview

This section provides a comprehensive understanding of a compact, efficient engine commonly used in various applications. Renowned for its reliability and performance, this power unit is a favored choice among professionals and hobbyists alike.

Key features of this engine include:

- Robust design for enhanced durability

- Excellent fuel efficiency, reducing operational costs

- Versatile applications, from agricultural machinery to construction equipment

- Low emissions, contributing to environmental sustainability

Notable specifications typically encompass:

- Three-cylinder configuration

- Air-cooled system for optimal temperature regulation

- Compact size for easy installation and maintenance

- High torque output for demanding tasks

This engine is widely recognized for its ability to meet the rigorous demands of various industries, providing consistent power and reliability. Its compact nature makes it an ideal choice for applications where space is at a premium.

Key Specifications of D902 Engine

The engine in question boasts impressive characteristics that cater to various applications, ensuring reliable performance and efficiency. Its design reflects a balance between power output and operational longevity, making it suitable for demanding environments.

Displacement: This powerhouse features a displacement of approximately 898 cc, allowing for significant torque generation.

Cylinders: With a three-cylinder configuration, it ensures smooth operation while optimizing fuel consumption.

Power Output: The engine achieves a maximum power of around 20.5 kW (27.4 HP) at 3000 RPM, delivering robust performance for diverse machinery.

Cooling System: An efficient liquid-cooled system maintains optimal operating temperatures, enhancing durability and reliability.

Fuel Type: Designed to run on diesel, it ensures effective combustion and energy output, making it economical for extensive use.

Weight: The compact design weighs approximately 110 kg, facilitating easier installation and maintenance.

Emission Standards: This engine adheres to stringent emission regulations, promoting environmental sustainability while providing exceptional power.

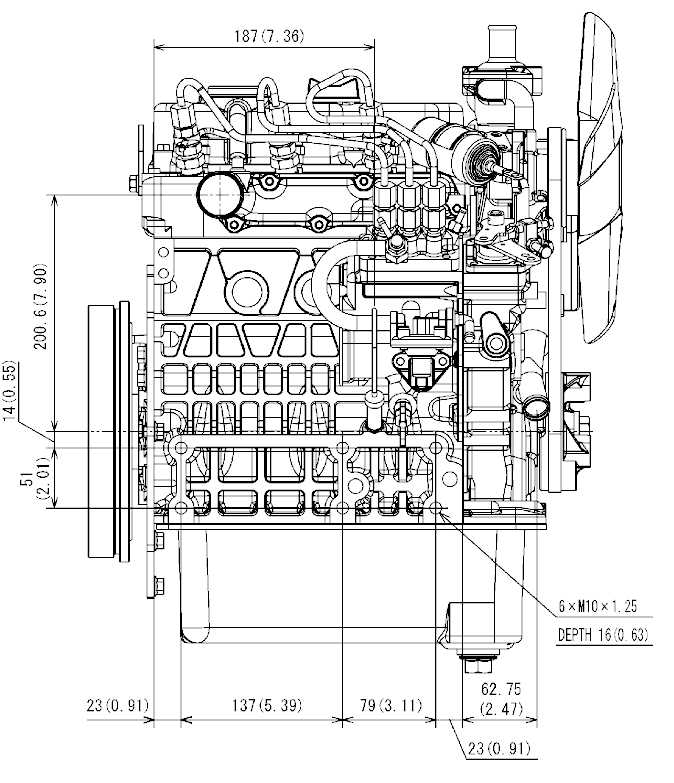

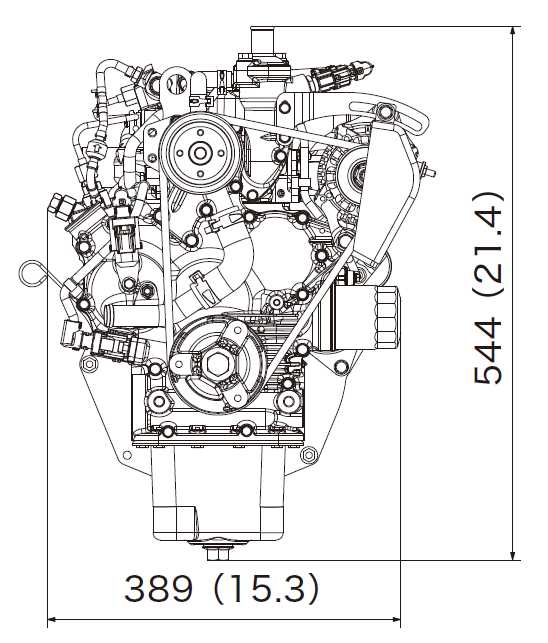

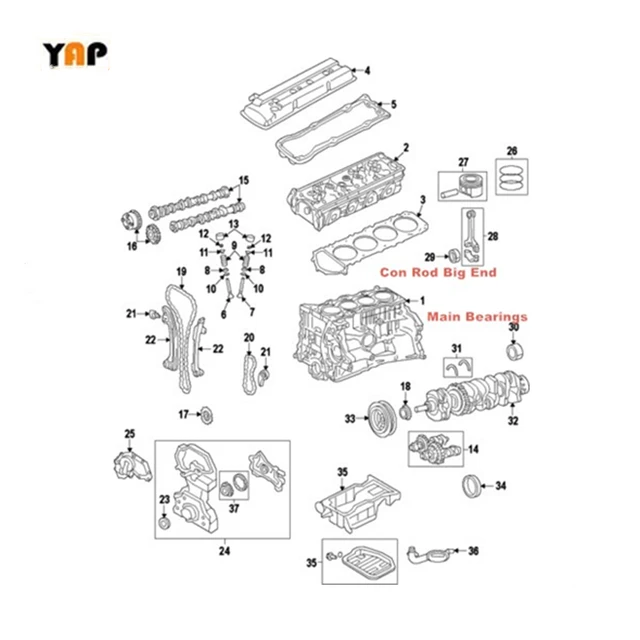

Understanding the Parts Diagram

Grasping the visual representation of components is essential for effective maintenance and repair. This schematic offers a comprehensive overview of each individual piece and its relationship to the whole, enabling users to identify parts easily and understand their functions within the system.

Importance of Clarity

A clear representation aids in troubleshooting by highlighting potential issues and guiding users towards the necessary components for replacement or adjustment. By familiarizing oneself with this layout, efficiency in repairs and maintenance can be significantly enhanced.

Navigating the Schematic

When examining the illustration, pay attention to labels and numbers that indicate specific elements. This systematic approach not only helps in locating items quickly but also facilitates communication with suppliers or technicians when discussing replacements. Understanding the layout ultimately empowers users to manage their equipment more effectively.

Common Parts and Their Functions

Understanding the essential components of machinery is crucial for optimal performance and maintenance. Each element plays a vital role in ensuring the equipment operates efficiently, contributing to the overall functionality and longevity of the system.

Engine Block: This is the heart of the machine, housing the cylinders and providing structure. It is responsible for containing the combustion process and supporting other components.

Fuel Injector: A key player in the fuel system, this component atomizes fuel for efficient combustion. Proper operation ensures enhanced performance and reduced emissions.

Cooling System: This includes radiators and water pumps, which regulate temperature. Maintaining optimal operating temperatures prevents overheating and damage to internal parts.

Transmission: This system transmits power from the engine to the wheels, allowing for movement and speed control. Its design affects the overall efficiency and responsiveness of the equipment.

Air Filter: Essential for maintaining clean airflow to the engine, this component filters out contaminants. A clean air filter enhances performance and protects engine integrity.

Maintenance Tips for D902 Components

Regular upkeep of engine components is essential for optimal performance and longevity. Implementing a systematic approach to maintenance can prevent issues and enhance efficiency. Below are key recommendations to ensure the reliable operation of your machinery.

| Component | Maintenance Tip |

|---|---|

| Filters | Check and replace filters regularly to ensure clean airflow and fluid circulation. |

| Oil | Change engine oil according to the manufacturer’s schedule to maintain lubrication and reduce wear. |

| Cooling System | Inspect coolant levels and hoses frequently to prevent overheating and system failures. |

| Belt and Hoses | Examine belts and hoses for cracks or wear, replacing them as necessary to avoid breakdowns. |

| Battery | Keep terminals clean and check the charge regularly to ensure reliable starting and operation. |

By adhering to these guidelines, operators can maximize the efficiency and durability of their equipment, minimizing unexpected downtime and costly repairs.

Identifying Wear and Tear Signs

Understanding the indicators of deterioration is essential for maintaining the longevity of machinery. Recognizing these signs early can prevent more significant issues and ensure optimal performance.

| Indicator | Description |

|---|---|

| Cracks | Visible fractures on surfaces indicating stress or fatigue. |

| Discoloration | Change in color suggesting overheating or chemical exposure. |

| Loose Fittings | Parts that do not hold securely may lead to misalignment. |

| Unusual Noises | Sounds that are not typical can signal internal damage. |

| Fluid Leaks | Any fluid escaping indicates potential seal failure. |

Where to Source Replacement Parts

Finding the right components for your machinery is crucial for maintaining performance and longevity. Whether you need to replace worn-out items or upgrade certain features, knowing where to look can save you time and money.

Here are several reliable sources for obtaining necessary components:

- Authorized Dealers: These outlets provide genuine products that guarantee compatibility and quality.

- Online Retailers: Websites specializing in equipment parts often have a wide selection and competitive prices. Popular options include:

- Amazon

- eBay

- Specialized e-commerce platforms

- Local Workshops: Many local mechanics and repair shops can order specific items directly from manufacturers.

- Salvage Yards: For those looking for budget-friendly solutions, salvage yards can offer used components that are still in good condition.

When sourcing, consider the following tips:

- Verify the seller’s reputation and read reviews.

- Ensure that the components meet your machinery’s specifications.

- Check for warranty or return policies to safeguard your investment.

By exploring these options, you can find suitable replacements that will keep your equipment running smoothly.

Assembly Process for D902 Engine

The assembly of a compact yet powerful engine involves a meticulous sequence of steps to ensure optimal performance and reliability. This process encompasses various components working in harmony to deliver the desired functionality. Each stage requires attention to detail and precision to achieve a well-functioning unit that meets industry standards.

Initial Preparation

The first step in the assembly procedure involves gathering all necessary components and tools. Ensuring that every piece is accounted for lays the groundwork for a smooth assembly. Proper cleanliness and organization are crucial, as contaminants can compromise engine performance. Furthermore, reviewing the assembly guidelines helps in understanding the sequence of operations and potential challenges.

Assembly Steps

Common Repair Issues and Solutions

When dealing with small engine machinery, various problems can arise that impact performance and functionality. Understanding these common issues and their solutions can enhance maintenance practices and prolong the lifespan of equipment.

Frequent Problems

- Starting Difficulties

- Overheating Engines

- Fuel Leakage

- Low Power Output

Solutions to Consider

- Starting Difficulties: Check the battery condition and ensure connections are secure. Clean the air filter and inspect the spark plug for wear.

- Overheating Engines: Inspect coolant levels and radiator condition. Ensure that air intake is unobstructed.

- Fuel Leakage: Examine fuel lines and connections for damage. Replace any worn or cracked components.

- Low Power Output: Clean or replace the air filter, and check the fuel filter for blockages. Regularly maintain the engine to keep it in optimal condition.

Upgrading D902: Compatible Enhancements

Improving the efficiency and performance of your engine can significantly enhance overall functionality. This section explores various upgrades that can seamlessly integrate with your existing setup, providing both power and durability without compromising compatibility.

Performance Boosters

Consider enhancing your system with advanced fuel injectors. These components are designed to optimize combustion, leading to improved fuel efficiency and power output. Additionally, a high-performance air filter can ensure better airflow, which contributes to more effective engine operation.

Durability Enhancements

Investing in reinforced gaskets and seals can prolong the lifespan of your engine. These parts can withstand higher pressures and temperatures, reducing the risk of leaks and failures. Furthermore, an upgraded cooling system can help maintain optimal operating temperatures, ensuring your engine runs smoothly for longer periods.

Safety Precautions During Repairs

When undertaking maintenance on machinery, prioritizing safety is essential to prevent accidents and ensure efficient work. Understanding potential hazards and implementing protective measures can significantly reduce the risk of injury. Proper preparation and awareness are crucial for anyone involved in repair tasks.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is vital. This includes gloves to protect hands from sharp edges and chemicals, goggles to shield eyes from debris, and steel-toed boots to guard feet against heavy objects. Additionally, ear protection may be necessary in noisy environments to prevent hearing damage.

Work Area Organization

Maintaining a clean and organized workspace is fundamental for safety. Clear away any unnecessary tools and materials to minimize trip hazards. Ensure that all equipment is in good working condition and that emergency exits are easily accessible. Implementing proper storage practices for hazardous materials can also prevent accidents and spills.

Resources for Further Learning

Expanding your knowledge about machinery components and their functionality is crucial for both enthusiasts and professionals. There are numerous resources available that provide insights into mechanical systems, maintenance practices, and troubleshooting techniques. Engaging with these materials will enhance your understanding and enable you to apply your knowledge effectively.

Online Forums and Communities

Participating in online discussions can be highly beneficial. Platforms dedicated to machinery and mechanical engineering often feature experienced users who share valuable tips and advice. Joining these communities allows you to ask questions, share experiences, and learn from the collective expertise of members.

Educational Websites and Tutorials

Several websites offer in-depth tutorials and articles focused on machinery maintenance and repair. These resources often include videos and step-by-step guides that make complex concepts more accessible. Utilizing these educational tools can significantly improve your skills and confidence when working with mechanical systems.